Best Practices Guide to Selecting & Installing, Doors, Windows & Skylights

Best Practices Guide to Selecting & Installing, Doors, Windows & Skylights

- POST a QUESTION or COMMENT about choosing, installing, & maintaining or repairing windows & doors - best practices guide

Best construction practices guide to windows & doors:

In this article series we discuss the selection and installation of windows and doors, following best construction and design practices for building lighting and ventilation, with attention to the impact on building heating and cooling costs, indoor air quality, and comfort of occupants.

We review the proper installation details for windows and doors, and we compare the durability of different window and door materials and types.

Discussed: Window materials & construction. Wood, vinyl-clad, solid vinyl, fiberglass, aluminum composit window & door properties. Window certifications & standards. Hurricane, wind & storm resistant windows & doors. Window efficiency features & energy ratings. Window shading, solar gain control. Window flashing & sealing guide. How to install flange-type windows.Skylights: choosing, installing, design issues, energy efficiency. Doors, Exterior Flashing Details. Window & door manufacturers list: where to buy windows & doors, flashings, skylights.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Best Practices Guide to Selecting, Inspecting, Diagnosing, Repairing Skylights, Windows & Doors

This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

Window Types, Guide

Details are at WINDOW TYPES, GUIDE. Excerpts are below.

Windows have a bigger impact on the quality of life in a home than almost any other building component. They affect heating and cooling costs, natural lighting levels, ventilation quality, and the comfort of occupants year-round.

[Click to enlarge any image or table]

Subjected to high ultraviolet (UV) exposure, extremes of weather, and hundreds of operations over their service lives, windows must be well-engineered from durable materials if they are to provide satisfactory service.

It is well worth investing the time and money to select the right windows for the job and to install them properly.

The most common types of operable windows are double-hung, casement, and sliding.

Awning-style windows are commonly used either near grade to let light into basements or high on a wall for privacy.

Tilt-turn windows, European imports that swing inward like a door on hinges, are often used in large sizes as emergency exits.

Windows with compression-type seals are the tightest, and windows that swing open provide the best ventilation (see Figure 3-1 above-left).

Common window types and their characteristics are summarized in Table 3-1 below. [Click any table or illustration for an enlarged, detailed version.]

Single- and Double-Hung Windows

The most common windows in the United States, doublehungs have upper and lower sash offset so both can slide up and down. Only the lower sash moves in the less common single-hung window. In older homes, the operable sash were connected by rope to heavy iron counterweights to hold the upper sash in place and to assist with raising the lower sash.

Modern double-hung windows ride up and down in metal or plastic tracks called jamb liners and use hidden springs in place of sash weights.

On many of the newer models, the sash are designed to tilt in for easy cleaning.

Because the top sash overhangs the bottom, and both are recessed in the frame, double-hung windows shed rain well and can be left open at the bottom in a light rain. They use exterior screens that are out of the way and inconspicuous. However, ventilation is limited to half the area of the frame, and visibility is somewhat hampered by the meeting rails, which often sit near eye level.

Also, because they rely on slide-by rather than compression-type weather-seals, many double-hungs have air leakage rates nearly twice that of casements. With improvements in materials and designs in high quality units, however, the performance gap has narrowed, at least when the windows are tested (with brand-new weather seals).

Although probably not the tightest windows in a high wind location, in general, double-hungs offer a versatile, moderately priced, and trouble-free option.

Sliding Windows: design features

Sliders can offer large horizontal expanses of glass and operable

sash that do not interfere with interior or exterior

space. They are more common in western states, while

double-hungs and casements prevail on the East Coast.

Sliders can offer large horizontal expanses of glass and operable

sash that do not interfere with interior or exterior

space. They are more common in western states, while

double-hungs and casements prevail on the East Coast.

Our photo (left) shows sliding windows (photo-right) and casement windows (photo-left) in a cabin in Two Harbors, MN.(DF)

Designing a window that slides sideways presents a few challenges.

First, the lower track must rely on weep holes to drain away water, and second, any grit that collects in the lower track tends to impair the sliding action.

If the weeps clog up, water may find its way into the sill or framing over time. Also, pushing a stuck window sideways is an awkward motion that tends to strain the back.

Also see STORM WINDOW WEEP HOLES.

As with double-hung windows, ventilation is limited to 50% of the framed opening, and slide-by weather-seals are less effective than compression seals.

To avoid problems with sliders, look for high-quality windows that slide freely. Also, consider alternatives such as a picture window with a casement along one side for ventilation.

Casement Windows - Natural Building Ventilators

Casement windows provide a more contemporary look than traditional

double-hungs and can provide large uninterrupted views.

If oriented to open into the prevailing winds, the sash acts

like a big wind scoop, directing breezes into the house.

Casement windows provide a more contemporary look than traditional

double-hungs and can provide large uninterrupted views.

If oriented to open into the prevailing winds, the sash acts

like a big wind scoop, directing breezes into the house.

And when closed, the compression seals create a tight fit that only gets tighter with oncoming winds.

Casement windows are not without problems, however. The outward swinging sash is vulnerable to water damage if the top is not fully clad, and the sash can clash with screen doors or encroach on deck spaces.

Or worse. Our casement window photo at left (DF) shows spectacularly poor planning: these windows cannot open more than a few inches without jamming against the soffit overhang!

Also, hardware problems such as stripped crank handles or broken linkages are not uncommon, particularly on lower-end units or large units with heavy sash. An occasional squirt of lubricant on the crank mechanism and hinges can go a long way toward preventing problems.

Large, heavy sash can also rack slightly out of square over time, requiring a push from the outside to fully close. Sometimes this can be fixed by tweaking the hardware, but a new sash may be required.

For best results with casement windows, choose units with sturdy sash construction, heavy-duty hardware, and sash that are protected on top from the elements.

Awning Windows and Hopper Windows: design features

Awning windows swing outward from top hinges, and hopper windows swing inward from bottom hinges. Awning windows s are useful for privacy windows and other high-up locations like clerestories, while hoppers are often used in basements.

A principal advantage of awning windows is that they can be left open for ventilation with less risk of water entry should a rain shower occur. Our photo (left) shows a modern awning-style window in a newly-renovated building in Buenos Aires, Argentina (-DF).

Both awnings and hoppers can be combined with fixed glazing to add ventilation below a picture window.

Because they rely on cranking mechanisms, these windows have some of the same problems as casements.

But without the heavy vertical sash, they are less prone to malfunction.

For hard-to-reach locations, a pole, pull-chain, or motorized operators can be used to open and close awning or hopper style windows.

Tilt-Turn Windows & Emergency Exit or Egress Windows for Basements

Developed in Europe, tilt turn windows rely on intricate

hardware controlled by a single lever that allows the windows

to either swing in like a door or tilt in at the top like

a hopper.

Developed in Europe, tilt turn windows rely on intricate

hardware controlled by a single lever that allows the windows

to either swing in like a door or tilt in at the top like

a hopper.

In tilt mode, the sash are open only a few inches, allowing the windows to provide ventilation in a locked house (see Figure 3-2 at left).

When closed, the lever locks the window tightly in four to six locations, providing the tightest fitting windows available as well as excellent security against would-be thieves.

And with their easy-to-operate in-swinging mode, large-sized tilt-turn windows often do double duty as emergency exits.

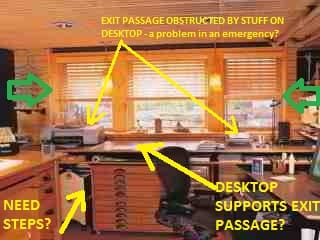

Our photo at left illustrates a hinged casement type window in use as an emergency exit for a building's basement. Inside the builder provided steps to provide access to this window from the basement floor level.

at SALVAGE BUILDING CONTENTS we described using this window and its exit path to toss cut up segments of soaked carpet and carpet padding outdoors without having to drag these messy items through the home following a basement flood.

