How to Inspect Septic Systems,

How to Inspect Septic Systems,

Online Course on Septic

Testing Methods & Procedures

- POST a QUESTION or COMMENT about how to inspect or test septic systems, septic inspection procedures, septic failure criteria, and septic inspection results reporting.

How to conduct septic inspections & report septic system conditions:

This septic system inspection and testing classroom presentation explains how septic systems are inspected & tested, from the basics of what a septic system is, what the components of a septic system are, how each component is found and inspected, and what constitutes a septic system failure at each component or step.

We give detailed procedures for visual inspection of septic systems, septic system testing including loading and dye tests and other procedures, invasive inspection methods, septic tank pumping, D-box examination, field inspection, septic capacity evaluation, & reporting the condition of septic systems, drywells, cesspools, leachfields, galleys and other onsite waste disposal systems and equipment. Future trends in on site waste / wastewater disposal & legislation pertaining to septic systems and groundwater contamination are also discussed.

InspectAPedia tolerates no conflicts of Interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Septic Inspection Procedure - Online Course

If you already know the basics about septic systems, tanks, drainfields, and septic inspection procedures in general, then you can skip immediately our list of individual, detailed septic inspection procedures found

at SEPTIC SYSTEM INSPECTION & TEST GUIDE

Home buyers who want less technical advice should see

the SEPTIC SYSTEMS, HOME BUYERS GUIDE to . There you'll find that we also provide a septic system guide for people selling their home and who wish to stay out of trouble.

Also see our septic & onsite wastewater disposal system home page

at SEPTIC SYSTEM INSPECT DIAGNOSE REPAIR

The text of this septic inspection class and guide follows the indexed contents listing immediately below.

Septic system inspection class with text and illustrations for the inspection, testing, and diagnosis of septic systems (onsite wastewater disposal systems) provided by Daniel Friedman at Inspection Training Associates Inspection Expo '98, Riviera Hotel, Las Vegas NV October 1-4, 1998 [updated and expanded through 079/11/2024]

Article Series Contents

- SEPTIC SYSTEM INSPECTION & MAINTENANCE COURSE

- WHAT IS A SEPTIC SYSTEM - What is Onsite Wastewater Disposal?

- EXPLAINING SEPTIC SYSTEMS TO CLIENTS to clients

- WHAT ARE THE FUNCTIONS OF A SEPTIC SYSTEM

- WHAT ARE THE COMPONENTS of a Typical Septic System (Onsite Waste Disposal System)

- SPECIAL TYPES OF SEPTIC SYSTEMS & Alternative Septic Designs

- SEPTIC FAILURE CAUSES - course chapter Defining "Failed" Onsite Wastewater Treatment or Disposal

- SEPTIC FAILURE CRITERIA

- CESSPOOL FAILURES (MA) Massachusetts

- SOIL ABSORPTION SYSTEM FAILURES (leach fields, drain fields, seepage pits)

- MAINTENANCE NEEDS OF SEPTIC SYSTEMS

- SEPTIC TANK PUMPING FREQUENCY depends on these variables:

- SEPTIC SYSTEM INSPECTION SAFETY & Health Concerns

- HOW TO INSPECT & EVALUATE the Condition of Septic Systems - On Site Waste Disposal

- COLLECT HISTORICAL INFORMATION about the Onsite Waste Disposal System

- VISUAL SITE INSPECTION of the Septic System:

- LOCATE THE SEPTIC SYSTEM

- INSPECT OUTSIDE WASTE PIPING

- PERFORM SEPTIC LOADING & DYE TEST

- PUMPING the SEPTIC TANK for Further Investigation of System Condition

- EXCAVATE & INSPECT SEPTIC DISTRIBUTION BOXES

- INSPECT THE SOIL ABSORPTION SYSTEM of an Onsite Wastewater Disposal System

- RECENT & FUTURE TRENDS in Onsite Waste Disposal Systems

- CONCERN FOR WATER QUALITY is increasing

- EFFLUENT DISPOSAL VS. TREATMENT

- LEGISLATION & Mandated Septic System Upgrades

- ALTERNATIVE AND ADVANCED Onsite Waste Water Treatment & Disposal Systems are Available

- GLOBAL WARMING & SEPTIC SYSTEMS

- SEPTIC SYSTEM INSPECTOR LICENSING OR QUALIFICATIONS

- SEPTIC SYSTEM INSPECTION LEVELS: level 0, level 1, level 2 defined

- SAMPLE SEPTIC INSPECTION WORKSHEETS & TEST REPORTS

What is a Septic System - What is Onsite Wastewater Disposal?

A "septic system," also referred to as a private, on-site waste disposal system, receives waste water and solids from a building's plumbing facilities (bathrooms, kitchens, shower, laundry), treats, and then disposes of the effluent from this waste, by permitting it to absorb into soils at the property.

As we elaborate at SEPTIC TANK & SYSTEM CARE BASICS, a septic system at a typical home consists of a septic tank or "holding Tank" where natural bacterial action decomposes human waste products into environmentally acceptable components - the major end-components being water, mixed with some other components that are not readily consumed by the bacterial action, gases, and undigested solids.

The end products, except the undigested solids, are then discharged to the on-site environment. In a conventional septic tank, sewage waste treatment is just partial, up to about 45% of what is needed. The remaining treatment of wastewater as well as the actual disposal of liquid waste (clarified effluent) is in the soils of the drainfield.

Wastewater or septic effluent treatment is accomplished by bacterial (and other microorganism) action in the "septic" or "treatment" tank and it is mostly accomplished by bacteria in the soil around and below the effluent absorption system, or "drain field." This bacterial action is needed to reduce the level of pathogens in the effluent discharges from the waste system into the soil.

In addition to reducing the level of pathogens and the reduction of organic waste to a combination of new cell masses, CO2, and water, wastewater treatment removes organic matter, nitrites and nitrates, and phosphorous. In an absorption field the soil performs an additional role of filtering the septic effluent.

Having a property served by a private or onsite septic system means that wastewater, that is blackwater from toilets and graywater from sinks, showers, washers, etc., is disposed-of on the property rather than being piped to a municipal sewage treatment plant. Actually this is speaking carelessly.

More precisely, solid waste is retained in a holding (septic) tank from which it is periodically removed for disposal at an approved dumping facility. Clarified effluent is discharged from the tank (onsite wastewater) and is allowed to seep into the soil on the property through a drainfield or other system.

Explaining septic systems to a home owner or home buyer

"Yuck! You mean sewage stays in my yard?" I don't want that stuff on my property!

Yep. But not to worry, properly installed and maintained, the system can be sanitary and unobtrusive. It's true however that some maintenance is needed, particularly periodically pumping the tank. We'll talk about that in a minute. First let's look at a very basic understanding of what's installed and how it works.

The principal components of a private on-site waste disposal system usually include the following:

- Wastewater Piping connecting the building to the treatment tank conducts wastewater from toilets, sinks, tubs, showers, out to a septic tank. Wastewater from toilets is called "black water" and wastewater from sinks is called "graywater"

- A septic tank or sewage treatment tank which retains solid waste, letting liquid waste flow to an onsite disposal system. Be sure to

see SEPTIC TANK PUMPING SCHEDULE since pumping the septic tank regularly is the single most useful thing you can do to extend the life of a septic system. - Effluent piping connecting and conducting clarified effluent from the treatment tank to a distribution box

- A distribution box connecting the effluent line from the tank to the absorption system or "drain field"

See SEPTIC D-BOX INSTALL, LOCATE, REPAIR - An absorption system which permits effluent to drain to soils below and some of it to evaporate to air above.

There are many ways to get rid of septic effluent, described

at SEPTIC SYSTEM DESIGN BASICS

and

at SEPTIC SYSTEM DESIGN ALTERNATIVES, or see the list and definitions

given

at DEFINITIONS, SEPTIC SYSTEM - A bio-mat or bio-mass of pathogen-digesting bacteria which forms in soil below the absorption system. The bio-mat is what makes the wastewater sufficiently sanitary to discharge into the ground.

Many variations on this general scheme are used, depending on local climate, soil conditions, available space, economy, and available materials. Special equipment and systems may be designed for problem or difficult sites such as rocky or wet ground, permafrost, or wet tropical marshlands.

