SIPs Structural Insulated Panels

SIPs Structural Insulated Panels

(Stress-Skin Panels) in Timber Frame, Modular, Panelized, & Cathedral Ceiling Construction

- POST a QUESTION or COMMENT about stress skin panel construction: installation, troubleshooting, repairs

Building with SIPS or Structural Insulated Panels, earlier referred to as Stress-skin Insulated Panels.

This article discusses the use of stress skin insulated structural panels for timber frame and other construction.

We describe the history and current uses of stress skin structural panels or SIPs, the properties of SIPs and their fire safety, R-value, and durability or life expectancy.

We also give details of how SIPs are constructed, how they are sold, and we list the current manufacturers and sources of stress skin insulated panels (SIPs). Illustration at page top and accompanying text are reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Page top photo: excerpted from SIPA's Structural Insulated Panels product guide cited on this page.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Stress Skin Panel Construction & SIP Properties

A SIP or Structural Insulated Panel typically has a polystyrene or polyurethane foam core faced on either side with a "skin" - generally plywood, composition board, OSB, or drywall.

A SIP or Structural Insulated Panel typically has a polystyrene or polyurethane foam core faced on either side with a "skin" - generally plywood, composition board, OSB, or drywall.

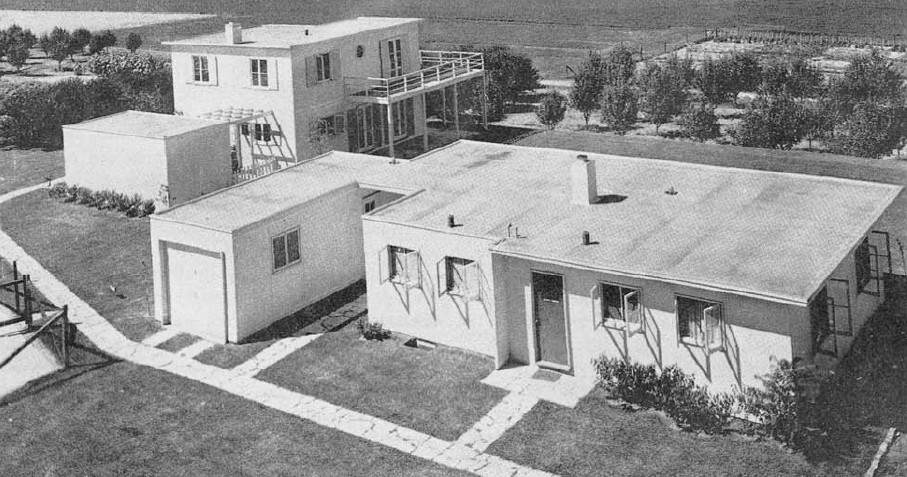

SIPs were introduced as a building panel concept in the U.S. by the Forest Products Laboratory in Madison Wisconsin in 1935.

In an important research project homes built in 1935 were disassembled and tested thirty years later in a study that we cite and link-to below. That study found that the SIPs performed well, having retained their initial strength.

Article Contents

- DEFINITION of SIPs, Structural Insulated Panels or Stress-Skin Panels

- STYRENE vs URETHANE STRESS SKIN PANELS

- FIRE SAFETY, R-VALUE, & COMPONENTS of SIPs

- LIFE EXPECTANCY & DURABILITY of SIP FOAM CORE PANELS

- US FPL STUDY of SIP DURABILITY

- DIY HOME MADE STRESS SKIN INSULATED FOAM CORE PANELS

- STRESS SKIN INSULATED BUILDING PANEL CONSTRUCTION DETAILS

- STRESS SKIN FOAM CORE PANEL MARKETING TACTICS

- INSULATED CEILINGS USING STRESS SKIN INSULATED PANELS

- ELECTRICAL WIRING DETAILS for STRESS SKIN SIP BUILDINGS

- SOURCES for STRESS SKIN PANELS for TIMBER FRAME & STRUCTURAL INSULATED PANEL HOMES

Besides plywood, OSB and drywall we just cited, modern SIP skin materials include sheet metal (good mold resistance, may not be load-bearing), fiber cement siding, fiberglass mat gypsum board, composite structural panels, and magnesium cement board.

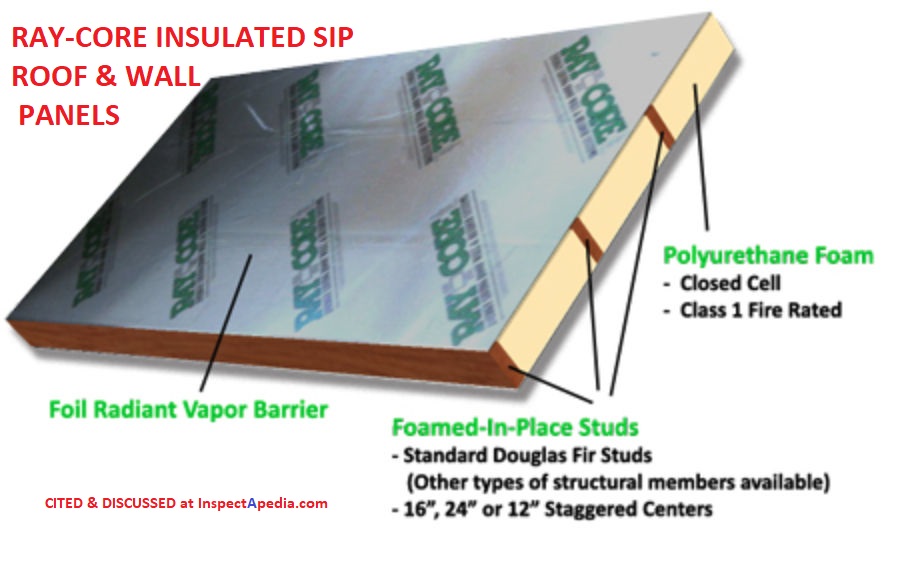

Some products such as Raycore SIPS include conventional wood framing members for rigidity and sport a 0-perm foil skin; most SIPS are constructed with OSB or plywood facing.

The SIP insulating foam core is most often Expanded PolyStyrene (EPS), Extruded Polystyrene (XPS), or Polyurethane (PUR) but some companies offer other specialty foam insulating products. EPS is least costly, XPS is stronger and has improved moisture resistance, PUR has highest R-value, strength, and water resistance (and is more-expensive and has other drawbacks).

SIPs can work as a structural panel: the panel itself is the main load bearing element in a roof or wall - typically for one-story homes, or SIPS can be used as panels to enclose timber frame (post and beam) constructed buildings.

SIPs are also used on more-conventionally framed roofs and walls.

But standardization ends there. Beyond the basic material options, stress skin panel products take off in a variety of directions that affect cost, performance, and durability.

