Detection & Hazards of Large vs Ultra-small Airborne Fiberglass

Detection & Hazards of Large vs Ultra-small Airborne Fiberglass

& Fiberglass Dust Fragments in buildings

- POST a QUESTION or COMMENT about forensic laboratory procedures for the detection of airborne fiberglass and similar particles in air & dust samples

Detection of airborne fiberglass:

How airborne particle size effects on air quality testing: This document provides information about the role of particle size and lab procedures in the detection of small particles of fiberglass fragments and indoor air quality fiberglass contamination issues in residential and light-commercial buildings.

This article describes risks of inaccuracies in airborne fiberglass and similar particle studies if the forensic analyst fails to use procedures that can detect very small particles & fragments.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Sources & Detection of Sub-Micron Sized Fiberglass Fragments in Building Air

Experienced forensic microscopists will almost certainly agree that it is very common to find fiberglass insulation fragments in indoor dust and air samples. Most often analysts recognize and identify large fiber particles - lengths considerably longer than other indoor dust analytes such as mold or pollen.

Experienced forensic microscopists will almost certainly agree that it is very common to find fiberglass insulation fragments in indoor dust and air samples. Most often analysts recognize and identify large fiber particles - lengths considerably longer than other indoor dust analytes such as mold or pollen.

Here we will discuss: Large Non-Respirable Fiberglass Insulation Particles. Special problems with very small fiberglass fragment particles down to sub-micron size.

Basic Dust Cleanup Advice for Indoor Fiberglass Fragments or other Small Particles. Prudent Avoidance Advice About Fiberglass Insulation Dust.

Photo: large fiberglass insulation fragments under the microscope.

Article Contents

- LARGE NON-RESPIRABLE FIBERGLASS PARTICLES

- SMALL FIBERGLASS PARTICLES

- INTACT vs DAMAGED FIBERGLASS HAZARDS

- PRUDENT AVOIDANCE of FIBERGLASS DUST

- FIBERGLASS DUST CLEANUP PROCEDURE

- DOES your TEST LAB CHECK for VERY SMALL FIBERGLASS PARTICLES? - "don't look, don't tell"

- FIBERGLASS HAZARD RESEARCH: LARGE vs SMALL PARTICLES

...

Larger Non-Respirable Fiberglass Insulation Particles - 3.5u & larger

These comparatively large fiberglass particles are typically low enough in frequency and large enough in size that experts will agree that they are unlikely to pose a health risk to building occupants.

Indeed, manufacturer MSDS sheets indicate that "There are no known health effects from the long term use or contact with non respirable continuous filament fibers.

As manufactured, PPG glass fibers are non respirable.

Non respirable fibers cannot reach the deep lung because they have a diameter of greater than 3.5 micrometers."[2]

...

Small, Respirable Fiberglass Insulation Particles - 1u - 2.5u range & possibly smaller

But what about the level of ultra-small [and respirable] fiberglass fragments that might be present in some buildings where insulation has been tramped-on, stomped about, or otherwise damaged and abused?

Kilburn (1992) found

Commercial rotary spun fibreglass used for insulating appliances appears to produce human disease that is similar to asbestosis.

Kilburn's findings were critiqued by Rossiter (1993) and currently many sources assert that while there may be health hazards from some fiberglass particle exposure, it's not classed as a carcinogen.

In 2018, the level of exposure in normal buildings and the hazards of such exposure to "small" fiberglass particles remain a topic of disagreement even when other studies have supported the assertion that there can be serious health hazards beyond dermatitis.

It would appear that "if you don't look for a particle, you won't find it and you won't report the particle" is a common problem with certain particles that may be present but not tested for.

That's particularly true if the mountant fluid used by the microscopist has a refractive index similar to glass (as in fiberglass) - the particles are there but they simply disappear from view under the microscope, regardless of magnification.

Watch out: Fiberglass, even when you can see it in the microscope, disappears under polarized light. That's actually one of the lab procedures we use in its identification.

In our experience, small fiberglass fragments in the 1u range may be present in a dust sample but will not be found unless the microscopist uses specific mounting media and scanning methods to detect these materials.

If a lab only notices and reports on large fiberglass fragments, unless the lab also specifically looked for very small fiberglass particles, the conclusion that no such particles were present is unreliable.