While tilt-turn windows offer several useful features, they are not commonly seen in the United States, perhaps because of the in-swinging sash and relatively high cost. Also, they do not typically come with screens, making them problematic in areas with summer pests.

While not heavily marketed in the United States, they can be found here in wood, aluminum, aluminum-clad, and solid vinyl frames, the least expensive option.

Escape Windows: Specifications for Emergency Exit Windows

Special egress windows are generally required for basements in which there is only a single access stairway. An enlarged, accessible window may be required to allow use of a basement room as a bedroom.

Special egress windows are generally required for basements in which there is only a single access stairway. An enlarged, accessible window may be required to allow use of a basement room as a bedroom.

Reader Chelan offered these comments

Is there somewhere to mention that windows in living areas, especially bedrooms, must comply with relevant Life Safety Code as to location and sizing for "second means of escape"?

I just inspected a garage being converted to a two-bedroom dwelling that had no windows meeting NFPA 101(2009):24.2.2.3.3, i.e., not large enough and too high from the floor.

Escape windows cannot be less than 20 inches wide, 24 inches high, clear opening of 5.7 square feet, nor more than 44 inches from the floor to the sill. They must also be operable from the inside without use of tools, keys or special effort. - Chelan 9/12/2014

Thanks for the suggestion, Chelan.

Please see details about emergency egress / rescue windows found now a

Guide to Window Materials and Construction

Details are at WINDOW MATERIALS & CONSTRUCTION. Excerpts are below.

For centuries, even before glass was used for glazing, windows were framed with wood set into building walls. Our photo (left) shows an antique wood-framed window in Rugat, Spain (DF).

Earliest wood framed windows were left open (such as this example from Xotolar, Mexico). Later in areas of more hostile climate windows were glazed with animal skins, then parchment, and finally, glass.

For many years, the material choices for "modern" or new residential windows were limited to wood, clad wood, and aluminum. Wood and clad wood remain the leading materials, accounting for almost 50% of the new and replacement window market. Wood use has been declining, however, with the rapid growth of solid vinyl windows.

Solid vinyl windows made inroads into the replacement window market in the mid-1980s; but they were not widely accepted in new homes until the 1990s, when their use skyrocketed. Solid vinyl windows now account for an estimated 30% of the new-home market and 60% of the replacement market.

Aluminum windows account for about 15% of window sales, with the remaining share of the market spread among fiberglass windows and a variety of hybrids and composites that have entered the fray, making window selection today anything but simple.

Wood and Clad-Wood Windows

Wood is the traditional material of choice for residential windows. It can be milled into highly detailed designs, such as true divided lites, and easily fashioned into just about any custom configuration.

In addition to its aesthetic appeal, wood has excellent insulation value, and if well maintained can last indefinitely. Our photo (left) of a wood-built casement window set into this stone wall in Barcelona, Spain, shows a window that is more than 100 years old.

On the downside, wood must be stained or painted and well-maintained or, over time, it will be vulnerable to peeling paint and decay. Windows with wood exposed directly to the weather, such as open casements, are particularly vulnerable.

Although wood is dimensionally stable with temperature changes, it does swell and shrink with changes in relative humidity, causing tight-fitting windows to stick in humid summer weather.

When selecting a wood window, look for materials that are factory-treated with a water-repellant preservative, which will help prevent decay and also improve paint retention and dimensional stability.

The vast majority of

wood windows made today have a vinyl- or aluminumclad

exterior. A clad exterior is the most practical choice,

providing a maintenance-free exterior with the look of a

wood window on the interior. The only downside is a limited

color choice.

Construction Details for Wood Windows

Some very high-end wood windows are manufactured from rot-resistant species, such as mahogany, but most use clear pine for the sash and visible portions of the frame. The hidden portions of most wood windows use some combination of solid wood, finger jointed lumber, and various types of engineered lumber, including laminated-strand lumber (similar to oriented strand board, or OSB).

Watch out: Leaks into wood window or door components can cause severe rot even on newer products, as our photo (left) illustrates.

And where finger-jointed wood is used for window or other wood parts exposed to the weather, if the wood is not kept painted and sealed, we find that finger joints may swell, separate, and invite rot or insect damage - DF.

Composite windows are beginning to be used as well, such as Fibrex, a proprietary wood-vinyl composite used in the subsills of some of Andersen’s replacement windows and patio doors.

In general, wood windows are sufficiently strong and rigid for most residential applications. However, it is always best to use windows approved by one of the three agencies that certify windows and doors (see Window Certification).

In coastal areas or other areas prone to high winds or hurricanes, look for products with a suitable pressure rating from the American Architectural Manufacturers Association (AAMA) or the Window and Door Manufacturer’s Association (WDMA).

Vinyl Cladding on Wood Windows

While vinyl cladding is only offered by a few manufacturers, one of them is Andersen Windows, by far the largest supplier of residential windows in the United States. Andersen’s clad windows’ strong record of durability, reliability, and moderate cost has helped make vinyl-clad windows one the most popular options today.

Good quality vinyl-clad windows have a heavy-gauge covering, and heat-welded corners to provide a durable seal against water entry. Vinyl cladding is also more energy efficient than aluminum and is preferred by some in coastal environments subject to salt spray.

Watch out: on some older versions of vinyl clad windows that leave wood exposed (typically at the ends of sills projecting outdoors) or where vinyl cladding over wood has been damaged, broken, or cracked, we often find rot as well.

On the downside, vinyl comes in only a few colors, typically white and beige, and cannot be painted.

Some manufacturers, such as Andersen, now offer a limited number of dark tones as well, using newer technologies that resist the fading and heat problems characteristic of dark colored vinyl.

Vinyl is also vulnerable to cracking in cold weather if struck by an errant baseball or hammer.

While all manufacturers cover the exterior frame and exterior face of the sash, some also protect the top of the sash, which is important in casement windows.

Andersen wraps the entire sash inside and out, providing excellent protection (see Figure 3-3 at left).

But for those seeking the look of wood on the interior of the sash, consider windows with exterior-only cladding, such as those from Weathershield and MW Manufacturing.

Aluminum Cladding on Wood Windows

A number of manufacturers offer aluminum cladding, using either relatively thin roll formed aluminum or heavier-gauge extruded aluminum. The advantage of extruded aluminum is that it adds strength and rigidity to the window and resists denting better than thinner stock.

Also, aluminum can be formed to crisper profiles than vinyl, creating a less bulky appearance. Other advantages of aluminum include a wider choice of colors and the ability to be painted if desired. One downside to aluminum cladding is a slight reduction in energy-efficiency compared to vinyl-clad windows. On average, a vinyl-clad unit has an R-value about 10% higher than for a comparable aluminum-clad window.

Properties of Fiberglass Clad Windows

A few manufacturers, including Marvin and Milgard, offer wood windows clad on the exterior with a tough fiberglass composite manufactured in a process called pultrusion (see Fiberglass Clad Windows).

Pultruded fiberglass is an ideal cladding material due to its durability, energy efficiency, and very low rate of thermal expansion. Unaffected by heat, cold, and moisture, manufacturers claim that pultruded fiberglass will never crack, peel, or warp. Fiberglass-clad windows come prepainted with a factory finish and can be repainted on site if desired.

Windows, Vinyl Guide

Details are at Windows, Vinyl Guide. Excerpts are below.

Solid vinyl windows can attribute their surge in popularity over the past decade to the fact that they have delivered a high-quality, maintenance-free product for about a third less cost than a clad window of comparable quality.

Contractors like the fact that the interior window sashes do not need painting, and homeowners like the notion that the frame and sill cannot rot (although vinyl windows do not live forever).

Solid vinyl windows have shed their image as cheap plastic replacement windows by continually improving to the point where premium quality vinyl windows are stronger and more dimensionally stable, more fade resistant, and better looking with crisper extrusions and better hardware (Figure 3-4).

