Creosote Hazards

Creosote Hazards

History, uses, carcinogenicity, bans of creosote

- POST a QUESTION or COMMENT about detecting, testing for, and removing building environmental hazards

Creosote history & hazards.

This series of articles gives in-depth advice on indoor and building related environmental hazard inspection, detection, remediation: Environmental Hazard Testing, Effects, Remedies, Prevention Procedures. Indoor Contaminant Detection, Testing, Cleanup, Illness, Symptoms, Diagnosis.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Creosote: definition, ingredients, uses, history, hazards

Creosote, a black or brownish oil consisting of a complex mixture of polynuclear aromatic hydrocarbons is prepared by distilling coal tar obtained from coal-coke or oil shale, was first patented in 1716 and was patented as a wood preservative in 1851.

Creosote, a black or brownish oil consisting of a complex mixture of polynuclear aromatic hydrocarbons is prepared by distilling coal tar obtained from coal-coke or oil shale, was first patented in 1716 and was patented as a wood preservative in 1851.

Creosote was produced in several forms from more than one source but the most-widely-used form of creosote used as a wood preservative and insecticide was coal tar - itself a complex mixture of about 300 organic compounds. (ATSDR) Coal tar pitch, coal tar creosote, and coal tar pitch volatiles are all similar in composition and similar in health risk.

Creosote has been used directly as produced or used in mixed forms including a blend of creosote and coal tar or separately, as a blend of 50% creosote (by volume) and petroleum oil to produce a more-easily applied penetrating wood preservative solution.

Currently it is recognized that both creosote used as wood preservative and creosote formed by burning wood or coal are potential carcinogens and in or on buildings may be a chimney fire hazard as well.

Here we discuss the ingredients in, history of, uses of, and health hazards from creosote in various forms.

Photo: heavy soot and creosote deposits at an unsafe chimney in a pre-1900 home in Dutchess County NY. In this context the more-immediate hazard than creosote itself is the risk of a chimney fire or building fire.

[Click to enlarge any image].

Watch out: Creosote is a coal tar product which contains varying amounts of mutagenic and carcinogenic substances such as polycyclic aromatic hydrocarbons (PAHs) and benzene. Marketing and use of creosote and preparations containing creosote, as well as creosote-treated wood, are regulated by a EU Directive. - (Holme 1999)

Creosote is a complex chemical mixture with major use as wood preservative. Recent chemical and biological investigations have shown that creosote contains a number of highly biologically active organic components and exerts toxic effects, especially against aquatic organisms.

Many components are also chemically and biologically stable and environmental contamination from creosote persists for many years.

he general use of creosote as a pesticide has accordingly been questioned and its use been restricted in some countries. - ( Sundström 1986)

In assessing the risk of human exposure to creosote hazards today, the U.S. ATSDR concluded:

In assessing the risk of human exposure to creosote hazards today, the U.S. ATSDR concluded:

The general public is unlikely to experience any significant exposure to liquid creosote through the direct use of wood preservative products because EPA canceled all non wood uses of the material and restricted use of coal tar creosote products to certified applicators in January 1986 (EPA 1986b; R.U.P. 1994).

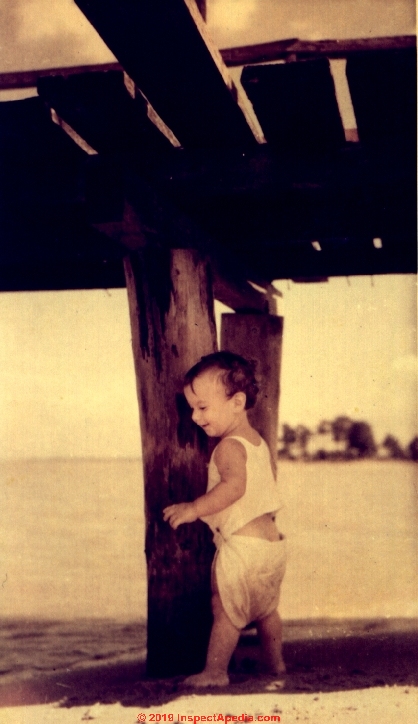

Opinion having been around creosote literally since I was in diapers (photo above), I figure that ATSDR is probably right - partially-so - as long as creosote-treated products are either left alone or are covered over.

However there may be creosote exposure risks from skin contact or from handling, sawing, moving creosote-treated wood that remains in many locations in the form of beams, posts, pilings, railroad ties, etc.

Other experts have cited the leaching of some harmful chemical compounds out of creosote-treated wood and into water either as surface-runoff or as contaminants leaching into water where creosote pilings, beams, or seawalls were driven into the bottom of bodies of water.

See seawall discussion at SINKHOLES in MINNESOTA

Above and in more photos below we describe a creosote-treated dock on which the author worked and walked and played in the 1940s, some components of which remain in place fifty years later and may still be in place in 2019.

The photo above shows the author, Daniel Friedman, ca 1945, still in diapers at the Rappahannock River, snuggling up to a creosote-coated dock piling.

As children we soon learned to avoid touching creosoted surfaces as the result was often painful.

How to Identify Creosote & Creosote-Treated Wood

Creosote is a yellowish to dark brown, oily liquid which is produced from heating and separation of Coal Tar. It is used in construction (roofing), railroad and utilities industries, and for wood treatment and waterproofing. - NJ DOH cited below.

Creosote is a yellowish to dark brown, oily liquid which is produced from heating and separation of Coal Tar. It is used in construction (roofing), railroad and utilities industries, and for wood treatment and waterproofing. - NJ DOH cited below.

In most countries creosote is either banned entirely or its use is very circumscribed today (2019) but it was widely used for nearly 100 years as a wood preservative and insecticide, principally on wood that was in ground or water contact such as railroad ties, dock and pier pilings, beams, decking, railroad and bridge trestle construction, outbuilding construction.

Our photo shows creosote-treated railroad ties for sale at a "Junkatique" along the highway between San Miguel de Allende and Dolores Hidalgo in Guanajuato, Mexico.

In the hot sun even these old creosote-treated beams and railroad ties can exude sticky tar-like creosote.

It would be unusual to find creosote used in the treatment of beams or posts in buildings built for human occupancy because most people found the smell objectionable even before its health risks were understood.

You can often identify creosote on existing wood products, some of which could easily be 50 to 75 years old by the context of use as well as by appearance and odor.

- Product labeling using the word creosote

- Product use: yellow-brown coating on wood in specific applications such as outdoor treatment of posts, pilings, telephones, and occasionally beams used in building or barn construction

- Product appearance: brown, tan, or black tarry-coated beams and lumber.

The black and brown beams shown here also exuded a characteristic "creosote" odor familiar to those who have worked with creosote treated wood or who have lived with or cleaned chimneys used to vent wood or coal stoves. - Product odor: Creosote or creosote treated wood will have a strong "smoky" odor similar to that of asphalt paving newly-installed.