See DUST ANALYSIS for FIBERGLASS for a description of lab analysis of fiberglass in dust.

About these small fiberglass fragments, one manufacturer explains:

Chopped, crushed or severely mechanically processed fiber glass installed in a building and that has not been otherwise damaged may contain a very small amount of respirable fibers that could reach the deep lung.

The measured airborne concentration of these respirable fibers in areas where severe processing of fiberglass occurred has been shown to be extremely low and well below the TLV.

Repeated or prolonged exposure to respirable glass fibres may cause fibrosis, lung cancer and mesothelioma. PPG fiber glass in the form supplied, [italics ours] does not contain respirable fibers.[2]

...

Possible Hazards of Intact vs. Damaged Fiberglass Insulation Particles

We agree with the assumption that, in proper and normal installations, intact fiberglass insulation sheds very little into the indoor environment, that the particles are large enough not to be inhaled deep into the lungs, and that at normal levels fiberglass is not likely to be hazardous to occupants.

We agree with the assumption that, in proper and normal installations, intact fiberglass insulation sheds very little into the indoor environment, that the particles are large enough not to be inhaled deep into the lungs, and that at normal levels fiberglass is not likely to be hazardous to occupants.

The concern for the carcinogenicity of fiberglass is not new, and was cited by Stanton's rat study back in 1977.

A decade later McCurdy (1988) concluded:

If the potential of these fibers to cause lung cancer is dose-related, as is the case for asbestos, then it is likely that less risk accrues to today's workers and that the danger to homeowners with attic insulation of synthetic mineral fiber is negligible.

Interestingly, that work cited long fibers as more hazardous than short ones (for some vitreous fiber types) based on the observation that the body is able to break down small vitreous fiber particles.

Researchers generally agree that the most common hazard to workers or others exposed to significant fiberglass dust is a form of dermatitis.

The microscope photo shown above, taken at relatively low magnification, perhaps 120x, shows indoor dust fragments including skin cells (pink) and also some long fiberglass fragments.

[Click to enlarge any image]

These particular fiberglass fragments are large enough to see easily.

DJF Opinion: Frequent presence of high levels of fiberglass fragments in air and some dust samples, might suggest insulation inside an HVAC duct system has been damaged or that exposed and mechanically damaged fiberglass insulation in the building may be contributing unwanted and potentially harmful levels of these fibers.

Small Fiberglass Particles May Not Have Been Detected Nor Adequately Studied

It is possible that the presence of and level of very small fiberglass particles has not been adequately studied, perhaps because those particles do not normally occur in intact fiberglass materials and perhaps because, as I've argued, they go undetected even when damaged fiberglass is present and being distributed in indoor air.

But having inspected several thousand buildings, we have certainly encountered conditions in which insulation has been installed or damaged in a manner risking an increased level of these small fragments.

Opinion: I frequently found fiberglass fragments in indoor air samples, particularly where fiberglass HVAC duct material are in a building and where fiberglass insulation has been left exposed in a living or occupied area (such as in the ceiling above an unfinished basement being used as an office or family play area).

It is perfectly normal to find some fiberglass in most indoor air and dust samples.

But sometimes we find a notable increase in the volume or number of fiberglass fragments in air and dust samples, and we may, if we look with care, find a high frequency of ultra-small micron-level fiberglass fragments - almost always in an environment where fiberglass insulation or duct liner has been mechanically damaged.

How does this happen? If someone has attempted to mechanically "clean" HVAC duct work which was lined with fiberglass insulation, it is likely that I'll find a higher presence of fiberglass fragments in indoor air and in settled dust.

The skin, eye, and respiratory irritant effects of exposure to fiberglass dust and particles has been widely acknowledged and appears, for example, in the MSDS for various fiberglass products. [1][2][3][4][5]

But in our opinion, a concern regarding abnormally-high ultra-small fiberglass fragments are present.

"Abnormally high" would benefit from a quantitative definition but given the current fiberglass exposure standards focus on large particles, we don't have a definition nor an exposure level for small fiberglass fragments.

Causes of Ultra-Small Fiberglass Particles: mechanical damage to insulation

What may be the sources of these fiberglass fragments? Here are some examples:

- Improperly cleaned fiberglass-lined HVAC ducts

in which mechanical means was used to "scrub" the duct interior - see FIBERGLASS HVAC DUCTS for details.

