Alternative Septic System Design Specifications

& Regulations

Alternative Septic System Design Specifications

& Regulations

- POST a QUESTION or COMMENT about alternative designs for septic system installations: mounds, raised beds, sand beds, evaporation/transpiration system specs.

Septic system design specifications for alternative installations:

This document uses the New York State wastewater treatment standard for individual household septic systems (Appendix 75-A) to provide an example of state regulated design and installation of alternative septic system designs, including raised septic systems, septic mound systems, intermittent sand filter septic systems, and evaportion-transpiration septic systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Design Specifications for Raised Bed, Mound, Sand Bed, Evaporation and Other Septic Systems

Model regulation and design specifications for septic systems, source: New York State Appendix 75-A.9 - Alternative Septic Systems [Regulation and System Design Criteria for Raised Septic Systems, Septic Mound Systems, Intermittent Sand Filter Bed Systems, Evaporation-Transpiration Septic Systems, Evaporation-Transpiration Absorption Septic Systems, and Other Alternative Septic Systems] Effective Date: 12/01/1990

Also find details about raised bed septic installations at RAISED BED SEPTIC SYSTEMS and for comparison,

see MOUND SEPTIC SYSTEMS.

NOTE: this section of NYS regulations discusses "alternatives" to onsite wastewater disposal systems such as raised bed, mound, sand filter, and evaporation methods to dispose of septic effluent. New York regulations (effective in 1990) do not discuss other septic and onsite wastewater handling methods such as aerobic septic systems. Readers should therefore also be sure to

see SEPTIC SYSTEM DESIGN ALTERNATIVES.

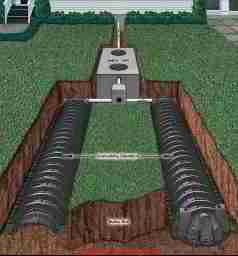

The chamber type septic system design illustrated at page top is discussed in detail

at GRAVELLESS SEPTIC CHAMBER SYSTEMS - Ed.

Design specifications for raised bed and mound septic systems and sand mound septics. Design specifications for intermittent sand filter septic systems. Design guidelines for evaporation transpiration septic systems. General Site Requirements for Raised Septic Systems of various types. New York State Septic System Design Regulations 75-A.9

(a) General Information about Alternative Septic System Designs

(1) Alternative systems described in this subsection must be designed and submitted by a design professional. The design professional shall certify to the local health department that the site/soil evaluation and the plans meet the minimum requirements of these standards.

Construction must be supervised by the design professional, and certification of construction in conformance with the approved plans shall be provided by the design professional to the local health department. Any of these requirements may be waived by a local health department which provides that particular service(s).

(2) Alternative designs not shown herein may be considered by the local health department on a limited experimental basis or for replacement systems on difficult sites, but are also subject to the requirements of Section 75-A.9(1). Performance monitoring of these systems should be required.

(b) Raised Septic Systems Design Criteria

(1) General: Raised Septic Systems

A raised septic system [or raised bed septic system] is an absorption trench system constructed in fill material with acceptable permeability placed above the natural soil on a building lot.

[DF: Note: while they are similar in design "raised septic systems" discussed here are not identical to "mound septic systems" discussed

at SEPTIC MOUND DESIGN SPECIFICATIONS which have different site requirements]

(2) Site Requirements for Raised Septic Systems

A raised system may be used where all the following conditions are found:

(i) There is at least one foot of original soil with a faster than 60 minutes percolation rate, above any impermeable soil layer or bedrock, but not more than two feet.

(ii) The maximum high groundwater level must be at least one foot below the original ground surface.

(iii) Slopes shall not exceed 15%.

(iv) All minimum vertical and horizontal separation distances can be maintained as described in Table 2.

(3) Design Criteria for Raised Bed Septic Systems

(i) Percolation tests shall be conducted in the fill material at the borrow pit and after placement and settling at the construction site. The slower percolation rate of these tests shall be used for design purposes.

(ii) The total area beneath the absorption trenches, extending 2.5 feet in all directions from the outer edge of all trenches, is defined as the basal area. The minimum size of the basal area of the raised bed shall be calculated based upon 0.2 gpd/sq.ft.

(iii) An absorption trench system as described

is designed using the percolation rate of the fill material. The use of slowly permeable soils for the fill material will result in a trench system that will have a basal area larger than the minimum area calculated in (ii) above.

(iv) Sufficient soil with a percolation rate of between 5 - 30 min/in is required to maintain at least two feet separation between the proposed bottom of the trenches and any boundary condition such as groundwater, bedrock, clay or other relatively impermeable soil or formation.