Creosote exposure limits

Photo below: chunks of creosote removed from Paul Galow's woodstove, discussed at

Creosote can be absorbed by skin contact and possibly some of its harmful chemicals by breathing its fumes, particularly in new or fresh applications.

There is no occupational exposure limit established for creosote, but this does NOT mean that creosote is harmless.

Creosote is a probable carcinogen in humans (and surely other animals). Most sources currently assert that there may be no safe level of exposure to a carcinogen, so all contact with creosote or creosote-coated materials (wood) should be avoided.

That means wearing appropriate protective gear when handling creosote-soaked or coated materials, washing immediately after exposure, and avoiding breathing sawdust produced by cutting creosoted wood beams or posts.

Medical Uses of Creosote

Beechwood creosote has been used [in the past] as a disinfectant, a laxative, and a cough treatment. In the past, treatments for leprosy, pneumonia, and tuberculosis also involved eating or drinking beechwood creosote.

[Creosote] is rarely used today in the United States by doctors since it has been replaced by better medicines, and is no longer produced by businesses in the United States. It is still available as an herbal remedy, and is used as an expectorant and a laxative in Japan. The major chemicals in beechwood creosote are phenol, cresols, and guaiacol. (US DEHS 2000)

Durability & Fire Hazards of Creosote-Treated Telephone Poles, Railroad Ties, Bridge Timbers

Creosote Treated Poles & Ties Along The Maybrook Railway Line (Dutchess Rail Trail)

The telephone pole shown above is one of many found along the 125-year-old Maybrook Railway Line, now the route of the Dutchess Rail Trail found in Dutchess County New York.

These creosote-treated poles and cross ties along with an occasional abandoned-railroad tie are visible along much of the Rail Trail, evidence of the durable nature of creosote-treated wood.

The Maybrook line, begun originally by the Dutchess & Columbia Railroad in 1871, was completed from Waterbury CT to Hopewell Junction NY by the New York & New England Railroad in 1892.

From that point the rail line connected with the D&C line to continue to the Hudson River - where the line crossed over to Highland NY.

Creosote-Treated Railway Tie Fire at the Poughkeepsie-Highland Railroad Bridge

Referred to as the Poughkeepsie-Highland railroad bridge first opened on 1 January 1889 and today a Walkway over the Hudson River, the bridge was the only train crossing over the Hudson River between New York City and Albany NY.

Referred to as the Poughkeepsie-Highland railroad bridge first opened on 1 January 1889 and today a Walkway over the Hudson River, the bridge was the only train crossing over the Hudson River between New York City and Albany NY.

The 6,768 foot long bridge is 212 feet above the Hudson River.

Creosote itself is highly combustible. Mixed with grease and oil and coating bridge timbers or railroad ties the result can be a fire hazard.

On the 8th of May in 1974, the last day that any train ever crossed the Poughkeepsie-Highland Railroad Bridge, attracted by plumes of dense black smoke, I [DJF] stood on Parker Avenue watching firemen fighting the a fire raging on the Poughkeepsie Railroad Bridge.

The fire forever stopped use of the bridge for train traffic.

Most-likely sparks from the brakes of a crossing train or possibly from the engine exhaust landed in the thick coating of grease and creosote atop the creosote-treated rail ties and bridge timbers to ignite an intense fire.

Below: The Poughkeepsie-Highland railroad bridge around the time of the 1974 bridge fire [photos by the author.]

Ten years later in 1984 Dutchess County purchased the Maybrook Line right-of-way as a potential highway route later terminated. Once a passenger and freight route, the Maybrook line had lost nearly all of its traffic by 1993.

The route was purchased by Metro-North in 1993 but in that same year Conrail sold all of the track to Maybrook Properties and remaining freight traffic was re-routed.

Today the route is referred to as the William R. Steinhaus Dutchess Rail Trail and provides 13.4 miles of a paved walkway used by hikers and bicycle riders. We estimate that the telephone poles along this route include creosote-treated standards that may be as much as 90 years old.

Below: The Poughkeepsie-Highland High Bridge over the Hudson River as it appeared from the Highland NY side in the late 20th century. Source: Wikipedia 2019/09/24.

The towers supporting the bridge are constructed of steel. Portions of the bridge itself were constructed using creosote-treated wood timbers along with creosote-treated railroad ties beneath the rails.

Occurrence of Types of Wood Rot in Creosote-Treated Utility Poles

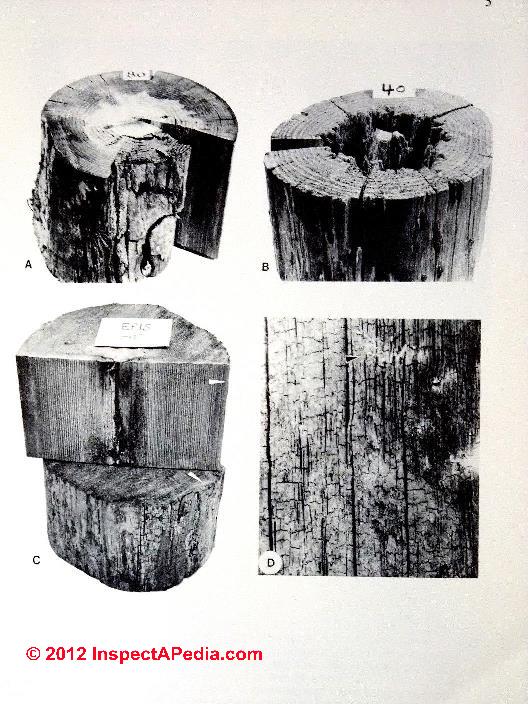

Above and continuing below, Wang and Zabel, studying the types of decay in utility poles in service in the eastern United States, point out that despite their history of being heavily treated with creosote, numerous fungi can infect and cause several types of wood decay or "rot" in utility poles.

The primary location of utility pole decay, in a phenomenon observed in other wood posts as well, decay development occurs principally just below the ground-line.

In the second photo above, four decay types are identified. The text discusses microscopic examination of wood decay, lab procedures for microscope slide preparation, and identification of the various genera/species of fungi involved in utility pole rot or decay. Excerpting:

A. Brown cubical rot

in the outer-treated zone of a creosote-treated southern pine distribution pole. The decay development was just below the ground line and note the associated wood shrinkage and collapse.

B. Advanced white rot

in the inner untreated and treated zones of the center of a 31-year-old creosote-treated southern pine distribution pole.

The decay was in the ground line zone of a street side pole encased in cement. Note the deep checks associated with decay development.

C. Soft rot

as seen on the surface of an older creosote-treated southern pine distribution p;ole. The maximum decay development was 15-30 cm below the groundline and the decay penetrated radially approximately 5 mm. (see arrows).

D. A surface view of soft rot

on a 15-year-old Cellon®-treated [pentachlorophenol in butane] southern pine pole at 15 cm below the groundline showing the shrinkage and rectangular patterns (see arrow) which the wood develops in the late states of development and prior to surface exfoliation.