Photo (above-left) U.S. Forest Products Laboratory Structural Insulated Panel based prefab houses developed in 1937, built for study and evaluation.

The text below paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Stress Skin Structural Panels, history, current use practices

While stressed-skin insulated panels, currently referred to as SIPs or structural insulated panels have been in use in the U.S. since the 1930's, builders continuously call for more pre-manufactured components.

Home buyers and regulators demand greater energy efficiency in new homes. This was true in 1964 when the U.S. FPS studied the durability of stressed skin panels, it was still true in the 1980's when we looked at the use of stress-skin panels in Solar Age Magazine [September 1986] and it remains true today, more than eighty years since the US FPL began studying SIPs.

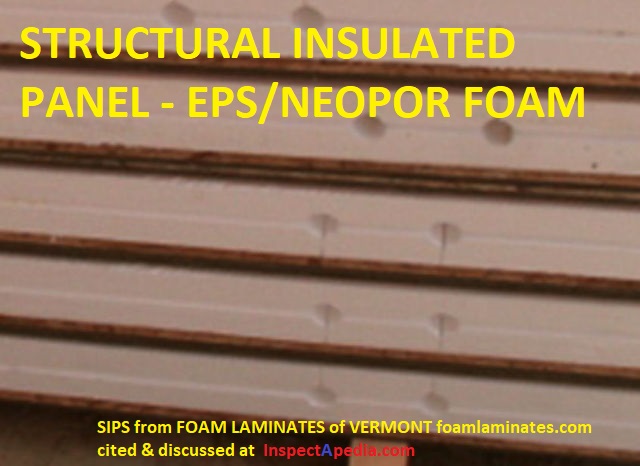

The illustration below, adapted from Foam Laminates of Vermont (FLV) (cited below) illustrates OSB-faced SIPs used as either a structural panel (below left) or as an enclosing panel in timber frame construction (below right).

FLV explains that when used as structural panels without an independent structural frame SIPs are typically confined to one-story buildings.

The R-value of SIPS vary by panel thickness and type of foam and facing, typically ranging from R-15 for a 4 1/2" thick panel to R45 for a 12 1/4" thick panel, both using EPS (Expanded PolyStyrene) foam.

As may other manufacturers, FLV also provides an alternative foam product, Neopor, to obtain higher R-values of R 18 to R63. The R63 structural panel is 14 1/8" thick.

Note: These are "assembly" R-values, a number a bit greater than the R-value of the foam core itself.

Solar Age Magazine Articles on Renewable Energy, Energy Savings, Construction Practices

Definition of SIPs, Structural Insulated Panels or Stress-Skin Panels

What is an SIP or stressed skin panel or structural insulated panel?

What is an SIP or stressed skin panel or structural insulated panel?

Quoting from the 1960's US FPL study cited later in this article:

Fundamentally, the [stressed skin insulated panel or SIP] system uses panels made of framing members to which plywood sheets or other facing materials are bonded either by glue-nailing or gluing by other types of pressure.

The gluing of these skins causes them and the framing members to act as an integral unit: therefore, under loading, the skins are stressed.

The use of the skins, structurally, allows a reduction in size of the framing material, and the elimination of sheathing and interior finishing materials reduces the weight of the construction considerably.

If it is desirable, the panels may be used only as a structural unit and any type of' exterior or interior finish may be applied.

The sketch of a structural insulated wall panel in cross section shown at left is from the above US FPL study

[Click any image to see an enlarged, detailed version.]

Roof panel SIPs used for roof covering on the 1936 US FPL study homes were nominal 6-Inch thickness units incorporating an air space between the top of the insulation and the underside of the roof deck.

Stress-skin panels are used to wrap around structural timber frames, to sheathe the roofs of cathedral ceilings, and even to build the entire building shell. All of the stress-skin panels for residential construction use similar components.

Rivalry Among Styrene & Urethane Stress Skin Panel Manufacturers

Back in 1986 foam panel user and virtuoso timber-framer Tedd Benson characterized the competition between styrene and urethane foam based stress skin insulated panels: "It's a war out there between the styrene and urethane panel manufacturers!"

Not quite a war, but the rivalry was and remains hot. The conflicts between competing types of insulating foam in building products in general have focused mostly on

- fire safety of various foam insulating products

- aged R-value of different foam insulations

- long term durability of foam insulation products

The vast majority of the stress-skin insulated panels use polystyrene - commonly called beadboard - for the simple reason that it is much cheaper than urethane foam.

William Porter of W.H. Porter Company, Holland MI, a producer of both types of panels indicated that in the 1980's beadboard-filled stress skin insulated panels were selling 10 to one over urethane foam based panels. Those who want the urethane, said Porter, are looking for higher R-values, "... but don't want to go to a foot-thick stress-skin panel."

Our photo (above, left) from the original Solar Age stress skin panel article illustrates wrapping the house with stress-skin panels with drywall on the interior and OSB on the exterior. If heavy siding is used or the exterior is shingled, the OSB has to be strapped. [Click any image for an enlarged, detailed view.]

Inch for inch, a urethane foam core stress skin panel may cost twice as much as a beadboard panel. But compared by R-value the differences are small, said Amos Winter of the urethane-panel manufacturing firm Winter Panel Corp. in Brattleboro, Vermont.

An average 5 1/2-inch foam core stress skin panel filled with beadboard cost [1980's prices] from $1.75 to $2.20 per square foot, said Winter, compared with $2.20 for a 3 1/2-inch urethane stress skin foam core panel with comparable R-value. Urethane foam offers R-6 to R-7 per inch (according to most sources) compared with beadboard's R-3.8 per inch.

How well either product holds its R-value over time is another bone of contention.

See INSULATION R-VALUES & PROPERTIES

and POLYSTYRENE FOAM INSULATION

and URETHANE FOAM DETERIORATION & OUTGASSING for current details.

Drawbacks of polyurethane PUR include that PUR-SIP panels are harder to modify in the field, may be limited in thicknesses available, and may use a flame retardant (chlorinated phosphate TCPP) that is hazardous.

Some sources continue to complain that PUR panels also suffer from R-value creep. EPS and XPS use HBCD (hexabromocyclododecane - a brominated fire retardant classified by the European Union (REACH program) as persistent, bio accumulative, and toxic (PBT) as a fire retardant.

Fire Safety of Types of Stress Skin Insulated Structural Panels

Urethane foam insulated panel loyalists are skeptical of the performance of beadboard insulation in a fire. Said one builder, "I just wouldn't feel safe in a house that would melt in a fire."

The problem, says Amos Winter, "... is that beadboard panels will fail structurally when the foam starts to melt at around 200 degF, whether the panels burn or not." He says that the melted styrene (it flows at around 250 degF) will feed a fire like molten wax from a candle.