As an added benefit, vinyl window manufacturers claim that their products can match the energy performance of wood windows.

While improvements in extrusions have made vinyl windows less bulky looking, they still do not have the crisp lines of a wood window, particularly on the interior, and vinyl window sash are unmistakably white plastic.

Still, vinyl windows have shed their stigma as a low-end product and are finding their way into more and more new homes across the spectrum from spec to upper-end custom.

Construction of Solid Vinyl Windows

Vinyl window quality starts with the chemistry.

\A number of additives are blended into the raw vinyl to make it more dimensionally stable and more resistant to UV radiation, which otherwise can cause the vinyl to fade, chalk, and become brittle over time.

The vinyl is then extruded into long sections with multiple internal chambers that give the material its rigidity and insulation value from the trapped air (see Figure 3-5 at left).

The thin-walled plastic ranges in thickness from about .065 to .085 inch. All other things being equal, the thicker the plastic, the stronger the window component. However, extrusions can gain strength from having a well-engineered profile, as well (many European windows use much heavier .125-inch plastic, but U.S. manufacturers feel this would make them less competitive).

The extrusions are then cut and joined to create frames and sash. Nowadays, most corners are heat-welded, producing the strongest joints, although some corners are still mechanically fastened.

Some manufacturers add steel or aluminum reinforcing, particularly to larger windows, to stiffen them and help them meet structural load requirements. Typical places for reinforcing are sills, which have a tendency to sag in hot weather, lock rails, and mullions between mulled units.

Vinyl Window Options

All vinyl windows have an integral nailing flange, simplifying watertight installations (see Window Flashing & Sealing Guide).

All standard window types, including tilt-turn, are available in solid vinyl today. All glazing types, except for true divided lites, are also available. For the look of divided lites, the options are either snap-in grilles or between-the-glass grills.

Typical exterior trims include brickmold or nominal 4-inch flat casings with either an integral or snap-on J-channel to receive the ends of wood, vinyl, or fiber cement siding.

Window trims designed for stucco are widely available in the western states and Florida. Colors are generally limited to white and beige, since dark colors absorb heat and raise vinyl temperatures to near 165°F, where it begins to soften and sag. On the interior, most vinyl windows will accept either wood extension jambs or drywall returns.

Quality Issues with Vinyl Windows

As with any building products, not all vinyl windows are created equal. Many early models were poorly made and subject to excessive thermal movement, often opening at corners, fading prematurely, and losing structural integrity from UV exposure, particularly in hot climates.

Most window manufacturers today have overcome these problems with better vinyl formulations, improved extrusion design, and heat welding at corners. Many also use metal reinforcing at strategic points, such as meeting rails, sills of large units, and between mulled units.

Since the chemistry, extrusion design, metal reinforcing, and other determinants of quality are hidden from view, however, the best approach is to stick with an established manufacturer and to look for a certification label from the American Architectural Manufacturers Association (AAMA).

AAMA established a separate standard for vinyl windows in 1997, which includes tests for strength, dimensional stability, strength of corner welds, heat and impact resistance, and weathering. The main features to look for include:

- Heat-welded corners

- Metal reinforcing, particularly on larger units

- Solid, heavy extrusions with little obvious flex

- Good quality hardware

Installation Procedure for Vinyl Windows

Details are at Installation Procedure for Vinyl Windows Excerpts are below.

High Rate of Thermal Expansion in Vinyl Windows

In general, vinyl windows install the same as other flange-type windows, although the installer must take into account vinyl’s high rate of thermal expansion.

A 6-foot-wide window can expand as much as 5/16 inch from 0°F to 100°F. To prevent problems, It is best to leave a 1/8 - to 1/4 -inch gap between the window and siding or wood trim (more in cold weather, less in hot). Good detailing of this joint is especially important with stucco, which can crack if set too tightly against the window or leak if the caulk joint fails.

Thermal expansion can also cause window sash to bind in hot weather if the rough opening is too small to accommodate the movement. And in very cold weather, some vinyl windows can bow inward due to temperature differences on either side of the window.

Sturdy extrusion profiles with metal reinforcing can help prevent this. A related concern is sagging of the sill during hot weather— vinyl starts to soften and distort at about 165°F, a temperature easily reached on the surface of a dark building in direct sun. To prevent sagging, some manufacturers reinforce the sill, and all recommend specific shim spacing under the sill.

Some vinyl window installations require continuous support along the length of the sill, which is easiest to achieve by using a double 2x sill with leveling shims in between.

Vinyl Window Nailing Recommendations

Nailing recommendations for vinyl windows also vary among manufacturers. Some recommend driving nails tight; some suggest leaving the nail heads proud. Some recommend against nailing the head flange or corners; others require it. To avoid warranty problems, it is always best to closely follow the manufacturer’s instructions regarding the rough opening, shimming, nailing, and other installation details. Other general recommendations that apply to all windows include:

- In hot weather, do not store vinyl windows in a container, such as a trailer, or lean them against a wall, as they can permanently deform.

- Seal around openings with flexible flashing before installing the window (see Window Flashing & Sealing Guide).

- Set the nailing fin in a bead of high-quality caulking.

- Before nailing, make sure the side jambs are plumb and do not bow in or out in the center. Some installers use a wood spacer to hold the two side jambs parallel.

- Do not puncture the nailing fin when installing trim or siding.

- Do not use expanding foam to seal around the window frame on the interior.

Windows, Fiberglass, Guide

Introduced in the early 1990s, a few manufacturers now offer windows built entirely of a tough composite called pultruded fiberglass.

Unlike the layers of fiberglass cloth and resin used in boat and car construction, fiberglass window components are made from continuous glass fibers saturated with a thermoset resin and pulled through a heated die in a process called pultrusion. The result is a thin, strong composite that can be formed into detailed shapes and is used in a variety of high-tech applications.

Pultruded fiberglass is noted for its high strength, durability, and corrosion resistance. It is unaffected by temperatures up to 350°F and has an extremely low rate of thermal expansion—about the same as window glass.

Because the frame and glass move at the same rate, temperature changes place less stress on the window frame and glass edge seals. Manufacturers claim that pultruded fiberglass will not crack, peel, or warp and is impervious to moisture, insects, salt-air, and UV exposure (Figure 3-6 at left).

Depending on the manufacturer, fiberglass frame components are either hollow or filled with foam or fiberglass insulation. The insulated frames are the most energy efficient on the market.

Most fiberglass frames are shipped with a high-performance baked-on factory finish, and they can be repainted on-site if desired. Installation is the same as for vinyl and other flange-style windows but without concerns related to sagging or thermal movement.

Manufacturers currently offering fiberglass windows include Milgard Windows and several Canadian manufacturers, including Fibertec and Thermotech Windows.

Windows, Aluminum, Guide

While aluminum is strong, light, and durable, with an anodized or baked-on finish, it has been steadily losing market share since the early 1990s due to its poor energy performance. Fewer than 15% of windows sold today are aluminum, and these are mainly in lower-end housing in cooling-dominated climates.

The poor insulating qualities of aluminum have less of an impact on cooling than they do on heating since the indoor and outdoor temperature difference is generally much smaller in cooling climates. Adding a thermal break can improve the energy performance of an aluminum window, but it still lags considerably behind wood and vinyl components.

Window Certification

It is always best to choose windows with third-party certification from American Association for Window Manufacturers (AAMA) or the Window and Door Manufacturers Association (WDMA, formerly the National Wood Window and Door Association, NWWDA).

Both the AAMA and WDMA are trade associations representing manufacturers of windows, doors, and skylights. The WDMA is limited to wood windows and doors, while the AAMA encompasses a wide range of materials, from wood, aluminum, vinyl, and fiberglass to the newest composites.