(v) The edge of the fill material shall be tapered at a slope of no greater than one vertical to three horizontal with a minimum 20 foot taper.

(vi) Horizontal separation distances shall be measured from the outside edge of the taper.

(vii) The system shall incorporate siphon dosing or pressure distribution except where the following conditions are met:

(aa) The local health department has a program incorporating site evaluation, system design approval, and construction inspection/certification.

(bb) A minimum of two feet of fill material with a percolation rate of 5 - 30 min/in shall be placed between the bottom of the trenches and the existing ground.

(viii) Curtain drains may be used to intercept and carry underground water away where high groundwater levels exist. Curtain drains shall be upslope from the system and at least 20 feet from the toe of slope of the fill material.

(4) Construction details for raised bed septic systems

(i) Heavy construction equipment shall not be allowed within the area of the system. The underlying soil shall be undisturbed although the surface may be plowed with at least a double bottomed blade/furrow plow and the furrow turned upslope.

(ii) A system shall not be built in unstabilized fill material. The fill material shall be allowed to settle naturally for a period of at least six months to include one freeze-thaw cycle.

(iii) The absorption trenches shall be constructed in the fill material.

(iv) The entire surface of the system including the tapers shall be covered with a minimum of six inches of topsoil, mounded to enhance the runoff of rainwater from the system and seeded to grass.

(v) On sloping sites a diversion ditch or curtain drain shall be installed uphill to prevent surface water runoff from reaching the bed area.

Mound Septic Systems Design Criteria

A mound septic system (or septic mound system) is a soil absorption system that is elevated above the natural soil surface in a suitable fill material. It is a variation of the raised bed utilizing sandy fill material but not requiring a stabilization period prior to the construction of the absorption area.

On sites with permeable soils of insufficient depth to groundwater or creviced or porous bedrock, the fill material in the mound provides the necessary treatment of wastewater.

The overall size of the mound system will normally be substantially smaller than a raised bed.

[DF: Note: while they are similar in design "mound septic systems" discussed here are not identical to "raised septic systems" discussed

at RAISED BED SEPTIC SYSTEMS which have different site requirements.]

(2) Site Requirements for Mound Septic Systems

A mound system may be used where all the following conditions are found:

(i) The maximum high groundwater level must be at least one foot below the original ground surface.

(ii) Bedrock shall be at least two feet below the natural ground surface.

(iii) The percolation rate of the naturally occurring soil shall be faster than 120 minutes/inch.

(iv) The natural ground slopes shall not exceed 12%.

(v) All minimum horizontal separation distances can be maintained as described in Table 2.

(3) Design Criteria for Mound Septic Systems

(i) The designer shall consult with the health unit having jurisdiction regarding the method for detailing the hydraulic design.

(ii) The basal area of a mound system is defined differently than a raised bed. The basal area for a system on level ground includes all the area beneath the absorption trenches or bed and the area under the tapers.

On a sloping site, the basal area includes only the area under the absorption trenches/bed and the lower or downhill taper. The basal area is designed upon the percolation of the naturally occurring soil.

Where the percolation rate is 60 min/in or faster, refer

to TABLE 4B - SOIL APPLICATION RATES.

For soils of 61 to 120 min/in, a rate of 0.2 gpd/sq. ft. shall be used for determining the minimum basal area required.

(iii) Percolation tests for the fill material shall be conducted at the borrow pit. Only soils with a percolation rate between five and 30 minutes per inch shall be used for the fill material. Sands with greater than 10% by weight finer than 0.05 mm material must be avoided.

At least 25% of the material by weight shall be in the range of 0.50 mm to 2.0 mm. Less than 15% of the material by weight shall be larger than a half-inch sieve. A sieve analysis may be necessary to verify this requirement. The required absorption area is based upon the percolation rate of the fill material as determined

from TABLE 4B - SOIL APPLICATION RATES.

(iv) The system shall be designed to run parallel with the contours of the site. The width of the system (up and down the slope) shall be kept to a minimum, but in no case shall the absorption area be wider than 20 feet. In a distribution network using a center pressure manifold, distribution lines shall have a maximum total length of 200 feet.

In a network using an end manifold, distribution lines shall have a maximum length of 100 feet.

(v) Mound dimensions shall meet or exceed those required by the health unit having jurisdiction.

(vi) A pressure distribution network shall be required.

(vii) A dual chamber septic tank or two tanks in series in addition to the dosing tank shall be provided.