Urethane foam burns more like wood, he says. It stays intact until it burns through. Winter believes that a styrene foam insulated panel system is more acceptable if it has fire-stops throughout and full structural supports - for example, a system with full 2-by splines at all panel joints and edges.

Our photo (above, left) from the original Solar Age stress skin panel article illustrates the installer improving the thermal performance of the stress skin panels by filling joints with one-part urethane foam.

Either type of insulated foam panel can be made to comply with the 15-minute thermal-barrier requirement. But the codes were not written [prior to 1986] "... for a system that melts." says Winter.

William Porter, who makes both beadboard and urethane foam core stress skin panels, points out that both will burn at higher temperatures. He feels that the code requirement for 1/2-inch drywall on studs and 1/2-inch wood on ceiling panels is adequate.

Using just drywall on a ceiling stress-skin panel is unwise, anyway, says Porter, because the panel could sag if the drywall ever got wet.

Styrene stress-skin foam core panel supporters counter by arguing that melting temperatures [of the foam insulating core] don't occur in walls or roofs under normal conditions or even during small fires. One manufacturer, Enercept in Watertown SD, says that its panel with drywall and waferboard on the interior surface passed the UL "corner test" intact.

In that Underwriters Laboratories fire test, a 35-pound wood pile is ignited in a full-scale mock-up building corner.

This type of test is challenged by Winter. He says it isn't representative of condition in a real fire because the space is not enclosed.

Longevity / Durability of Stress-Skin Insulated Foam Core Panels

Discussions about long-term performance of stress skin panels are equally contentious. Under moist conditions, says Porter, urethane expands slightly as it ages and styrene beadboard contracts. "Too much of either is not desirable," he says.

In a batch of urethane panels produced early on in the 1980's, the foam shrunk and warped the panels, said Winter, who removed and replaced them.

The foam core panel shrinkage problem was solved, he says, by improving the chemistry of the foam insulation. The message is clear: Urethane foam "needs a good cook" to insure good performance.

Our photo (above, left) from the original Solar Age stress skin panel article shows an employee of Atlas Industries, Ayer MA, preparing stress skin foam insulated panels by routing out space to allow spline inserts where panel edges meet. The company has produced stress skin insulated foam core building panels since the mid 1970's.

More important to the durability of stress skin panels is the longevity of the foam core itself and the bond of the foam insulating core to the facing materials of the panel.

Many distrust the life expectancy of 1-pound density styrene beadboard, which has a soft, breakable consistency.

To get a good bond, the adhesive must penetrate into the beadboard, says Winter. He prefers urethane adhesive with beadboard cores. Urethane, on the other hand, is difficult to bond to because the cells on the surface are cut open "like cracked egg shells".

US FPL study on the durability of stressed skin panels or SIPs

See STRESSED SKIN PANEL PERFORMANCE AFTER TWENTY-FIVE YEARS OF SERVICE [PDF]

Quoting from that document's summary, and recognizing that panels, foam insulation, and adhesives have surely improved since the original 1962 study:

Wall panels used in construction of a prefabricated house, built in 1937, were removed in 1962 to determine their performance characteristics after 25 years’ service. The panels were evaluated for stiffness and bending strength, and the glue joints in the plywood and between the plywood and the framing members were evaluated for shear strength.

Replacement panels. placed in the prefabricated house in 1962, were evaluated to equivalent design loads of 20 pounds per square foot prior to being placed in the house. Panels of a construction similar to the replacement panels were evaluated to failure.

The panel stiffness evaluations showed that span deflection ratios at design load, both for panels removed after 25 years’ service and for recently fabricated panels, exceeded by several times the normal allowable design values for walls. Failing load also exceeded design values by factors of more than 10.

Evaluations of plywood in shear, after the conventional exterior-type boil-dry cycle test, indicated relatively little change in quality of the glue joints after 25 years’ service. Results of dry shear tests of the casein-glued joints between plywood and the framing members showed little evidence of deterioration.

The panels were designed and maintained to control moisture effects and the entry of water during the 25 years’ service.

Stress Skin Panel Facings & Bonding

There are as many ways to fashion stress-skin foam core building panels as there are manufacturers. With some foam core panels, the urethane is best foamed in place between the sheets, providing its own integral bond between the cured foam insulation and the panel surfaces.

More commonly, the plastic foam insulation core is laminated to the sheets of the panel with a contact adhesive or a pressure-set adhesive.

Our photo (left) from the original Solar Age article shows stress skin panels and timber frame components for a completely pre-cut kit house using polystyrene panels and a simplified timber frame system sold by Northern Energy Homes.

"Laminating [foam core insulated building panels] is tricky", says Porter. "If you haven't made a mistake you haven't been in the business long."

At one point, he says, his company used an adhesive with a plasticizer that dried up over time and eroded the bond to the stress skin panel.

Most glues are sensitive to air temperature and moisture content. They require industrial-type clamping to get good performance.

If laminating is difficult, foaming stress skin panels in place is even more so, says Winter, a veteran urethane foamer. The process is technically complex, chemically volatile, and as much art as science.

Do-it-yourself Home Made Stress Skin Insulated Foam Core Building Panels?

The manufacturers do seem to agree that it's best to avoid home-grown stress-skin insulated building panels - particularly if the panels will bear structural loads. The bond of foam to facing is what transfers the loads to the panel skin and gives the panels their strength.

Stress Skin Insulated Building Panel Construction Details

Best Skin Material for Stress Skin Panels

As for the best skin material for stress-skin foam core panels, there is little agreement. Timber-framer Benson experimented with plywood on the exterior. He says he had problems with the plies delaminating. By the early 1980's he had switched from waferboard panels to Oriented Strand Board (OSB) because it is stronger and holds nails better than the waferboard.

Stress Skin Panel Strapping for Siding

All panel facing materials have to be strapped, he says, to receive heavy sidings, because there are no studs.

Another timber-framing company, Northern Energy Homes [photo above] tried waferboard panels before switching back to plywood skinned panels. The waferboard had a "negative appeal to clients" and the savings in cost over plywood were marginal.

Interior Facings for Stress Skin Foam Core Panels

On the interior face, Northern Energy Homes uses either 3/4-inch T&G Pine or 1/2-inch drywall. The 1/2-inch drywall is backed by 1/4-inch waferboard - there to keep the panels a uniform thickness and to provide a nailbase for interior trim.

With just a drywall skin, hanging finish materials such as kitchen cabinets can present a problem. Tedd Benson has 2x4's custom fitted into the kitchen stress-skin wall panels where wall and base cabinets will attach. For lightweight items, he says, molly bolts into the foam work just fine.

Joints, Grooves & Slots in Stress Skin Building Panels

Like most building products, "an insulated stress-skin building panel is only as good as its installation," says Benson. The key is having a good system to attach one panel to another. Most stress-skin panels use some spline system to get continuity between panels.

