Water Tank Pressure Gauges, Location, Installation, Use, Repair

Water Tank Pressure Gauges, Location, Installation, Use, Repair

Use a water pressure gauge to measure or monitor building water pressure or to adjust water pressure

- POST a QUESTION or COMMENT about finding, using, diagnosing, repairing, or replacing water pressure gauges on private well systems.

Water pressure gauges:

This article describes the location, use, and operation water tank pressure gauges, how to read, use, repair or replace water pressure gauges.

We discuss water pressure gauge location, accuracy, and uses on water well pump and tank systems. A well pump gauge can help diagnose a variety of well and pump problems including leaks, bad check valves, bad well pumps and more.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Pressure Gauge: types, location, uses, accuracy, repairs

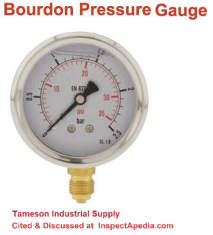

In this photo the water tank pressure gauge is visible mounted on a special brass fitting which is in turn connected to the bottom of the water pressure tank.

The water tank pressure gauge is showing about 37 PSI.

[Click to enlarge any image]

Note that water tank pressure gauges give a general idea of the water pressure measured at the water tank, and that the pressure shown on the gauge will normally drop down to the "pump cut-in pressure" at which point the water pump should start operating, and the gauge pressure will then rise up to the pump "cut out pressure" when the water pump stops.

Article Contents

- WATER PRESSURE GAUGE ACCURACY

- WATER PRESSURE GAUGE REPAIR

- TYPES OF PRESSURE GAUGES

- WATER PRESSURE GAUGE TROUBLESHOOTING

...

Water Pressure Indicator Gauge Accuracy

Typical residential water system pressure gauges found at the water tank or water pump are only approximate and are not lab instrument grade, but the water pressure gauge is a very helpful diagnostic when you're diagnosing a loss of water pressure or pump operating problem as well as when you're adding air to a water tank.

For details on the accuracy of water pressure gauges please

...

How to Repair or Replace the Water Pressure Indicator Gauge on a Water Tank or Pump

The text below describes the steps in replacement of a broken or leaky or otherwise defective water pressure gauge.

The text below describes the steps in replacement of a broken or leaky or otherwise defective water pressure gauge.

If you are installing a new pressure gauge where none has been previously installed, or for more water pressure gauge mounting location options

see WATER PRESSURE GAUGE INSTALLATION.

How to Replace a Broken Water Pressure Gauge, or How to Correct A Water Pressure Gauge that Reads too High or Too Low

If the water pressure GAUGE GLASS BROKEN or MISSING [link to article on water tank air volume controls], or if the gauge is visibly rusty or damaged, or if the gauge simply stops changing what it indicates despite the water system pressure changing (in other words the pressure shown on the gauge never changes) you should replace the gauge itself.

The well pump is turned off, pressure is drained from the system (you do not have to let all of the water out of the tank, just be prepared for a little spillage). Then the new water pressure gauge is prepared for installation (make sure the gauge bottom threads match those of the old unit being replaced as diameters vary from 1/4" to 1/2").

- Get the parts needed:

Have at hand a new water pressure gauge of the proper pressure sensing range - and be sure that the pipe thread diameter of the gauge mounting base is the same as that on the old gauge so that you won't also need an adapter to mount the new gauge in the old position.

Have on hand the teflon tape, tools, and any other parts you may need before starting. - Turn off power to the water pump and

- Release water pressure:

drain most or all water pressure from the system. - Prepare the new pressure gauge

mounting threads by wrapping with teflon tape or applying pipe joint sealing compound - keep the compound away from the opening at the bottom of the gauge through which water passes, or you may clog your new gauge early.

We put our teflon tape or pipe dope on the new gauge threads before trying to remove the old gauge. Then the old gauge is removed by using a wrench on the brass fitting at the bottom of the gauge. - Remove the old water pressure indicator gauge.

Watch out: Use a wrench on the brass base of the old gauge to unscrew it. DO NOT try to remove a water pressure gauge by twisting the gauge body itself - you'll just break it off and you may get cut or start a water leak.