Voluntary Standards for Window Manufacturers

In 1997, the two groups joined forces to establish a unified standard for evaluating fenestration products, known as AAMA/NWWDA 101/I.S. 2-97 “Voluntary Specification for Aluminum, Vinyl and Wood Windows and Glass Doors.” It establishes four performance requirements for a completed window or door.

- Structural ability to resist wind loads

- Resistance to air leakage

- Resistance to air infiltration

- Resistance to forced entry

Products that are certified under 101/I.S. 2-97 are designated by a four-part code that denotes the type of window, the performance class, and performance grade. For example, the code C-R15 indicates a casement window (C) recommended for residential applications (R), with a performance grade of 15.

Performance Grade and Design Pressure for Windows

How well a window performs when subjected to heavy rains and high winds is indicated by its performance grade and design pressure. The design pressure is a structural rating only, while the performance grade also indicates that a window has met the water resistance and air infiltration standards for that grade (see Table 3-2 below).

The minimum recommended design pressure for residential doors and windows is 15 psf. A design pressure of 15 means a window has been tested to withstand sustained wind pressures of 22.5 psf, roughly equivalent to a 95-mph wind, applied to either side of the window, simulating both positive and negative wind pressures.

The test pressure is always 150% of the rated design pressure to provide a safety factor. To earn a performance grade of 15, a window must also pass a water pressure test of 2.86 psf, which simulates rainfall of 8 inches per hour with a wind speed of 34 mph. In coastal areas or other areas prone to heavy winds or hurricanes, higher grade windows are recommended and may be required by code.

Also see WINDOW TYPES - Photo Guide.

Guide to Hurricane, Wind, & Storm-Resistant Windows

As detailed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

In response to the devastating impact of Hurricane Andrew in 1992, Florida enacted stringent codes to protect homes from severe storms. Other coastal states have followed suit in recent years, and now similar provisions in the International Residential Code (IRC) apply to coastal areas from Texas to Maine.

Protect the Window Openings

Researchers attributed much of Andrew’s destruction to wind penetration into homes through broken doors and windows, leading to extensive water damage and, in many cases, roofs blown off and houses destroyed.

Our photo (left) shows storm-exposed beach-front hotel windows at Boca Raton, FL.

The keys to preventing these problems were strengthening roofs and protecting windows and doors from wind and wind-borne debris. To protect windows, the new code allows three options:

- code-approved storm shutters,

- 9/16-inch plywood panels screwed over windows at 8 inches on-center, or

- impact-resistant windows.

The trend in new home construction is toward impact-resistant windows, sometimes marketed as “storm resistant” or “hurricane-rated.”

Miami-Dade County Standards for Storm-Resistant Windows

Miami-Dade County enacted the most stringent standard and test protocols, subjecting windows (and storm shutters) to a test in which a 9-pound 2x4 is hurled into the glass at 50 feet per second, followed by 4,500 cycles of positive and negative wind loads equivalent to a 146-mph wind.

Miami-Dade also conducts AAMA/NWWDA testing for design pressure and water intrusion, but it conducts the water intrusion test after the structural test is completed rather than on a new window. Windows and doors that pass the Miami-Dade Product Control Standards are required throughout Miami-Dade County and most other coastal areas in Florida.

International Residential Code for Impact-Resistant Windows

The International Residential Code (IRC) requires impact-resistant windows in all hurricane-prone regions along the Gulf and Atlantic coasts from Texas to Maine. Depending on the wind-speed zones established in the IRC, windows need to meet design pressures ranging from 30 to 80 psf, and they must meet impact-resistance standards under ASTM E1886 or E1996.

The design pressure required depends on both an area’s design wind speed, found on IRC maps, and the building’s exposure rating from A to D. Most buildings are rated Exposure B for “urban and suburban areas or wooded areas” or Exposure C for flat, open terrain with scattered obstructions of less than 30 feet. Waterfront buildings exposed to winds flowing over open water for at least a mile are rated Exposure D, the most severe.

Storm-Resistant Window Construction

Under pressure from both the building codes and insurance industry, most major window manufacturers have developed impact-resistant windows for residential applications that feature laminated glass along with heavier frames and hardware. The glass is similar to auto windshields with a plastic interlayer, but it is significantly heavier. Double-glazed units get a second layer of tempered glass either on the interior or exterior.

Vinyl-framed windows are heavily reinforced with aluminum, and all windows use metal mullion bars anchored to the framing between mulled units. Window-to framing attachment methods are also beefed up to comply with the new codes, and in some cases, metal clips are used to anchor the window to the frame.

Storm-resistant windows cost from two to four times as much as standard windows; but under pressure from code agencies and insurance companies, these windows will soon become standard fare in coastal construction and other storm-prone areas.

Performance Grade and Design Pressure for Windows

How well a window performs when subjected to heavy rains and high winds is indicated by its performance grade and design pressure. The design pressure is a structural rating only, while the performance grade also indicates that a window has met the water resistance and air infiltration standards for that grade (see Table 3-2 below).

The minimum recommended design pressure for residential doors and windows is 15 psf. A design pressure of 15 means a window has been tested to withstand sustained wind pressures of 22.5 psf, roughly equivalent to a 95-mph wind, applied to either side of the window, simulating both positive and negative wind pressures.

The test pressure is always 150% of the rated design pressure to provide a safety factor. To earn a performance grade of 15, a window must also pass a water pressure test of 2.86 psf, which simulates rainfall of 8 inches per hour with a wind speed of 34 mph. In coastal areas or other areas prone to heavy winds or hurricanes, higher grade windows are recommended and may be required by code.

Also see WINDOW TYPES - Photo Guide.

Guide to Window Efficiency Features & Ratings

According to Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

Windows have a large impact on a home’s energy consumption, accounting for up to 25% of a typical home’s heating bills in cold climates and up to 50% of cooling bills in hot climates, according to the Environmental Protection Agency’s (EPA) Energy Star program.

Even the best windows, with an R-value of 3 to 4, are thermal holes compared to today’s average R-19 wall. In addition to conductive heat losses, older windows add substantially to a home’s air leakage.

Beyond fuel bills, windows can also have a dramatic effect on occupant comfort. Sitting next to a leaky single glazed window in winter will make an occupant feel cold regardless of the thermostat setting, due to both cold drafts and to radiant heat losses from his or her body to the window surface.

Cold window surfaces also cause condensation, potentially leading to mold, peeling paint, and wood decay of window components.

(Also see CONDENSATION or SWEATING PIPES, TANKS

and DEW POINT TABLE - CONDENSATION POINT GUIDE

as well as HUMIDITY LEVEL TARGET.)

Energy Certification for Windows

Evaluating a window’s energy performance is a complex task that has been made a lot simpler by two programs developed in a collaborative effort between government and industry. The groups have developed standardized testing procedures and ratings, and provide simple recommendations based on climate zone.

The NFRC Label for Windows

The National Fenestration Rating Council (NFRC), with support from the U.S. Department of Energy, created test procedures and rating systems for the energy performance of windows, glazed doors, and skylights. Any window making energy claims without an NFRC label should be avoided.

For every window, the NFRC label rates the U-factor, Solar-Heat-Gain Coefficient (SHGC), and Visible Transmittance (VT). Air Leakage (AL) and Condensation Resistance (CR) are optional ratings. The ratings are explained briefly in Figure 3-7 and in more detail in the following sections. Ratings should appear on the window label when delivered but can also be found on the NFRC website at www.nfrc.org.

Whole Window Energy Ratings

It is important to note that NFRC ratings apply to the entire window, including the sash and the frame. NFRC uses a single standard size to simplify testing and to make it easier for consumers to make apples-to-apples comparisons between windows.

The actual energy performance of windows significantly larger or smaller than the standard test size will vary somewhat from the label since the relative effect of the glass edge and frame is greater on smaller windows.