Our photo (left) from the original Solar Age article illustrates a bowed-roof cape design using structural panels on a home from Winter Panel Corp.

How finicky one must be at the stress skin panel joint is a matter of judgment. A full wood spline - for example, a 2x6 for a nominal 6-inch foam core panel - is the most common treatment at a joint. A full spline nailed through from both faces, and sometimes glued, provides good structural continuity.

But the stress-skin panel joint is a weak link thermally. This will often result in "melt lines" or "frost lines" showing on the roof. Full splines can also lead to cracked drywall joints on the building interior if the wood spline swells during the first winter.

To beef up the stress skin panel joint thermally, many have switched to a double-spline system. This improvement is still vulnerable to thermal, air, and moisture leaks.

To bridge the gap thermally, Benson intentionally leaves a 3/8-inch gap in the foam between the splines. The gap is foamed through 1/4-inch holes drilled about every 10 inches from the outside. Northern Energy Homes uses a 1 1/2 x 2-inch foam spline to get thermal continuity. Its panels are slightly beveled, leaving a gap on the outside to be foamed for an airseal.

Special Considerations for Stress-Skin Insulated Panel Roofs

Stress-skin roofs face another nuisance. Sometimes roof shingles refuse to lie flat over the stress-skin panel joints. The cause is attributed to expansion of the waferboard, which buckles the shingles.

This problem has also been reported on conventional roofs with waferboard roof sheathing.

One solution, reports Winter, is to seal the waferboard edges with roofing cement and then wet down the roof to "condition" it to its normal moisture content. Some waferboard manufacturers are said to be responding to the problem by preconditioning their panels.

Tedd Benson says that his solid foam-to-foam joint seems to prevent this problem, which he blames in part on moisture that escapes and condenses under the shingles.

Stress-Skin Foam Core Building Panel Market Tactics

Stress-skin building panels can't beat the cost of conventional building systems. But they are carving out a niche in the market for low-energy houses. Stress skin should be come more competitive since the costs of labor and materials for conventional buildings are increasing faster.

Most would agree that stress-skin panels are used to their best advantage in manufactured and pre-cut panelized housing, where the increased material costs are offset by labor savings and quicker scheduling.

Enercept pre-cuts homes to the customer's plans.

The company supplies a complete system through a dealer/contractor network. Enercept's building construction system is frameless with patented wood and metal connectors for wall and roof stress-skin panels.

Vertical loads are picked up by thermally broken studs placed in the panels 4-feet on center.

Once the foundation is in, an average house shell can be completed in two or three days, says Enercept's Ken Norberg.

Using Stress Skin Insulated Foam Core Panels for Insulated Ceilings

The W.H. Porter Company markets some insulated foam core stress skin panels with a tubular-steel octagonal frame. It's aimed at the recreational and vacation-home market. Most of Porter's panels are sold for roofs of conventional houses, and some for site-built panelized homes.

Porter sees great promise for OSB-faced roof stress-skin panels that can san up to 24 feet. "There's no better product," he says, "for cathedral ceiling applications."

Northern Energy Homes supplies completely pre-cut house packages - using styrene core foam panels and a simplified timber frame. "Each piece is pre-engineered and pre-cut for each house," says Northern Energy's Richard Clancy. "This way," he says, "we don't leave our technology up to the contractor." The standard package includes such energy amenities as Heat-Mirror windows, integrated night insulation, and ground water heat pumps.

Other companies garget specialty markets for stress skin insulated building panels.

Several pre-fab sunspaces use foam-core stress-skin panels for end-walls and roof sections. Energy Saving Products, a company that specializes in indoor swimming pool equipment, markets stress-skin insulated panels for swimming pool enclosures.

The company's Rita Welebob says urethane panels are viewed as a one-step solution to problems caused by rusty nail heads and soggy insulation.

While no figures were available in the 1980's, manufacturers reported rapid growth over the middle of that decade. Enercept's Ken Norberg forecasted growth from 50 to 100 percent per year in stress skin panel use in the mid 1980's.

No one speaks as if stress-skin building panels are panaceas. But arguments and rivalry aside, everyone predicts a bright future for the foam core panel system that can provide structural integrity, exceptional energy performance, and freedom from moisture concerns.

This article is reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

In this energy savings article series we include solar energy, solar heating, solar hot water, and related building energy efficiency improvement articles reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

Stress Skin SIP Panel Electrical Wiring Details

Here we include example excerpts from Enercept's electrical wiring guide for Structural Insulated Panels.

Watch out: this guide and its discussion of the factory-designed locations for wiring chaseways and electrical box locations is specifically for Enercept SIPs and will not necessarily be even close to how wiring was run and electrical panels or boxes located in SIP buildings using panels made by other manufacturers.

In response to a question from leentest (September 2022) we looked for explicit details on the installation of electrical panels, boxes, and wiring in SIP Stress Skin or Structural Insulated Panel construction.

We found several sources, most quite thin and minimal and from Enercept (cited below) a detailed guide on locating fixtures, electrical boxes and running wires in SIP buildings.

SIP Wiring Procedures & Details

Some obvious details are omitted from some SIP electrical wiring instructions, so don't forget, before assembling SIPs to form a wall or roof:

- In SIP construction electrical wires are pulled through factory pre-formed chases that run horizontally or vertically through the SIPs.

Alternatively in some SIP designs wiring is run in wiring raceways cut behind baseboard trim or in a cavity found behind a beveled spacer on SIP roof-to-wall connections.

Alternatively in some SIP buildings wiring is run through surface-mount wiring mold or in gaps left in drywall or flooring. - The electrician can access the chaseways to install specific boxes and devices along the chaseway route by cutting a small access opening through the SIP skin.

- Drill 1 1/2" diameter wiring holes through splines to permit pulling electrical wires through horizontal chaseways

- Drill (where required) 1 1/2" diameter wiring holes in top or bottom plates to align with vertical wiring chases

- Take care to align horizontal wiring chaseways when adjoining SIPS and be sure that construction debris doesn't enter/block any wiring openings or chaseways.

- Cut for electrical boxes as needed, but do not cut through to panel edges.

- Do not cut panel skins for electrical chases

Enercept's thoughtful SIP electrical wiring advice makes a few basic points very clear:

- Watch out: Call with any questions, and DEFINITELY call before you cut

- but CALL THE MANUFACTURER of YOUR SPECIFIC SIP product. Below we include Enercept's contact information but if your panels were made by someone else, call that company.

We cannot stress it enough: CALL BEFORE YOU CUT! We'd much rather answer your questions before a panel is damaged or improperly cut.