- Clean any debris around the gauge mounting hole - or water squirting out may do this for you.

- Install the new pressure gauge:

Calmly screw in the new pressure gauge even if water is flowing out of the gauge mounting hole.

Screw in the new gauge first by hand to be sure that you are threading it correctly don't "cross" thread the gauge into the mounting opening or it will leak. Finish tightening the water pressure gauge in place with a wrench around the brass gauge base.

Tighten the new gauge carefully in position with a wrench on the gauge bottom brass fitting. Do not over-tighten, but screw in the new gauge until there is no water leakage.

Watch out: Screw in the new gauge first by hand, finishing it with a wrench around the brass gauge base. - Turn pump electrical power back on.

- Check gauge operation:

Observe new gauge pressure indications for normal operation. If you are confident that the new pressure gauge is properly installed and in good condition but water pressures are incorrect, the problem may be at the water pump pressure control itself. - Check for leaks - and fix any that appear

For more details about installing a new or replacement water pressure gauge please

see WATER PRESSURE GAUGE INSTALLATION - procedures & manuals

...

Types of Pressure Gauges

- Bourdon Tube Pressure Gauge:

Illustrated just above, this is the most-common type of water pressure gauge found on building water pumps, tanks or supply piping.

Bourdon tube pressure gauges are also the most-common type found on heating boilers where the gauge measures the pressure of either steam or hot water in the boiler.

The Bourdon tube is one of the most common and widely used pressure gauge measurement techniques. It consists of a flattened tube coiled into a circular arc.

When pressure is applied, the tube straightens out, and this movement gets transmitted to a pointer via a series of linkages, resulting in a pressure reading on the dial.

Bourdon tube gauges are suitable for measuring low and high pressures, making them versatile for various applications.

- Contact pressure gauges (shown above)

Contact pressure gauges are used whenever it is necessary to monitor limit values and visually indicate local process pressures.

Contact pressure gauges are basically pressure gauges with an integrated pressure switch.

Depending on the pointer position of the indicating measuring instrument, switch contacts make or break circuits.

The contacts can be used to trigger an alarm if a reading exceeds or falls below a set value; this is why they are also "alarm contacts". The contact pressure gauge can also be used to start, stop, or switch processes.

- Diaphragm Pressure Gauge (above)

Diaphragm pressure gauges employ a flexible diaphragm, typically metal or elastomeric material.

The diaphragm deforms under pressure, and this displacement is translated into the pointer's movement on the gauge face. Diaphragm gauges are useful for measuring relatively low pressures and are often used in corrosive or viscous fluids applications. - Manometer pressure measurement

A manometer consists of a U-shaped tube partially filled with the fluid whose pressure will be measured. The pressure difference between the fluid in the tube and the external environment causes the fluid level to change in the arms of the U-tube.

Manometers can be of various types, including simple U-tube manometers, inverted U-tube manometers, and well-type manometers.

- Differential Pressure Gauge (above is a Differential Pressure Indicator)

Differential pressure gauges measure the difference in pressure between two points in a system.

They are commonly used to monitor and control pressure drops across filters, heat exchangers, and flowmeters. These gauges are essential for optimizing system performance and ensuring efficiency in fluid flow processes.

- Digital pressure gauge (above)

Digital pressure gauges are modern electronic instruments that directly display pressure readings on a digital screen. They have various sensing technologies like piezoelectric, capacitive, or piezoresistive to convert pressure into an electrical signal.

Digital gauges offer advantages such as high accuracy, easy readability, and the ability to store and transmit data for further analysis.

Special thanks to Maria Schmidt from Tameson Industrial Supply, who provided the pressure gauge descriptions above.

- Contact: Charles Kolstad , Tameson Industrial Supply, Torenallee 20 - 5617BC Eindhoven - Netherlands CoC: 72902531 Email: ckolstad@tameson.com or support@tameson.com Web: Tameson.com

...

Water Pressure Gauge Troubleshooting

On 2021-03-06 by (mod) - how to stop leak at broken-off water pressure gauge

@Mariah,

@Mariah,

You need to turn off the pump Inlet pressure drain from the system in order to stop the immediate crisis. Then you will need an extractor to remove the broken off bit of probably quarter inch iron pipe in the threaded mounting opening.