Additional photographs and text in this outstanding study of wood rot illustrates microscopic examination of wood rot properties down to the level of individual wood cells.

- Wang, C.J.K., & R.A. Zabel, (Ed.) Fungi From Utility Poles in the Eastern United States, Identification Manual for, , Allen Press, 1990, ISBN 0-93-0009-31-2

History & Toxicity of Creosote as a Wood Preservative or Produced by Wood-Burning

- American Seal, NO-D-K CREOSOTE OIL WOOD PRESERVATIVE [PDF] (ca 1985) American Seal Manufacturing Co., subsidiary of Monseyt Products Co., E. Rutherford NY and other locations, restricted use pesticide,

- Freeman, Michael H., Todd F. Shupe, Richard P. Vlosky, H.M. Barnes, PAST, PRESENT, AND

FUTURE OF THE WOOD

PRESERVATION INDUSTRY [PDF] Forest Products Journal, Vol. 53, No. 10, pp. 8-15, (2003) retrieved 2019/09/24, original source: https://pdfs.semanticscholar.org/705a/f7eb52d17171ba6b11322fe8606d14e00332.pdf

Excerpts:

The Boucherie Process developed in 1839 provided the basis for modern-day sap displacement methods such as the SlurrySeal® Process, PresCap®, and Gewecke methods. In 1874, Julius Rütgers of Mannheim, Germany, developed a process for treating wood with zinc chloride and creosote, which was later modified by J.B.Card (Hunt and Garratt 1967) in 1906 in the United States and used until the mid-1920s to treat crossties.

Other full-cell treatments developed in the late 1800s to early 1900s, but no longer in use, include the Allardyce treatment, Creoaire treatment, and the Wellhouse method.

In 1884, Boulton published his classic work “On the Antiseptic Treatment of Timber,” which provided the basis for the boultonizing process for seasoning wood. The high price of oil made the creosote process expensive, so an empty-cell process was developed by Max Rüping of Germany, and patented in 1902.

This process utilizes an initial application of air pressure (usually 30 to 50 psig) before filling the cylinder and applying a higher pressure (usually 100 psig above the initial air pressure) to inject the preservative.

...

In the United States, the first Bethell-Process plant was built in 1865 in Somerset, Massachusetts.

The first commercial plant for waterborne salt treatments was built in 1848 in Lowell, Massachusetts, for Kyanizing (soaking in mercuric chloride) timbers.

The advent of modern timber preservation in the United States is linked to the railroads and the production of crossties by the L & N Railroad at a plant in West Pascagoula, Mississippi, in 1875. - Gauntt, James C., RAILWAY TIE ASSOCIATION RESPONSE TO

WOOD PRESERVATION CHRONOLOGY REQUESTRAILWAY TIE ASSOCIATION RESPONSE TO

WOOD PRESERVATION CHRONOLOGY REQUEST [PDF] Railway Tie Association, Fayetteville GA (2015), Original source: https://www.rta.org/assets/docs/Research/WoodPreservation1/railway%20tie%20association%20response%20to%20bnsf%20wood%20preservation%20chronology%20request%20%20april%202015%20final-final10.docx

Excerpts:... an independent brief history of wood preservation techniques and a current overview of the marketplace.

The goal of this response is to outline how the railroads arrived at this point in time with a status quo that creosote or creosote/borate dual treatments are used for approximately 98.5% of the treated wood tie market and with other AWPA standardized wood preservatives now accounting for 1.0-2.0% of that market.

1716 patent for Spirit of Tar (creosote) awarded Dr. William Crook

1848 Bethell Process for treating wood with creosote patented

1865 first treating plant to treat ties with creosote erected in Somerset, MA

1875 Louisville & Nashville RR builds tie treating plant in Pascagoula, MS

Between 1865 and 1880 new, more environmentally friendly, and cost effective empty-cell methods for creosote treatment of ties were developed (Rueping-Lowry Processes) – these methods (with further modifications and inclusive of best management practices) are still employed today.

Around the turn of the 19th century (~1902), experiments were conducted with many various additives to creosote: Coal Tar, Water-Gas Tar and Petroleum Oils. Coal Tar and Water-Gas Tar are no longer in use but Petroleum Oils remain important blending components for creosote systems.

1929 - Creosote and its solutions reaches peak use (203 plants treating 60 million+ wood crossties). For a short period of time, zinc-chloride was added to creosote (discontinued in 1934).

During WWII, shortages of creosote developed, so heavier oils and Copper Naphthenate were used as creosote extenders – these practices were discontinued for a variety of production related issues as available creosote supplies returned to normal near the end of the war.

During the late 1940s, pentachlorophenol (penta) was approved for use with wood crossties. Penta is an excellent wood preservative that is still in use in the wood utility pole industry. During the next decade, or so, penta was either added to creosote for ties (proving to be highly corrosive) or used as a standalone treatment by railroads in small quantities, in various methods of application, for wood ties (Cellon process, heavy oil carriers, etc.). The practice of using penta for ties fell out of favor with RRs in the early 1960s.

Chromated Copper Arsenate (CCA), a highly effective waterborne wood preservative in softwoods, was investigated for ties in the 1970s and 1980s but was found to be ineffective against certain decay fungi in hardwoods. Thus, even though it remains an important commercial product for softwood utility poles, its use in crossties has never been a major factor with only specialized use exceptions in softwood bridge ties.

Numerous other non-efficacious products have come and gone, including waterborne sodium-silicate based products that were examined in US Naval shipyard tests and found to have no merit whatsoever.

Since the early 1980s, creosote and its solutions have been the exclusive preservative for all wood tie applications.

1987 in-railroad-service experiments were begun by RTA/AAR /MSU into dual treatments using borates as a pre-treatment followed by standard creosote treatment.

After the 1992 initial follow-up to the 1987 study, in which dual treated ties were found to be performing well, a shift in AAR priorities at TTCI led to AAR releasing this research project to industry. RTA and MSU continued to follow the ties in test and in 2003 produced a follow-up research report outlining the favorable performance of dual treated ties in high decay areas (see all dual treatment research).

In 2004, both Norfolk Southern and then Canadian National helped commercialize the dual treatment process for widespread railroad use.

In 2010, further follow-up to the 1987 test yielded additional positive results, which eventually lead to all Class 1 RR’s employing the technology in some manner.

Since 2010 other wood preservative systems have been standardized for wood tie use. Copper Naphthenate (CuN) with oil carriers (AWPA Proceedings from 2000) has seen some use with Norfolk-Southern using approximately 250,000 ties annually in Northern and Mid-Atlantic States, and for bridges in general. Other railroads, including UPRR, have also approved CuN for bridge tie applications. CuN may also be used with borates in a dual treatment process.