Enercept has excellent customer service; if you have any questions or concerns, please call us at 605-882-2222. - Wiring chaseways and electrical box locations

are usually pre-cut and set by the SIP manufacturer; the locations of these devices after the building has been completed, finished, sided, painted, etc. will be indicated only by the presence of specific electrical components such as light fixtures, receptacles, junction box covers, and of course the electrical panel itself. - Electrical-code-required backer boards or supports

may be required and may have built-in to specific SIP locations to support, for example, a wall-mounted electrical panel, particularly, depending on the panel's weight.

(Most electrical panels and meter boxes will weigh less than 90 lbs. and the SIP's OSB or plywood skin or backer-board may be sufficient.)

In replacing or repairing wall damage, leaks, rot, around an electrical panel or electric meter box you may need to

- do nothing to the electrical meter or panel without help from a licensed electrician

- drop power to the building

- remove the electric meter box or panel

- cut and repair any damaged SIP skin and backer board used to support the weight of the meter or panel

- replace the electrical components with proper sealants against future water intrusion

- Enercept SIP ELECTRICAL WIRING GUIDE [PDF] Enercept Co., 3100 9th Ave. SE, Watertown SD 57201 USA, Tel: 800-658-3303, Web: www.enercept.com, retrieved 2022/09/02 original source: https://cdn2.hubspot.net/hubfs/3823653/E-BOOKS/Electrical%20Guide%202009.pdf

- SIPA STRUCTURAL INSULATED PANELS PRODUCT GUIDE [PDF] (2018) Structural Insulated Panel Association, retrieved 2022/09/02, original source: https://tolko.com/wp-content/uploads/2018/10/OSB-Product-Guide-Structural-Insulated-Panels-SIPs-APA.pdf

Includes some notes on electrical wiring in SIPS and the illustration shown just above - see SIPA contact information given in detail along with references to more SIPA documents

at SOURCES for STRESS SKIN PANELS for TIMBER FRAME & STRUCTURAL INSULATED PANEL HOMES

Excerpts:

Electrical wiring chaseways in SIPs

Enercept typically provides a 1 1/4 inch Horizontal Chase 16 inches from the bottom in wall panels, 44-inch Chases are provided in kitchen, utility rooms and bathrooms where countertops would be located.

Enercept typically provides a 1 1/4 inch Horizontal Chase 16 inches from the bottom in wall panels, 44-inch Chases are provided in kitchen, utility rooms and bathrooms where countertops would be located.

Vertical Chases from the bottom of the panel to the 16-inch Chase are provided in 4' wide panels and below window openings.

SIP wall with blue electrical markings A 1 1/4 inch Vertical Chase is typically provided in each panel adjacent to door and window openings.

[Illustrated above - click to enlarge any image]

A floor plan should be obtained which contains actual dimensions of all wall, window, and door swing locations.

The electrician must mark on this plan where they will need non-standard chases or larger chases to accommodate multiple wires along with the N.E.C. required receptacles, switches, light fixtures, etc.

Do not cut across the panel face/skin for wiring chases

The wiring chases installed by Enercept are for electrical wiring installation only.

They are not for the plumber or the H.V.A.C. contractor. We mark on the interior side of the panel with blue permanent the locations of the pre-installed chases.

Single gang electrical box knockouts are cut into all 4' wide panels and lower window panels for access from the floor systems. The electrician may choose to use these cutouts or cut in their own where they need them.

Ceiling fixture locations must be noted on the electrical drawings

Enercept SIP Roof/Ceiling panels may have factory installed 12-3 Type NM-B cable in place for ceiling wiring.

When installing these pre-wired roof panels, the builder or electrician must route the wiring from the roof panel into the appropriate vertical wire chase in the wall panels leading to switches, electrical termination or sources.

If your roof panels are not pre-wired, you first install the wiring, then set the panels in place.

Watch out: Remember the roof panels are insulated with foam, DO NOT USE REGULAR RECESSED LIGHT FIXTURES IN EPS CORE PANELS.

LED surface-mounted lights can be used instead.

All Enercept roof panels with factory installed wiring will have a 2 1/4" x 9 1/2" backer board in place for each for each ceiling fixture.

Additional support/engineering may be needed for fixtures more than 90 pounds.

Watch out: Call with any questions, and DEFINITELY call before you cut

We cannot stress it enough: CALL BEFORE YOU CUT! ... if you have any questions or concerns, please call us at 605-882-2222.

Stress Skin Insulated Panel Repairs

Please see STRESS SKIN INSULATED PANEL REPAIR

Stress Skin Panels / Structural Insulated Panels (SIPs) Guides, Sources, Standards

CONTACT us to add stress skin and structural insulated panel SIP producers and experts to this list - no fees.

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided free to the public - we have no business or financial connection with any manufacturer or service provider discussed at our website. We do not sell products nor services.

- AcmePanel, 1905 West Main Street

Radford, VA 24141 USA, Tel: (877) 331-4266

Email: info@acmepanel.com Website: http://www.acmepanel.com/

AcmePanel notes that the company uses solar panel in the production of their product, claiming a cleaner, more-efficient SIP. Panel Thicknesses: 4.5" to 12.25", R-values R-16 - R48.

The company provides "Nail Base" SIPs used for walls and roofs, using EPS foam core (R 3.8 / Inch) and 7/17" OSB on one surface. The company also provides ACME MgO (Magnesium Oxide Board) panels made with "Jetboard MGO Board Skins.

Jetboard is a non-combustible

Excerpt:

The panels are typically made by sandwiching a core of rigid foam plastic insulation between two structural skins of oriented strand board (OSB). Other skin material can be used for specific purposes.

JETBOARD™ BROCHURE [PDF] describes this product, retrieved 2019/11/09 original source: http://acmepanel.com/pdf/Jet_Products_Brochure.pdf

Contact Jetboard directly at www.Jet-Board.com TEl: 877-453-8868 Email: LearnMore@Jet-Board.com

Really? Well yeah but geez I sure wish that Jetboard or AcmePanel could have included a simple description of what a Jetboard MgO product actually is - what it's made of. Just saying magnesium oxide isn't a filling meal. For those who want to be filled, JetBoard is a cement board made using magnesium oxide to form magnesium cement. The result is a product with good fire-resistance superior to drywall with zero flame spread and about the same R-vale and impact resistance as plywood (R 1.2 / Inch). - ANSI ANSI/APA PRS 610.1-2018: STANDARD FOR PERFORMANCE RATED STRUCTURAL INSULATED PANELS IN WALL APPLICATIONS [PDF] (2018) ANSI, APA, - retrieved 2022/09/02 original source: https://www.sips.org/documents/ANSI-Standard-for-SIPs-in-Wall-Applications.pdf

Excerpt from foreword:

This standard provides requirements and test methods for the qualification and quality assurance for performance-rated structural insulated panels (SIPs), which are manufactured with a foam plastic insulation core bonded between two wood structural panel facings intended for use in wall applications. Product performance requirements are specified.

