Plastic Septic Tank Inspection & Installation

Plastic Septic Tank Inspection & Installation

How to Inspect or Install Poly, Plastic or Fiber Reinforced Polymer (FRP) Septic Tanks

- POST a QUESTION or COMMENT about fiberglass or plastic septic tanks: special problems, inspection, installation, troubleshooting, repairs, age, durability

Plastic, poly (polyethylene), or fiberglass or FRP (Fiberglass Reinforced Plastic) septic tanks: install, inspect, maintain, repair.

Here we provide instructions for installing plastic, poly, or fiberglass septic tanks or buried cisterns. Special measures are needed to prevent damage to the tanks during installation and to protect them from damage when in use.

This document also describes how to inspect the condition of a fiberglass or plastic septic tank, as those systems are subject to different stresses & possible failure or damage than concrete or steel tanks (that have their own concerns).

The plastic septic tank shown at page top is courtesy of thenaturalhome - cited below. This article series answers just about any question about septic system installation or inspection procedures, defects in onsite waste disposal systems, septic tank problems, septic drainfield problems, checklists of system components and things to ask.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Plastic or Fiberglass Septic Tanks

Installing plastic or poly or fiberglass buried tanks used for septic systems or cisterns requires special measures to avoid damage to the tank and its piping. And iInspecting plastic or fiberglass septic tanks addresses a key component in onsite wastewater disposal systems.

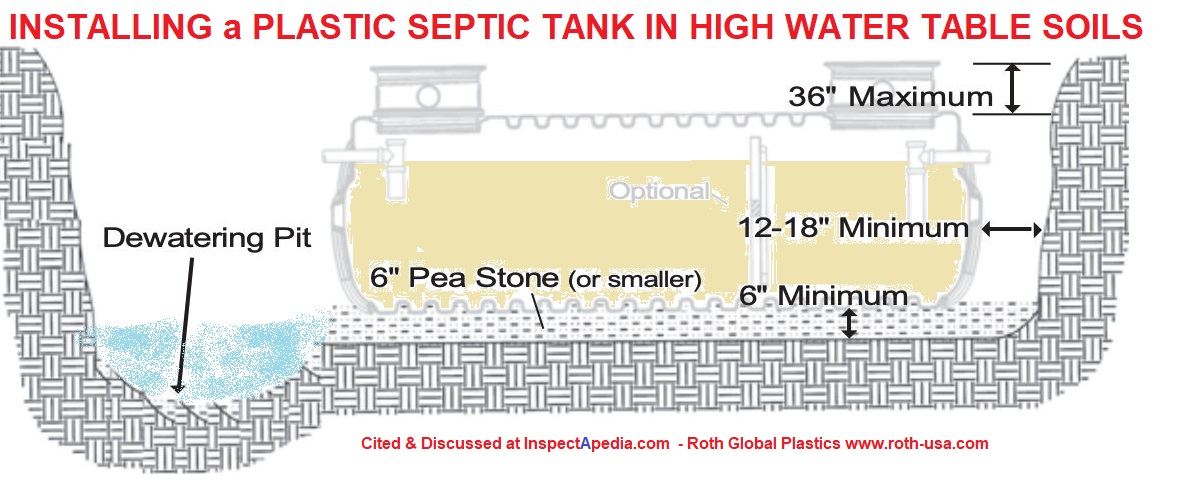

Illustration of a de-watering pit is from Roth Global cited below on this page. When installing a plastic tank in high-water table soils measure are taken to remove water from the excavation and to prevent the tank from floating up out of the ground.

Fiberglass or Plastic Septic Tanks:

are very resistant to some of the problems occurring with

concrete (cracks) or steel (rust) septic or home made (collapse) septic tanks.

But plastic septic tanks can have their own special considerations, particularly during installation and possibly when the plastic or fiberglass septic tank is being pumped.

Fiberglass, FRP, or Plastic Septic Tank Inspection Points

Here are some things to watch for when inspecting a plastic septic tank or a fiberglass septic tank:

- Low effluent level

in a fiberglass or plastic septic tank may be discovered when the tank is opened for pumping.

After the tank is emptied, check to see if a plastic plug from the tank bottom has been lost. One reader wrote to tell us that when her septic tank was pumped the pumping process itself dislodged and removed a plug from the tank bottom.

The loss was discovered several years later when the tank was opened for pumping again.

After cleaning the plug was replaced.