Glass-Only Ratings on Window Energy

Where glass-only ratings are needed, for example, for passive solar design, these can usually be obtained from the window manufacturer or the manufacturer of the insulated glass unit (IGU) installed in the window or door.

Energy Star Label for Windows

Launched by the U.S. EPA to promote the use of energy-efficient appliances and equipment, the Energy Star label was added to doors, windows, and skylights in 1998. An Energy Star Label certifies that the window or skylight meets the U.S. Department of Energy’s (DOE) energy guidelines for the climate zones listed on the label (see Table 3-3 below).

For windows without the label, you can still use the Energy Star guidelines in Table 3-3 (above) as a selection guide. Remember that these guidelines are based on NFRC whole-window ratings, not just the glass. For cold-climate buildings designed to use passive-solar heating, look for a whole-window SHGC of .55 or above.

Window U-Factor

A window’s ability to conduct heat (not including solar effects) is usually given as a U-factor or U-value. The lower the U-value, the more insulation value a window provides. Low U-values have the biggest impact in heating dominated climates but help reduce cooling loads as well. For climates with substantial heating or cooling loads, choose a total window U-value of .35 or less. The U-value is the inverse of the more familiar R-value.

For example, standard double glazing has a center- of-glass U-value of about .5, which equals an R-value of 2 (1/0.5). Typical glazing U-values are shown in Table 3-4 (below). U-values for the entire window, however, must take into account the edge spacers, sash, and frame, as discussed below.

Gas Filled Window Glazings

Filling low-E coated glass with the inert gas argon or krypton will reduce heat loss through the glass by 10 to 15%. Krypton outperforms argon somewhat, but it is usually not enough to justify the higher cost.

Since argon fill is now available on most low-E windows for little or no cost, getting the boost in R-value is always a good idea. In addition to reducing heat loss, it increases the temperature of the inside surface of the window, improving comfort and reducing condensation.

Studies indicate that about 10% of the gas will leak out of a well-built sealed glass unit in about 20 years.

Also see SUNGAIN, FILMS, LOW-E GLASS.

(Also see CONDENSATION or SWEATING PIPES, TANKS

and DEW POINT TABLE - CONDENSATION POINT GUIDE

as well as HUMIDITY LEVEL TARGET.)

Sash and Frame Effects on Window Energy Ratings & U-Value

The U-value of the entire window, as reported on NFRC labels, includes the effects of the glass edge, sash, and frame.With high-R glass, standard edge and frame materials often lower than the overall R-value compared to the center-of-glass measure.

Aluminum sash and frames without thermal breaks are the worst, contributing to both thermal losses and condensation in cold climates.

Thermally broken metal frames are better but should still be avoided in cold climates.Wood and hollow vinyl or fiberglass components all have moderately good thermal properties. Insulated vinyl and fiberglass frames offer the best thermal performance (Table 3-5).

Warm-Edge Spacers Effect on Window Energy Ratings

Because of their high thermal conductivity, standard aluminum edge spacers lower the insulating value of insulated glass units (IGUs) and often cause condensation along the bottom of the window. The loss of insulation value is more pronounced in very high R-value windows and small windows where the window edge accounts for a larger proportion of the window area.

Starting in the mid-1980s, manufacturers have responded with a variety of innovative solutions that are now used in about half of all new IGUs.

Solutions include using less conductive metals with an improved shape (PPG’s Intercept Spacer) or switching to a plastic or synthetic rubber spacer with little or no metal content (TruSeal’s Swiggle Seal or EdgeTech’s Super Spacer). Warm-edge windows can raise the glass temperature at the perimeter of the window by 6°F to 8°F, significantly reducing the condensation potential.

The biggest risk in using a new edge technology is that the seal will fail prematurely, resulting in a fogged unit. To guard against this, it is best to stick with a technology that has proven itself in the marketplace and is backed by a good warranty and a reliable window manufacturer.

(Also see CONDENSATION or SWEATING PIPES, TANKS

and DEW POINT TABLE - CONDENSATION POINT GUIDE

as well as HUMIDITY LEVEL TARGET.)

What are Low Emissivity (Low-E) Coatings for Windows?

Low-emissivity, or “low-E,” coatings are microscopically thin metallic coatings applied to a glass surface, which reflect back radiant heat.

Different low-E coatings transmit different amounts of visible light, short-wave and longwave infrared, and ultraviolet radiation (Figure 3-8 at left).

The most common type, called “soft coat” low-E, is applied to one of the inner surfaces of sealed insulated glass units (Figure 3-9 at left).

Hard-coat, or “pyrolitic,” low-E, which has a slightly lower R-value, is used in high-solar-gain glass and can also be used on storm windows and other removable glass panels exposed to the air.

Low-E window glass coatings can also be applied to a clear polyester film, called Heat Mirror, which is suspended between two panes of sealed glass, yielding insulation values as high as R-5 with one layer of film or R-8 with two layers.

Also see SUNGAIN, FILMS, LOW-E GLASS.

Spectrally Selective Low-E Windows

The newest generation of low-E glazing, often referred to as “spectrally selective,” provides an ideal combination of high R-values, low heat gain, and high-visible-light transmittance.

Spectrally selective windows generally outperform all other window types in mixed and hot climates, but they reap the greatest benefit in homes with significant cooling loads.

Because of their high insulation value, spectrally selective windows even perform well in cold climates, particularly in homes with significant air-conditioning loads or large amounts of west facing glass (see Window Orientation).

One exception is a house designed to use passive solar gain in winter, which would perform better with high-solar-gain glass.

See SUNGAIN, FILMS, LOW-E GLASS.

Choosing Window Glazing Based on Climate

As detailed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

Due to its significantly lower U-value, low-E glass outperforms standard double glazing in all climates. However, which type of low-E glazing is optimal for a building depends on several factors, including the heating load, cooling load, and orientation of the glass. In general, the windows with the lowest U-values will yield the greatest savings in cold climates, while windows with the lowest solar heat gain will yield the greatest savings in hot climates.

Performance comparisons of different window types in different climates, based on computer modeling, are shown in Figure 3-10. Also see SUNGAIN, FILMS, LOW-E GLASS.

Some window manufacturers market different glazing types in different parts of the country and may be able to provide different glazing types by special order. General recommendations from the EPA’s Energy Star program are shown in Table 3-3 below.

- Window Glazing Recommendations for Cold climates. In climates dominated by heating

loads, select a window with a low U-value (high

R-value). Windows with high solar gain will slightly

favor winter performance and windows with low solar

gain will slightly favor summer performance, but

annual energy costs are determined primarily by the

U-value.

Two exceptions to this are passive solar homes, which should use high-solar-gain glass, and homes with a lot of west-facing glass, which should use low-solar-gain spectrally-selective

(Spectrally Selective Window Glazing) glass. - Window Glazing Recommendations for Mixed climates. Spectrally selective glass or low-E glass

(SUNGAIN, FILMS, LOW-E GLASS) with moderate solar gains are good choices in mixed climates.

The greater the cooling load, the more important a low solar-heat-gain factor will be. However, the differences in annual fuel bills between using high, low, or moderate solar-heat gain glass in these climates will usually be small. Other issues like overall U-value, UV light transmission, cost, and durability might be the more important factors in choosing a window.

- Window Glazing Recommendations for Hot climates. In climates dominated by cooling

loads, choose a glazing type with low solar-heat gain.

Spectrally selective coatings provide an ideal combination of high R-values, high visible-light transmission, and low solar-heat gain. UV radiation, which causes fading, is also cut significantly.

Spectrally selective glass is a big improvement over tinted glass, which blocks solar gains, but also obscures views and creates glare and reflections when viewed from outside.

Our photo of a warm-climate window (above, left) is in Rabat, Morocco, a climate that ranges from warm to hot (-DF).