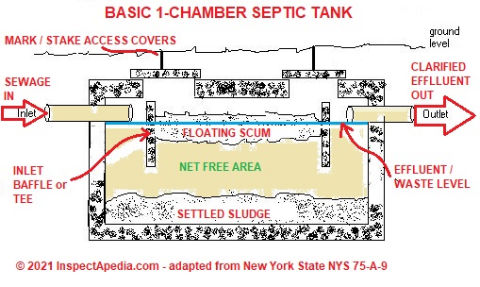

Below is a simple sketch of a septic tank showing how solid waste is retained inside the tank while liquid effluent flows to the drainfield. (Click images to see an enlarged version - adapted from New York State NYS 75-A-9).

Key articles for people unfamiliar with septic systems are given at the end of this page.

What are the Functions of a Septic System?

In a typical modern system, waste from house plumbing, (kitchen sink, bathroom sink, shower, toilet, laundry) flows through house waste pipes into a two-part system: a septic tank, whose job is to retain all solid waste, and a soil absorption system whose job is to permit clarified effluent (liquid from the tank) to seep into the soil.

In the absorption system bacteria which occur naturally in the soil digest septic bacteria and other pathogens so that the liquid is eventually sanitary and doesn't contaminate the private wells, ponds, or streams. There is some bacterial action in the tank but most of it, and all of the important action occurs in the soil absorption system.

What are the Components of a Typical Septic System (Onsite Waste Disposal System)

What is the Septic Tank and What's its Function?

The septic tank in a modern system is a water tight container, usually concrete, sometimes fiberglass. Older steel tanks were used in many areas but might be considered a problem because of both small size and because eventually they rust out and fail.

The tank is normally "full" of liquid and waste all the time. Since the tank is normally water tight, if we run 100 gallons of water in the house, 100 gallons of water enters the tank and pushes 100 gallons of effluent out of the tank into the soil absorption system.

The job of the septic tank is to keep solid waste from flowing out into the absorption system where it would clog the soil absorption system. Floating debris such as grease collects in the scum layer. Heavier solid waste eventually settles to the bottom of the tank.

Some wastewater treatment occurs in the tank, up to perhaps 40% of the total treatment needed before wastewater is discharged to the environment. Treatment in the septic tank includes mostly anaerobic bacterial action and conversion of organic nitrogen to ammonia.

Anaerobic treatment in a conventional septic tank is slow and incomplete. You can see that the "tees" or baffles to permit only liquid effluent to flow out of the tank to the absorption field.

Alternative septic system designs, and there are quite a few, include aerobic septic systems which, by adding oxygen and air to the septic tank, increase the level of treatment there. Septic tanks require periodic cleaning to remove solids - more on that later

Alternative septic system designs such as aerobic septic tanks use a pump to add air (oxygen) to the septic tank or other methods to increase the level of sewage treatment in the tank. But beware of just adding an air pump to a conventional septic tank not designed for that purpose: the continued agitation waste in such a tank can lead to rapid clogging failure of the drainfield.

See SEPTIC SYSTEM DESIGN BASICS for a wide variety of alternative septic system designs including aerobic and others.

More Reading about Septic System Basics and Septic Tanks

- HOME BUYERS GUIDE to SEPTIC SYSTEMS- Inspection & Testing - What to Do, Step by Step.

- SEPTIC TANK & SYSTEM CARE BASICS - An Engineer's View & Septic System FAQ's

- TEN STEPS to KEEP a SEPTIC SYSTEM WORKING - suggestions from the U.S. EPA, edits and additions by DJF

- EFFLUENT RETENTION TIME - Septic Tank Pumping Guide discusses retention time and "net free area" in a tank (allowing for sludge and scum layers)

Above you can see sketches of two commonly-used concrete septic tanks.

What is the Septic Leach Field. What are its Components and its Function?

Clarified effluent flows from the tank into a soil absorption system, (SAS), also commonly called a drainfield, leach field, leaching bed.

The drainfield is typically made of perforated pipes buried in gravel-filled leaching trenches or in a leaching bed. There are other types of SAS as well, and in the case of alternative or slightly more sophisticated septic systems, perhaps a raised bed or sand bed system.

The job of the soil absorption system is to treat the effluent by removing contaminants. This happens as the effluent soaks into the soil where bacterial action and filtration take place to convert unsanitary liquid to a sanitary condition before it flows onward deeper into the soil or ultimately to other locations. A biological mat forms below the SAS and performs this treatment.

Here's a sketch of side and top views of a system. Notice the three "drop boxes" also called distribution boxes which are used to connect several perforated pipes together.

Here's an idea of how effluent flows into the soil from the soil absorption system:

The job of the distribution box, or drop-box, or "d-box" is to provide equal distribution to each absorption pipe or trench, or in some cases to allow you to adjust the flow of septic effluent unevenly among various leachfield lines if that's needed.

Notice that in proper operation the effluent is moving down, not up to the surface.

The Homeowner is Responsible for Septic System Maintenance & Repairs

Septic systems are costly to install and they are not entirely care free. In the septic tank, undigested solids (sludge) in the bottom of the septic tank should be pumped out every two to four years, depending on usage and tank size - exactly when to pump or clean out the septic is given

at SEPTIC TANK PUMPING SCHEDULE.

If the septic tank sludge is not removed periodically, it will eventually carry over into the leach field and cause the field to fail.

A well designed septic system can handle a reasonable amount of normal household chemicals such as drain cleaners, laundry detergent and bleach; excessive usage can be detrimental. You should avoid putting in chemicals that are toxic to the bacteria, such as paint thinner, solvents, insecticides, etc.

See WHAT CAN GO INTO TOILETS & DRAINS? for details of what should not be flushed down toilets or other drains. And if a garbage disposal is used, more frequent tank pumping may be needed.

See GARBAGE DISPOSAL vs SEPTICS

Depending on the size of the tank and your location, plan on a cost of about $200 each time the tank is pumped. When the tank is pumped, your service person should also check the tank baffles for possible damage; ask them to do this inspection before you contract with them. While the tank is open, the service technician can also run some water from a hose into the distribution box to get an indication that the leach field is also still functioning; ask if the company offers this service.

More Reading about Septic System Drainfields or Leach Fields

- SEPTIC DRAINFIELD SIZE size and specifications for leach fields, absorption beds, gravelless systems, seepage pits

- Absorption Fields Trench Length has an example of calculating leach line trench length.

- SEPTIC DRAINFIELD SIZE specifications for leach fields, absorption beds, gravelless systems, seepage pits

- SOIL PERCOLATION TESTS septic soil tests, deep hole tests

- PLANTS & TREES OVER SEPTIC SYSTEMS trees, shrubs, groundcover over the septic system: what can you plant over or near septic system components without causing a problem?

- WASTEWATER TREATMENT BASICS describes the basic processes that occur in wastewater treatment processes

- [3] Alaska DEC, HOW to MAINTAIN YOUR SEPTIC SYSTEM [PDF] Alaska Department of Environmental Conservation, Division of Water, retrieved 8/8/12, original source: http://dec.alaska.gov/water/wwdp/onsite/maintain_septic.htm

Special Types of Septic Systems and Alternative Septic Designs

Older properties used systems such as cesspools, or tanks connected to DRYWELL DESIGN & USES or seepage pits which worked but often have more limited capacity and/or life.

Special land forms may require special systems. In areas where there is limited space, rocky soil, or other limitations, mound systems (bring in fill for rocky sites), dosing systems (pumps to overcome elevation restrictions) , sand filter beds (alternative treatment) , and other special systems such as recirculating sand filters and even systems that inject chlorine into effluent for discharge into waterways may be installed.

We discuss special systems if we have reason to believe that one is installed at the property being inspected. Different test procedures may be required!

See

- CESSPOOLS explained, design specifications, safety, photos, sketches

- DRYWELL DESIGN & USES Home Buyer's or Owner's Advice

- SEPTIC SYSTEM TYPES for a wide variety of these alternative septic system designs.