Screw extractor & Plug temporary repair:

Choose a screw extractor whose diameter is just small enough to insert into the remains of the broken-off brass water pressure gauge base that remains threaded into the mounting tee or fitting at your water tank.

[Click to enlarge any image]

The screw extractor is screwed into the broken-off remains of the gauge base that in turn was left screwed into an NPT (National Pipe Thread) threaded opening into which the gauge was originally installed.

The extractor, mounted in a small Tee-handle so that you can turn it, is a bit like those shown in my illustration.It is reverse-threaded so that as you turn it counter-clockwise (the direction to un-screw the remains of the broken-off pressure gauge base), it bites ever more tightly into the broken part as it un-screws it from the mounting opening.

With the broken off gauge base remains removed you can either screw in a new gauge or temporarily a pipe plug that's the proper diameter - typically 1/4".

The screw extractor set including bits and the turn-handle into which they mount as well as the NPT pipe plug are available at your local hardware store, at building supply stores, or of course from online vendors.

If you've never done this before you may find it's worth hiring a plumber who can do the job more quickly.

Emergency leak repair:

leather and a C-clamp; in an emergency we are sometimes able to stop a leak by using a C-clamp and a bit of leather (like a work glove) or other as material that we simply clamp over the top of the opening that's leaking.

On 2021-03-06 by Mariah - Our pressure gauge in our water pump just snapped off

Our pressure gauge in our water pump just snapped off and we now have water starting a mini flood, how do we stop the water from pouring out!?

On 2020-04-28 - by (mod) -

Frank

What you describe is

- normal, if you are getting a minute or longer of water draw-down before the pump cycles on

- abnormal if the pump is cycling on and off more-rapidly. In that case the most-common cause of trouble is a water-logged pressure tank.

See the diagnostics at WATER PUMP SHORT CYCLING - home

and let me know if you have success or if you have further questions.

Thanks for asking.

On 2020-04-28 by Frank

Well pump pressure gage varies fro high setting to low setting 40# to 80# continuously while we are running water! Is this a problem with gage or do I need a plumber

On 2020-01-03 - by (mod) -

No, Anna the pressure gauge is a passive device that simply senses water pressure.

HOWEVER the same debris that clogs up a water pressure gauge might also clog up the sensor port on a pressure control switch, causing the switch to stop working properly.

On 2020-01-03 by Anna

If my pressure gauge isn't working will affect the pressure switch from working?

On 2018-12-17 - by (mod) -

Ann,

The air bubbles in water symptom you describe suggests there's a leak in the well piping,

possibly that's the same reason that you lost pump Prime in the first place.

On 2018-12-17 by Ann Jones

I lost the prime on my above ground 2 line well pump. When I removed the pressure gauge and refilled the lines there was excessive bubbles that didn't stop. I replaced the pressure gauge and the pump primed. However, I've never seen it bubble like that before. Is that normal? P.s. this is the 3rd time in 5 years it has lost its prime.

On 2018-09-06 - by (mod) -

Thanks for the follow up, that will help other readers. I'm glad to hear that you were successful.

On 2018-09-06 by Steve - found calcium obstruction of water pipe

Me back again.

Found problem When I took of the pressure gauge ,there was a calcium obstruction in the pipe

Gave it a little tap with an awn and it came clean. It was amazing how much pressure was still there even with the tank drained.

Make sure you have the power off (I did) ,there was quite a jet of water that came up once the obstruction was moved.

Reader Question: 8/9/14 Andrew said:

Hi I recently replaced our submersible water pump (DAB Pulsar 40/50 M), because of a faulty electrical component in the pump.

I looked around to see if I could get it repaired but the cost was excessive compared the a new one. (It was over 10 years old).

There is a float switch attached to the pump which works in conjunction with a pressure switch and gauge mounted on top of the pressurized cold water cylinder.

The system is set to a max pressure of 3 bar. When the pressure drops to about 1.5 bar the pump automatically recharges the water cylinder. After I replaced the pump everything was working fine again, until recently.