Also, ACZA (Ammoniacal Copper Zinc Arsenate) has been standardized for both hardwood and softwood ties with limited use to date, predominantly on the west coast with Douglas-fir (AREMA Paper 2010).

ACZA may also be used with borates and oils in single/dual treatment process.

In 2008, RTA, in conjunction with MSU, Class 1 RR’s, wood treaters and wood preservative manufacturers, initiated PHASE 1 of a comprehensive side-by-side full size tie comparative research project into all known alternative wood preservative products for potential wood tie use.

PHASE 2 of this study was initiated in 2012 for products that were AWPA standardized after PHASE 1 was initiated. PHASE 1 of this study is now in the 7th year of the projected 20-year study. PHASE 2 of the study is in its 3rd year. PHASE 1 & PHASE 2 Dorman Lake test sites visits are included in 2015 RTA Field Trip agenda.

A review by AAR in 1989 (R-744) covering the time period of 1900 to 1989 revealed that contact was made with 18 railroads, the U.S. and Canadian Forest Products Laboratories, the American Wood Protection Association, the Railway Tie Association, the National Technical Information Service and the Transportation Research Information Service.

This resulted in locating records on 305 individual wood tie tests. These tests covered alternative wood preservatives and creosote related research plus comprehensive wood species research.

The most comprehensive 156-page USDA handbook “Preservative Treatment of Wood by Pressure Methods” provides an all-encompassing review, through the early 1950s, of much of the material referenced above.

Other historical research documents on wood preservation are available. Of particular note is the paper by D.L. Davies on treating plant operations. This review covers different tie seasoning methodologies including a very helpful historical review of Air-Drying and Boultonizing, which are the only seasoning methods employed by railroads today.

Research on Creosote Hazards & Bans & Effectiveness of Creosote in Preventing Wood Rot

Photo above: the author and his sister atop the creosote-treated dock built extending into the Rappahannock River, Dunnsville Virginia, ca. 1948 (no longer in diapes) and extended to include a large boathouse in 1952.

My sister Linda is the cute one. I'm the one in the short pants.

Notice that we were smart enough to put on tennis shoes rather than walk barefoot on the splinter-prone pier boards, creosote or not.

Second photo (below): portions of the same long pier extending out into the Rappahannock, visited by the author in fifty years later; most of the dock and pier were blown away by Hurricane Hazel in 1956.

The remains of the boat house are visible at the right end of the dock. Following the 1956 hurricane the aluminum roof and huge steel I-beams that supported chain hoists used to lift boats out of the water were found upside down, otherwise intact, several miles upstream.

The creosote-treated pilings that remain include wood that was hammered into the Rapphannock river bed in the 1940s and 1950s!

[Click to enlarge any image]

Below: Creosote-treated pilings and dock timbers at the remains of the Newburg N.Y. ferry terminal photographed by the author ca 1969.

- ATSDR, CREOSOTE CAS # 8021-39-4, 8001-58-9, 8007-45-2 FACT SHEET [PDF] (2002) Agency for Toxic Substances and Disease Registry, Division of Toxicology, 1600 Clifton Road NE, Mailstop F-32, Atlanta, GA 30333 USA, Tel: 1-888-4228737, retrieved 2020/10/19, original source: https://www.atsdr.cdc.gov/toxfaqs/tfacts85.pdf

Excerpt: The Occupational Safety and Health Administration (OSHA) has set an exposure limit of 0.2 milligrams of coal tar pitch volatiles per cubic meter of air (0.2 mg/m3) in workplace air during an 8-hour day, 40-hour workweek. - ATSDR: CREOSOTE POTENTIAL for HUMAN EXPOSURE [PDF] ATSDR, retrieved 2019/08/19 original source: https://www.atsdr.cdc.gov/ToxProfiles/tp85-c6.pdf

Overview excerpt:

Creosote has been identified in at least 46 of the 1,613 hazardous waste sites that have been proposed for inclusion on the EPA National Priorities List (NPL) (HazDat 2002). However, the number of sites evaluated for creosote is not known.

The frequency of these sites can be seen in Figure 6-1. Of these sites, all 46 are located within the United States and none are located in the Commonwealth of Puerto Rico (not shown).

Coal tar creosote is a complex commercial mixture of some 300 organic constituents. The most common forms are derived from coal tar distillation, yielding coal tar creosote in temperature ranges between 210 and 280 EC.

Coal tar and coal tar pitch share many of the polycyclic aromatic hydrocarbons (PAHs) components of coal tar creosote. For the coal tar derivatives, the composition of the mixture varies from batch to batch depending on the coking process used. Creosote consists primarily of PAHs and, therefore, the fate of many of the components of the mixture is similar to that of PAHs.

Coal tar creosote has been widely used as a wood-treatment pesticide since the turn of the century. As a result of this widespread and long-term use, workers in the wood-preserving industry have been exposed to coal tar creosote for many years.

Human exposure to coal tar creosote can occur by inhalation or direct dermal contact. Studies have indicated that dermal exposure to creosote used in wood treatment or in coking oven processes contributed more significantly to the total body burden than respiratory exposures (Klingner and McCorkle 1994; Malkin et al. 1996; Van Rooij et al. 1993b).

In other industries, such as rubber processing, occupational exposure to coal tar pitch volatiles may lead to excessive respiratory exposure to PAHs, including benzo[a]pyrene (Rogaczewska and Ligocka 1994). Individuals working in wood-preserving facilities are one of the largest exposed groups.

Exposure may also occur during handling and installation of treated wood products in structures such as bridges, piers, retaining walls, cross ties, and fencing; as a result of burning treated scrap wood; and through contact with contaminated media at hazardous waste sites.

The general public is unlikely to experience any significant exposure to liquid creosote through the direct use of wood preservative products because EPA canceled all nonwood uses of the material and restricted use of coal tar creosote products to certified applicators in January 1986 (EPA 1986b; R.U.P. 1994). - Agency for Toxic Substances and Disease Registry (ATSDR). 2002. Toxicological Profile for Creosote (Update). Atlanta, GA: U.S. Department of Health and Human Services, Public Health Service.

- COAL TAR PITCH HAZARDS [PDF] New Jersey DOH, retrieved 2019/08/19 original source: https://nj.gov/health/eoh/rtkweb/documents/fs/0519.pdf

Excerpts:

Coal Tar Pitch is a dark brown to black, thick liquid, with a strong odor, that remains after the distillation of Coal Tar. It is used as a base for coatings and paint, in roofing and paving, and as a binder in Asphalt products.

Coal Tar Pitch is on the Right to Know Hazardous Substance List because it is cited by OSHA, ACGIH, DOT, NIOSH, NTP, IARC, and NFPA. This chemical is on the Special Health Hazard Substance List.

- CREOSOTE HAZARD ADVICE [PDF] New Jersey DOH, retrieved 2019/08/19 original source: https://nj.gov/health/eoh/rtkweb/documents/fs/0517.pdf

Excerpt:

HAZARD SUMMARY

Creosote can affect you when breathed in and by passing through your skin.