Mechanical thrashing of cleaning equipment inside of fiberglass lined air ducts risks damaging that insulation.

In addition, routing HVAC air over or through conventional building insulation may also both contaminate that insulation with organic dust (supporting mold growth) and may pick up and transport small fragments of the material - more so if the insulation is damaged. - Foot traffic on old building insulation in an attic -

repeated walking on fiberglass insulation, loose fill or in batts, that has been placed atop of an attic floor or simply over joists (or the bottom chord of roof trusses) that support the ceiling below, can grind and damage fiberglass insulation. - Improper dust control

during the blow-in process for a chopped fiberglass insulation retrofit might also be a source of small particles but we have not supporting data for that hypothesis.

Heath Risks from Small Fiberglass Fragments? Maybe.

Watch out: While the fiberglass industry does not necessarily agree these particles in homes constitute a hazard, independent studies and warnings at US government health-related websites suggest that there may be carcinogenic or respiratory health hazards from exposure to high levels of fiberglass particles in some buildings and/or work environments.

Really? The exposure level of small airborne fiberglass particles is likely to depend on

- the size and actual exposure level of such particles in the building

- where the fiberglass is located

- what means of transport are present (HVAC air returns, foot traffic, carrying dusty materials out of an attic into occupied space)

- the exposure level of the occupants

- other factors such as the health and health vulnerabilities of building occupants

Small particles in the 2.5u and below range are easily breathed deeply into the lung where they can be hard to expel. Some studies cited the ease with which the body dissolves or handles these ultra-small particles.

Yet small particulates are considered an indoor air pollutant. Airborne particles in the PM 2.5 size range (fine particles defined as 2.5 u and smaller in diameter ) to PM 10 (coarse particles) have been identified as an air pollution and as a human health hazard.

...

Prudent Avoidance Advice About Fiberglass Insulation Dust

It is possible that small fiberglass particles in air may constitute a meaningful health risk though most of the research that we've reviewed did NOT come to that conclusion.

For any particle, chemical, or mateiral, the potential hazard depends on the overall exposure level, and the detection of its presence - or failure to detect it - could fall short if the inspection and test procedures are inadequate.

We suggest that that prudent avoidance would be appropriate for any elevated levels of any indoor dust and debris.

Watch out: Improper cleaning or treatment of fiberglass ducts with biocides may in fact increase rather than decrease indoor air quality problems in a building, particularly if occupants have other respiratory or pulmonary concerns/vulnerabilities.

...

Basic Dust Cleanup Advice for Indoor Fiberglass Fragments or other Small Particles

If we find frequent presence of fiberglass fibers in air or interior dust samples, further investigation, cleaning, and particularly investigation of air handling equipment and duct systems in the building would be appropriate.

If fiberglass HVAC duct work has been installed, I very often find significant fiberglass levels in interior air and dust samples.

Because these materials cannot be mechanically cleaned and because I do not recommend encapsulant sprays, replacement could be in order.

We would not expect and do not usually find evidence of movement of significant levels of fiberglass fragments from insulated attics, nor from enclosed (finished) walls, ceilings into living areas under normal conditions.

Photo above: reader NH was worried about fiberglass shed from a tear in a mattress cover, discussed in excruciating detail just below.

Advice by InspectApedia Publisher - Best dust cleanup procedures when using HEPA Vacuuming and Damp Wiping

@NH,

Good question.

I've already commented on additional environmental testing in my prior reply.

Opinion on best dust cleanup procedures when using HEPA Vacuuming and Damp Wiping

Having done both damp wiping and HEPA vacuuming, I would

1. Do all the HEPA vacuuming first. That includes vacuuming all reasonably accessible surfaces and areas, including tops of books, shelving, etc.

2. Then go back and damp-wipe surfaces that suit your degree of meticulousness, such as horizontal trim over windows and doors (harder to reach with that HEPA vac wand), shelf surfaces etc.

Wipe working your way DOWN from highest surfaces to floor level.

Watch out: I've done field lab tests of damp-wiping exercises at a mold contamination cleanup job.

We tested surfaces of many items before and after they were "wiped".

