UV Light Systems for Water Treatment of Contaminated Drinking Water

UV Light Systems for Water Treatment of Contaminated Drinking Water

- POST a QUESTION or COMMENT about choosing, installing, & maintaining or repairing UV light water treatment systems or "water purifiers"

UV Water Purification Systems guide:

Here we explain procedures & reasons for using permanently-installed UV light (ultra violet light) treatment systems to address bacterial contamination in drinking water or well water - one of the options for correcting unsanitary or unsatisfactory drinking water.

We discuss the following: How does an ultra violet light fixture correct bacterial contamination in well water? How do UV lights work?

Details of proper UV light installation and maintenance for well water treatment. Water treatment methods for contamination, bacteria, lead, minerals, etc. Water treatment choices for odors, smells, sediment, cloudiness.

Choices of types of water treatment equipment.

This series of articles explains many common water contamination tests for bacteria and other contaminants in water samples.

In these articles we describe what to do about contaminated water, listing common corrective measures when water test results are unsatisfactory.

We include water testing and water correction measures warnings for home owners and especially for home buyers when certain conditions are encountered, with advice about what to do when these circumstances are encountered.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

UV - Ultraviolet light as a Water Purifier - Installation, Inspection & Maintenance Guidelines for UV Water Treatment Systems

UV water treatment systems used to disinfect drinking water combine the following components:

UV water treatment systems used to disinfect drinking water combine the following components:

- Water disinfection chamber

(a quartz tube or quartz sleeve that contains an ultraviolet light and keeps the bulb physically separated from the water), - Quartz UV light bulb

that kills bacteria in water as water passes past the light source - Electrical and plumbing connections

that provide electrical power to the bulb, allow water to pass through the unit, and include shutoff and drain valves for the equipment. The shutoff valves make unit cleaning and maintenance easier. - Optional controls

to sound an alarm or stop water flow if the UV system stops working

For the UV treatment system illustrated in most of the photographs in this article, at a U.S. property in New York we installed a Siemens Ultraviolet Water Disinfection System (formerly produced under the name Sunlight systems) shown in the photograph at above/left.

The UV disinfection system is installed either in a kitchen or point of use, or when protecting a whole building it is installed where water leaves the well pump and pressure tank and enters the building, so that water flowing through the disinfection system is exposed to a UV lamp to carry out the water disinfection process.

The "UV" light can indeed kill bacteria in water, provided that the flow rate of water through the device is not too fast (needs exposure time) and provided that the water is not too obstructed with sediment and provided that the light source is cleaned - the bulb needs to be changed periodically.

Steps in a Proper UV Disinfection System Installation

Our photograph (below) of UV disinfection system equipment and the water softener and filters required for effective UV treatment are from a water treatment system installed by Norberg Godinez in 2017 at a property in San Miguel de Allende, Guanajuato, Mexico.

Our photograph (below) of UV disinfection system equipment and the water softener and filters required for effective UV treatment are from a water treatment system installed by Norberg Godinez in 2017 at a property in San Miguel de Allende, Guanajuato, Mexico.

For an effective water treatment system in an area where water is hard (high in minerals), to protect piping and water heating equipment as well as the UV disinfection system, city water is passed through the following sequence:

[Click to enlarge any image]

1. Water from the rooftop water storage tank passes through

2. A Grundfos® SCALA2 water pressure booster pump to lift water up and through water treatment equipment as well as to provide improved building water pressure, through

3. A sediment filter (to prevent debris-blocking of the water softener and later of the UV disinfection light)

4.A charcoal filter (to remove colors, odors in water and for added filtration) then through

5. A water softener (not shown) to remove minerals, principally calcium and magnesium, then

6. Through the Aqua Plus™ UV disinfection light (size chosen for a whole-house treastment system) and finally

7. To the building plumbing fixtures including both cold water and hot water provided through a tankless water heater that is also protected from scale blockage by this system.

Requirements for Effective UV Water Disinfection

How do we know the UV light is properly installed and effective in treating drinking water?

How do we know the UV light is properly installed and effective in treating drinking water?