Define "Failed" Septic System: Onsite Wastewater Treatment or Disposal

This section is now found

at SEPTIC FAILURE CAUSES - course chapter - also

see SEPTIC FAILURE SIGNS - separate article

Maintenance Needs of Septic Systems

A principal measure to avoid system failure is periodic tank pumping. Systems can appear to "work" for a long time without maintenance. Modern system failure theory talks about systems that "crash."

This means that a system can appear to be ok for a long while but may actually be getting in so much trouble that by the time a problem is noticed it's too late to do anything about it.

The system crashes and is beyond repair. When a tank is not pumped sufficiently often there is less settling time for waste entering the tank, so small bits of floating solids are pushed out into and begin clogging the soil absorption system, shortening and eventually ending its life. I've found 9-year old systems which were in total failure for this reason.

Septic Tank pumping frequency depends on these variables:

- Septic Tank size or capacity

- The volume of wastewater (number of occupants)

- Amount of solids in wastewater (garbage disposers)

Table I at SEPTIC TANK PUMPING GUIDE: When, Why, How provides details of tank size in gallons, number of occupants in the building, and tank pumping frequency in years.

Septic tanks will not fail immediately if they are not pumped. However, an un-maintained septic tank is no longer protecting the soil absorption field from solids. Continued neglect may result in system failure and even replacement of the soil absorption field. In some cases, site limitations may make replacement of the absorption field impossible.

Septic System Inspection Safety & Health Concerns

This information is now found

How to Inspect & Evaluate the Condition of Septic Systems - sequence of steps

Septic systems should be conducted in as non-intrusive a manner as possible. Depending on the level of service being provided by the inspector, local conditions, and client/owner requirements, the depth of information collected and extent of testing performed will vary widely. The steps described below give a general outline of types of investigation possible.

Collect Historical Information about the Onsite Waste Disposal System

Collect existing information from owner, realtor, municipality, if available: Original "as approved" or "as built" plans showing system components, layout, type of use, design flow, water use records, service (pumping) and repair records.Visual Site Inspection of the Septic System:

Examine the site for possible component locations & other clues:- On a property by a stream, pond, storm sewer, watch out for "repairs" that extended the SAS into these locations.

- Look for site problems: rocky areas, wet areas, areas taking surface or roof runoff and prone to flooding, odors, unusual growth, green stripes marking leach trenches, soggy sewage erupting at the surface, signs of recent excavation.

- If a well casing is visible note its location and distance from actual or most likely septic component locations.

- Notice dry as well as wet areas; if you perform a loading/dye test you'll want to look for changes anywhere on the property.

Even if you are not performing a septic inspection or test, if you are able to notice obvious signs of failure and fail to report them, you may be considered not to have conducted your inspection with professional diligence in behalf of your client.

How to Locate Septic System Components

We're talking about mostly buried stuff here. Remember that unless you actually find and open an access cover and confirm flow from the house into it, all you're doing is identifying typical or likely component locations in order to assist in understanding the property and to look for signs of failure.

- Septic Plans: Never assume that the system was installed exactly according to plan. Never assume that components are located in the most likely space unless you have hard evidence. Never assume that a tank cover you see is for a system still in use; it may have been abandoned.

- Main waste pipe in house indicates only the point of exit and a likely direction for septic components; components may be anywhere, even off the property or actually non-existent! Look for room for a tank and for room for the SAS.

- Septic Tanks: are often buried close (10' or more) to the building as that's where there is backfill and a place to bury this large object; but they can be quite remote.

- Rectangular outline, depression,

dry or green growth may mark a concrete septic tank;

Round outline about 5' in diameter may mark a steel tank. Watch out for unsafe covers! - Recent excavations: may mark septic components.

- Tank covers, cleanout-access ports: may be visible;

- On a fairly new property one would not expect the SAS to be located on a rocky ridge or amongst dense mature trees where a backhoe would not have been able to pass for excavation.

- Sewage does not flow up-hill unless there is a pump-system or siphon system installed

- Basement plumbing: may not empty into the main system - notice the level at which the main waste line exits the building; if it's above basement fixtures and there is no sewage pump system you should be looking for additional septic components.

- Special equipment: is available to locate pipes and tanks, using snakes and electronic sensors. A septic contractor or plumber in your area may have these tools; even a simple plumbing snake from the main house cleanout can indicate probable distance to a tank.

- Distances between septic system components and wells, streams, etc. are detailed in my Table of Septic and Well Distances citing various authorities and distances to streams, lakes, farm buildings, etc.

- Depressions in the ground, especially near a building, may indicate the location of a septic tank; depressions in the drainfield often will mark the locations of leach bed lines, and similarly, a depression in the drainfield area in the shape of a small rectangle may indicate the location of a septic distribution box.

SEPTIC CLEARANCES - Online Table of Required Clearances: Distances Between Septic System & Wells, Streams, Trees, etc.

Details about septic system clearances are at Online Table of Required Septic Clearances: Distances Between Septic System & Wells, Streams, Trees, etc. but text is repeated here for readers who scroll down rather than linking to the separate chapter.

Common guidelines are at least 50' clearance or distance between the well and the septic system tank or 150' between the well and the septic drainfield or leaching bed. Beware that local soil and rock conditions can make these "rules of thumb" very unreliable. See "One and Two Family Dwelling Code, Section P-2510-Combined Seepage Pits and Disposal Fields," and Table P-2504, "Location of Sewage Disposal System." Other references are cited at the end of this table.

Typical clearances for septic tank, soil absorption system (SAS), etc. This table describes distance requirements between septic components and wells, streams, trees, property boundaries, lakes, etc.

A second section of the table gives distances from wells to septic systems and other encumbrances. NOTE: these distances are for conventional onsite waste disposal systems which specify clearances presuming that effluent is being disposed-of after minimal treatment such as is received by a septic tank or cesspool.

Advanced onsite wastewater treatment systems, such as those described by Jantrania and Gross (2006), permit substantial reduction in these clearances, depending on the level of treatment achieved.

Inspecting Outside Waste Piping

Outside waste piping conducts sewage (black water and gray water) from the building to the treatment tank or "septic tank," and from the treatment tank to the distribution box. These lines should be of solid, non-perforated material and need to be protected from mechanical damage (such as by vehicles).

Piping extending from the distribution box into drain fields is normally perforated, though solid lines might be used if effluent is being processed by more specialized devices such as seepage pits, galleys, or a sand-bed system.

House to tank

This line may become blocked by waste, damaged by collapse of a section, or invaded by roots. Detection of these conditions is fairly easy by routing a snake or power snake from the building drain to the septic tank. An experienced power snake operator can often tell by "feel" that a drain line is collapsed, partially collapsed, or invaded by roots.

While you may make a temporary "repair" of such a condition by drain-cleaning, if the line is broken or root-invaded, you should expect to have to excavate and replace it soon.

Tank to Distribution Box

The same failures can occur on this line as from house to tank. Opening the D-box can also show whether or not effluent is being directed uniformly into each of the leach lines.

A tipped D-box can overload one line and cause early failure of the absorption system. If this is happening, flow adjustment end-caps (eccentric holes) can be installed in the distribution box on the inlet end of each of the drain lines, permitting adjustment of effluent delivery into each line, perhaps relieving the problem line and redistributing effluent into the others.

Drain field piping

In a conventional "drain field" of perforated pipes buried in gravel-filled trenches, a drain line may be invaded by tree roots. This is why experts advise keeping tree and shrub plantings away from drain fields. Vehicle traffic can also collapse this or any outdoor waste piping, which is why experts advise against ever driving over a drainfield or over any other septic system components.

Performing A Septic Loading & Dye Test

Septic Loading and Dye Testing is a useful, somewhat controversial, and not conclusive test of a system involving placing a tracer dye in a toilet, flushing the dye into the system, and running a reasonable test volume of water (minimum 150 gallons or 50-gallons per bedroom) into the system to look for signs of blockage in the building, backup in the building, or breakout of effluent (possibly dyed) anywhere on or around the property.

There is no question that this procedure is useful in that it has disclosed numerous septic failures and has proven that preexisting wet areas did, in fact, come from the septic system. It will NOT find every failure condition. Below I describe the general procedure for performing a loading and dye test of an onsite waste disposal or "septic" system.