Creosote should be handled as a CARCINOGEN--WITH EXTREME CAUTION.

Skin contact can cause irritation, burning, redness, rash and itching, which is made worse by exposure to sunlight.

Repeated exposure can cause changes in skin pigment.

Contact can cause severe eye irritation and burns and may cause loss of vision.

Creosote may affect the nervous system.

CONSULT THE NEW JERSEY DEPARTMENT OF HEALTH AND SENIOR SERVICES HAZARDOUS SUBSTANCE FACT SHEETS ON COAL TAR PITCH, COKE OVEN EMISSIONS, BENZO(a)PYRENE, CHRYSENE AND ANTHRACENE FOR FUTHER INFORMATION. - CREOSOTE HAZARD INFORMATION, US EPA [PDF] Registration Eligibility Decision for

Creosote

(Case 0139), United States Environmental Protection Prevention Agency , Pesticides

and Toxic Substances, EPA 739-R-08-007 September 2008

(7510P) retrieved 2019/08/19 original source https://archive.epa.gov/pesticides/reregistration/web/pdf/creosote_red.pdf

- Boutwell, R. K., and Dorothy K. Bosch. THE CARCINOGENICITY OF CREOSOTE OIL: ITS ROLE IN THE INDUCTION OF SKIN TUMORS IN MICE [PDF] Cancer research 18, no. 10 (1958): 1171-1175.

Summary

Mice were treated with 9,10-dimethyl-1,2-benzanthracene (DMBA), creosote oil, or croton oil, alone or in several combinations of two of the agents. The incidence of papillomas and carcinomas as well as the tumor induction time of each were reported.

The effective nature of creosote as a skin carcinogen was confirmed, and its ability to act as an initiating agent prior to applications of croton oil was shown.

The average induction times for papillomas and carcinomas by the different treatments were found to vary independently. - Elovaara, Eivor, Pirjo Heikkilä, Lauri Pyy, Pertti Mutanen, and Vesa Riihimäki. "Significance of dermal and respiratory uptake in creosote workers: exposure to polycyclic aromatic hydrocarbons and urinary excretion of 1-hydroxypyrene." Occupational and environmental medicine 52, no. 3 (1995): 196-203.

Abstract:

OBJECTIVES--To evaluate workers' exposure in a creosote impregnation plant by means of ambient and biological monitoring.

METHODS--Naphthalene (vapour phase) and 10 large molecular polycyclic aromatic hydrocarbons (PAHs) (particulate phase) were measured in the breathing zone air during an entire working week. 1-Hydroxypyrene (1-HP) was measured in 24 hour urine as a metabolite of the pyrene found in neat (dermal exposure) and airborne creosote.

RESULTS--Naphthalene (0.4-4.2 mg/m3) showed 1000 times higher concentrations in air than did the particulate PAHs.

In total, the geometric mean (range) of three to six ring PAHs was 4.8 (1.2-13.7) micrograms/m3; pyrene 0.86 (0.23-2.1) micrograms/m3, and benzo(a)pyrene 0.012 (0.01-0.05) micrograms/m3. There was no correlation between pyrene and gaseous naphthalene.

The correlations between pyrene and the other nine particulate PAHs were strong, and gave a PAH profile that was similar in all air samples: r = 0.83 (three to six ring PAHs); r = 0.81 (three ring PAHs); r = 0.78 (four to six ring PAHs).

Dermal exposure was probably very high in all workers, because the daily output of urinary 1-HP exceeded the daily uptake of inhaled pyrene by < or = 50-fold. Urinary 1-HP concentrations were very high, even on Monday mornings, when they were at their lowest (4-22 mumol/mol creatinine).

1-HP seldom showed any net increase over a workshift (except on Monday) due to its high concentrations (16 to 120 mumol/mol creatinine) in the morning samples. 1-HP was always lower at the end of the shift (19 to 85 mumol/mol creatinine) than in the evening (27 to 122), and the mean (SD) change over the working week (47 (18)) was greater than the change over Monday (35 (32)). The timing of 1-HP sampling is therefore very important. CONCLUSIONS--

Urinary 1-HP proved to be a good biomarker of exposure to three to six ring PAHs but not to airborne naphthalene. Hence, biomonitoring based on 1-HP has to be completed with exposure assessment for naphthalene as a marker for creosote volatiles that mainly enter the body through the lungs.

- Heikkilä, Pirjo R., Mervi Hämeilä, Lauri Pyy, and Paavo Raunu. "Exposure to creosote in the impregnation and handling of impregnated wood." Scandinavian journal of work, environment & health (1987): 431-437.

Abstract

Exposure to creosote in the impregnation and handling of impregnated wood.

The major components of vapors and polycyclic aromatic hydrocarbons in paniculate matter were identified and quantified in two creosote impregnation plants and in the handling of treated wood. The vapors were collected on XAD-2 resin (recovery in the range of 82—102 %) and analyzed by gas chromatography.

Paniculate polycyclic aromatic hydrocarbons were collected on glass fiber filters and analyzed with high-pressure liquid chromatography with a fluorescence detector.

The main components of the vapors were naphthalene, methyl naphthalenes, indene, phenol, and its methyl homologues, benzothiophene, diphenyl, acenaphthene and fluorene. The exposure of the workers to vapors varied between 0.1 and 11 mg/m³.

The concentrations of paniculate polycyclic aromatic hydrocarbons varied between 0.2 and 46 µg/m³.

The benzo(a) pyrene concentration was under 0.03 µm/m³ except in manual metal-arc welding and in the boring of railroad ties, where it was 0.24—0.89 µm/m³. In the measurement of creosote vapors, naphthalene could be used as an indicator agent. - Holme, J. A., M. Refsnes, and E. Dybing. "Possible carcinogenic risk associated with production and use of creosote-treated wood." Tidsskrift for den Norske laegeforening: tidsskrift for praktisk medicin, ny raekke 119, no. 18 (1999): 2664-2666.

Abstract:

Creosote is a coal tar product which contains varying amounts of mutagenic and carcinogenic substances such as polycyclic aromatic hydrocarbons (PAHs) and benzene. Marketing and use of creosote and preparations containing creosote, as well as creosote-treated wood, are regulated by a EU Directive.

According to the EU classification of such mixtures, inclusion of a warning against creosote as a carcinogen is not necessary if the contents of benzo[a]pyrene (BaP) and benzene are lower than 50 ppm (parts per million) and 1000 ppm, respectively.

A recent well designed skin painting study in mice clearly indicates that the creosote preparations had a five-fold higher potency to induce skin cancer than the potency based on BaP content. Furthermore, it was estimated that creosote containing 50 ppm BaP would induce a significant incidence of skin cancer.

Preliminary results from determination of concentrations of various carcinogens (BaP and benzene) in the air close to creosote impregnation plants as well as the crudely estimated exposure of children to dermal contact with creosote-treated wood, indicate that the life-time cancer risk from such exposures is in the order of one per 10,000.