If you are relying on a UV light to treat bacterial contamination in drinking water these considerations apply:

- Proper UV light selection for water treatment:

The UV light must have been properly selected to handle the volume and flow rate of the water supply where it is installed. If ultra violet light is not of sufficient capacity to treat water flowing past its bulb it will not be effective.

This AquaPlus UV light intensity [sic] is listed as 254 nm (I'd call that wavelength). According to the manufacturer, to function effectively this UV light should receive water within the parameters listed below.

This explains why water filtration, treatment for hardness, and protection of the water source (storage tank) from excessive heat from direct sun exposure:

- Turbiedad - Turbidity < 5 UTN

- Color 0.0 UPC

- Dureza total - Total Hardness <100 mg/L

- Hierro - Iron < 0.3 mg/L

- Maganeso - Magnesium < 0.15 mg/L

- Sulfatos - Sulfates <400 mg/L

- Temperatura del agua - Water temperature 5-25°C or 41°F-77°F

- The water flow rate must be within the UV light specifications -

the manufacturer of the UV light for water treatment will specify the maximum permitted water flow rate through the light fixture.

If water flow rate exceeds that number (7 gpm, for example), the light might not be fully effective in killing all bacteria in the water. (This risk is higher if the starting bacteria count was high.)

The AquaPlus UV light shown above, produced by Industrias Mass S.A. de C.V. in Mexico (www.indmass.com.mx / indmass@indmass.com.mx) is a stainless-steel system sold in models 4 to 24 and capable of water flow rates from 15 Lpm (4 gpm) to 91 Lpm (24 gpm).

Watch out: Shown above is a label providing the serial number for the UV water disinfection light in the UV light installation photograph with all of those arrows and notes. For our installation, the contractor selected an AquaPlus model 12SS which can handle a flow rate of 45 lpm (11 gpm).

If the water flow rate through the building piping system exceeds this rate then the UV treatment will be ineffective.

Typically at 20-40 psi a residential plumbing system will deliver 2-6 gpm at an unrestricted bath shower and about 3 gpm where a flow restrictor is installed. We find 2-4 gpm at a typical kitchen sink faucet. See details

at WATER FLOW RATE CALCULATE or MEASURE

A UV light kit will often include a flow control device (or one is purchased at a local plumbing supplier) that is installed at the inlet side of the fixture - a small disc that is inserted into the plumbing connection on the light fixture. - The UV light water treatment system must be properly installed -

at the right location in the water system. Normally the UV light is installed after the necessary filters and water softener (if the water hardness exceeds the permitted level).

Below you can see the electrical power connections for the UV light. We took a bit of extra care to tie the low-voltage power supply for the light to a nearby water pipe (yellow arrow).

- Sanitize the building water tank & piping: 13 Steps to Disinfect building piping:

the UV disinfection system manufacturer may also recommend that the building's water piping be disinfected after the light has been installed. We accomplished this process for the installation shown here as follows:- Turn off electrical power

to the UV light disinfection system. - Turn off water

at the point of entry into the whole house water filter; leave the water filter bypass loop closed as well. - Drain building piping:

connect a garden hose to the UV disinfection system drain or another convenient piping drain point, and drain water out of the building piping. - Remove the whole house filter

canister and set the filter aside on a clean surface (paper towels are fine). - Fill the water filter canister with bleach solution;

- Replace the bleach-filled canister

onto its mount

- Turn on water:

Slowly open the water supply into the bleach-filled canister and into the building, first making sure that building faucets have been turned OFF.

This will send disinfecting bleach-water mix into the building piping. (An accurate measure length of time that bleach-solution needs to be in contact with a surface to disinfect it is a function of the strength of the solution.)

- Fill building piping with bleach solution:

By opening building faucets (photo above, right), re-fill the UV disinfection device and house piping with the bleach solution.

We used chlorine test strips (photo at left) to confirm that we had adequate bleach solution in the piping by testing at each faucet.

The right-hand square shows the chlorine concentration between 4.0 and 10.0 ppm in this sample. The other color squares report on water pH, alkalinity, hardness, etc.

A low-tech method often used is to run water at each fixture until you smell bleach, then turn the fixture off. - Replace water filter cartridge:

Turn off water at the point of entry to the whole house water filter, remove the water filter canister and replace the filter cartridge.

