Water Pump Wiring Damage

Water Pump Wiring Damage

Cause & cure for damaged well pump wiring

- POST a QUESTION or COMMENT about checking electrical wiring to diagnose well pump problems such as tripping breakers, blown fuses, weak pump performance or no water delivery from a well water pump

Causes, cures & how to prevent well pump wiring damage: cuts, nicks, abrasion, broken splices in the well casing.

This article series describes troubleshooting submersible well pump wiring problems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Causes Of & Cures For Broken Submersible Well pump Wiring

Question: Why would the wires in my well keep breaking?

Question: Why would the wires in my well keep breaking?

2091 03 05 Anonymous said:

Why would the wires in my well keep breaking

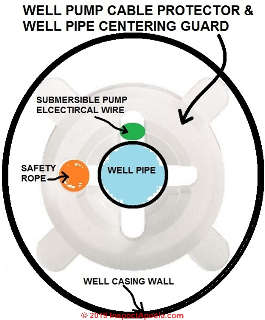

Illustration: a submersible pump wiring cable guard can protect against cable abrasion damage, tears, breaks inside the well casing.

[Click to enlarge any image]

Reply: Five Common Causes of broken submersible well pump wiring when wires break in the well

1. Inadequate taping, poor support of the wire

en route down the well, usually taped to piping, wire may not be taped sufficiently strongly or not tapes securely along the full drop of piping in the well.

This is probably the most-common cause of broken or damaged pump wiring.

You can also install a well pump cable protector that keeps the piping and wiring centered in the well casing - as shown in our drawing.

2. Excessive or abnormal well pipe torquing or twisting

when the pump starts and stops - this can also break well piping or cause piping leaks;

special fittings are available for attachment to well piping to control twisting or torquing of the piping in the well casing as the submersible pump operates.

See SUBMERSIBLE PUMP TORQUE PROBLEMS & SOLUTIONS for help stopping well pipe twist or torque damage problems to both piping and wiring.

See also WELL PIPING LEAK DIAGNOSIS

Below: well pump wiring loose in the well casing such as shown in our photo invites abrasion damage to pump wiring.

3. Dropping well pipe:

pump or piping sliding down a bit in well, while the pump wire is bound tightly at well casing top - can pull the wiring apart somewhere along its length

4. Poorly-made splice connections

anywhere in the well piping.

Our photo (below) shows a worker from Rasmussen well service, Two Harbors MN, re-making the pump wiring splices at a well head in Two Harbors.

5. Abnormal short-cycling of the well pump,

combined with torquing of the pump and piping in the well, combined with wire not properly routed, thus being abraded and worn by rubbing on well casing, piping, other contact surface.

When you pull the pump and wiring check the wiring along its length for signs of abrasion or twisting.

Also inspect the well casing (use a well camera) to inspect for protrusions, obstructions, abrasion at piping supports or torque controllers.

See details at WATER PUMP SHORT CYCLING - home

...

Continue reading at WATER PUMP WIRING REPAIR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SUBMERSIBLE PUMP TORQUE PROBLEMS & SOLUTIONS - stop twisting pump causing wiring or piping damage

- WATER PUMP ELECTRICAL SWITCHES

- WATER PUMP PRESSURE CONTROL SWITCH

- WATER PUMP PROTECTION SWITCH

- WATER PUMP RELAY SWITCH

- WATER PUMP WIRING DAMAGE

- WATER PUMP WIRING REPAIR

Suggested citation for this web page

WATER PUMP WIRING DAMAGE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.