See complete details at

SEPTIC LOADING & DYE TEST PROCEDURE a detailed step by step outline. how to perform a Septic Loading and Dye Test - the complete procedure for septic loading & dye testing, a septic function test

Excavating & Pumping Septic Tanks for Further Investigation of System Condition

This task is handled by a septic pumping company or a company working along with a septic system inspector. I schedule the pumper to arrive several hours after starting my inspection so I can do my loading test if one is to be performed. A detailed septic report (such as required by MA Title 5) includes:

- Description of septic tank: age, size, condition, location

- Distance between bottom of scum layer and bottom of outlet tee (want 2" or more else need pump)

- Distance between top of scum layer and top of outlet tee (want 2" or more else need pump)

- Thickness of scum layer

- Depth of sludge layer and distance from top of sludge to bottom of outlet tee (want 12" or more else need pump)

- Evidence of leakage into our out of tank (abnormal liquid top level)

- Evidence of effluent backup (runs back into tank during pumpdown). Note that a backup due to a plugged line is not a system failure; backup due to leach area (SAS) plug is considered a system failure.

- Other defects such as damaged baffles and unsafe tank covers.

Inspect the Septic Tank Condition

Details about septic tank inspection are at Septic Tank Condition - How to Inspect Septic Tanks. Excerpts are below.

The purpose of the treatment tank or "septic tank" is to contain solid waste and to permit the beginning of bacterial action to process sewage into a combination of clarified effluent, settled sludge, or floating scum in the tank. An intact, un-damaged septic tank is normally always filled with these materials. However the inspector performing a "visual" check of the septic system needs to be alert for some important findings:

- Subsidence at the tank location - may risk dangerous, potentially fatal collapse

- Evidence of recent work

- Evidence of backup or effluent breakout at the surface in the tank area

Only by pumping and visual inspection can actual tank capacity and condition be completely determined. Probing in the area of a tank, without excavation, is not recommended as the probe may damage a steel or fiberglass tank. When a tank is uncovered for pumping additional critical details may be observed before the pumping operation

- Condition and safety of the tank and access covers

- Liquid and waste level in the tank - evidence of waste passing over the baffles - a flooded system, an indicator of system failure

- damage to the tank baffles

When the tank is opened and to be cleaned or pumped out additional information is available:

- Thickness of scum and sludge levels: Septic tank maximum scum and sludge buildup prior to pump out, and instructions for measuring the floating scum

layer thickness and settled sludge layer thickness in a septic tank are available in a separate chapter

at SEPTIC TANK PUMPING SCHEDULE - Back-flow of effluent into the tank during pumpdown - an indicator of flooded leach fields

- Additional evidence of damage to the tank baffles

- Evidence of damage to the tank itself - cracks, leaks

Steel septic tanks

Steel tanks typically last 20-25 years, then rust, and collapse. Before this time steel baffles may rust off (damaging the drain field with sludge) or the tank top may become rusty and unsafe. Since steel tank tops can be replaced while leaving the old tank in place, the condition of the top itself is not a reliable indicator of tank condition.

Rusting steel tank covers can cause death! Rusted covers can collapse. I have reports of children and adults who have died from this hazard, as recently as December 1997. In 2000 I consulted in a fatality involving an adult falling into a cesspool. At a building inspection I myself stepped through a hidden, rusted-through steel septic tank cover.

Falling into a septic tank, drywell, or cesspool is quickly fatal, either from being buried by falling soils and debris, or by asphyxiation. Septic gases are highly toxic and can kill in just minutes of exposure. Even leaning over an empty (just pumped) tank has led to collapse and fatality of a septic pumper.

Steel tank baffles: rust out and fall off, permitting solids to enter the soil absorption system

Steel tank bottoms rust out permitting effluent to leak into soils around the tank, possibly giving a large void in tank at time of testing, thus subverting a loading or dye test.

Concrete septic tanks

Concrete tanks at an existing septic installation are usually viable, but might have damaged baffles or cracks that permit seepage of groundwater in or septic effluent out around the tank. Occasionally we've seen tanks made of poor-quality concrete (insufficient portland cement) which eroded badly.

If the tank outlet or absorption system have been blocked, examination of the tank interior may show that effluent is or has been above the top of the baffles (see "baffles" below) thus indicating a system failure discussed next.

Concrete tanks can crack or sections may separate causing leaks with the result of not only improper disposal of effluent (wrong location) but also subverting an attempt at a septic loading and dye test since when the system is un-used the tank liquid levels drop abnormally.

The inspector may detect this condition only if there is a tank inspection port which is readily and safely accessible for before, during, and after inspection when running a loading and dye test.

Home made or "site built tanks

Site built systems, in my experience, are often under-sized and worse, dangerous. There is a serious risk of collapse of old rotting wood covers, collapsing concrete block dry-laid tank or "cesspool" walls, etc. Other types of tanks and home-made onsite systems are described below

at SEPTIC TANK TYPE, Capacity, Material Details

Baffles: Inspecting the Condition of Septic Tank Baffles

Baffles in a septic tank are provided to keep solids and floating scum and grease inside the tank. Baffles are provided at both the inlet to the tank (from the building) and the outlet from the tank (to the absorption system).

Broken baffles or high sludge levels can cause solids to flow out of the tank and into the absorption system. The result is reduced absorption into surrounding soil and eventual failure of the system. Floating scum thickness and settled solids thickness can be measured through access ports into the tank or cesspool.

Finding solids at or covering the outlets or damaged baffles should result in report of a very questionable adsorption system and possible major repair cost.

Concrete tank baffles: may erode from chemicals, detergents, poor concrete mix, water flowing over top of baffles, or may be broken by improper pumping procedures

If baffles are lost or damaged (rusted off on a steel tank or broken off on a concrete tank), they can be repaired or replaced. For example at a steel tank the contractor may simply insert a plastic piping "Tee" into the tank inlet or outlet to create a new baffle system.

However, depending on how long the tank was used without good baffles, the volume of solids and grease that moved from the tank to the absorption system will have begun clogging soils there and will have reduced the future life expectancy of the absorption system.

Baffle damage and repair, or even a complete tank replacement when the absorption system has been left alone always lead the author to warn the building owner that the future life of the absorption system may be in doubt and that additional expense will be involved.

Solids: Inspecting the Level of Accumulated Solids, Sludge and Floating Scum in Treatment Tanks

Solids entering a septic tank are intended to remain there until pumped out during tank service. A large portion of solids settle to the bottom of the tank as sludge. Grease and floating scum remain at the top of the sewage in the tank. Baffles (discussed above) help keep solids, scum, and grease in the tank. Bacterial action in the tank make a modest reduction in the solids volume and begin the processing of sewage pathogens, a step later completed by soil bacteria in the absorption fields.

Net free area: If the sludge level becomes too high or the floating scum layer too thick, in addition to risking passage of solids out of the tank (damaging the absorption system), the remaining "net free area" of liquid in the tank is reduced.

When the net free area becomes too small, there is insufficient time for waste entering the tank to settle out as bottom sludge or top floating scum. That is, for an in-use septic tank with a small net free area, the frequent entry of solid and liquid waste will keep the tank debris agitated, thus forcing floating debris into the absorption system where the life of that component will be reduced (due to soil clogging).

The importance of keeping an adequate net free area in a septic tank is the reason that tanks need to be pumped at regular intervals. Building owners who never pump a tank until it is clogged have already damaged the absorption system.

Measuring septic tank sludge thickness & scum layer

Septic tank maximum scum and sludge buildup prior to pump out, and instructions for measuring the floating scum layer thickness and settled sludge layer thickness in a septic tank are available in a separate chapter

at SEPTIC TANK PUMPING SCHEDULE: When, Why, How to Pump A Septic Tank

Septic Tank Types, Capacity, Material Details

Septic Tank Types: concrete and steel septic tanks and warnings are discussed

at SEPTIC TANK INSPECTION PROCEDURE

Septic Tank Size Requirements and How to Calculate the Size and Volume of a Septic Tank are discussed in a separate chapter,

SEPTIC TANK SIZE TABLES Septic Tank Capacity vs Usage in Daily Gallons of Wastewater Flow & How to Calculate the Size (in gallons) of a Septic Tank

Other septic tank types: might include site-built cesspool using concrete blocks or rubble, steel drums, or other. Beware of very limited capacity, failure to comply with local codes, etc. Steel tanks are at high risk of rust and collapse, and higher risk of loss of baffles; frequently tank cover is damaged by excavation for pumping if no cleanout opening is provided.