We add a few ounces of bleach again into the canister to disinfect the filter cartridge after touching it, then we flush this water out of the system as described below. - Disinfection time:

Allow the bleach solution to remain in the piping for 24-hours.

- Turn off electrical power

- Turn on electrical powe

r to the UV light disinfection system - Thoroughly flush out bleach

from the system before using the water supply. Run water at least until there is no bleach odor at any faucet. - SAFETY WARNING:

Failure to flush out all disinfecting bleach from building water piping is dangerous - drinking bleach is poisonous and can be fatal; leaving even a small amount of bleach in the building piping can result in accidental bleaching of the next laundry load, and it could accidentally subvert a follow-up bacteria test.

See CHEATING ON WATER TESTS. - The UV light water treatment system must be properly maintained -

follow the manufacturer's instructions for periodic inspection and maintenance. If the bulb becomes dirty or is in fact not operating (burned out) it may not be obvious without inspecting the unit.

Do not touch the UV light bulb

glass surface when installing a new bulb. Oils from your fingers may cause damage to the bulb. We discuss UV disinfection system maintenance and detail below

at UV LIGHT MAINTENANCE INSTRUCTIONS - A whole house filter may be necessary

or recommended by the installing plumber. When a UV-light water treatment system is installed on a water supply that contains high levels of sediment or iron, those particles can settle on the UV bulb surface, ultimately blocking light and interfering with the UV water treatment system's effectiveness.

A whole house filter can protect the Ultra Violet Light bulb from debris clouding. For the UV treatment system illustrated in most of the photographs in this article, we installed an Aqua-Pure whole house filter.

Also see in this

article: WATER TEST AFTER UV INSTALLATION - Automatic shutoff valve on UV disinfection systems:

some UV light disinfection systems include a "normally closed" solenoid switch. This switch will "open" or turn off the water flow in the building if the UV lamp burns out or if the UV intensity fails.

This switch will also stop water flow during a power failure. (At a home with a private well and well pump, a power failure will also stop the well pump from running anyway.)

Some UV solenoid switches include a manual override (look for a white toggle switch on Siemens units) that can be used in emergency to deliver water even though the disinfection system has stopped working.

If the UV solenoid switch turns off the water supply (other than during a power failure) you will need to determine and correct the problem:- There may have been a power failure

- The UV lamp may have burned out

- The UV lamp intensity may have fallen too low

- The solenoid switch itself may have been damaged

- See NO WATER PRESSURE for a detailed procedure for diagnosing loss of water pressure, since there are other possible causes of that problem.

Maintenance Instructions for UV Light Water Disinfection Systems

...

...

- How to tell if the UV light is on:

even with the cover installed, on some UV disinfection systems you may see a small amount of purple or violet light shining on a nearby wall or leaking out of the cover (photo above-left). Removing the cover on a UV unit will show the light more easily.- UV Bulb light:

As we show in our photo above, with the UV disinfection system cover in place, look for visible UV light from the UV bulb itself.

It may be necessary to loosen or remove the cover to see light from the bulb (photo above-right) but be sure to see our safety warning just below - do not look directly at the bulb and do not pull the UV bulb out of its quartz tube when power is on to the unit. - UV Shutoff valve:

If an automatic UV disinfection system shutoff solenoid valve is installed, review our description of that device at Automatic shutoff valve above. - UV Indicator light:

Some UV disinfection systems include a status indicator lamp or bulb: a green LED indicates that the UV lamp is on and the UV disinfection system is operating. - UV Audible alarm:

Some UV disinfection systems include an audible alarm that sounds if the unit stops working (and provided that there has not been a power failure) - UV Monitoring:

UV disinfection systems that include an indicator light or alarm also include circuitry that monitors the effectiveness of the bulb disinfection system. The monitor is watching the bulb output, not water purity

- UV Bulb light:

With the extensive protection of filters and water softening equipment described above we don't expect this UV light or its surrounding quartz tube in San Miguel de Allende, to require frequent cleaning.

The inspection for lit UV bulb can be most-safely done using a cellphone camera that gives a good view without direct exposure of the inspector's eye to a strong UV light.