Despite the uncertainty related to such estimates, these risk levels give reasons for some concern. A further reduction in the content of PAH and benzene in creosote preparations should be considered.

- Koppers, CREOSOTE MSDS [PDF] for Creosote - Petroleum Pressure Treated Wood, retrieved 2019/08/19 original source https://www.chemadvisor.com/Koppers/Database/koppers_na/msds/00230/00230493000220003.PDF

- Koppers, CREOSOTE MSDS v2 [PDF] for Creosote - Petroleum Pressure Treated Wood, retrieved 2019/08/19 original source https://www.cemc.org/documents/msds--creosote.pdf

Excerpt:

Creosote Handling Procedures

Use methods to minimize dust. Avoid frequent or prolonged inhalation of sawdust from treated wood. When power-sawing and machining, wear goggles to protect eyes from flying particles. Whenever possible, these operations should be performed outdoors to avoid indoor accumulations of airborne sawdust from treated wood.

Avoid frequent or prolonged skin contact with creosote-treated wood; when handling the treated wood, wear longsleeved shirts and long pants and use gloves impervious to the chemicals (for example, gloves that are vinylcoated). Use protective skin cream on exposed skin before and during work shift.

To reduce sun sensitivity a sunblocking lotion (SPF 15+) can also be applied prior to application of a protective cream. After working with the wood, and before eating, drinking and use of tobacco products, wash exposed areas thoroughly. If oily preservative or sawdust accumulate on clothes, launder before reuse. Wash work clothes separately from other household clothing. - Marsden, David H. "Studies of the creosote fungus, Hormodendrum resinae." Mycologia 46, no. 2 (1954): 161-183.

- Minnesota DOT, PRESERVATION AND PROTECTION OF TIMBER BRIDGES [PDF] Minnesota Department of Transportation, retrieved 2019/09/24 original source: http://www.dot.state.mn.us/bridge/pdf/insp/USFS-TimberBridgeManual/em7700_8_chapter04.pdf

Excerpt:

Creosote, which was first patented in 1831, ushered in the age of effective wood protection. It is a black or brownish oil consisting of a complex mixture of polynuclear aromatic hydrocarbons. Creosote is derived either from the destructive distillation of coal to produce coke (a byproduct of steel production) or by distillation of oil shale.

Although creosote can be manufactured from other materials, such as wood or oil, all creosote used for commercial wood treatment is derived from coal tar. Because it is not a primary product, the composition of creosote has varied widely over the years.

However, more restrictive requirements now ensure the availability of relatively uniform creosote. Because it is a complex mixture of nearly 300 compounds, the toxic mechanisms and migration of creosote from wood are still poorly understood more than 150 years after the chemical was patented.

Creosote has a long record of satisfactory use as a wood preservative, with many case histories documenting more than 50 years of proven performance in both railroad and highway use. This chemical has performed well in almost every environment except in areas where marine borer hazards are high because of attack by Limnoria tripunctata (this species of borer is capable of attacking creosoted wood in warmer marine saltwaters).

Creosote provides the added advantages of protecting the wood from the effects of weathering and retarding the checking and splitting associated with changes in moisture content.

- Morrell, J.J., WOOD POLE MAINTENANCE MANUAL [PDF] (1996) , USDA, Forest Research Laboratory, Oregon State University College of Forestry,

- Motohashi, Noboru, Kunihiro Kamata, and Roger Meyer. "Chromatographic separation and determination of carcinogenic benz [c] acridines in creosote oils." Environmental science & technology 25, no. 2 (1991): 342-346.

- Petruska, Michael and José E. Labiosa, BEST DEMONSTRATED AVAILABLE TECHNOLOGY (BDAT) BACKGROUND DOCUMENT FOR WOOD PRESERVING WASTES F032, F034, AND F035 [PDF] U.S. Environmental Protection Agency Office of Solid Waste 401 M Street, S.W. (5302W) Washington, D.C. 20460 April 15, 1996 retrieved 2019/09/24 original source: https://archive.epa.gov/epawaste/hazard/web/pdf/bdat_bd.pdf

- Roe, F. J. C., Dorothy Bosch, and R. K. Boutwell. THE CARCINOGENICITY OF CREOSOTE OIL: THE INDUCTION OF LUNG TUMORS IN MICE [PDF] Cancer research 18, no. 10 (1958): 1176-1178.

Summary

Mice obtained from a commercial supplier were found to have a very high incidence of lung tumors, whereas the progeny of the same mice bred in this laboratory in stainless steel cages had a low incidence. The use by the animal supplier of creosoted wooden cages for breeding was the suspected cause for the high tumor incidence in the parent mice.

Creosote applied to the skin of mice led to a high incidence of both skin and lung tumors.

Mice reared in creosoted wooden boxes and also painted with creosote had a higher lung tumor incidence than mice reared in metal cages and painted with creosote.

In a second experiment it was shown that quantities of creosote too small to cause skin tumors were nevertheless effective in giving rise to lung adenomas.

Excerpt: There is, of course, no reason to think that the oncogenic effect of creosote on the lungs of mice is secondary to that on skin, or vice versa. The histological appearances of the two tumors are quite different.

Moreover, each type of tumor may be induced separately: urethan applied to the skin induces lung tumors but no skin tumors (17); [beta]-propiolactone produces skin tumors but no lung tumors (14). On the other hand, it is probable that tissues other than skin and lung are affected by exposure to creosote, and it is possible that the tumor incidence of other tissues is increased.

Creosote oil has been utilized as a wood pre servative and disinfectant in many animal colo nies, and it has been only within the past few years that its use has been abandoned by some of the larger commercial breeders of mice in the United States4 (16). Every effort should be made to dis courage the use of creosote oil in all other animal colonies. - Ryan, A. P., and AFOM UK DOH. COMMUNITY HEALTH EFFECTS RELATED TO EXPOSURES FROM CREOSOTE AND/OR CCA WOOD TREATMENT PLANTS [PDF] U.K. Department of Occupational and Environmental Health, Nelson R. Mandela School of Medicine, retrieved 2019/08/19 original source: https://www.sawpa.co.za/documents/CommunityHealthEffectsRelatedToExposure.pdf

This paper discusses the t reatment of wood in South Africa and an investigation of a specific treatment plant following health complaints from a nearby community.

Excerpt:

Environmental health concerns with respect to timber treatment operations have been recorded elsewhere. In the USA, such plants feature among the National Priorities or Superfund list of industrial sites in need of remediation. A review of public health assessments (PHA’s) of such sites confirms that:

1. Wood treatment products may contaminate soil, water and sediment on and beyond wood treatment sites, and this contamination may persist in the long term.

Off-site contamination may be aggravated by incidents such as spills, fires and flooding, as well as drainage of waste into off-site ditches or unlined reservoirs. These eventualities should be included in environmental impact assessments and risk management plans.