A gas baffle or other outlet modification that enhances solids retention is recommended.

(4) Construction Procedures for Mound Septic Systems

(i) Heavy construction equipment shall not be allowed within the basal area and area downslope of the system which will act as the dispersal area for the mound.

(ii) The vegetation shall not be scraped away, roto-tilled, or compacted. Excess vegetation shall be removed with trees cut at the ground surface but stumps left in place.

The area shall be plowed to a depth of seven or eight inches with a double bottomed blade/furrow plow and the furrow turned upslope.

(iii) The fill material is placed from the upslope side of the system to the full depth required in the design and shall extend to the edge of the basal area at a slope not to exceed one vertical to three horizontal.

(iv) The absorption area is then formed within the mound. A minimum of six inches of aggregate shall be placed beneath the distribution lines.

(v) The pressure distribution lines are placed parallel to the contours of the slope and a minimum of two inches of aggregate is placed above the lines.

(vi) A permeable geotextile is placed over the entire absorption area to prevent the infiltration of fines into the aggregate.

(vii) On sloping sites a diversion ditch or curtain drain shall be installed uphill to prevent surface water runoff from reaching the absorption area.

(viii) A minimum of six inches of finer materials such as clayey loam is placed over the top of the absorption area, and the entire mound including the tapers is then covered with six inches of top soil and seeded to grass.

(d) Intermittent Sand Filter Septic Systems Design Criteria

(1) Sand Bed Septic Systems - General

In a sand filter septic system, the septic tank or aerobic unit effluent is intermittently spread across the surface of a bed of sand through a network of distribution lines. Collector pipes beneath the filter collect treated effluent after it has passed through the sand.

(2) Site Requirements for Sand Filter Bed Septic Systems

(i) All horizontal separation distances shown in Table 2 must be met and the minimum required vertical separation to groundwater must be met from the bottom of the collector pipes.

(ii) An environmental assessment determines that the development of the site with a sand filter is consistent with the overall development of the area and will cause no adverse environmental impacts.

(3) Design Criteria for Sand Filter Bed Septic Systems

(i) Septic tanks installed before a sand filter shall have dual compartments or two tanks in series. The use of a gas baffle on the outlet is strongly recommended.

(ii) The direct discharge of sand filter effluent to the ground surface or to a body of water shall not be approved by the Department of Health or a local health department acting as its agent.

(iii) Distributor lines shall be placed at three foot center lines as level as possible.

(iv) Collector pipes shall be centered between distribution lines at a slope of 1/16 to 1/8 inch per foot.

(v) Effluent shall be distributed to the sand filter by means of pressure distribution or siphon dosing. Pressure distribution lines shall be a minimum of 1.5 inches and a maximum of three inches in diameter. If siphon dosing is allowed, the distributor pipe(s) shall have a diameter of three to four inches.

(vi) The distribution system shall be designed to dose the filter at least three times daily based upon the design flow rates with each dose.

(vii) The sand media shall have an effective grain size of 0.25 to 1.0 mm. If nitrification is not required by the local health department, the effective grain size shall be in the range of 0.5 to 1.00 mm. All sand shall pass a 1/4 inch sieve.

(viii) The uniformity coefficient of the sand shall not exceed 4.0.

(ix) The maximum allowed daily sand loading rate shall be 1.15 gal/day/sq. ft.

(x) Effluent from the collector pipes shall be discharged to an absorption bed located below the original ground level or a mound that is built up above the original ground surface. The size of the bed/mound shall be based upon the estimated quantity of effluent reaching the collector pipe and an application rate of 1.2 gal/day/sq. ft. regardless of the underlying soil percolation.

The fill material for the bed/mound shall consist of medium sand with a percolation rate, tested at the borrow pit, not faster than five minutes per inch. All minimum vertical and horizontal separation distances shall be maintained as described in Section 75-A.4.

(4) Construction of Sand Bed Septic Systems

(i) After excavation, the collector pipe shall be placed in 3/4 inches to 1 1/2 inches size aggregate.

(ii) There shall be a minimum of four inches of this aggregate beneath the entire system above the collectors.

(iii) A three inch layer of crushed stone or clean gravel with a size of 1/8 inches to 1/4 inches is carefully placed on top of the aggregate.

(iv) A minimum of 24 inches of the approved sand is placed above the crushed stone or gravel.

(v) The distributor pipes are placed in a layer of aggregate that provides a minimum of four inches across the entire surface of the filter and at least two inches above and below the distributor pipes.