- Watch out: Avoid exposure to the UV light when the system is on. UV light may be difficult or impossible to see when the UV disinfection system is operating - by design.

Exposure to UV light is harmful to skin and eyes. If a cover has been removed from a UV disinfection system that is operating, do not look directly into the light. Unplug the unit before installing or removing the UV lamp. - How to tell if the UV disinfection system is working effectively: periodic water testing for bacteria

is recommended when relying on a UV light to handle bacteria in the water supply.

OPINION: It is uncertain how one knows that a UV light water sterilizer system is working without periodic testing and when necessary, UV bulb replacement.

Furthermore, UV light treatment systems do not remove other contaminants (if any are present in the water supply, such as chemical contaminants, odors, or other problems that may be present. - Periodic changeout of the whole house water filter cartridge

will be necessary, depending on the level of sediment and debris in the water supply. If your filter becomes visibly dirty, if the building water pressure drops, or if the water pump begins rapid short-cycling on and off, a clogged water filter could be the cause.

See WATER FILTERS, HOME USE for details. - Periodic changeout of the UV light bulb:

the manufacturer recommends that the bulb be changed annually (or every 8000 hours of use) and that the quartz sleeve around the light bulb should be cleaned regularly.

What quartz sleeve? Some UV light disinfection systems include a quartz tube cleaning system that permits the owner to clean the quartz sleeve without having to disassemble the disinfection chamber.

Otherwise, if the quartz sleeve becomes soiled with sediment you will need to turn off power to the unit, remove the cover, carefully remove and set aside the UV quartz bulb, shut off water to the disinfection unit, drain the unit, and remove the quartz sleeve for cleaning.

Watch out: Be careful not to drop the quartz sleeve - it breaks easily. If you do break the UV light disinfection system quartz sleeve, don't panic: order a new sleeve from the manufacturer.

The disinfection system model and serial number are on the unit, or on its cover.

UV Disinfectant Light Bulb Life Expectancy:

Industrias MASS who produces the AquaPlus UV disinfection light described in this article says that the anticipated life of the bulb is 8000 hours of continuous use. That's 333 days of bulb life.

The company recommends that the bulb be replaced every 9 months in order to assure the effectiveness of the ultraviolet radiation.

UV Lamp Water Disinfection System Troubleshooting

This discussion has moved to UV ULTRAVIOLET LIGHT WATER TREATMENT REPAIR

What Contaminants are Removed by a UV Light Water Treatment System

Nothing is removed from the drinking water, but if the system is working properly, the UV light will kill bacteria in the water supply. The dead bacteria, along with other water contaminants (if there are other contaminants in the drinking water) are not removed by the light.

Nothing is removed from the drinking water, but if the system is working properly, the UV light will kill bacteria in the water supply. The dead bacteria, along with other water contaminants (if there are other contaminants in the drinking water) are not removed by the light.

OPINION: Property sellers often install this quick and least-expensive "solution" in the course of a real estate transaction in order to meet the minimum requirements of a buyer's lender to provide "potable water."

Since the lending bank usually requires only a bacteria test as a measure of water potability, the new owner/residents may not know whether or not there are chemical or other contaminants in the water supply.

When a UV light has been installed on a water supply, our recommendations for further diagnostic testing are outlined just below.

Look For the Source of Bacterial Contamination in a Well

Since one of the most common ways that bacteria enters a well is through a defect at the pitless adapter (joining the water pipe to the well casing) or at a buried well cap that is leaky or open. In such cases the presence of bacteria in water is really an indicator of ground water leakage into the well.

Surprisingly we have found significant non-coliform bacteria levels in well water traced to

Spiders living in the top of a well casing: the spiders eat insects, dropping flies or other insects into the well casing, a possible source of un-wanted bacteria.

Dead animals in the well? On occasion a mouse or other small rodent falls into a well casing, causing temporary contamination.

Well contamination sources such as these are easily corrected by sterilizing the well and its casing interior.

See WELL CHLORINATION & SHOCKING.

Should You Test for Other Contaminants in Well Water?