We found that the crew were re-using the same filthy cloths and wipes over and over - effectively simply spreading contaminants from one surface to another, sometimes even from a dirty surface to one that was more clean than after they wiped it.

So to be effective you want to use disposable wipes and "dispose" of each wipe after it has been used, clean side folded out, used again, etc., moving on to new clean wipes very frequently. More frequent means cleaner results.

Although this guide is referring to asbestos rather than your issue of fiberglass, the damp wiping procedure is the same. This guide refers to rags but wipes are just fine, too.

Be sure to see

by NH - is vinegar a better damp wipe liquid than water?

@InspectApedia Publisher, Thank you so much!! This is so, so helpful. Going from highest surfaces and working down towards floor makes a lot of sense - will do. And same with avoiding reusing wipes.

Do you think using 6% cleaning vinegar would be OK for damp wiping instead of water? And is it worth vacuuming/wiping the ceiling, or is that less likely to harbor fiberglass dust?

Oh, and do you think running a HEPA air purifier after all this vacuuming/wiping is done is safe?

by InspectApedia Publisher - No "air purifier" really removes all contaminants that might be present in indoor air

@NH,

Vinegar is an effective and safe household cleaner but I'm not sure when you're simply wiping up dust fibers that you need to use a disinfectant. But it's most likely harmless if you want to add that feature.

If you are simply wiping up dust there should be no need to disinfect building surfaces.

See details at DISINFECTION of BUILDING SURFACES

and see

- Culveer, Alicia, Chris Geiger, Ph. D., Deanna Simon,SAFER PRODUCTS and PRACTICES for DISINFECTING and SANITIZING SURFACES [PDF]

No "air purifier" Really removes all contaminants that might be present an indoor air but it can reduce the level of airborne contaminants. Just how effective it is depends entirely on the local environment and on the level of contamination and particularly on the contaminant source.

Please read

and see

and for a more-scholarly explanation read

- Mainka, Anna, Walter Mucha, Józef S. Pastuszka, Ewa Brągoszewska, and Agnieszka Janoszek. NON-COMMERCIAL AIR PURIFIER—THE EFFECTIVENESS AND SAFETY [PDF] Buildings 10, no. 6 (2020): 104.

Consider that if you were for example standing in the kitchen waving a vacuum cleaner in the air it wouldn't pull dust from beneath living room couch.

by NH

@InspectApedia Publisher, Thank you so, so much again - your answers are truly so helpful and insightful! I was wondering:

if I've been running a HEPA air purifier while the room was still contaminated - would it be harmful if I continued to run it *after* cleaning the room? In that it would re-introduce the fiberglass dust right back into the room?

by InspectApedia Editor - an air filter is not going to 're-introduce' dust or particles back into the room

@NH,

An air filter is not going to 're-introduce' dust or particles back into the room. If that were the case, then it would be doing it while you are cleaning the room to begin with.

The owner's manual for your air purifier will explain proper usage AND needed maintenance.

Of course if your air filter was dirty or damaged it's time to replace it.

Keep in mind that there are various types of filters for different purposes. Learn more about them at

by NH

@InspectApedia Editor , Got it, thank you! Reading the link you sent now. Last but not least, do you think paper towels would suffice in place of rags for damp-wiping?

Reply:

That sounds reasonable; the chief risk of a bad damp-wiping dust removal job is re-using a dirty dusty rag over and over, simply spreading dust around rather than removing it.

So a disposable wipe of any sort is probably a better approach.

Wipe, fold to a new clean surface, wipe again, then toss out the wipe.

...

How to confirm whether or not a lab is examining for small fiberglass size particles?

Our InspectApedia reader asked:

Do you have any advice for how to confirm whether or not a lab is examining for small fiberglass size particles?

My dad and I are trying to confirm that his house is clear of fiberglass after it was contaminated some time ago with small mechanically broken down fiberglass from insulation underneath the house during a repair.