2. Contamination of soil, water and sediment may result in the exposure of human populations through inhalation, skin absorption and ingestion.

3. Complaints of health symptoms by residents in the vicinity of wood treatment plants have been documented elsewhere. These have included non-specific symptoms such as respiratory irritation and headaches, as well as increases in specific types of cancer.

...

It is clear that there is a need for wood treatment plant operators to be concerned about the potential effects of their operations on surrounding communities, for reasons of social responsibility and concern for public health as well as out of regard for the possible legal and economic consequences. - Schoket, Bernadette, Alan Hewer, Philip L. Grover, and David H. Phillips. "Formation of DNA adducts in human skin maintained in short‐term organ culture and treated with coal‐tar, creosote or bitumen." International journal of cancer 42, no. 4 (1988): 622-626.

- Sundström, G., Å. Larsson, and M. Tarkpea. "Creosote." In Anthropogenic Compounds, pp. 159-205. Springer, Berlin, Heidelberg, 1986.

Abstract:

Creosote is a complex chemical mixture with major use as wood preservative.

Recent chemical and biological investigations have shown that creosote contains a number of highly biologically active organic components and exerts toxic effects, especially against aquatic organisms. Many components are also chemically and biologically stable and environmental contamination from creosote persists for many years.

The general use of creosote as a pesticide has accordingly been questioned and its use been restricted in some countries. - TWLCMC MANAGEMENT of USED TREATED WOOD PRODUCTS [PDF] Treated Wood Life CYcle Management Coalition, retrieved 2020/10/18 original source: https://www.rta.org/assets/docs/mngt%20of%20%20used%20treated%20wood%20products.pdf

Excerpts:

This paper provides the party managing thematerial, as well as the receiving party, with the basic information needed for making cost effective andenvironmentally sound management decisions regarding the reuse or disposal of treated wood products.

...

Treated wood is not a pesticide and therefore is not subject to regulation under FIFRA.

Treated wood when reused in a manner consistent with its "intended enduse" is not being disposed and therefore should not be classified as a solid waste.

Treated wood that is disposed is not a hazardous waste under federal law becauseit has not been listed and testing has demonstrated that it does not exhibit ahazardous characteristic. Therefore it can be managed in any waste managementfacility (e.g., landfill or combustion system) authorized under state and local lawto manage the material - U.S. Army TECHNICAL GUIDE 146 GUIDE FOR HANDLING, REUSE, AND DISPOSAL OF CHEMICALLY TREATED WOOD MATERIAL [PDF] (2017) U.S. Army Public Health Center, APHC,

Excerpts:

Due to the toxicity associated with these chemical preservatives, handling, reuse and disposal issues arise when chemically treated wood items are no longer viable for their original use.

This technical guide (TG) is intended for use as an aid for determining proper handling, reuse, and disposal practices for chemically treated wood items generated by Department of Defense (DOD/DoD) activities, primarily of wooden pallets and ammunition boxes, railroad ties and crossarms, utility poles, and construction and demolition debris since these items may contain Federal or State regulated hazardous constituents depending on the chemical wood preservative used (i.e., arsenic, chromium, copper, cresols (constituents of creosote), polycyclic aromatic hydrocarbons (PAHs), and PCP).

Though the EPA does not classify treated wood as a hazardous waste under Federal regulations, Department of the Army (DA) and DOD facilities must continue to manage treated wood in accordance with all applicable State and local regulations and policy.

Overall, Federal, State, local, DA and DOD regulations and policy promote the reuse and recycling of chemically treated wood materials in an effort to conserve natural resources and reduce human and environmental health risk associated with the disposal. Reuse and recycling also reduces treatment/disposal costs for DOD facilities. - U.S. EPA REREGISTRATION ELIGIBILITY DECISION FOR CREOSOTE (CASE 0139) [PDF] (2008) U.S. Environmental Protection Agency, retrieved 2020/10/18 original source: https://www3.epa.gov/pesticides/chem_search/reg_actions/reregistration/red_PC-025004_25-Sep-08.pdf

Abstract: The Environmental Protection Agency (EPA or the Agency) has completed the human health and environmental risk assessments for creosote and is issuing its risk management decision.

The risk assessments, which are summarized below, are based on the review of the required registrant submitted data supporting the use patterns of currently registered products, citations from open literature, and additional information received through the docket.

The risk assessments have been revised, as needed, according to information received since they were last made available to the public in April through June 2008.

After considering the risks assessments, available information about alternatives to creosote, public comments, and risk mitigation options, the Agency developed its reregistration eligibility and risk management decision for wood preservative uses of creosote.

As a result of this review, EPA has determined that creosote containing products are eligible for reregistration, provided that risk mitigation measures are adopted and labels are amended accordingly. The reregistration eligibility decision and associated risk mitigation measures are discussed fully in this document.

Excerpt:

The Agency is aware that materials such as utility poles or railroad ties may be sold for reuse after their original intended use has ended. The typical lifespan for a utility pole or railroad tie is approximately 10 to 30 years, depending on climate, setting and other factors. These materials are often sold into a secondary market where they may be installed in residential settings for garden borders, etc.

Because the lifespan of these treated materials is fairly long, the Agency believes that the creosote leaching from the treated material is significantly less than when it was originally placed into service.

The Agency has not conducted a risk assessment of these secondary uses of creosote-treated materials but has begun to evaluate these uses and has found that other options such as disposing of these materials in a landfill, or incinerating these materials for energy generation are also currently practiced.

Further evaluation of the potential risks and benefits associated with these secondary uses of creosote-treated materials will be conducted during the Registration Review for this active ingredient. - U.S. DHS, PUBLIC HEALTH ASSESSMENT for CREOSOTE [PDF] Federal Creosote, Manville, Somerset County NJ, 22 Sept. 2000, retrieved 2019/08/19 original source: https://ntrl.ntis.gov/NTRL/dashboard/searchResults/titleDetail/PB2001100165.xhtml Prepared By:

New Jersey Department ofHealth and Senior Services

Hazardous Site Health Evaluation Program

Consumer and Environmental Health Services

Division ofEpidemiology, Environmental and Occupational Health

Under a Cooperative Agreement with the

Agency For Toxic Substances and Disease Registry

Excerpt from summary: The Federal Creosote site is a 53-acre site which includes a 15-acre shopping/commercial area and a 35-acre housing development. These two areas were built over a former wood treatment facility in which railroad ties were treated with coal tar creosote from approximately 1910 to 1956.

After operations ceased, two lagoons and two canals containing used coal tar creosote were covered with fill, the site was graded, and the area developed for commercial and residential purposes. The residential portion, built in the mid-1960s, is known as the Claremont Development. - US DEHS, TOXICOLOGICAL PROFILE FOR CRESOLS [PDF] (2008) U.S. Department Of Health And Human Services Public Health Service

Agency For Toxic Substances And Disease Registry. Agency for Toxic Substances and Disease Registry

Division of Toxicology and Environmental Medicine/Applied Toxicology Branch 1600 Clifton Road NE

Mailstop F-32

Atlanta, Georgia 30333 This was an update to the 2006 draft.