If ground water or surface runoff have been leaking into a well, this means that anything that is on the ground or in the soil around the well is likely to be entering the water supply.

So treating for bacteria may be failing to address other contaminants. Further testing for other contaminants would be appropriate if a well fails a bacteria test.

In particular, if the well is located at a property where chemicals are likely to have been applied nearby, such as near an orchard, farm property, animal barns or pens, or where pesticides have been in use, or close to a gas station, or where other contaminants are known to have been in local ground water, tests for those specific contaminants are a good idea.

If a property is in a residential neighborhood that has not included farms, orchards, barns, gas stations, or nearby industrial processes, the chance of finding these other contaminants in a well is certainly much less.

See WATER TESTING ADVICE for an outline of when to test for what contaminants in well water.

See WATER TESTS for CONTAMINANTS for a list of articles on water contaminants and water tests.

Advice for Testing Water Systems after UV Light Installation

Often conditions cause for follow-up water testing after a UV water treatment light has been installed.

For example a property owner may discover bacterial contamination in the water supply when a home is being sold. If the initial water test shows that the starting bacteria count is low - just a few CFU's/L, and if there is no reason to have concerns for other water contaminants, testing for bacteria again after the UV light has been installed is proper procedure, and should produce acceptable results.

Here are some post-UV-light installation water testing considerations:

- If the water flow rate through the UV treatment device is higher than the device manufacturer specifies,

then that condition can also interfere with and reduce the effectiveness of the UV light in killing bacteria in the incoming water. - If the installer did not install a whole house filter upstream

(before) the UV light, if there is debris and sediment in the water, that material can obscure the UV bulb and interfere with its effectiveness.

What if the UV Light is Installed Without a Water Filter?

A reader recently asked for advice for a case in which the UV installer forgot to install the water filter.

The water filter was to be re-installed the next day, but the homeowner had already observed a lot of debris coming out of faucets in the building after the new UV light was installed.

That high level of debris may have been due to disturbances of piping and water tank during the plumbing work, or the incoming water supply might simply be high in debris and sediment.

Actually, flushing out the plumbing system before re-installing the cartridge in the water filter is not a bad idea because often during plumbing work lots of extra debris is stirred up or even introduced into the system. But the filter needs to be in place to protect the UV light from becoming obstructed.

We advised the following for this case:

If the person taking the sample fully flushes the system and piping before collecting the water test sample it is likely to "pass" with acceptable results (in most U.S. communities that's a count of less than 1 CFU/L or in a "presence/absence" test, with a result of "absent").

When we recently installed a UV light water treatment system, preceded by a whole house filter (which is important for UV effectiveness as it keeps debris off of the bulb), we also sterilized all of the house piping using the well shock procedure

at WELL CHLORINATION & SHOCKING.

The reasoning is that having been running a building plumbing system with bacteria in the water supply, there might be pockets of bacteria in debris trapped in the system.

In the particular case under discussion, the water test for a home buyer was planned for the day after the water filter was to be installed. Thus the home owner would not have time to go through the well shocking procedure in time for the water test.

Therefore the homeowner needs to either

- delay the test

for at least a week or better two (thus making the later test most reliable and avoiding any charges of tampering after the well shock), perform the well shock procedure, and flush out and wait period (4 days minimum, longer is more reliable), then perform the water test.

OR

- perform the water test on schedule

with a thorough flush-out of the building water supply piping at the test point first. As the starting bacteria level was in this case reported to be low, in this case it's likely the test will produce acceptable results.

If it does not, then go through the well shock procedure as described and things will either be just fine, or the UV system is not properly installed or not properly working.

Limitations of UV Disinfection Systems for Drinking Water

Shown above: Mini-Pure, Mighty-Pure, Sanitron UV water "Purifiers" that can handle a range of water flow rates.

[Click to enlarge any image]

Watch out: Factors that affect the effectiveness and operating time of any UV light used to treat water in an effort to make it potable, or at least improve its potability include at least the following:

- What contaminants are present

in the water. UV treatment does not address chemical contaminants, nor do some water filters. - The water temperature.

(The SteriPen includes a temperature sensor) - The water clarity -

the level of particles in the water and particle size have important effects on the UV disinfection process.