Limited Capacity of site-built equipment: Homemade systems are very likely to be in violation of local plumbing codes and standards; significant costs to cure may be involved. Tanks smaller than 900 gallons are below minimum size in some jurisdictions. Areas of wet soils, or very small yards should suggest that there may not be room for a conventional absorption system.

Extra costs will be involved in repairing or extending such installations. Sand-bed filtration systems may have to be replaced with other more costly systems when their operation fails or a use permit expires. Systems that dump into local waterways may require periodic inspection and re-certification by state departments of environmental conservation, or may be outlawed. Use of "drywells" to separate graywater from sewage may be clues of limited system capacity. Graywater may not be discharged to the surface nor to storm sewers.

More Reading:

SEPTIC TANK PUMPING SCHEDULE which gives the tank pumping schedule as a function of tank size and wastewater usage (or occupants).

SEPTIC TREATMENTS & CHEMICALS and advice about using them to "help" or "inoculate" or "fix" your septic system.

More Reading About Pumping and Inspecting Septic Tanks

- SEPTIC TANK BAFFLES septic tank baffles defects and inspection suggestions

- CESSPOOL SAFETY WARNINGS include dangers of cave-in and fatality

- MEASURE SEPTIC TANK SCUM & SLUDGE in Septic Tanks - Measuring the Level of Accumulated Solids, Sludge and Floating Scum in Treatment Tanks

- SEPTIC TANK INSPECTION PROCEDURE - How to Inspect Septic Tanks and evaluate the septic tank condition, baffles, sludge levels, damage, evidence of septic failure, etc.

- SEPTIC TANK, HOW TO FIND - How to Find the Septic Tank, how deep will the cover be, how to document its location

- SEPTIC TANK PUMPING SCHEDULE Frequency Guide for Septic Tanks: When, How, What to Watch For when pumping or cleaning septic tanks

- SEPTIC TANKS, CONCRETE defects and inspection suggestions for concrete septic tanks

- SEPTIC TANKS, FIBERGLASS / PLASTIC defects and inspection suggestions for fiberglass or plastic septic tanks

- SEPTIC TANKS, STEEL defects and inspection suggestions for steel septic tanks

- SEPTIC TANKS HOME MADE SITE BUILT defects and inspection suggestions for home made or site built septic tanks

Excavating & Inspecting Septic Distribution Boxes

- Evidence of solids carryover from the tank

- Leakage in or out of the D-box

- Flow not moving equally into each distribution SAS line

- Evidence of backup of effluent: stains showing liquid level has been above the outlet tee - this would be considered evidence of a system failure.

INSPECTING THE D-BOX - Inspecting the Septic System Distribution Box

This chapter is maintained at INSPECTING the D-BOX but text is repeated here for readers who scroll down rather than linking to the separate chapter.

The distribution box (more than one may be in use) connects a single effluent line from the septic tank to a network of absorption system components such as drainfield leach lines or to a network of seepage pits or galleys.

The photo shows the adjustable weir outlets that permit balancing flow among drainfield lines. (Source EPA who used photo from Ayres Associates.) More sketches of D-box layouts and configurations are shown in this EPA drawing.

Regulating effluent distribution: In good system design the outlet openings from the distribution box to each drainfield line can be adjusted to regulate the flow among the various absorption lines.

Elegantly simple, a plug with an eccentric hole is inserted into the end of each leach line fed from the D-box.

By turning the plug in the end of the leach line pipe one can place the eccentric hole higher or lower with respect to the bottom of the distribution box, thus compensating for a slightly tipped box, differences in leach line length, or differences in leach line condition.

Uneven effluent distribution: If a distribution box becomes tipped (or clogged) effluent may be routed to only a portion of the absorption system, thus overloading it and leading to a "breakout" of effluent at the surface or to clogging and system backup.

An examination of the box interior may show flood lines in the box if the drain field has been clogged or saturated in the past even if at the time of inspection the box is not flooded.

If the fields have been flooded you should be pessimistic about the remaining life of the absorption system. If the box is tipped and/or effluent has not been uniformly distributed among the drainfield lines (assuming they are of equal length and in equally good soils), only a simple adjustment of the outflow may be needed.

Round plugs with eccentric openings may be present or can be inserted in the D-box outlet openings to regulate flow among the individual absorption lines. (C)Trap Daniel Friedman Copyright Protected text.

Tipped or flooded distribution boxes, resulting in uneven loading of soil absorption system lines. This condition can flood one or two lines leading to early field failure.

Inspecting the Soil Absorption System of an Onsite Wastewater Disposal System - the Drainfield or Soakaway Bed

The purpose of this component is to perform final treatment of effluent in a conventional or advanced design septic system by permitting treated effluent to flow from the septic tank (or other treatment tank) into the soil.

Bacterial action and filtering there remove additional pathogens to bring the discharged effluent to an acceptable level of sanitation, thus permitting its discharge into the environment. "Soil absorption system" is a general term for what people call the "leach field," "leachfield," "drainage bed," "seepage area," "drip area" (usually in newer alternative design systems), "septic mound" "galleys," "drain trenches" or similar terms. If you have synonyms to add to this list, contact me and I'll add it here.

- Signs of hydraulic failure

- Condition of surface vegetation

- Ponding in the disposal area

- Encroachments into the SAS area (building a pool, for example)

- Other sources of hydraulic loading in the SAS area (downspouts or area drainage)

INSPECTING FIELDS - Inspecting the Absorption System or Drainfield

Details about inspecting septic drainfields are at SEPTIC DRAINFIELD INSPECTION - Septic Failure Causes: How Does Each Septic System Component Fail? - What to Look For During a Septic Inspection. Excerpts are below.

This article explains types of septic system failure in the drain field, leach field, seepage bed, or similar component. We list the causes of each type of septic component failure, and list the septic component failure criteria or in other words what conditions are defined as "failure"?.

The detailed "how to" steps instructing how to inspect specific septic components for signs of failure are discussed in the text above.

Absorption Field Failure Causes of drainfields and leaching beds

This topic has moved to SEPTIC DRAINFIELD FAILURE CAUSES

DISPOSAL vs TREATMENT - Effluent Disposal and Drain Clogging Failures

In simplest terms, there are two visible septic effluent or onsite wastewater disposal failures:

- Toilets or other fixtures back up into the house - but first

- see "Diagnosing Clogged Drains then return here using your browser's "BACK" button.

- Effluent or sewage appears at the surface of the yard, or the neighbor's yard!

Septic odors may also indicate a system failure or an imminent failure. But such odors may also be produced by defects in the plumbing vent system or other site conditions. Beware, sewer gas contains methane and is explosive if it reaches a dangerous concentration inside a building.

Typical causes range from things that are easy and cheap to repair, to a need for complete system replacement:

- Clogged pipes

- Broken pipes

- Damaged tank

- Tipped distribution box

- Clogged/broken soil absorption piping

- Clogged absorption soils (grease & solids)

- Saturated soil absorption area

However there can also be septic effluent treatment failures. Effluent may not back up or appear on the surface, but if insufficiently treated effluent reaches a private well or any stream or waterway, the environment is being contaminated -- an unacceptable condition.

Historically many people have just worried about disposal. As the quality of drinking water deteriorates in many areas and as population grows in many previously thinly-populated areas, proper treatment has become the real concern for everyone's health.

For example, if there is not sufficient soil between the bottom of the soil absorption system trenches and the local groundwater, the local environment is being contaminated.

Soil Absorption System Failures: (leach fields, drain fields, seepage pits)

Drainfield life: What destroys or shortens the life of the absorption system?

It's easy to ruin or shorten the life of a drainfield/leaching bed:

- install a drainfield in wet weather (which compacts the soil)

- drive over the drainfield or build a parking lot over it (compacts soil, breaks pipes)

- plant trees on the septic absorption field (roots enter pipes)

- put a swimming pool in the middle of a drainfield - yes I've seen people do this!