- Eagle Panel Systems, Inc., Structural Insulation, Stress Skin Panels, Eagle Panel Systems, Inc. / P.O. Box 247 / Mulberry Grove, IL 62262-0247 sales@eaglepanelsystems.com / Phone: (800) 643-3786 Web: eaglepanelsystems.com

- Enercept SIPs, 3100 9th Ave SE Watertown, SD 57201

USA Email: info@enercept.com

Tel: 605-882-2222 Website: enercept.com

OSB / EPS SIPs for foundations, walls, roofs. - Enercept SIP ELECTRICAL WIRING GUIDE [PDF] Enercept Co., 3100 9th Ave. SE, Watertown SD 57201 USA, Tel: 800-658-3303, Web: www.enercept.com, retrieved 2022/09/02 original source: https://cdn2.hubspot.net/hubfs/3823653/E-BOOKS/Electrical%20Guide%202009.pdf

Enercept provides a detailed electrical wiring guide for Enercept SIP panel construction, including details about the location of wiring chaseways, electrical boxes, fixtures, and important warnings against cutting across SIP panels. - Energy Panel Structures Inc SIP CONSTRUCTION STANDARDS & DETAILS [PDF] (2011) Energy Panel Structures, Inc. 102 East Industrial Park Graettinger, IA 51342 USA, Tel: 800.967.2130 Email: sales@epsbuildings.com Website: www.epsbuildings.com

- Extreme Panel Technologies, 475 East 4th Street North (P.O. Box 435) Cottonwood, MN 56229 USA Phone: 800-977-2635 or 507-423-5530 Fax: 507-423-5531 Email: info@extremepanel.com Website: https://www.extremepanel.com/

- Foam Laminates of Vermont, Structural Insulated Panel (SIP) Manufacturer, 22 Varney Hill Rd., Starksboro VT 05487 USA, Tel: (800) 545-6290 or 888-683-5968, Email:

info@foamlaminates.com Web: foamlaminates.com

Website excerpt:

The standard structural insulated panel (SIP) – as its name suggests – is the typical configuration.

This SIP is composed of the foam insulating core sandwiched between two OSB facings and bonded with urethane glue. SIPs are used as load bearing walls and as roof insulation. SIPs can be used to completely enclose a home or building and can partition individual rooms if desired.

Foam Laminates of Vermont makes extremely versatile SIPs. In fact, sheetrock, wood, vinyl siding, and other construction materials can be applied directly to the facings to result in a fast, efficient, and superior finished wall. - Foard Panels, 53 Stow Drive West Chesterfield, NH, 03466 USA Phone: \(866) 354-8893 or (604) 359-8179 Email: pete@foardpanel.com

- Foam-Tech Superinsulation Products, Building Envelope Services, Inc./ FOAM-TECH, PO Box 87, N. Thetford, VT 05054, Tel: 802-333-4333 Web: http://www.foam-tech.com

- Habitat Post & Beam Wall Systems, Habitat Post & Beam, Inc. 21 Elm Street, South Deerfield, MA 01373 800.992.0121 info@postandbeam.com Web: http://www.postandbeam.com

- Insulspan SIP System, Insulspan – USA: Blissfield

9012 East US Hwy 223

Blissfield, Michigan 49228 USA, Tel: 517-486-4844, 866-848-8855 (west) or 800-726-35a0 (east) or in

Canada: Insulspan – Delta #1 – 600 Chester Road Annacis Business Park Delta, BC, Canada V3M 5V8 or Insulspan – Calgary #300, 2891 Sunridge Way NE Calgary, AB Canada, T1Y 7K7

Insulspan can provide fabricated panels cut to match your needs. The company offers SIP construction training and a range of technical documents, of which one is cited below:

INSULSPAN SIPs INSTALLATION GUIDE [PDF] (2018) retrieved 2019/11/09 original source: https://www.insulspan.com/wp-content/uploads/2019/02/InsulspanInstallationGuide.pdf NOTE that the company provides documents and guides at no cost but asks that you register your identity with Insulspan before downloading more items.

Excerpt: This manual covers the details commonly encountered with the Insulspan structural insulated panel (SIP) system in residential and commercial construction applications. It is intended as a general guide only.

Be sure to follow the specific instructions shown on Insulspan SIP System shop drawings and the manufacturers of any other building products that interface with the Insulspan SIP System, as well as all applicable building codes.

This manual shall be used with training provided by Insulspan Site Advisors, Sales Representatives and/or the Insulspan dealer network in conjunction with the architectural and engineering drawings and specifications. (An Insulspan representative can assist with applications using the Insulspan SIP System.)

- Insulspan, INSULSPAN STRUCTURAL INSULATED PANELS (SIPs) MASTERFORMAT SPECIFICATION [PDF] (2019)Plasti-Fab Ltd.

Insulspan SIP Plant

600 Chester Road

Delta, BC, Canada V3M 5Y3

Phone: 866.848.8855 - retrieved 2022/09/02, original source: https://sweets.construction.com/swts_content_files_nas/154456/Structural-Insulated-Panels-(SIPs)-4682703.pdf?source=internal

- Malko Paul & Alison Moynihan, SIDING & ROOFING SYSTEM RECOMMENDATIONS using SIPs [PDF] Foard Panels, Op. Cit., retrieved from Foard Panels 2019/11/09

Excerpt: There is no one correct wall or roof build-up for SIPs. The interactions between the building design, desired finish, and climate vary too much for one solution to work everywhere. The best practices outlined here are based on a combination of our experience and our best understanding of building science.

Because most of Foard Panel's experience and customer base is in the northeast, these recommendations should be taken as guidelines and only directly applied in areas with roughly similar climate and weather. We are confident that these details will work in most any climate, but they may be overkill for mild/dry climates.

We've learned that some amount of liquid water will always infiltrate a building's envelope/weather-protection assembly. We are very skeptical of claims about being 100% waterproof after 50 New England winters.

The sources of water vary from extreme wind driven rain, condensing fog, imperfections in flashing details, vapor drive from inside to outside, and many other sources.

- Murus Structural Insulating Panels, The Murus Company, Inc. PO Box 220 3234 Route 549 Mansfield, PA 16933 Tel: 800-626-8787, email: info@murus.com Web: http://www.murus.com/

- Owens Corning provides panel and other products for foundations, walls, and roofs, focused on either sloped metal roof decks or flat/low-slope roofs using a variety of systems over concrete or metal roof decks; Contact: https://www.owenscorning.com/insulation/commercial/enclosure/applications/roof

Illustrated here: a Ray-Core Insulated SIP used for roof or wall construction - cited below.