Watch out: DO NOT ENTER A SEPTIC TANK for any reason, including replacing a plug, unless you are trained and have the required breathing equipment and a buddy watching - methane gas hazards in septic tanks can be fatal in minutes. - Damage during installation:

a fiberglass or FRP septic tank may be damaged during installation, such as having been dropped or hit by equipment during installation.

The resulting crack and leak may not be evident until later when the plastic or fiberglass septic tank is pumped. Look for abnormally low effluent levels and no missing drain plug. - Damage to piping connections:

if a fiberglass / FRP or other light-material septic tank is left empty after installation or after pumping, and if the septic tank in an area of wet soils or rising ground water the tank can float up out of the ground, breaking plumbing connections and damaging the tank. - Soil disturbance or mounding over the septic tank:

If a fiberglass, HDPE, or FRP or other plastic type tank has been buried but left empty, in conditions of wet soils or rising groundwater there is a risk of the septic tank actually floating up out of the ground. If you see mounding over the septic tank there may be a risk that this is already happening - breaking or damaging piping connections and leading to a sewage backup and spill.

See OIL or SEPTIC TANKS FLOATING UP

Instructions for Installing Buried Plastic Septic Tanks or Cisterns

Illustration: a Norwesco 1000 gallon plastic septic tank with two 20" manhole access openings. This tank weighs about 360 lbs. and is 127" long x 60" wide x 51" tall.

Norwesco also providdes risers or "manhole extensions" of various dimensions as well as smaller septic tank risers used to provide more-limited pumping access.

The specifications of this tank meet Illinois' septic tank requirements for underground septic tanks, waste tanks, sewage tanks.

Plastic / Fiberglass Septic Tank Specifications

- Septic tanks are available in fiberglass, polyethylene and Acrylonitrile-butadiene-styrene (ABS) construction materials with fiberglass reinforced plastic being the most common.

- Fiberglass septic tanks shall be constructed according to ASTM D3299

or International Association of Plumbing and Mechanical Official (IAPMO) IGC3-74 as applicable. - Wall and bottom thicknesses will be determined by the specific application to meet the worst structural loading condition.

- Because of their light weight, plastic septic tank installations should consider antiflotation measures.

- Deterioration of fiberglass has been known to occur by wicking along the glass fibers should fiberglass become exposed to moisture.

- Wicking may be reduced by application of resin rich coating or a gel coat applied to all surfaces. - FL DEP cited below

Watch out: Depending on where the tank is to be installed and taking into consideration how wet the ground is and rainfall expectations, if not properly installed, the plastic tank could be at risk of floating up out of the ground as well as damaging or breaking its piping connections.

See more about the prevention of this risk at

- FLOATING OIL & SEPTIC TANKS - warnings about tanks that float up out of the soil

You'll also see that poly or plastic or fiberglass buried tanks require special installation methods when installing in high ground-water conditions. (See Roth below).

Test the Fiberglass or Plastic Septic Tank Before Installation

- To insure water tightness,fiberglass or plastic septic tanks shall be tested by filling with water to the soffit, left standing for twenty-four hours and examined for leakage. This is most important when installed in an area of high groundwater.

- Fiberglass septic tanks

normally require only testing of a representative

sample. - FL DEP cited below

Fiberglass or Plastic Septic Tank Installation Procedure

- Septic tanks shall be installed in accordance with the sound engineering practice.

- The excavation backfill adjacent to the installed septic tank should be placed in 150 mm (6 inch) lifts watered to optimum and compacted to 90% of relative density.

- Stones or debris having a diameter of 102 mm (four inches) or larger should not be included in the backfill material.

- Backfill in the vicinity of the septic tank inlet and outlet piping should be manually placed and consist of crushed rock to a depth of 150 mm (6 inches) over the inlet or outlet pipes with the remaining backfill placed in the same manner as adjacent to the septic tank.

- Septic tanks installed in soft or yielding soils should be bedded on crushed rock having a thickness of not less than 150 mm (6 inches).

- When septic tanks are installed in areas where groundwater will be

above the septic tank floor the septic tank shall be secured against floatation.

See also our warning above about floating-up tanks of metal or plastic/fiberglass/poly. - FL DEP cited below

Watch out: Also be sure to follow the manufacturer's installation instructions such as in the instructions from Norwesco below. You can see that when installing a buried plastic septic tank or cistern, if you don't do the job properly there is risk of costly damage or even completed loss of the tank!

Plastic, Poly, or Fiberglass Septic Tank Risers

If the soil cover depth over the septic tank is more than a few inches (varying by jurisdiction) you should install a septic tank riser to permit easy and safe access to the septic tank cleanout openings.