Solar-Heat-Gain Coefficient Rating for Windows: SHGC

A window with an SHGC of .70 captures about 70% of the available solar energy falling on the window. Clear double glazing has an SHGC of about .75 versus .60 to .70 for standard low-E and about .40 for spectrally selective low- E. Which type of glazing is optimal for a given project depends on the climate, summer and winter fuels costs, and how glass is used in the house design.

- Low SHGC. Low-solar-gain glass blocks unwanted

solar gain and provides significant savings in both

peak and annual cooling loads in hot climates. For

example, switching from clear double glass to low-

SHGC glazing can reduce air-conditioning bills by

15 to 20% in a typical home in Phoenix or Miami (see Figure 3-10 above).

Spectrally selective glass , introduced in the 1990s, combines very low solar gains with high visible light transmittance and high R-values (up to R-4 with gas fill). While this yields the greatest savings in hot climates, it is also a good choice in any climate with significant cooling loads or large amounts of un shaded west-facing glass.

(see Spectrally Selective Window Glazing). - Moderate SHGC. In northern cities like Boston or Chicago or mixed climates with more-or-less equal heating and cooling costs, moderate-gain glass is a reasonable choice, balancing moderate solar gains in winter with moderate blocking of solar gains in summer.

- High SHGC. High solar-heat-gain glass is a good

choice in cold climate homes with enough south glass

to take advantage of passive solar gain, called “sun

tempering.” Savings on winter heating bills will be

partially offset by the increased cooling load in

summer, however.

To avoid overheating, south-facing glass should range from 4 to 7% of the total floor area (avoid sloped glass, which tends to overheat in summer and fall).With south glass in excess of 7% of floor area, thermal mass may be needed to prevent daytime overheating and to store heat for nighttime use. A designer with expertise in passive solar can help determine the right amounts of glass and thermal mass.

Visible Transmittance Ratings for Windows

People install windows primarily for daylighting and

views, so the higher the percentage of visible light

transmitted (VT), the better. Clear double-glazing has a

VT of about 80% (see Table 3-4, below). With hard-coat

low-E, that figure drops to 75%, and down to about 70%

with the new spectrally selective coatings

(Spectrally Selective Low-E Windows).

All low-E coatings reduce visible light transmittance to some extent and some may appear slightly tinted or more reflective under certain light conditions. The new spectrally selective glazings are fairly color-neutral, but they may appear slightly darker compared to clear glass.

In general, most people do not notice tinting until the VT of the glazing falls below about 60%. The visible light transmittance ratings listed on NFRC window labels can be confusing since they include the sash and frame, not just the glass.

The VT for the glass only should be available from the window or glazing manufacturer upon request. Beyond the numbers, it is always a good idea to examine a sample of the glass before purchasing. View the glass from both outdoors and indoors under different light conditions to check for tint and glare.

Also see SUNGAIN, FILMS, LOW-E GLASS.

Window Air Leakage

In older homes, leaky windows contributed significantly to heating loads (less to cooling loads), and the drafts made occupants feel cold despite the thermostat setting. While windows built today are, in general, much tighter, the effect of air leakage can still be significant on cold, windy days, particularly on windows with direct wind exposure.

Most windows today are built with a leakage rate of .30 cfm/sq ft of glass area or less, the minimum allowed under the AAMA/NWWDA standard. The best windows have leakage rates near .10 cfm/sq ft.

Windows with compression seals, such as casements and awnings, tend to be tighter than windows with sliding seals, such as double-hungs and sliders. Also slide-by weather-stripping is more prone to wear out over time and more likely to be breached by high winds that cause the window to flex.

With any weather-stripping system, look for long-lasting materials such as EPDM and silicone and heavy-duty construction that can withstand years of use and exposure to water, freezing and burning temperatures, and UV radiation.

Fading of Interior Carpets & Furnishings due to UV Light

Most interior materials, including fabrics, carpeting, paint, and artworks, fade from exposure to sunlight. Although the most potent effect is from ultraviolet (UV) radiation, research has shown that the shorter wavelengths of the visible light spectrum also cause fading.

To account for the relative effects of both UV and visible light on typical materials, researchers have developed an approach called “damage-weighted transmittance” (T-dw), which was recently standardized by the International Standards Association (ISO/CIE 89/3).

Typical T-dw numbers range from about 60% for clear

double glazing to about 30% for spectrally selective glazing

(see “UV Light Transmittance,” Table 3-4 above and

see Spectrally Selective Low-E Windows.

Lower ratings are available with triple glazing or tinted glass, primarily used in commercial construction. Low numbers for UV transmittance and T-dw indicate less fading potential, but some fading will still occur. The best approach with valuable rugs, artworks, and other light sensitive furnishings is to place them in areas with minimal exposure to windows or to use shades or draperies that substantially cut light transmission.

Also see SOLAR SHADES & SUNSCREENS.

Condensation Resistance Ratings for Windows: Window Condensation or "Sweating"

To rate a window’s resistance to condensation, NFRC recently developed a method that evaluates the window’s frame, glass, and glass edge at a standardized set of temperature and humidity conditions.

Based on the coldest part of the window assembly, it is assigned a rating from 1 to 100.

The higher the rating, the better the window is at resisting condensation, but the rating doesn’t predict condensation under specific conditions. The voluntary minimum for a “thermally improved window” under the AAMA/NWWDA standard is 35.

The best protection against condensation is low-E glass with gas fill, combined with warm-edge spacers and a nonmetallic window frame, such as wood, vinyl, fiberglass, or one of the newer composites. Table 3-6 (below) provides a general guide to when condensation is likely to form on different types of glazing. Without warm-edge spacers, condensation will occur at window edges first.

(Also see CONDENSATION or SWEATING PIPES, TANKS

and DEW POINT TABLE - CONDENSATION POINT GUIDE

as well as HUMIDITY LEVEL TARGET.)

Window Orientation - Which Way a Window Faces

Which way a window faces has a big impact on its contribution to comfort, heating and cooling loads, and daylighting.

- West-facing glass is the most problematic, because in

summer the afternoon sun shines directly on the glass,

causing glare and overheating the house already

warmed by increasing afternoon temperatures. Provide

shade with plantings or light-colored shades (exterior

shades are most effective). Overhangs do not help

much due to the low angle of the sun.

Also see SOLAR SHADES & SUNSCREENS. - South-facing glass (within 30 degrees of true south) gets direct sun exposure in the winter when it is desirable, at least in climates with significant winter heating loads. In summer, the sun is high on the south side, moderating the solar gain. Also, it is easier to block the high summer sun with appropriately sized overhangs or awnings. South-facing glass should not exceed 7% of the building floor area, unless thermal mass is used.

- East-facing glass provides desirable morning light and modest solar gains on cold winter mornings. Too much un shaded east glass, however, can cause overheating in summer.

- North-facing glass provides diffused light that is free of glare and solar gains, which is ideal for daylighting and is sought after by artists for its consistent color and intensity.

In most cases, one type of glazing can work on all sides of the house. In houses with large amounts of west glass, however, it makes sense to use tinted or spectrally selective glass at least on the west face to reject the summer sun. This will dramatically improve comfort and reduce both peak and annual cooling loads.

If the house is also designed to take advantage of passive solar heating, high-heat-gain windows are preferable on the south face. Mixing glazing types can get tricky, however, and should be handled by an experienced solar designer. One caution, also, is that the slightly different tints of the two glazing types might be objectionable to some clients.

Window Shading to Reduce Solar Gain

As described in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

Shading of glass with overhangs, plantings, or shades will reduce cooling loads and increase comfort in any climate with significant cooling loads.

Shading of windows will also reduce glare (Figure 3-19, below), fading of furnishings, and localized overheating in rooms with south- or west-facing glass. Window overhangs, plantings, or exterior shades that block the sun before it strikes the glass are the most effective approach since the heat never gets into the building. But light-colored interior shades can also substantially reduce heat gains.