I started getting erratic re-filling of the tank. The pressure would drop and the pump wouldn't cut in to recharge the cylinder.

5 minutes later the system would recharge. There is plenty of water in the well, so naturally I thought it was the switch or gauge.

I've just replaced both.

The problem now is that when the pump is switched on the system recharges but the gauge is not registering any pressure and the switch doesn't turn the pump off. If I let it run I'm sure it would explode.

[dysfunctional links removed]

I've read through your extensive notes and explanations but can't find anything which specifically relates the our problem.

I would really appreciate your advice and or comments to help resolve this issue. Many thanks in advance.

Andrew

contact@englishwhynot.fr

Reply:

Andrew

If your water supply contains silt, iron, debris or the like, I suspect that the gauge pressure port is clogged and possibly there is similar clogging of the pressure sensing port of the pressure control switch.

Try replacing the gauge, and cleaning or replacing any clogged small-diameter piping - same for the pressure switch. Keep us posted.

Reader question: relation of water pressure gauge to well pump short cycling

Will a broken pressure gauge on a water pump for a two line well system cause short cycles when pumping water into the tank on the interior of the house.

Reply:

No Bev. Pressure gauges are passive devices - they do nothing but reflect system pressure.

Water pump short cycling causes are given

at WATER PUMP SHORT CYCLING CAUSES

But it is worth noting that some of the causes of improper or erratic water pump operation, such as debris clogging of a pressure switch sensor port can also cause erratic pressure gauge operation by clogging its own pressure sensor opening as well.

On 2011-07-08 - by (mod) - Pressure gauge is ticking

If the water pressure gauge is sticking or acting weird it may be that debris has entered the gauge or the small diameter pipe on which the gauge may be mounted. Try replacing the gauge.

On 2011-06-22 by Anonymous

the pressure guauge is ticking pressure is flucuating and making a loud ticking sound what does that mean

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-07-0 y InspectApedia Publisher (mod) - can a water pressure gauge be connected to a basement gas tank?

@Debbie Leiby,

No, a water pressure gauge would have nothing to do with a gas tank.

I'm not sure what kind of gas tank you are discussing, perhaps an LP tank? That would be outdoors. And oil storage tank? Some other kind of fuel storage tank?

LP gas storage tanks indeed have a gauge that indicates the amount of fuel remaining. That would have nothing to do with water pressure.

Perhaps you could attach a photo so we can be sure we understand the question.

On 2023-07-09 y Debbie Leiby

Can your water pressure Guage be on a pipe connected to the gas tank in basement

On 2023-07-06 by InspectApedia Publisher (mod) - pressure gauge readings differ at pump and downstream

@Rob,

No, it's not an immediate sign of pump malfunction, but it might be a sign that the gauge at your pump should be replaced. The sensor port on the pressure gauge may be debris clogged. Let's replace it before the gauge deteriorates further and perhaps leaks.

On 2023-07-06 y Rob

My pressure gauge at the pump is showing different cut in and cut off pressure then pressure gauge downline from pump. Downline gauge shows the correctly set in/out pressures of 30 and 50 psi. Is this any cause for concern?

On 2022-10-08 by InspectApedia-911 (mod) - is water in the pressure gauge face normal?

@Rose Powley,

No, the gauge is defective or was damaged dyring installation, and it should be replaced promptly - before it bursts and leaks into your building.

It's possible that during installation the gauge body was twisted instead of the proper brass nut that should have been used to tighten it.

That can sometimes cause a cage to break internally and leak

On 2022-10-08 by Rose Powley

I had a new well pressure gage installed and now it has water in it. Is this normal

On 2022-03-25 y Inspectapedia Com Moderator (mod) - normal vs. abnormal pressure fluctuations on a gauge

@Linda Leigh Daniel,

If the pressure is fluctuating slowly that's normal, but the loud BANG is perhaps water hammer (needing a check valve or foot valve replacement perhaps)

If the pressure is fluctuating rapidly - every 15 seconds or less, then the pump is short cycling - see diagnosis and repair at

WATER PUMP SHORT CYCLING - home

https://inspectapedia.com/water/Short_Cycling_Pump.php

On 2022-03-25 by Linda Leigh Daniel

When outside faucet is on, pressure gauge is fluctuating (from 40 psi to 70 psi) & a loud bang noise can be heard outside the well house coming from the pressure tank.