- forget to pump out the septic tank regularly (solids/grease are discharged into the fields, clogging the soil)

- direct roof runoff or surface runoff across the drainfield or into the septic tank (flooding the system)

- install the drainfield in an area of high seasonal water tables (flooding the system)

- use the septic system to dispose of illegal oils, chemicals, fats, greases - one system in New York near the Taconic State Parkway was connected to house in which was operated an illegal drug manufacturing operation. So much contaminant was flushed down house drains that the workers contaminated their own well and poisoned themselves

- discharge excessive salts or other chemicals which destroy the The formation, clogging, and measures to protect and extend the life of the biomat is discussed at biomat in the drainfield

Soil Absorption System Failure Criteria

- Breakout of effluent observed (& I consider odors as well)

- BOH evaluation in MA if within 100 ft of surface water supply

- within Zone 1 of a public well

- within 50ft of a private well

- between 50ft and 100ft of a private well if well fails bacteria test.

The Drainfield: Leaching Bed Soil Condition & Liquid level

The absorption system or "drain field" has two jobs. First, it disposes of liquid effluent by permitting it to seep into the soil below. Second, a "bio-mat" of bacteria which forms in the soil below the drainage field processes pathogens in the septic effluent to make the effluent sufficiently sanitary as to avoid contaminating nearby ground water.

This distinction between successful "disposal" and successful "treatment" is important to avoid groundwater contamination but has not been addressed by regulation in every municipality. Municipalities which require a minimum distance between the bottom of the drain field trenches (or equivalent component) and the top of the seasonal high ground water table have recognized the importance of a working bio-mat and the need to provide adequate dry soil for it to function.

Even in a well-designed drainage field, eventually the soil surrounding the drainfield device (perforated pipe in gravel trench or other seepage system) becomes clogged with grease and debris. Examining an excavated cross-section of a failed drainfield will often display a black or gray band of sludge and grease of about 1" thickness at the inside perimeter of the gravel trench.

When this layer of soil becomes sufficiently clogged the passage of effluent into the soil below is slowed and eventually blocked, leading to the need for replacement. Keeping a tank pumped so as to reduce the passage of debris and grease into a drain field will extend its life.

This is the most expensive problem to correct. Look for septic effluent seepage to ground surface in area of equipment or downhill from such equipment. Look for (illegal) drain field line extensions to nearby streams, storm drains, or adjoining properties where the temptation to "fix" a failing system by sending the effluent to an improper destination overwhelmed a previous owner or repair company. In some areas inspectors use septic loading and dye test.

Seepage may be due to overloaded tank, failed absorption system, or blocked/broken piping (may be less costly).

An excavator or septic contractor will often explore one or more drain lines (or similar components) by excavating a portion of it to look for evidence of flooding or soil clogging. We've used a simple probe at the end and along a leach bed to check for flooding of that component. (Be careful not to break or collapse old piping.)

Guide to Septic Drainfield PERC TESTS - Septic Soil Percolation Requirements and Soil Depth Requirements for Septic Absorption Systems / Septic System Drainfields

This chapter is maintained at SEPTIC SOIL & PERC TESTS but excerpts from that text are giveb here for readers who prefer to scroll down rather than linking to the separate chapter.

Perc Tests: What is a septic system soil percolation test?

In specifying the size and type of absorption field (leach field, seepage pits, galleys, other) a septic engineer or health department official will require that a soil percolation test or "perc" test be performed. You may hear it described as a "deep hole test."

The first time I participated in this procedure I found myself smiling with surprise at how low-tech the procedure actually was (in New York State.)

After identifying the most-likely location on the lot for placement of a septic drainfield, the excavator used a backhoe to dig a rough hole about 5 ft. deep. Happily no groundwater immediately filled in the hole (which would have been bad news).

Perhaps this is why builders try to have this test done in July which is the period of most-dry weather and lowest groundwater table levels. After digging this rough hole, the septic engineer poured a 5-gallon (joint compound) bucket of water into the hole. In some cases a few buckets might be dumped therein.

After that sophisticated move, the observers simply watched the rate at which the water disappeared. a one-inch drop in water level in this hole in three minutes was considered very good. If the water was found still in the hole at no drop in level the next morning, this was considered seriously bad and probably requiring some soil exchange or other special design measures.

What are the soil perc test standards and other soil requirements for septic systems?

I like the Massachusetts Title 5 Septic Inspection criteria for defining a (at least possibly) functional drainfield, as the text explains the role of the biomass below the absorption bed, sets soil depth requirements, and recognizes the importance of keeping the bottom of the working biomass area in well drained soil sufficiently above the seasonal high water table.

Here is an example of soil requirements for a functional drainfield. This version is particularly clearly written and is for residents of Ohio but the principles apply anywhere. "In Ohio, soil absorption systems can be used in areas where the percolation rate of the soil is between 3 and 60 minutes per inch (soil permeability between 1 and 20 inches per hour).

At least 4 feet of suitable soil is required under the soil absorption system to provide adequate treatment of the septic tank effluent. To accommodate the construction of the system and provide adequate soil cover to grade, a minimum of 5 1/2 to 6 1/2 feet of suitable soil is needed above the limiting layer.

A limiting layer may be bedrock, an impervious soil layer (hardpan, fragipan) or a seasonally high water table (gray soil or mottles). The soil absorption system must be at least 8 feet from any drain line on the lot, 50 feet from a water supply, and 10 feet from the property line, right-of-ways and the house. Septic systems cannot be placed on the flood plain and are limited to areas with less than a 15 percent slope." http://ohioline.osu.edu/aex-fact/0743.html Ohio State University Fact Sheet "Septic Tank - Soil Absorption Systems"

FIELD SIZE - Septic Leach Field or Septic Absorption Field Size: How large does the absorption field need to be?

Details about determining septic drainfield size or soakaway bed size are

Drainfield trench/line specifications

In the most common design of drainfield, perforated pipes are buried in gravel-filled trenches to form the drainfield. Pipes are placed across the slope line of sloped property (so that all of the effluent doesn't simply rush down to and leak out at the end of the drain line pipe). While some experts describe the bottom of these trenches as "level" in practice they are dug to slope slightly, perhaps 1/8" per foot or less.

A typical septic leach field trench is 18 to 30 inches in depth, and 8 to 12 inches wide. The trenches are dug about 6 feet apart which allows, in good design, space for a set of replacement trenches to be placed between the original ones when the first set fails. The maximum length of a trench is typically about 150 feet but I've found installations that were three times that length.

Where lot space does not permit drainfield trenches such as I've just described, a septic engineer may specify that seepage pits or galleys are to be installed. These fit in a smaller space since a single pit may be 6' to 8' in diameter. But the depth to which effluent is being delivered (4' or more) means that the sewage effluent is unlikely to be fully treated by a biomass. These systems may successfully "dispose" of effluent but they are probably not adequately "treating" it.

See SEPTIC DRAINFIELD SIZE TABLES and mound systems, USDA, soils, guide.

to SEPTIC SOIL & PERC TESTS, trench dimensions, loading in gpd per foot. e.g. , moderately limited perc rate of 5-10 min/inch has max sewage loading rate to trench and bed bottom of 1 gallon per square foot per day per trench and .5 gal per bed.

The Biomat: The formation, clogging, and measures to protect and extend the life of the biomat, or organism layer below and around soil absorption system effluent discharge piping is discussed

at SEPTIC SYSTEM ABSORPTION SYSTEM BIOMAT FORMATION as a subchapter of this text.

MOUND SYSTEMS - Septic mound systems

Details about septic mound systems are

at MOUND SEPTIC SYSTEMS. Excerpts follow.

To build a mound system, extra soil is brought to a site and sculpted to form a drainfield of adequate thickness and area. These systems are common where soils are rocky or where there simply is not enough soil above the local water table to provide adequate absorption.

A mound system may be fed by gravity at some sites but it's also common for the effluent to reach the mound by having been "pumped-up" from a septic tank.

Pump-up (to elevations higher than the building main drain exit) and some septic mound systems use a single or duplexed pump either in a clear baffled section of the tank, or in a separate effluent pumping chamber. Duplexed systems offer more reliability. If the first pump fails the second takes over, and an alarm bell or light are turned on.