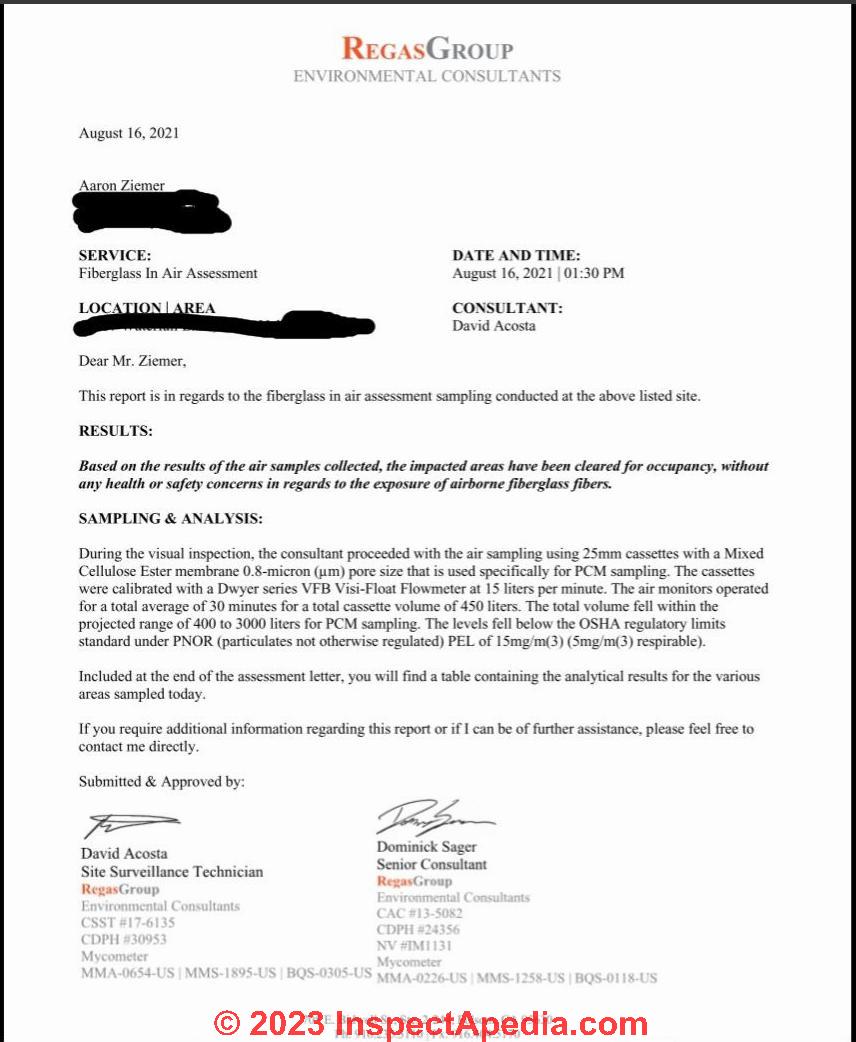

We have got the following test report, which came back with all samples absent of fiberglass. The lab claimed they could detect fiberglass particles of any size, but I wasn't sure if there were specific questions we should ask to confirm that they were correct about that.

For folks with experience, does this testing protocol look like one that should be able to detect small fiberglass particles?

Thanks,

Aaron On 2021-08-22 by Aaron Ziemer

Suggestions by inspectapedia.com.moderator - small fiberglass particle testing and hazards

@Aaron Ziemer,

Thank you for a helpful question on small fiberglass particle testing and hazards.

First, let's be accurate:

NO building will be completely "clear" (to use your word) of fiberglass fibers and fragments. It's completely normal and generally harmless to find at least some fiberglass fibers in building dust including house dust, even when there's no obviously-exposed fiberglass insulation.

Next:

Decades ago I thought that the small fiberglass particles, hard to see without special effort in the lab, might be particular hazardous as are other PM2.5 small particles as they're breathed deeply into the lung and might be hard to expel. Early researchers often had that view or conclusion.

Subsequent research, some of it financed by the fiberglass industry, concluded that the hazard was probably not there or was exaggerated. I heard from some pretty irate industry reps on this topic and have made an effort to include significant research on the question.

Where we are today is without unequivocal evidence of the hazard and confounding research that leads away from that view.

Next:

If a lab isn't reporting small fiberglass fragments then they probably are not using the special methods necessary to look for them; but you ought to be able to get a straight answer by asking the lab directly. (Let us know what you're told as that'll be important to other readers.)

Finally:

The sampling method, using MCE filter cassettes, is capable of collecting very small particles in or even below the PM 2.5 range, but that doesn't tell you one iota of a nanobit whether or not the dust in the filter was then processed and examined using methods designed to identify both large and very small fragments.