Spectrally Selective Window Glazing

From a shading standpoint, using spectrally selective glass (SHGC below .40) is like having shades or blinds on standard low-E glass.

However, adding good shading to spectrally selective glass can reduce cooling costs by another 10 to 15%. This would make sense in very hot climates or on houses with large expanses of glass on the south or west side. In many cases, the shading adds no cost or serves other design needs. For example, a porch on the east or west side of a house provides effective shading as well as outdoor living space.

Plantings for Window Shading

Deciduous trees can provide very effective summer shade on the south side but, depending on the type of tree, may block 20% or more of the solar radiation in winter. Because trees follow the local seasons rather than the calendar, the shading tends to occur when needed most.

For example, leaves appear earlier in the spring and last longer in the fall in warmer climates, which need spring and fall shading. Trees also cool the area around them by their natural evaporative cooling—as water evaporates from the leaves.

Other options for shading south-facing windows include trellises with dense foliage or evergreen trees. Evergreens should be tall enough to block the summer sun but trimmed so their canopies allow the low winter sun to reach the windows.

On the east and west sides of the house, trees or large shrubs can provide very effective shading, since the problem times are morning and afternoon when the sun is low in the sky and easily blocked by a well-placed planting, either deciduous or coniferous. Fixed Overhangs.

These are commonly used on the south side of homes with clear glass or high-solar-gain glass. To be effective, the overhangs must be sized correctly to reject the high summer sun but allow in the low winter sun. In most temperate climates, a 1 1/2 - to 2-footwide overhang is adequate for average size windows. However, to provide full shading from March to September in hot climates may require a 3-foot or wider overhang.

One limitation of fixed overhangs is that the shading will be the same on March 21 and September 21, although the heating and cooling needs at these times may be very different. The following guidelines for shading south facing glass strike a balance between summer and winter performance:

- Cold climates: Above 6,000 heating-degree days (HDD), locate the shadow line at mid window, based on the June 21 noon–sun angle (see Figure 3-11 below). This will shade the window 50% in mid-summer and provide full sun penetration from late September to late March. If more shading is required in summer, locate the shadow line closer to the window sill.

- Moderate climates: In climates with less than 6,000 HDD and less than 2,600 cooling-degree days (CDD), locate the shadow line at the window sill based on the June 21 sun angle at noon. This will allow full sun exposure from late October to mid-February.

- Hot climates: Above 2,600 CDD, locate the shadow line at the window sill using the March 21 sun angle at noon. This will provide full shading from late March to late September and about one-third shading in mid-winter.

Guide to Window Awnings and Shutters

Old-fashioned awnings are very effective at blocking solar gain—up to 65% on south facing windows and up to 80% on east and west windows.

Light-colored awnings are more effective, since they will reflect more solar radiation.

To be most effective, the awning’s “drop” should cover 65 to 75% of an east or west window and 45 to 60% of a south-facing window (see Figure 3-12 at left).

Other low-tech, but very effective exterior options for windows that are difficult to shade include wooden shutters, bamboo shades, and rolling shutters.

- Light-colored interior shades can reduce heat gain by 15 to 20%, depending on the density and reflectivity of the material.

- Interior blinds typically reduce heat gain by 10 to 15%, depending on reflectivity.

- See SOLAR SHADES & SUNSCREENS for details.

Solar Screening for Windows

This dark plastic or fiberglass screening is mounted on the exterior of the window in a frame or retractable roller or, in some cases, applied directly to the glass. Depending on the weave, it can reduce a window’s solar heat gain by 40 to 70%. Solar screening reduces glare and fading, but it also reduces daylight and obscures views.

Solar screens are best used on difficult to shade areas, such as west-facing glass or skylights. Some are designed to also serve as insect screens.

See SOLAR SHADES & SUNSCREENS for details.

Interior Shades for Windows

Though not generally as effective as exterior shading, light-colored drapes, shades, or blinds can reduce solar gain by 10 to 50% (for typical curtains or blinds) to as high as 70% for an insulated, reflective shade that seals tightly around the window perimeter.

The performance of an interior shade depends on the reflectivity of its outer face, the density and R-value of the material, and whether it seals around the window. Between-the-glass pleated shades or mini blinds, available from Pella and some smaller manufacturers, are more effective in blocking solar gain than interior shades, because they block the heat before it enters the building interior.

Installation Guide to Window Flashing & Sealing

As discussed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

While modern flange-type window frames appear to simplify window installation, how best to integrate the nailing flanges with the sheathing wrap and siding has been a subject of debate, and recommendations vary among different window manufacturers, sheathing wrap manufacturers, and contractors.

The approaches shown below represent a broad consensus of leading manufacturers and experienced contractors, but other approaches that follow the same basic principles can also work. These are:

- Always lap higher flashings over lower to shed water.

- Do not rely on caulking as a waterproof barrier, as it is likely to fail over time. see CAULKS & SEALANTS, EXTERIOR

- With heavy exposure to wind-driven rain and snow, use pan flashing to protect the sill and use flashing tape to seal the head flashing to the sheathing.

- Leave horizontal joints unsealed at the top and bottom of the window frame to allow trapped water to escape.

Window Installation, Flange-Type

All clad and solid-vinyl windows come with an integral nailing flange or one that is friction-fit into a slot in the frame. In addition to simplifying the nailing, the flange helps to create a weather-tight seal at the head and sides of the window.

The most critical details are the head flashing, which should seal to the sheathing to pick up any dripping water from above, and the sill or pan flashing, which should freely drain to the exterior. The following approaches take advantage of the newer peel-and-stick flashing tapes, which have simplified the flashing of flange type windows.

Watch out: as our window photos above demonstrate, installing any window without proper flashing and sealing is likely to result in leaks into the building interior. The owner of this new home was very unhappy that each time it rained water ran down the inside of her walls at this window.

Installing Housewrap at Window Openings Before Installing the Windows

Figure 3-13 above shows how to flash a window installed after the plastic housewrap is in place. After cutting a modified “I” in the plastic housewrap, fold in the flaps, staple every 6 inches, and trim the excess.

- Pan flashing. The next step, the pan flashing, is often

omitted but is critical for leak-free performance in

harsh weather exposures.

The pan flashing can either be a custom metal pan, an adjustable plastic pan, or one formed in place from flexible flashing tape, as shown (Figure 3-14 below). If using flashing tape, first add a piece of beveled wood siding to the rough sill, sloping to the exterior.

Remember to increase the rough opening height by 1/2 inch. Add patches of flashing tape to bridge the gap at the cut corners. - Install window. Next install the window, slipping the

top flange under the housewrap.

Most manufacturers recommend bedding the side and top flanges in a bead of high-quality sealant to create a backup seal, a good idea in harsh weather exposures.

Watch out: Do not caulk the bottom flange, however, which must be left unsealed so any trapped water can freely drain. To facilitate drainage at the sill, set the window on shims. - Side and head splines. Side splines of peel-and-stick

flashing tape go on next, sealing from the window

flanges to the sheathing wrap, extending 6 inches

above the top of the window opening and lapping over

the pan flashing.

Finally, the head spline is slipped under the housewrap, sealing the window’s top flange to the sheathing. Patches of tape seal the diagonal slits in the housewrap. - Drip cap. If the window is trimmed on the exterior

with wood casings, use a metal drip cap on top of the

head casing and seal the drip cap to the sheathing tape

with peel-and-stick flashing tape.

When the siding is installed, do not caulk the horizontal joints above or below the window, which would create a water dam. Leave all horizontal joints unsealed to drain away any trapped water.Figure 3-14: Formed-in-Place Pan Flashing for Windows or Doors.

As we note above, the pan flashing can either be a custom metal pan, an adjustable plastic pan, or one formed in place from flexible flashing tape, as shown (Figure 3-14 below).