Qualls (1983), in a study discussing the advantages of UV light as an alternative to chlorination, point out that filtration is often necessary to reduce the level of suspended particles in water for UV treatment to be effective. Abstract excerpts:

It is well known that aggregation of bacteria and viruses provides some degree of protection from halogen and ozone disinfection. Adsorption of microbes to inorganic surfaces such as clay provides little protection.

However, organic particles can protect organisms from disinfectants and can become a major limiting factor in disinfection. Particulate materials also effect [sic] UV disinfection.

Clays do little to inhibit UV disinfection because they tend to scatter UV light rather than absorb it. Oilver and Cosgrove attributed the difference between microbial survival in irradiated raw wastewater and secondary effluent to differences in particle sizes.

They believed that bacteria inside aggregates of particulate matter were at least partially protected from UV light. They found that a sample dispersed by ultrasonication was more sensitive to UV disinfection. - Giardia cysts:

Not all water disinfection experts agree that UV light will reliably and effectively kill cysts. In particular, Giardia cysts may not be adequately killed by UV light disinfection systems, as we discuss in more detail

at UV vs GIARDIA LIMITATIONS

Watch out: even the best water filter system + water softener + UV disinfection system will not remove all water contaminants. Some such as arsenic may still remain.

In addition to the Giardia warning above, see

also ARSENIC in DRINKING WATER

Research on the Effectiveness of UV Disinfection of Drinking Water

- Adeyemo, Folasade Esther, Gulshan Singh, Poovendhree Reddy, Faizal Bux, and Thor Axel Stenström. "Efficiency of chlorine and UV in the inactivation of Cryptosporidium and Giardia in wastewater." PLoS One 14, no. 5 (2019): e0216040.

- Betancourt, Walter Q., and Joan B. Rose. "Drinking water treatment processes for removal of Cryptosporidium and Giardia." Veterinary parasitology 126, no. 1-2 (2004): 219-234.

- Craik, Stephen A., Gordon R. Finch, James R. Bolton, and Miodrag Belosevic. "Inactivation of Giardia muris cysts using medium-pressure ultraviolet radiation in filtered drinking water." Water Research 34, no. 18 (2000): 4325-4332.

- Einarsson, Elin, Staffan G. Svärd, and Karin Troell. "UV irradiation responses in Giardia intestinalis." Experimental parasitology 154 (2015): 25-32.

Abstract

The response to ultraviolet light (UV) radiation, a natural stressor to the intestinal protozoan parasite Giardia intestinalis, was studied to deepen the understanding of how the surrounding environment affects the parasite during transmission.

UV radiation at 10 mJ/cm(2) kills Giardia cysts effectively whereas trophozoites and encysting parasites can recover from UV treatment at 100 mJ/cm(2) and 50 mJ/cm(2) respectively.

Staining for phosphorylated histone H2A showed that UV treatment induces double-stranded DNA breaks and flow cytometry analyses revealed that UV treatment of trophozoites induces DNA replication arrest.

Active DNA replication coupled to DNA repair could be an explanation to why UV light does not kill trophozoites and encysting cells as efficiently as the non-replicating cysts.

We also examined UV-induced gene expression responses in both trophozoites and cysts using RNA sequencing (RNA seq).

UV radiation induces small overall changes in gene expression in Giardia but cysts show a stronger response than trophozoites. Heat shock proteins, kinesins and Nek kinases are up-regulated, whereas alpha-giardins and histones are down-regulated in UV treated trophozoites.

Expression of variable surface proteins (VSPs) is changed in both trophozoites and cysts.

Our data show that Giardia cysts have limited ability to repair UV-induced damage and this may have implications for drinking- and waste-water treatment when setting criteria for the use of UV disinfection to ensure safe water. - Li, Dong, Stephen A. Craik, Daniel W. Smith, and Miodrag Belosevic. "Survival of Giardia lamblia trophozoites after exposure to UV light." FEMS microbiology letters 278, no. 1 (2008): 56-61.

- Linden, Karl G., Gwy-Am Shin, Gaetan Faubert, William Cairns, and Mark D. Sobsey. "UV disinfection of Giardia lamblia cysts in water." Environmental science & technology 36, no. 11 (2002): 2519-2522.