For a plastic septic tank the septic tank riser or wetwell and its cover will usually be made of fiberglass or plastic.

Septic tank risers and wetwell covers shall be secured to preclude desired removal, but be provided sufficient clearance to vent hydrostatic pressure should a check valve fail and backflow enter the tank, unless other forms of pressure relief are provided.

Unauthorized removal of the septic tank riser or wetwell covers should be discouraged through use of a tamper-resistant construction or locking device. - FL DEP cited below

See details

Plastic & Fiberglass Septic Tank Installation Guides, Codes, Manuals

- Florida DEP, DESIGN AND SPECIFICATION GUIDELINES

FOR LOW PRESSURE SEWER SYSTEMS [PDF] (1981) - retrieved 2022/04/25, original source: https://floridadep.gov/sites/default/files/guide_lowpres.pdf

Excerpt:

Fiberglass septic tanks shall be constructed according to ASTM D3299 Standard Specification for Filament-Wound Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant Tanks, or International Association of Plumbing and Mechanical Official (IAPMO) IGC3-74 as applicable.

Other Excerpts given in the article above. - Everhard, POLYMER SEPTIC TANK INSTALLATION MANUAL [PDF] (2006) Everhard Co, Australia, Web: www.everhard.com.au

- Norwesco UNDERGROUND CISTERN INSTALLATION MANUAL [PDF] Norwesco Inc. 4365 Steiner Street P.O. Box 439 St. Bonifacius, MN 55375-0439 TEL. (800) 328-3420 FAX (800) 874-2371 www.norwesco.com

Norwesco produces plastic / fiberglass tanks used in a variety of applications including cisterns and septic tanks.

Excerpts: (These are NOT the complete set of instructions for installing a below-ground plastic tank)

Excavate to a depth that will provide a minimum of 6" and a maximum of 30" of cover over the top of the tank. This will avoid collapse and over-expansion of the tank and possible leakage.

Allow 18" to 24" on both sides and both ends of the tank. Failure to comply with allowance ranges could cause tank collapse.

The preferred tank bedding material [for plastic tanks to be buried] is well packed sand with minimums of 6" in soil terrain and 12" in rock terrain. Native soil can be used if it is flowable, compactable, rock free, and can provide uniform tank support in the recessed rib areas. The tank should be installed level

Inlet and outlet piping should be solvent welded to the adapters using standard PVC cement.

CAUTION: Fill tank with water as you backfill, keeping water level even with backfill level as you go to prevent possible collapse.

Backfill with 12" layers and compact each layer. ALWAYS COMPACT ENDS FIRST.

Maximum backfill over the top of the tank is 30". Mound soil over the top to provide positive drainage.

The sand/gravel mixture [used for back-fill around and over a plastic tank to be buried] should be a mixture of sand and gravel, 100% smaller than 1½", and about 50% smaller than ¼".

Note that certain plastic septic tanks made of heavier materials can be back-filled with native soils. - Norwesco, LOW PROFILE UNDERGROUND PLASTIC TANK INSTALLATION INSTRUCTIONS [PDF] Norwesco, Op. Cit. - retrieved 2022/04/23 original source: https://www.norwesco.com/_site_components/

- Norwesco, POLYETHYLENE SEPTIC TANK INSTALLATION GUIDE [PDF] Norwesco, Op. Cit., for sales in Puerto Rico, - retrieved 2022/04/23 original source: http://literature.puertoricosupplier.com/007/MO7195.pdf

- Orenco Systems, AdvanTex® AX-RT SEPTIC TANK TREATMENT SYSTEM INSTALLATION MANUAL [PDF] Orenco Systems, Inc., 814 Airway Ave., Sutherlin OR 97479 USA, Tel: 1-800-348-9843 Web: www.orenco.com - retrieved 2022/04/23 original source: https://api.ferguson.com/

Excerpt:

This provides general instructions for each installation step along with references to detailed installation documents for specific components. Many Orenco products come with installation instructions and all of these instructions are also provided in hard copy form in our Orenco Installer Binder. Contact your Dealer or Orenco for a copy of the binder, or find individual instructions online in the Orenco Document Library at www.orenco.com.