Ask the lab, and tell us what they reply.

Also be sure to see FIBERGLASS SHEDDING from MATTRESSES

by Aaron

@inspectapedia.com.moderator,

Thanks for the quick reply! I'll be sure to ask them. Do you have any advice on how to phrase the question to get the most accurate response? Should I ask about what size range they look for or just about small fiberglass particles in general?

Or maybe ask about the mountant they used? Or any other thoughts on how to get them to take the question seriously and respond in a useful way?

by inspectapedia.com.moderator

@Anonymous,

Asking more technically precise questions like what was the refractive index of your mountant? will probably just embarrass us and annoy the lab;

From what you can read here, it's not clear that you should be very worried about this, but if you want to know what the lab included in their scan or report on fiberglass fragments present in your air or dust sample just ask what particle size range is included in their analysis.

...

Small vs Large Fiberglass Particle Hazard Research

Research of health hazards associated with fiberglass exposure have focused on specific industries such as boat building, and catastrophic events such as bombings in London that disturbed fiberglass in buildings.

See FIBERGLASS HAZARD RESEARCH for more detailed citations.

- Albrecht, Matthew A., Cameron W. Evans, and Colin L. Raston. "Green chemistry and the health implications of nanoparticles." Green chemistry 8, no. 5 (2006): 417-432.

- Guo, Jie, Qunli Rao, and Zhenming Xu. "Effects of particle size of fiberglass–resin powder from PCBs on the properties and volatile behavior of phenolic molding compound." Journal of hazardous materials 175, no. 1-3 (2010): 165-171.

- Kilburn KH, Powers D, Warshaw RH. PULMONARY EFFECTS OF EXPOSURE TO FINE FIBREGLASS: IRREGULAR OPACITIES AND SMALL AIRWAYS OBSTRUCTION [PDF] Br J Ind Med. 1992 Oct;49(10):714–720. retrieved 2018/07/11 original source: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1012147/pdf/brjindmed00022-0044.pdf

Abstract:

OBJECTIVE--Man made mineral fibres imitate asbestos and produce tumours of the pleura in animals.

To answer the question, Does prolonged exposure to fibreglass adversely affect pulmonary function or produce radiographic abnormalities in human subjects? we studied workers in a midwestern appliance plant where refrigerator doors and previously entire cabinets were insulated with fibreglass sheeting and loose rotary spun fibreglass.

METHODS--Spirometry and lung volumes were measured, respiratory and occupational questionnaires were administered, and chest x-ray films were read for pneumoconiosis using International Labour Office (ILO) 1980 criteria in 284 workers with exposure of 20 years or more.

RESULTS--Expiratory flows were reduced including FEV1 (mean 90.3% of predicted (pr), FEF25-75 (85.5% pr), and FEF75-85 (76.2% pr). Forced vital capacity was significantly reduced (92.8% pr) and total lung capacity was significantly increased (109.2% pr). In white male smokers, a group large enough for comparisons, parameters of pulmonary function were reduced further in the presence of irregular opacities.

Forty three workers (15.1%) had evidence of pneumoconiosis on chest radiographs: 26 of these (9.1%), had no known exposure to asbestos and 17 (6.0%) had some exposure. The best judgement was that in 36 (13.0%), pulmonary opacities or pleural abnormalities were due to fibreglass.

CONCLUSION-- Commercial rotary spun fibreglass used for insulating appliances appears to produce human disease that is similar to asbestosis. - Kim, Seong Chan, Matthew S. Harrington, and David YH Pui. "Experimental study of nanoparticles penetration through commercial filter media." In Nanotechnology and Occupational Health, pp. 117-125. Springer, Dordrecht, 2006.

- McCurdy, Stephen A. "Carcinogenicity of Synthetic Mineral Fibers." Western Journal of Medicine 148, no. 1 (1988): 75.

- Rossiter, C. E. PULMONARY EFFECTS OF EXPOSURE TO FINE FIBERGLASS: IRREGULAR OPACITIES AND SMALL AIRWAYS OBSTRUCTION [PDF] Letter, British journal of industrial medicine 50, no. 4 (1993): 382.