Illustrated here: a Ray-Core Insulated SIP used for roof or wall construction - cited below.

- RayCore SIP Roof Panels and Wall Panels, RAY-CORE SIPs ™

305 E. Elva Street

Idaho Falls, ID 83401 USA Tel: 1.877.552.2440 Email:

info@raycore.com Website: https://raycore.com/

RayCore's 4 ft. wide SIPs are produced in standard wood framing dimension thicknesses: 2x4 (3 ½”) – R26, 2x6 (5 ½”) – R42, 2x8 (7 ¼”) – R52 and in lengths Precuts: 92 5/8, 104 5/8 inches or Full: 8, 10, 12 feet

Website excerpt:

RAYCORE's Structural Insulated Roof Panels and Insulated Wall Panels (SIPs) are NOT A SANDWICH PANEL SIP that consists of two sheets of OSB, glued to a solid foam core. RAY-CORE SIPs ™ are far superior - eliminating all the problems associated with traditional Sandwich Panel SIPs.

RAYCORE takes the proven structural reliability of studs, adds a state-of-the-art custom blend of closed cell polyurethane foam insulation and wraps the panel with a foil radiant barrier to combine these three technologies into one strong, lightweight, structurally sound, labor saving and easy to use insulated SIP roof panel, insulated wall panel and insulated header framing panel system.

- R-Tight Stress Skin Panels, PO Box 700 Jeffersonville, VT 05464-0700, Tel: 802-644-2500, email info@rtight.com Web: http://www.rtight.com/

- RayCore SIP Roof Panels and Wall Panels (shown just below), RAY-CORE SIPs ™

305 E. Elva Street

Idaho Falls, ID 83401 USA Tel: 1.877.552.2440 Email:

info@raycore.com Website: https://raycore.com/

Raycore describes their product line as DIY or "Do-It-Yourself-Friendly SIPs Panels". The company provides wood-frame supported foil faced polyurethane foam panels like the image shown above. See this

RAY-CORE DIY USER's INSTALLATION GUIDE for SIPS [PDF] retrieved 2019/11/09 original source: https://raycore.com/media/1991/raycore-sips-installation-guide.pdf - Vermont Timber Works, 36 Fairbanks Road N. Springfield, VT 05150 (802) 886-1917 Web: http://www.rtight.com/ http://www.vermonttimberworks.com/

- SIPA, Structural Insulated Panel Association, P.O. Box 39848,

Fort Lauderdale, FL 33339 USA, Tel:

(253) 858-7472

Email info@sips.org

Website excerpt:

The Structural Insulated Panel Association (SIPA) is a non-profit trade association representing manufacturers, suppliers, dealer/distributors, design professionals, and builders committed to providing quality structural insulated panels for all segments of the construction industry.

SIPA has been in existence since 1990 and has made tremendous progress in advancing energy-efficient construction with structural insulated panels.

Mission: SIPA will provide an industry forum to increase the acceptance and use of SIPs. - SIPA, BUILDING WITH SIPS - NEED TO KNOW [PDF] Op. Cit. retrieved 2020/06/18. Printed copies of this document are available from SIPA's Store at: https://www.sips.org/products

- SIPA, DESIGNING WITH SIPS - CONSIDERATIONS [PDF] Op. Cit.

- Simon, Keith, Michelle Weinfeld, Thomas Moore, Kent Robinson, "Structural Insulated Panels (SIPs)", Whole Building Design Guide (WBDG), program of the National Institute of Building Sciences (NIBS), 1090 Vermont Avenue NW,

Suite 700,

Washington, DC 20005

wbdg@nibs.org retrieved 2019/11/09 original source: https://www.wbdg.org/resources/structural-insulated-panels-sips

We recommend this article for a thoughtful overview of SIPs

Introduction: Today's architects are faced with the urgent task of achieving energy-efficient and high-performance building enclosures. Structural Insulated Panels are an option for part of the enclosure assembly that can help achieve these goals. SIPs do an impressive job of slowing down the transfer of heat, air, and vapor through the assembly.

They also dramatically reduce the drying potential of the enclosure, lessening its ability to recover from inadvertent water intrusion. Such an airtight assembly with great thermal resistance can result in a high-performance and durable enclosure if detailed and built correctly, or it can result in the rapid rot and decay of a building's primary structure if detailed or built incorrectly. - SIPA, Structural Insulated Panel Association, P.O. Box 39848, Fort Lauderdale, FL 33339 USA, Tel: (253) 858-7472 Email: info@sips.org Website: sips.org

SIPA offers both free and for-sale technical publications about the industry and about using Structural Insulated Panels, two of which are given below.

Website Excerpt:

Structural insulated panels (SIPs) are a high performance building system for residential and light commercial construction.

The panels consist of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB). SIPs are manufactured under factory controlled conditions and can be fabricated to fit nearly any building design.

The result is a building system that is extremely strong, energy efficient and cost effective. Building with SIPs will save you time, money and labor. - SIPA, SIP ENGINEERING DESIGN GUIDE [PDF] (2019), DRAFT, retrieved 2019/11/09, original source: sips.org

Excerpts:

The SIP Engineering Design Guide has three sections – Design Specification, Commentary and Design Examples. The Structural Insulated Panel Design Specification (SIP-EDG01-19S) is intended to be used in conjunction with competent engineering design, accurate fabrication, and adequate supervision of construction.

The Guide allows design professionals to access the innovative strength, span, and loading characteristics inherent to SIPs while taking advantage of the system’s simple and fast installation in even complicated, multistory light commercial structures.

SIPA, SIP SCIENCE & ENGINEERING BROCHURE [PDF] , retrieved 2019/11/09, original source: sips.org - This document describes what SIPs are and gives whole wall R-value comparisons. - Thermocore SIPs, 1801 Hancel Parkway, Mooresville, Indiana 46158

USA Tel: (317) 831-8888 / 877-550-08973 Website: https://www.thermocore.com/ SIPs using polyurethane foam (R 6.9/Inch) and an OSB skin. The company's polyurethane foam includes a fire-retardant additive. The OSB is bonded to the polyurethane foam core mechanically, chemically, and with adhesive.

THERMOCORE SIP INSTALLATION MANUAL [PDF] retrieved 2019/11/09 original source: thermocore.com/resources/sips-technical-library - Urban Industries, STRUCTURAL INSULATED PANEL INSTALLATION GUIDELINES [PDF] Urban Industries, Inc., P.O. Box 27 Galion, Ohio 44833 419-468-3578 USA, Web: www.urbanindustries.com, retrieved 2022/09/02, original source: http://urbanindustries.com/files/Urban_SIP_Installation.pdf

Excerpt re:

Electrical wiring in SIPs

Electrical In the wall panels, horizontal chases are included at the 16” level (for outlets) and at the 44” level (for switches and counter height outlets). Vertical chases, which are located at 4’ O.C., allow wire to run vertically through the wall panels to access switch locations and at other locations as needed to provide vertical wiring options for the electrician.