Grinder/Ejector pumps are used at both private and public sewage disposal systems to pump up from low areas (such as a basement toilet) where the sewer line exits the building at a higher level and where gravity drains are therefore not workable.

Flush-up toilets, systems that use a venturi-system rather than a grinder pump, may be encountered but may be in violation of local plumbing codes as they may comprise an unsanitary cross- connection (using house water pressure to force sewage up and out).

What ruins a septic mound system?

A good way to ruin a septic mound system or to build one with a short life is very common in the Northeastern U.S. where I find what I call "pseudo mound septic systems" in which the builder has killed two birds with one stone.

Instead of clearing an area and bringing in the proper volume and type of soil to build the mound, the builder finds a spot into which s/he can push all of the tree stumps and construction debris from the building project.

The stumps and trees are then buried with backfill to produce an nice looking "mound" with just enough soil to bury a network of drainfield pipes. If you see a mound system that has horizontal trees sticking out of its base, or if it has mysterious pipes leaving its base, I would be very suspicious about the design and longevity of the system, as well as concerned about its legality.

Septic Pumps and Alarms for Septic Tanks and Mound Systems

[TBA] Additional data on this topic for Canada: see Ministry of the Environment, Class 4 Sewage Systems, on hand via AC

More Reading about Septic Mounds

SEPTIC MOUND SYSTEMS as Components of Alternative Septic Systems for Difficult Sites

MOUND SYSTEM INSTALLATION AND DESIGN DETAILS from New York State Septic System Design Regulations 75-A.9 Alternative Septic Systems.

Ohio State University has a nice web page describing Septic Mound Systems. http://ohioline.osu.edu/aex-fact/0744.html

CESSPOOLS for onsite wastewater disposal

See CESSPOOLS for details about these systems. Excerpts are below.

A cesspool combines the septic treatment tank and absorption system into a single component.

Basically a cesspool is a stone or concrete block or (safer) pre-cast concrete (photo) lined pit into which sewage is discharged. Solids remain in the pit, effluent is absorbed into soil below and at the sides of the cesspool.

This older design was often used where there is limited physical space, and where the soil absorption rate high. We have more to add to this section, but the bottom line is that for most installations you should consider this an obsolete, limited capacity system likely to need replacement, and involving significant cost. Some immediate concerns are stated next.

Cesspool Safety Warnings

Now found at CESSPOOL SAFETY WARNINGS

Cesspool Failure Criteria (MA)

Moved to CESSPOOL FAILURE CRITERIA

Drywells for Graywater Disposal: Warnings

Details about drywells are found

at SEPTIC DRYWELLS - SEEPAGE PITS

Recent & Future Trends in Onsite Waste Disposal Systems

Concern for Water Quality is increasing

Text under revision.

Effluent Disposal vs. Treatment

In many states including my own New York, focus has traditionally been on successful "disposal" of effluent which has received Level-1 treatment by a septic tank. Successful onsite wastewater "disposal" means we don't see the waste water on the surface of a property and that a dye test does not detect it being discharged into nearby surface streams or lakes.

But successful onsite wastewater treatment means we are not contaminating the ground water. The Massachusetts Title 5 Septic Inspection standards and procedures make this distinction but many states have not adopted such rigorous standards (as of January 2006).

Legislation & Mandated Upgrades

Alternative and Advanced Onsite Waste Water Treatment & Disposal Systems are Available

A "conventional" septic tank and drainfield just won't work at some sites for reasons like these:

- The site is too rocky for a conventional septic system or perhaps there is no soil at all.

- The site is too small for a conventional septic system

- The site is too wet for a conventional septic system

- The site is too dry for a conventional septic system

- The site is too steep for a conventional septic system

- The site is too close to a lake or stream for a conventional septic system

- The community or occupants cannot afford a conventional nor an expensive alternative septic system design.

There are solutions for most site problems, including septic handling and wastewater treatment systems that can fit in a very small space and operate completely above ground.

Alternative septic system designs and products have increased significantly in number in the past 20 years as experts have experimented with media treatment systems and alternative materials for treatment, septic tanks, and soil absorption or even evaporation systems.

Systems that use no water or only very little water, and very important, systems that re-use graywater from a site have been designed. We have published a large article series describing a variety of alternative septic system designs and also have collected reference sources: books, government resources, online articles. These articles and resources for alternative septic system designs are organized and listed

Global Warming and Onsite Waste Disposal Issues

12/4/2006: different areas will experience quite different concerns as weather conditions, sea levels, and soil moisture are amended by the effects of global warming in the coming century, or perhaps much sooner.

- Areas of Rising Sea Level and Effects on Septic Systems:

Rising sea levels will saturate soils and make conventional in-soil disposal and treatment ineffective, raising serious health concerns for very large populations of the earth who currently live at or close to sea level and in coastal areas. - Amended Weather Patterns

Resulting in More Rain and Effects on Septic Systems:: may occur in some areas as both sea currents (Gulf Stream) relocate and air currents (Jet Stream) relocate. Areas of increased rainfall resulting in increased soil moisture levels will reduce effluent disposal capability of conventional septic systems in those areas and may interfere with treatment of effluent in the biomat. - Amended Weather Patterns Resulting in Less Rainfall and Effects on Septic Systems

areas becoming very dry may ease effluent disposal in soils up to a point. But soil pathogens necessary to form and function as the biomat that treats septic effluent require soil moisture. Too-dry soils may interfere with successful treatment.

Septic System Design Improvements and Products

- New materials and products for septic tanks permit systems to be installed where there is no soil perc, or no soil at all. Wastewater treatment systems are available which also can significantly reduce the distance required between septic components and wells, streams, lakes, etc.

- See Jantrania & Gross, Advanced Onsite Wastewater Systems Technologies - http://www.advancedonsitesystems.com

- Advanced onsite wastewater treatment system types discussed in the above text include the following:

- Aerobic treatment units

- Media filters, single pass and recirculating

- Natural systems for polishing or recycling secondary effluent

- Waterless toilets, graywater systems, alternatives to flush toilets

- Disinfection systems

Septic Inspector Qualifications/Licensing

If you perform septic inspections you are obligated to do so with proper information, training, procedures, and in some communities a license is required. Some states (e.g. CA, CT, NJ, MA) have specific certification requirements for inspectors of septic systems, as well as specific regulations regarding the performance of the inspection itself.

Be sure to obtain information pertinent to your own state, usually from the state health department or state department of environmental protection. For example, Massachusetts septic inspectors will want to look at the links and the Title 5 regulations at our page on

the Massachusetts SEPTIC TESTING LAW TITLE 5

Other links to septic system installation and inspection regulatory agencies are at

our "Local, State, U.S. Federal Government, & International Agencies & Resources for Septic Systems Wastewater Treatment" page.

Septic System Inspection Authorities

See SEPTIC AUTHORITIES, DESIGN REGS -

Definitions of Levels 0-1-2-3 of Septic System Inspection and Testing

Details about levels of septic inspections are

at SEPTIC SYSTEM INSPECTION LEVELS - Level 0, Level 1, Level 2 & Level 3 Septic Inspections

Septic Dye Test Warnings

Now found at SEPTIC DYE TEST WARNINGS

Sample Septic Inspection & Test Reports

Here are links to examples of field data collection sheets used in preparation of a septic inspection report Examples of final, written septic inspection and testing reports are available and can be provided on request to the author.

- SEPTIC SYSTEM INSPECTION LEVELS - include data collection forms & checklists for each septic inspection level

- SEPTIC INSPECTION WORK SHEETS - data collection forms for septic system inspections

- SEPTIC TANK INSPECTION PROCEDURE- what sorts of tank failure evidence can be seen & reported

- SEPTIC DRAINFIELD INSPECTION - what evidence of drainfield failure can be seen & reported

- INSPECTING SEPTIC D-BOX - problems found & reported at the septic distribution box

- SEPTIC DRAINFIELD INSPECTION - what signs of drainfield or soakaway bed failure can be observed & how are they reported?

...