- Stanton, Mearl F., Maxwell Layard, Andrew Tegeris, Eliza Miller, Margaret May, and Elizabeth Kent. "Carcinogenicity of fibrous glass: pleural response in the rat in relation to fiber dimension." Journal of the National Cancer Institute 58, no. 3 (1977): 587-603.

Abstract:

Seventeen fibrous glasses of diverse type or dimensional distribution induced different incidences of malignant mesenchymal neoplasms when implanted in the pleurae of female Osborne-Mendel rats for periods of more than 1 year. Neoplastic response correlated well with the dimensional distribution of fibers.

Fibers less than or equal to 1.5 µ in diameter and greater than 8 µ in length yielded the highest probability of pleural sarcomas, and probability trends suggested that pleural sarcoma incidence increased with increasing lengths of fibers with diameters of less than 1.5 µ.

Morphologic observations indicated that fibers less than or equal to 8 µ in length were inactivated by phagocytosis. In fibers greater than 8 µ in length, the correlation of carcinogenicity with increasing length was difficult to explain.

Since neoplastic response to a variety of types of durable fibers, particularly asbestos fibers, was similar, our experiments reinforce the idea that the carcinogenicity of fibers depends on dimension and durability rather than physicochemical properties and emphasize that all respirable fibers be viewed with caution. - U.S. EPA, OVERVIEW OF PARTICLE AIR POLLUTION (PM2.5 AND PM10) AIR QUALITY COMMUNICATION WORKSHOP [PDF] of a power point presentation],

San Salvador, El Salvador

April 16-17, 2012 retrieved 2018/07/11, original source: https://www.epa.gov/sites/production/files/2014-05/documents/huff-particle.pdf

Note: this presentation does not specifically focus on fiberglass. Excerpts:

Particulate matter (PM) is a general term for very small solid and liquid particles in the atmosphere

There are many different sources of PM, including natural and anthropogenic (man-made) sources

PM is hazardous to human health – it causes acute and chronic effects to the respiratory and cardiovascular systems

PM causes a variety of human health and economic impacts each year (e.g., mortality, morbidity, DALYs, lost income from work absences, costs of health care) - [3] "Fibrous Glass Material Safety Data Sheet.", GAF Materials Corporation,1361 Alps Road, Wayne, NJ 07470, Tel: 800 – 766 – 3411, MSDS # 1001, MSDS Date: November 2008. Web search 01/03/2011, original source: Fiberglass_MSDS__1001-309-280-v1.pdf

- [4] "Insulation Overview", Healthy House Institute, Web search 01/03/2011, original source: Insulation_ Insulation Overview - HealthyHouseInstitute.pdf, website: healthyhouseinstitute.com

- Fiberglass carcinogenicity: GLASS WOOL FIBERS EXPERT PANEL REPORT, Part B - Recommendation for Listing Status for Glass Wool Fibers and Scientific Justification for the Recommendation [PDF]

The Report on Carcinogens (RoC) expert panel for glass wool fibers exposures met at the Sheraton Chapel Hill Hotel, Chapel Hill, North Carolina on June 9-10, 2009, to peer review the draft background document on glass wool fibers exposures and make a recommendation for listing status in the 12th Edition of the RoC.

The National Institute of Environmental Health Sciences is one of the National Institutes of Health within the U.S. Department of Health and Human Services. The National Toxicology Program is headquartered on the NIEHS campus in Research Triangle Park, NC.

Following a discussion of the body of knowledge, the expert panel reviewed the RoC listing criteria and made its recommendation. The expert panel recommended by a vote of 8 yes/0 no that glass wool fibers, with the exception of special fibers of concern (characterized physically below), should not be classified either as known to be a human carcinogen or reasonably anticipated to be a human carcinogen.

The expert panel also recommended by a vote of 7 yes/0 no/1 abstention, based on sufficient evidence of carcinogenicity in well-conducted animal inhalation studies, that special-purpose glass fibers with the physical characteristics as follows longer, thinner, less soluble fibers (for 1 example, > 15 μm length with a kdis of < 100 ng/cm2/h) are reasonably anticipated to be a human carcinogen for the listing status in the RoC.