Excerpts: A peer review panel was assembled for cresols. ... These experts collectively have knowledge of cresol's physical and chemical properties, toxicokinetics, key health end points, mechanisms of action, human and animal exposure, and quantification of risk to humans.

When a substance is released either from a large area, such as an industrial plant, or from a container, such as a drum or bottle, it enters the environment. Such a release does not always lead to exposure.

You can be exposed to a substance only when you come in contact with it. You may be exposed by breathing, eating, or drinking the substance, or by skin contact.

If you are exposed to cresols, many factors will determine whether you will be harmed. These factors include the dose (how much), the duration (how long), and how you come in contact with it.

You must also consider any other chemicals you are exposed to and your age, sex, diet, family traits, lifestyle, and state of health. - US DEHS, TOXICOLOGICAL PROFILE FOR WOOD CREOSOTE, COAL TAR CREOSOTE, COAL TAR, COAL TAR PITCH, AND COAL TAR PITCH VOLATILES [PDF] US DEHS, Choudhary, Gangadhar, Mario J. Citra, and Antonio Quiñones-Rivera (September 2002).

- US DEHS, DRAFT TOXICOLOGICAL PROFILE FOR

WOOD CREOSOTE, COAL TAR CREOSOTE, COAL TAR,

COAL TAR PITCH, AND COAL TAR PITCH VOLATILES [PDF] (2000) Agency for Toxic Substances and Disease Registry

Division of Toxicology/Toxicology Information Branch

1600 Clifton Road NE, E-29

Atlanta, Georgia 30333 USA retrieved 2019/08/19 original source: http://www.seagrant.umn.edu/water/report/chemicalsofconcern/creosote/creosote.pdf

[Note: This is the most exhaustive and technically interesting exposition of creosote and its hazards that we have found to date - Ed. ]

Excerpts:

Wood creosote, coal tar creosote, coal tar, coal tarpitch, and coal tar pitch volatiles are rarely formed in nature. Creosote is the name used for a variety of products that are mixtures of many chemicals. Coal tar creosote, coal tar, and coal tar pitch are similar in composition. For this reason, many times throughout the profile, we will refer to coal tar creosote, coal tar, and coal tar pitch simply as creosote.

Creosotes are created by high-temperature treatment of beech and other woods (beechwood creosote) or coal (coal tar creosote), or from the resin of the creosote bush (creosote bush resin).

Wood creosote is a colorless to yellowish greasy liquid with a characteristic smoky odor and sharp burned taste. It is relatively soluble in water. Creosote prepared from coal tar is the most common form of creosote in the workplace and at hazardous waste sites in the United States.

Coal tar creosote is a thick, oily liquid that is typically amber to black in color.

It is easily set on fire and does not dissolve easily in water. Coal tar and coal tar pitch are the by-products of the high-temperature treatment of coal to make coke or natural gas.

They are usually thick, black, or dark brown liquids or semisolids with a smoky or aromatic odor.

Coal tar residues can also be found in the chimneys of homes heated with coal, especially if insufficient oxygen is present.

Chemicals in the coal tar pitch can be given off into the air as coal tar pitch volatiles when coal tar pitch is heated. - Washington State, TREATED WOOD WASTE [PDF] retrieved 2020/10/18 original source: https://ecology.wa.gov/Regulations-Permits/Guidance-technical-assistance/Dangerous-waste-guidance/Common-dangerous-waste/Treated-wood-waste

Excerpts:

Treated wood waste commonly comes from demolition sites. To encourage proper disposal of this material, there are exemptions for managing this waste in the dangerous waste regulations. We offer guidance for both commercial generators and homeowners.

Treated wood is full of chemicals. Outdoor and structural wood is preserved from deterioration and natural decay caused by insects, fungi, and marine borer worms by dipping, spraying, or pressure-treatment with pesticides that contain harmful chemicals.

Since dangerous levels of pesticides are hard to see, it is important that wood waste from commercial sites is properly designated.

Household wastes are excluded from the dangerous waste regulations.

If you have treated wood waste from your household: Dispose of treated wood in your trash collection. Do not burn treated wood waste in open fires, stoves, fireplaces, or residential boilers. Toxic chemicals may be produced as part of the smoke and ash. - World Health Organization. CRESOLS: HEALTH AND SAFETY GUIDE (1996) [PDF] . Common name: Cresols (a, m, p-isomers) Formula: C7HsO and Common synonyms for creosote include: 2-methyl phenol 2-hydroxy toluene a-{;resylic acid a-kresol (German) 3-methyl phenol 3-hydroxy toluene m-{;resylic acid m-kresol (German) 4-methyl phenol 4-hydroxyl toluene p-{;resylic acid p-kresol(German)

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Does creosote that is created by burning woodchips to smoke meats have the same risks as coal tar creosote?

does creosote that is created by burning woodchips to smoke meats have the same risks as coal tar creosote?

i have to clean the smoke generators and flu pipes for a commercial smoke house company a lot and they don't offer any good PPE.

I have gotten creosote on my hands quite a lot from said activities. - On 2022-08-01 by sbc -

Reply by InspectApedia-911 (mod) - Difference Between Wood Fire Creosote & Coal Tar Creosote

@sbc,

The toxicity of coal tar creosote (such as was used on railroad ties) is a bit different from the creosote created when burning wood, and wood creosote varies considerably further depending on the wood species burned and its moisture or sap content. (Green wood - more creosote).

There are other variables too like oxygen supply to the fire and fire temperature that affect the creosote deposited in the wood burning appliance or chimney.

Take a look at this citation from the page above

TOXICOLOGICAL PROFILE FOR WOOD CREOSOTE, COAL TAR CREOSOTE, COAL TAR, COAL TAR PITCH, AND COAL TAR PITCH VOLATILES

https://inspectapedia.com/Environment/Creosote-Toxicology-USDEHS.pdfContinuing, in that document the authors compare the two creosote types

4.2.1 Wood Creosote - see page 216

4.2.2 Coal Tar Creosote, Coal Tar, and Coal Tar Pitch - see page 220

...

Continue reading at ENVIRONMENTAL HAZARDS at BUILDINGS - home page or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

See CREOSOTE HAZARD FAQs - questions & answers posted originally on this page.Or see these

Recommended Articles

- BURMA SHAVE - life along the Rappahannock

- CHIMNEY STAINS & LEAKS

- CREOSOTE FIRE HAZARDS

- CREOSOTE ODOR CURE / REMOVAL

- FIRE & SMOKE ODOR REMOVAL

- SMELL PATCH TEST to FIND ODOR SOURCE

Suggested citation for this web page

CREOSOTE HAZARDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ENVIRONMENT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.