There are also steps in this manual covering operations performed before and after the AX-RT unit is installed that are necessary to successfully complete the installation. - Premier Plastics, PLASTIC TANK INSTALLATION INSTRUCTIONS [PDF] Premier Plastics Inc. 8328 River Way, Delta, B.C., Canada, V4G 1C4 Phone: (604) 952-6686 Toll Free: 1-800-661-4473 (Canada & USA) Fax: (604) 952-6696 E-Mail: office@PremierPlastics.com (U.S. & Canada), Web: premierplastics.com - retrieved 2022/04/23 original source: https://premierplastics.com/installation-instructions/

- Roth, Fralo POLY SEPTIC TANK INSTALLATION PROCEDURE for HIGH GROUNDWATER AREAS [PDF] (2008) Roth Global Plastics, Inc., Tel: 866-943-7256, Web: www.roth-usa.com

Excerpts:

Max burial depth is 36" below grade, unless deep burial instructions (steps 11 & 12) on “Key Installation Facts” are followed.

Absolutely no clay should be used for backfill

Absolutely no water is required for backfill. The tank is designed to be backfilled without water. Filling the tank with water prior to backfilling is not necessary and may cause installation problems. A nominal amount of water (6-8") may be used to ballast the tank during backfilling.

Width and length of excavation shall be 12-18" greater than the tank on all sides and ends (FIG.1).

Depth of the excavation shall be 6" greater than the tank (FIG.1).

Lengthen and deepen excavation at one end to provide dewatering pit as necessary.

Do no over excavate or "belly-out" the excavation. - U.S. EPA, SEPTIC SYSTEM TANKS [PDF] U.S. EPA, retrieved 2022/04/25 original source: https://www3.epa.gov/npdes/pubs/septic_system_tank.pdf

Fiberglass or Plastic Septic Tank Warranties & Life Expectancy

Plastic or fiberglass septic tanks or cisterns installed as a buried component of the septic system typically last about 30 years. That's compared with a typical 15-20 year life for a steel septic tank an a 40 year or longer life for a concrete septic tank.

But as we warn in this article series, damage during installation or damage that occurs after installation if heavy vehicles drive over the tank can reduce the tank's life substantially.

- See additional warranty information in the tank installation documents listed above.

- Agricultural Fact Sheet #SW-161 "Septic Tank Pumping," by Paul D. Robillard and Kelli S. Martin. Penn State College of Agriculture - Cooperative Extension, edited and annotated by Dan Friedman (Thanks: to Bob Mackey for proofreading the original source material.)

- Dauphin Environmental Equipment, Inc., (Fiberglass wastewater storage tanks), (fiberglass septic tanks) Dauphin Environmental Equipment, LLC

721-B Lakeside Drive West

Mobile, AL 36693-5125, Website: http://www.dauphinenv.com/ Orenco fiberglass tanks, Xerxes wastewater treatment, helpful documents at http://www.dauphinenv.com/fiberglass-storage-tank-documents/

Retrieved 4/6/13, copy of [one year] septic tank warranty on file as Xerxes_Septic-Tank-Warranty.pdf - [2] thenaturalhome.com kindly provided the image of the plastic or fiberglass septic tank used at the top of this page. Naturalhome provides septic system products and consulting as well as consulting and products for composting toilets, passive solar construction, sunscreens and geotextiles, and other products. Web: http://www.thenaturalhome.com

- SEPTIC TANK/SOIL-ABSORPTION SYSTEMS: HOW TO OPERATE & MAINTAIN [PDF] - , Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf.

...

Continue reading at SEPTIC TANKS HOME MADE SITE BUILT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRIVING or PARKING OVER SEPTIC

- OIL or SEPTIC TANKS FLOATING UP

- SEPTIC TANKS - home

- SEPTIC TANK BAFFLES

- SEPTIC TANK COVERS

- SEPTIC TANK DEPTH

- SEPTIC TANK DESIGN DEPTH

- SEPTIC TANK DESIGN SPECIFICATIONS

- SEPTIC TANK DESIGN STRENGTH SPECS

- SEPTIC TANKS FLOATING UP

- SEPTIC TANK, HOW TO FIND

- SEPTIC TANK INSTALLATION - home

- SEPTIC TANK INSTALLATION, FIBERGLASS / PLASTIC

- SEPTIC TANK RISERS

- SEPTIC TANK SAFETY

- SEPTIC TANK SIZE

- SEPTIC TANK TEES

Suggested citation for this web page

SEPTIC TANK INSTALLATION, FIBERGLASS / PLASTIC at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Pennsylvania State Wastewater Treatment Fact Sheet SW-161, Septic System Failure: Diagnosis and Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-162, The Soil Media and the Percolation Test

- Pennsylvania State Wastewater Treatment Fact Sheet SW-l64, Mound Systems for Wastewater Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-165, Septic Tank-Soil Absorption Systems

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.