The major considerations discussed that led the panel to its recommendation include the observations of tumors in multiple species of animals (rats and hamsters). Both inhalation and intraperitoneal routes of exposure produced tumors, although inhalation was considered more relevant for humans. - World Health Organization International Agency for Research on Cancer - IARC Monographs on the Evaluation of Carcinogenic Risks to Humans - VOL 81 Man-Made Vitreous Fibers, 2002, IARCPress, Lyon France, pi-ii-cover-isbn.qxd 06/12/02 14:15 Page i - World Health Organization, 1/21/1998. -

Fiberglass insulation is an example of what IARC refers to as man made vitreous fiber - inorganic fibers made primarily from glass, rock, minerals, slag, and processed inorganic oxides. This article provides enormous detail about fiberglass and other vitreous fibers, and includes fiberglass exposure data. - Also see citations atReferences or Citations at the end of this page.

...

Continue reading at FIBERGLASS HAZARDS - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see FIBERGLASS DETECTION in BUILDING AIR & DUST FAQs - questions & answers posted originally at this page

Or see these

Recommended Articles

- FIBERGLASS HAZARDS - home

- AIR FILTERS, FIBERGLASS PARTICLES

- DUST ANALYSIS for FIBERGLASS

- FIBERGLASS DETECTION in BUILDING AIR & DUST

- FIBERGLASS ENVIRO-SCARE

- FIBERGLASS FRAGMENT HAZARDS in AIR or DUST

- FIBERGLASS HAZARD RESEARCH

- FIBERGLASS INSULATION EXPOSURE LIMITS

- FIBERGLASS PARTICLE CONTAMINATION TEST

- FIBERGLASS REINFORCED PLASTICS

- FIBERGLASS SHEDDING from MATTRESSES

- FORMALDEHYDE in FIBERGLASS INSULATION

- FIBERGLASS HVAC DUCTS

- FIBERGLASS INSULATION IDENTIFICATION & PROPERTIES

- FIBERGLASS UNDER the MICROSCOPE - example photos, summary of technical issues

- LAB IDENTIFICATION OF FIBERGLASS - forensic lab procedural notes about fiberglass particles.

- MORGELLONS SYNDROME

Suggested citation for this web page

FIBERGLASS DETECTION in BUILDING AIR & DUST at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to FIBERGLASS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- NAIMA, North American Insulation Manufacturers Association, 11 Canal Center Plaza Suite 103, Alexandria VA 22314 USA, Tel: 703-684-0084 Website: https://insulationinstitute.org

Website excerpts:

NAIMA (North American Insulation Manufacturers Association) is the recognized voice of the insulation industry, bringing together North American manufacturers of fiberglass and mineral wool insulation products. - Original source: https://insulationinstitute.org/about-naima/

NAIMA and its members are committed to protecting the health and safety of consumers, employees and workers who manufacture and install fiberglass, rock wool, and slag wool insulation products. NAIMA cooperates with government organizations to provide documentation that demonstrates that the products are safe to manufacture, install and use. NAIMA and its members have invested tens of millions of dollars in independent health and safety research projects in the United States and abroad.

- [1] "Prepared Glass Fiber (Textile and Plastic), PPG Industries, Inc. Raw Material Specification" 06/26/97, rev 11/30/10, Specification Number: CO-1272, R. R. Eustace, Web search 01/03/2011, original source: PPG Technical PPG_Bulletin-Processed Fibers Specs-Revision 7.pdf

- [2] "Fiber Glass, Continuous Filament", [including the products listed below]. PPG Material Safety Data Sheet MSDS, 2/27/2004, Web search 01/03/2011, original source: MSDS TAP Chopped Fiberglass.pdf

Chopped strand: ChopVantage®, MaxiChop®, Delta Chop®, Chopped Strands for Nonwovens

Coated Yarn: Hercuflex® Strand HF and HFO lines

Direct Draw: Hybon®, TufRov™, Innofiber™ NTY

Yarn: FiberGlass Yarn, Hybon® RCY, L.E.X.® Yarn, TEXO® Yarn

Mat: MPM 5 Chopped Strand Mat, Needled Mat for AZDEL, MatVantage II, Texo® HTM

Roving: Panel Roving for Continuous Laminating, Roving for Pultrusion/Filament Winding, Roving

for SMC, Hybon® Roving for Spray Up, Hybon® Woven Roving - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.