If using flashing tape, first add a piece of beveled wood siding to the rough sill, sloping to the exterior. Remember to increase the rough opening height by 1/2 inch.

Add patches of flashing tape to bridge the gap at the cut corners.

Installing Windows Before Housewrap

When windows are installed before the building is wrapped, the key is to detail the pan flashing so it can properly lap over the housewrap. One approach is to leave the paper facing on the outer flap of the pan flashing so it can layer over the housewrap when installed.

Another approach, shown in Figure 3-15 below, is to seal the pan flashing to a flap of sheathing wrap that will be layered over the housewrap when installed.

Whether to seal the side window flanges directly to the sheathing or the housewrap is a matter of personal preference. Since few leaks originate at the sides of windows, either detail can work well as the flashings are detailed so each sheds water to the layer below.

Felt Paper Flashing or as Housewrap Around Windows

When using felt paper, paper up to the bottom of the window. Then install the pan flashing, window, and side and head flashings as shown in Figure 3-15 just above. When installing the building paper later, layer successive courses over the side and head flanges, setting them into a bed of sealant at the sides of the window (see Figure 3-16 at left).

Leave the building paper unsealed at the head flashing, however, to allow any trapped water from above to escape.

Head Flashing Details for Round-Top Windows

To create a head flashing on round-top windows, one approach is to patch together several short pieces of flashing tape, making sure to start at the bottom and lap each upper piece over the preceding lower piece.

Another option is to use a flexible membrane such as DuPont’s Flexwrap® tape, which can be bent to conform to the curve without cutting.

Sealing Details ford Mulled Windows

Where multiple windows are mulled together in the field, treat the space between the windows like a small section of sidewall. Make sure horizontal mullions are lapped properly so the sill flashing above laps over the cap flashing below.

Use peel-and-stick flashing tape on vertical mullions, overlapping the vertical tape onto any horizontal mullions that intersect.

Window Installation, w/ Integral Brickmold

As reported in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

If installing windows with integral brickmold, proceed the same way as shown for flange-type windows above.

However, since there are no side flanges on the window, the brickmold goes over the side splines, which can be either felt paper or flashing tape.

Flashing tape is of less value with brickmold since the windows have no flange to seal to.

Apply a continuous bead of sealant on the backside of the brickmold before installing the window (Figure 3-17 at left)..

As an extra precaution against wind-blown rain entering behind the side casings, you can fold back the inside edge of the spline to form a one-inch hem, a detail developed by Pennsylvania contractor Carl Hagstrom.

At the head casing, a metal drip cap is required to protect the brickmold and provide a watertight seal. Slip the metal drip cap under the sheathing wrap and seal it to the sheathing with flashing tape.

SKYLIGHTS, Guide to Choosing & Installing

As detailed in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

A well-positioned skylight can help transform a dreary interior

room into a pleasing sunlit space with a feeling of

connection to the outdoors.

A well-positioned skylight can help transform a dreary interior

room into a pleasing sunlit space with a feeling of

connection to the outdoors.

Our photo (left) shows how even a small skylight can bring light into a tight space, in this case, in a roof in Molde, Norway -DF.

In addition, venting skylights can play a significant role in exhausting hot, moist air from kitchens and bathrooms, and can enhance ventilation in any room with limited cross ventilation.

However, skylights can also be a source of problems, such as roof leaks in winter and overheating in summer, if the installer does not pay attention to glazing type, installation, and flashing details.

Skylight Options

Like windows, skylights come in a wide variety of shapes, sizes, frame materials, and glazing options. In addition, they have an ever increasing variety of screens, shades, and motorized, automated, and computerized controls, providing convenience and good energy performance in almost any situation.

Skylight Glazing Types

Many lower-cost skylights use acrylic or polycarbonate glazing in single or double layers instead of glass. In general, plastic glazings resist breakage, but they can become scratched or brittle over time and are prone to yellowing. Unless specially coated to block UV transmission, plastic glazings allow high levels of UV radiation, which causes fading with many interior furnishings and finishes.

Most higher-end units use sealed insulated glass. Codes require the glass to be either tempered or laminated safety glass. When laminated glass is broken, the plastic interlayer holds the pane together. Tempered glass is harder to break, but it breaks into small, rounded fragments rather than dangerous shards.

Double-glazed skylights with safety glass typically have the safety glass on the interior and tempered glass on the outside, combining high impact resistance on the exterior with protection from falling glass below.

Skylight Window Sizes

Most manufacturers offer a wide variety of sizes, including narrow models designed to fit 24-inch rafter spaces. At least two manufacturers, Roto and Pella, make a 14-inch-wide model designed to fit between 16-inch on center framing. Many standard widths are designed to fit in a double 16- or 24-inch bay.

For narrow spaces, such as a short section of attic roof above a knee wall, Andersen offers several units wider than they are tall, measuring either 16 or 24 inches high by 38 to 72 inches wide. Some manufacturers are tooled up to offer custom sizes for a moderate up-charge.

Skylight Window Controls

Operable skylights use either metal arms that swing out or a concealed chain that unrolls and stiffens as the sash is cranked open. How many turns it takes to open the sash and how wide it opens vary considerably among units. For out-of-reach skylights, all manufacturers offer either extension poles or motorized controls. Some extension poles can be challenging to engage in the crank mechanism, making it a chore to open and close the skylight.

Motorized controls simplify the task, and manufacturers have been refining their offerings in this area. Some need hard wiring from the controller to skylight, while others need only a power connection and are controlled by a convenient hand-held remote. Other options include a battery backup, which could be useful during a power outage, and a rain sensor that automatically closes the skylights at the first drops of rain.

Guide to Skylight Shades and Screens

The tendency of south- and

west-facing skylights to cause summer overheating can be

greatly moderated with the new spectrally selective glazing

(SHGC below .40)

(Spectrally Selective Low-E Windows).

Still, shades and screens can be used to further reduce heat gains and UV radiation and to provide more diffused light with less glare. Numbers vary from one manufacturer to another, but typical shading effectiveness is as follows:

- Exterior solar screens can reduce heat gain by 40% or more.

- Light-colored interior shades can reduce heat gain by 15 to 20%, depending on the density and reflectivity of the material.

- Interior blinds reduce heat gain typically by 10 to 15%, depending on reflectivity.

In a bedroom, a client might also want shades for room darkening. Manufacturers offer a wide variety of shades, mini blinds, and solar screens, most of which can be controlled by the same motors that control the skylights. Pella’s between-the-glass shades and blinds offer better energy performance than interior shades and never need cleaning, a big advantage with out-of-reach units.

Also see SOLAR SHADES & SUNSCREENS.

Skylight Light Tubes

ntroduced in the early 1990s, light tubes consist of a small plastic rooftop dome that conducts light to the interior through a rigid or flexible tube with a reflective interior.

On a sunny day, the diffuser at ceiling level provides about as much light as a bright electrical ceiling fixture (see Figure 3-18 at left)

Skylight Light Tubes range from 10 to 22 inches in diameter, and one manufacturer, Sun-Tek, offers a multi tube model that supplies up to four tubes from a more conventional looking skylight panel.

Used primarily in remodeling where it is too difficult or expensive to install a skylight, light tubes offer an economical way to bring daylight into bathrooms, walk-in closets, and other small interior spaces.

For details about skylights see

Skylight Window Design Issues

As stated in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) Chapter 3, BEST PRACTICES GUIDE: WINDOWS & DOORS:

Skylights can add a dramatic element to any room in addition to providing high levels of pleasing natural daylight. In the case of operable skylights, they can provide effective ventilation as well. On the other hand, too many skylights can produce uncomfortable glare and significant summertime overheating. A few simple guidelines can ensure a successful installation.

Sizing Advice for Skylights

A small skylight can go a long way toward brightening a space. However, too much direct sunlight can produce very uneven room lighting, excessive glare, and localized overheating.