Continue reading at SEPTIC SYSTEM INSPECTION LEVELS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SEPTIC SYSTEM INSPECTION & MAINTENANCE COURSE

- SEPTIC or SEWER CONNECTION? - If you don't know if your building is connected to a public sewer or a private septic system

- SEPTIC GUIDE FOR HOME BUYERS OR OWNERS

- SEPTIC LOADING & DYE TEST PROCEDURE

- SEPTIC SYSTEM CARE GUIDE

- SEPTIC SYSTEM INSPECTION LEVELS - Level 0, Level 1, Level 2 & Level 3 Septic Inspections

- SEPTIC SYSTEM INSPECTION & TEST GUIDE - if you already know the basics about septic systems, tanks, drainfields, and septic inspection procedures in general, then you can skip immediately our list of individual, detailed septic inspection procedures

- SEPTIC TANK PUMPING SCHEDULE - When, Why, How to pump the septic tank

- SEPTIC CLEARANCE DISTANCES - required distances Between Septic System & Wells, Streams, Trees, etc.

- TEN STEPS TO KEEPING A SEPTIC SYSTEM WORKING - suggestions from the U.S. EPA, edits and additions by DJF

- SEPTIC TANK & SYSTEM CARE BASICS - An Engineer's View & Septic System FAQ's

Suggested citation for this web page

SEPTIC SYSTEM INSPECTION & MAINTENANCE COURSE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how to inspect or test septic systems, septic inspection procedures, septic failure criteria, and septic inspection results reporting.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see " Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- New York State Department of Health, APPENDIX 75-A WASTEWATER TREATMENT STANDARDS - INDIVIDUAL HOUSEHOLD SYSTEMS , [PDF] New York State Department of Health, 3 February 2010, retrieved 3/1/2010, original source: https://www.health.ny.gov/regulations/nycrr/title_10/part_75/appendix_75-a.htm

- The complete set of septic system inspection, testing, design, and repair references is maintained at SEPTIC REFERENCES.

- "EPA Design Manual: Onsite Wastewater Treatment and Disposal Systems," R. Otis et al, EPA 625/1-80-012. GPO Bookstore, 26 Federal Plaza, Room 110, New York NY 10278 212-264-3825.

- "Septic Systems," T. & A. Ferrero, Tri State ASHI Seminar, November 6-7 1993, and attachments listed below.

- "Septic Tank Pumping," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-161, Agricultural Engineering Department, 246 Agricultural Engineering Building, University Park PA 16802 814-865-7685 814-863-1031 FAX.

- "Preventing Septic System Failures," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-162.

- "Mound Systems for Wastewater Treatment," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-164

- "Septic Tank Soil Absorption Systems," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-165

- "The Soil Media and Percolation Test," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-163

- "Level 1 Septic System Inspections During Real Estate Transactions," Paul D. Robillard, Kelli S. Martin, Penn State College of Agriculture, Cooperative Extension, Agricultural Engineering Fact Sheet SW-166

- "Take Care of Your Septic Tank," Washington State Septic Tank Pumpers Association, (WSSTPA) (Les Eldredge, President, 206-334-8263); Courtesy of Bob Kelwitz, 10/93. Items 3-9 provided courtesy of Jules Falcone.

- "Cottage Country, Environmental Manual for Cottages," 6th Ed., 1989, ISBN 0-7729-5085-7, Environment Ontario, 135 Clari Ave. West, Suite 100, Toronto Ontario M4V 1P5

- Septic Tank Maintenance," Circular 1343/January 1990, and "Why Do Septic Systems Fail?," K. Manci & J.A. Moore, Extension Circular 1340/January 1990, Oregon State University Extension Service, and "Know your Septic System," a home buyer's guide to on-site septic systems, Washington Association of Realtors, Govt. Affairs Dept, PO Box 719, Olympia WA 98507 206-943-3100, provided by Len Sherr, Bend OR

- One and Two Family Dwelling Code, Section P-2506, Septic Tank Design and Construction.

- "The Septic Tank Home Wastewater Treatment and Disposal System," Southern Rockingham Regional Planning District Commission, 19 Main St., Salem NH 03079 603-893-5766

- "Septic Tank News & Views," Stanley Carraway, Florida ASHI Seminar, October 9-10, 1993 available from FLASHI Chapter, includes some USDA tables and charts on design, loading, and references the New (1992) Chapter 10D-6, Florida Administrative Code, Standards for Onsite Sewage Disposal Systems.

- Pennsylvania Septic Management Association, RD 3 Box 3231, Moscow, PA 18444

- HUD Handbook 4910.1 (Well Clearances)

- "Private Sewage Disposal, Some Suggestions," RES-I-TEC, 145D Grassy Plains St., Bethel CT 06801 1989

- "A Homeowner's Manual for Septic Systems," Robert Berg, Wastewater Facilities Management Element Bureau of Construction and Connection Permits, State of New Jersey Department of Environmental Protection, Division of Water Resources, January 1990, 609-984-4429, courtesy of Lewis Home Inspections

- "What Remodelers Should Know About Septic Systems,", Russ Lanoie, Journal of Light Construction [New England Builder], July, 1988, p. 31-36, RR#2, PO Box 146, Richmond VT 05477

- "Water Conservation and Wastewater Disposal," R. Siegrist et al., 1978, ASAE Pub. 5-77:121-136

- "Soil Infiltration Capacities as affected by septic tank effluent application strategies. In: Proceedings of the 3rd national Symposium on Individual and Small Community Sewage Treatment." ASAE Pub. 1-82 pp. 72-74. ASAE PO Box 410, St.Joseph MI 49085

- "Aerobic on-site systems studied in New Mexico," Asbury R. and Hendrickson C., 1982, Journal of Environmental Health, 45:86-87

- "Soil Clogging: Mechanisms and Control," R. Otis, Proceedings of the 4th National Symposium on Individual and Small Community Sewage Treatment, ASAE Pub. 07-85 pp. 238-250, ASAE, 2590 Niles Rd., St. Joseph MI 49085-9659

- "Residential Graywater Management in California," A. Ingham, 1980. California State Water Resources Control Board, PO Box 100, Sacramento CA 95081

- "On-site disposal of small wastewater flows," R. Otis, 1977, Department of Civil and Environmental Engineering, University of Wisconsin, Madison.

- NAHB Library, several resources listed, contact NAHB, 15th and M Streets NW, Washington, DC 20003 202-822-0203. "Pumped septics - improved waste-water systems distribute effluent from septic tanks over a wide area, preventing contamination of drinking water," Noele Stuart, Popular Science, My 1989, p. 84; "Septic tank effluent pump systems: an alternative to conventional sewers and grinder pump systems," Small Flows, October 1991, p 4. Courtesy of Heather Groves, NAHB Library and Information Center. 800-368-5242 Ext 204 (CD ROM search service, fees involved, for GTHBA members and NHBA members)

- "Septic Tank/Water Softener, potential effects of water softener use on septic tank soil absorption on-site wastewater systems; the effect of home water softener waste regeneration brines on individual aerobic wastewater treatment plants," Water Quality Research Council, Water Quality Association, 477 E. Butterfield Road, Lombard IL 60148

- "Design Handbook, Grinder Pumps, Low Pressure Sewer Systems," Environment One Corporation, 2773 Balltown Road PO Box 773, Schenectady NY 12301 518-346-6161 (Richard C. Grace, Sales Mgr.)

- "What you should know before buying a home served by a septic system," State of Connecticut, Department of Health Services, 150 Washington St., Hartford CT 06106, via Allspect, Westhaven CT and Butterly's Building Inspection Service, CT.

- "Soil infiltration capacities as affected by septic tank effluent application strategies," D.L. Hagett, et al, 1982, In: Proceedings of the 3rd National Symposium on Individual and Small Community Sewage Treatment." ASAE Pub. 1-82, pp. 72-84. ASAE, PO Box 410, St Joseph MI 49085, current address: ASAE, 2950 Niles Rd., St Joseph MI 49805-9659, courtesy of Bob Stead, ASHI.

- "Aerobic on-site systems studied in New Mexico," R. Asbury and C. Hendrickson, Journal of Environmental Health 45: 86-87,

- "Soil clogging: mechanisms and control," R. Otis, 1985, in National Symposium on Individual and Small Community Sewage Treatment." ASAE Pub. 1-82, pp. 238-250.