On 2021-05-04 by danjoefriedman (mod) - signs of a debris-clogged pressure gauge

@Luwana Faulkenburg, if the new gauge is mounted where the old one was, I suspect either debris clogging at the gauge input port or a bad gauge.

Neither of those add-on fittings would be expected to have one iota of impact on how the pressure switch itself works, though of course if we foul up the air charge in a pressure tank while working on it, that can cause trouble.

If you think that's a concern take a look at WATER TANK AIR, HOW TO ADD in the ARTICLE INDEX

On 2021-05-04 by Luwana Faulkenburg

Above ground well pump pressure gauge worked fine until I put in a pressure relief value, and a new pressure gauge. Now pump is fine but the pressure gauge is not working. Any ideas

On 2021-03-06 by danjoefriedman (mod)

@Mariah,

You need to turn off the pump Inlet pressure drain from the system in order to stop the immediate crisis. Then you will need an extractor to remove the broken off bit of probably quarter inch iron pipe in the threaded mounting opening.

With a broken off pipe removed you can either screw it a new gauge or temporarily a pipe plug that's the proper diameter. If you've never done this before you may find it's worth hiring a plumber who can do the job more quickly.

On 2013-03-23 - by (mod) - what constitutes "high" water pressure?

Joe,

I can't tell enough from your question to have an opinion. What's "high"? And are we sure the problem is actually excessive water pressure or just a gauge that may be reading inaccurately?

Your pressure control switch will normally operate a residential building at 20/40 or 30/50 psi. If you are seeing pressures over 60 or 70 there are risks of leakage, burst pipes, and if the water pressure tank is not protected with a pressure relief valve, an unsafe condition as well.

If that's the case perhaps someone misadjusted the pressure control switch, or it is not properly sensing pressure. Ask for help from your installing plumber.

On 2013-03-23 by Jose

Purchased new water heater, water tank and pressure switch everything was installed correctly , the problem is when I turned the system on the pressure was reading high. Does anyone have any ideas what the problem may be

On 2012-10-11 by position of the pressure gauge

If the gauge is connected by a flexible hose to a tank 1 metre tall and positioned half way up the outside of the tank it is possible to prevent all the water from draining out of the hose when the tank water level is low by selecting a smaller diameter hose e.g. 3mm diameter? thanks

On 2012-05-30 by se lvin

gauge inside water have any broplem

On 2012-03-04 by chad

what is the best way to drain the tank before relacing the pressure gauge? when i release the air from the top, after the awhile, water starts shooting out from the air nozzle. Also I'm not sure if the spicket at the bottom is to drain the tank, or is it just pumping water up from the well? I'm just rtrying to replace my pressure gauge. thanks

On 2011-11-06 by Marlin

I replaced a water pressure guage at the tank, it was all rusted and was not reading pressure correctly,so replaced. when i started up the pressure guage will go up to 70 or 80 psi before I manually shut off, afraid of over pressure in tank. I dont know what previous owner had pressure set at. would it be in the switch not cutting out when pressure is past normal.

...

Continue reading at WATER PRESSURE GAUGE ACCURACY or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER TANK PRESSURE GAUGE FAQs - questions and answers posted on this page.

Or see these

Recommended Articles

- GAUGES, HYDRONIC BOILER

- GAUGES, STEAM BOILER

- WATER PRESSURE FALLS BRIEFLY THEN STOPS - after the pump turns off pressure falls a few psi

- WATER TANK PRESSURE GAUGE

- WATER PRESSURE GAUGE ACCURACY

- WATER PRESSURE GAUGE INSTALLATION - procedures & manuals

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - home

- WATER PRESSURE MEASUREMENT to buy or make your own portable water pressure measurement gauge

- WATER PUMP SHORT CYCLING - home

Suggested citation for this web page

WATER TANK PRESSURE GAUGE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to readers Nancy and Eric for questioning water pump gauge inaccuracies 11/2/2009

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.