(vi) A permeable geotextile, two inches of hay or straw, or untreated building paper is placed over the entire bed area to prevent the infiltration of fines into the filter.

(vii) The entire surface of the filter shall be covered with six to 12 inches of topsoil, mounded to enhance the runoff of rainwater from the system and seeded to grass.

(viii) The bed/mound following the filter shall be covered with 12 inches of topsoil and seeded to grass.

(e) Evaporation-Transpiration (ET) and Evapo-Transpiration Absorption (ETA) Septic Systems Design Criteria

(1) Evaporation/Transpiration/Absorption Septic Systems - General

ET systems rely on the upward movement of moisture through the soil, surface vegetation and into the air rather than absorption into the soil. ETA systems also use the absorptive capabilities of the soil and are less dependent on evaporation and transpiration.

(2) Site Requirements for Evaporation, Transpiration-Absorption Type Septic Systems

(i) All systems previously discussed, except intermittent sand filters, have been determined to be unacceptable for the planned building site.

(ii) An expansion area equal to or greater than 50% of the required basal area shall be available on the site.

(iii) All minimum vertical and horizontal separation distances can be maintained as described in Table 2 from both the edges of the basal area and the designated expansion area.

(iv) An environmental assessment determines that the development of the site with this system is consistent with the overall development of the area and will cause no adverse environmental impacts.

(3) Design Criteria for Evaporation, Transpiration-Absorption Type Septic Systems

(i) The designer must consider all of the items listed below and be able to document from reliable sources (i.e., National Weather Service, Soil Conservation Service) the parameters used and show that the net outflow from the system exceeds the inflow without the exposure of sewage or partially treated sewage on the surface of the ground:

Total rainfall and snowfall.

The percentage of the rainfall and snowfall that will infiltrate into the soil and the percentage that can be expected to runoff the system.

The annual land evaporation rate of the area.

The vertical rise of water than can be expected in the soil due to capillary action.

The amount of transpiration expected from the surface vegetation.

The permeability of the underlying soil and the impact the system will have on the groundwater level.

(ii) The design must provide for a trench depth that is not greater than 30 inches below the surface.

(iii) Pressure distribution of effluent throughout the system is required.

Volume: A-1a

...

Continue reading at RAISED BED SEPTIC DESIGN SPECIFICATIONS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SEPTIC CONSULTANTS, DESIGNERS, ENGINEERS

- DESIGN SPECS HOLDING TANKS, WATERLESS TOILETS

- DICTIONARY of SEPTIC SYSTEM & WASTEWATER TERMS for a more complete dictionary of septic system and wastewater terminology

- HOLDING TANK SEPTIC SYSTEMS

- SEWAGE TREATMENT PLANTS, RESIDENTIAL

- SEPTIC CODES & REFERENCES

- SEPTIC DESIGN SPECIFICATIONS for ALTERNATIVE SYSTEM

- SEPTIC SYSTEM DESIGN ALTERNATIVES - home

- SEPTIC SYSTEM DESIGN BASICS - home

- SEPTIC & SEWAGE TREATMENT CODES & REFERENCES - home

- TYPES OF SEPTIC SYSTEMS - master list

- U.S. SEPTIC AUTHORITIES & DESIGN SPECIFICATIONS - start of this series

Suggested citation for this web page

SEPTIC DESIGN SPECIFICATIONS for ALTERNATIVE SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about alternative designs for septic system installations: mounds, raised beds, sand beds, evaporation/transpiration system specs..

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- New York State Department of Health, APPENDIX 75-A WASTEWATER TREATMENT STANDARDS - INDIVIDUAL HOUSEHOLD SYSTEMS , [PDF] New York State Department of Health, 3 February 2010, retrieved 3/1/2010, original source: https://www.health.ny.gov/regulations/nycrr/title_10/part_75/appendix_75-a.htm

- Pennsylvania State Wastewater Treatment Fact Sheet SW-161, Septic System Failure: Diagnosis and Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-162, The Soil Media and the Percolation Test

- Pennsylvania State Wastewater Treatment Fact Sheet SW-l64, Mound Systems for Wastewater Treatment

- Pennsylvania State Wastewater Treatment Fact Sheet SW-165, Septic Tank-Soil Absorption Systems

- Document Sources used for this web page include but are not limited to: Agricultural Fact Sheet #SW-161 "Septic Tank Pumping," by Paul D. Robillard and Kelli S. Martin. Penn State College of Agriculture - Cooperative Extension, edited and annotated by Dan Friedman (Thanks: to Bob Mackey for proofreading the original source material.)

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.