The SIP manufacturer typically installs wire chases per this standard, but wire chases can be installed to exactly match an electrical plan. If required, custom wire chase placement should be specified when panel layout drawings are made.

A little forethought toward the design of the electrical system can save a lot of time and aggravation. Generally all, or most all, wiring can be accomplished after panel installation, provided that access to the electrical chase is established during installation.

It is recommended that an electrician be on site during the panel installation to ensure that there is adequate access for the required wiring. - U.S. DOE, STRUCTURAL Insulated Panels (SIPs) [PDF] (2021), U.S. Department of Energy, retrieved 2022/09/02, original source: https://basc.pnnl.gov/resource-guides/structural-insulated-panels-sips

Excerpt:

SIPs consist of two layers of plywood or OSB that “sandwich” an inner core of insulating rigid foam. SIPwalls meet or exceed typical dimensional lumber construction structural properties.

Because less framing is needed with SIP panels, there is also less thermal bridging than in a stick-built wall.

Studies have found that framing comprises 25% of a stick-built wall and 14% of an advanced framed wall but only 8.7% of a SIPwall.

SIP panel walls are less susceptible to air leakage and convection and resultant potential condensationproblems than stick-built walls

An Alternative to SIPs: Composite Insulating Concrete (walls only)

Bautex proposes their Composite Insulating Concrete Form (ICF) alternative concrete-column & block-wall building system illustrated here.

Bautex proposes their Composite Insulating Concrete Form (ICF) alternative concrete-column & block-wall building system illustrated here.

Bautex,

5602 Central Texas Drive

San Marcos, TX 78666

USA Tel: (855) 922-8839

Tel: (512) 637-1200 Email: info@bautexsystems.com Website: https://www.bautexsystems.com/

Bautex, 8 DISADVANTAGES of STRUCTURAL INSULATED PANELS SIPs Bautex cites the following concerns that affect some SIP products.

Fire safety: Some SIPs made using plywood, OSB and composite structural siding panels may lack adequate fire-performance ratings

Moisture, mold, rot risks [Opinion:and repair can be difficult -

see STRESS SKIN INSULATED PANEL REPAIR - Ed.]

Insect attack into the foam [Opinion:this is not a problem unique to SIPS - Ed.

Durability - [Opinion: this inflates the defect count as it's same as moisture, mold, rot - Ed.]

Lack of Thermal Mass - [Opinion: high R-values are ultimately more energy efficient than reliance on thermal mass for comfort - Ed.]

Hard to modify - [Opinion: yeah but ... some SIP manufacturers will produce panels to whatever dimensions you require Ed. ]

Structural limitations - [Opinion: imposed by having to work with the dimensions of the panels, limits placed on building shape / complexity - possibly redundant gripe with "hard to modify above - Ed.

Roofs? Bautex block wall system is, as the company acknowledges, not usable for building roofs where SIPs or other construction systems have a role - Ed.

Original article

The link to the original Q&A article in PDF form immediately below is preceded by an expanded/updated online version of this article.

- Stress Skin Panel Construction PART 1 - PDF version, use your browser's back button to return to this page. Original article, Solar Age Magazine, September, 1986, adapted and updated for InspectAPedia.com XXX 2010.

- Stress Skin Panel - PDF form, PART 2, use your browser's back button to return to this page.

- Stress Skin Panel - PDF form, PART 3, use your browser's back button to return to this page.

- Stress Skin Panel - PDF form, PART 4, use your browser's back button to return to this page.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: how is foam inserted into the stress skin box to fill it completely?

I understand that urethane foams are made from a two part process.

How are they inserted into a stress skin "box" to get to all areas of the box? - wallspalomar@aol.com 2/27/12

Reply:

Walls: there are other approaches, but most often the plastic foam insulation core is laminated to the sheets of the panel with a contact adhesive or a pressure-set adhesive. Using that approach there are no air voids.

On 2019-05-31 by Roger Kimmel - SIP is leaking in freezing weather

Leaking during freezing season

On 2019-05-31 by (mod) -

Troubling of course,

but we need to find exactly where the leak is occurring.

The leak may have nothing to do with the fact that it's a stress skin panel construction, it could be an ice dam or a roof flashing defect for example.

On 2017-03-14 by Heidi - SIPs for energy efficiency

i was told for energy efficiency it must be done

On 2017-03-14 by (mod) -

Heidi

Construction is packed with people who have vehement opinions, state them as fact, and haven't read the instructions on the box. We're in a political climate that disregards facts, science, engineering - at our own peril.That's why I suggested that an authoritative answer to the question of using sealant at Stress-Skin-Panel joints would come from the manufacturer of your specific panels.

The reasonableness of what you were told as "must be done" is that air leaks would be bad. But if the panel design is relying on splines or gaskets, sealant may be totally besides the point. Let's find out what the authority says.

On 2017-03-14 by Heidi - caulk inside home between beams & stress skin panels

do you have to caulk inside home between beams & stress skin panels in a post & beam home?

On 2017-03-14 by (mod) -

Heidi,

I don't know of any benefit of nor reason to caulk between supporting beams and stress-skin panels passing over them in this type of construction.

Butt-joints between stress skin panels or between a panel and a beam if a panel were in-set, do need to be protected against air leaks; usually that is done with a spline but at a panel to beam abutment the manufacturer may specify use of a sealant.

That's a general opinion and is about as specific as I can get without a specific product in mind.

...

Continue reading at STRESS SKIN INSULATED PANEL REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- STRESS SKIN STRUCTURAL INSULATED PANELS, SIPs history, current use practices

- STRESS SKIN INSULATED PANEL REPAIR

Suggested citation for this web page

STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs) at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ENERGY SAVINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Solar Age Magazine was the official publication of the American Solar Energy Society. The contemporary solar energy magazine associated with the Society is Solar Today. "Established in 1954, the nonprofit American Solar Energy Society (ASES) is the nation's leading association of solar professionals & advocates. Our mission is to inspire an era of energy innovation and speed the transition to a sustainable energy economy. We advance education, research and policy. Leading for more than 50 years. ASES leads national efforts to increase the use of solar energy, energy efficiency and other sustainable technologies in the U.S. We publish the award-winning SOLAR TODAY magazine, organize and present the ASES National Solar Conference and lead the ASES National Solar Tour – the largest grassroots solar event in the world."

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - CSI Section 06 12 16: Stressed Skin Panels

- Stressed Skin Panel Performance After Twenty-Five Years of Service, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison WI, web search 01/22/2011, original source: http://www.fpl.fs.fed.us/documnts/fplrp/fplrp18.pdf

- Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.