Abstract:

The human and animal pathogen Giardia lamblia is a waterborne risk to public health because the cysts are ubiquitous and persistent in water and wastewater, not completely removed by physical-chemical treatment processes, and relatively resistant to chemical disinfection.

Given the recently recognized efficacy of UV irradiation against Cryptosporidium parvum oocysts, the inactivation of G. lamblia cysts in buffered saline water at pH 7.3 and room temperature by near monochromatic (254 nm) UV irradiation from low-pressure mercury vapor lamps was determined using a “collimated beam” exposure system.

Reduction of G. lamblia infectivity for gerbils was very rapid and extensive, reaching a detection limit of >4 log within a dose of 10 JM-2.

The ability of UV-irradiated G. lamblia cysts to repair UV-induced damage following typical drinking water and wastewater doses of 160 and 400 JM-2 was also investigated using experimental protocols typical for bacterial and eucaryotic DNA repair under both light and dark conditions.

The infectivity reduction of G. lamblia cysts at these UV doses remained unchanged after exposure to repair conditions. Therefore, no phenotypic evidence of either light or dark repair of DNA damage caused by LP UV irradiation of cysts was observed at the UV doses tested.

We conclude that UV disinfection at practical doses achieves appreciable (much greater than 4 log) inactivation of G. lamblia cysts in water with no evidence of DNA repair leading to infectivity reactivation. - Mofidi, Alexander A., Ernest A. Meyer, Peter M. Wallis, Connie I. Chou, Barbara P. Meyer, Shivaji Ramalingam, and Bradley M. Coffey. "The effect of UV light on the inactivation of Giardia lamblia and Giardia muris cysts as determined by animal infectivity assay (P-2951-01)." Water research 36, no. 8 (2002): 2098-2108.

Abstract

This study measured the effect of germicidal ultraviolet (UV) light on Giardia lamblia and Giardia muris cysts, as determined by their infectivity in Mongolian gerbils and CD-1 mice, respectively.

Reduction of cyst infectivity due to UV exposure was quantified by applying most probable number techniques. Controlled bench-scale, collimated-beam tests exposed cysts suspended in filtered natural water to light from a low-pressure UV lamp.

Both G. lamblia and G. muris cysts showed similar sensitivity to UV light. At 3 mJ/cm2, a dose 10-fold lower than what large-scale UV reactors may be designed to provide, > 2-log10 (99 percent) inactivation was observed.

These results, combined with previously published data showing other protozoa and bacteria have similar, high sensitivity to UV light, establish that UV disinfection of drinking water is controlled by viruses which may require over 10-fold more UV dose for the same level of control.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-05-11 by (mod) Owner's Manuals & Contact Info for VIQUA UV Disinfectant Lamps & Advice on Glowing PVC pipe

@Fernando Garcia,

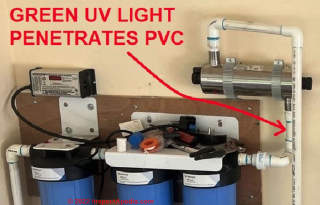

I have written to Viqua / Trojan Technologies showing them your photo of green light penetrating the PVC at your Viqua VH200 installation and asking advice.

We will post the company's reply here.

In case you don't have it, you can find the manual for your UV light system, the VIQUA VH200, in the list below.

I don't see any mention of PVC piping nor damage to PVC piping or leak risk from the effects of UV light in any of the manuals we found for these UV water "purifiers" - listed below.

The lamp used in these UV disinfection systems is branded Sterilight.

VIQUA UV Water Disinfection Equipment Manuals & Contact

- Contact: Viqua, 3020 Gore Road

London, Ontario, Canada

N5V 4T7

Tel: 1 (888) 220-6118 (North America) (+31) 73 747 0144 (Europe only)

E-mail: info@viqua.com

www.viqua.com

Viqua is a Trojan Technologies Company: Trojan Technologies 3020 Gore Road, London, Ontario, Canada N5V 4T7 www.trojanuv.com Email: residential@trojanuv.com 1-800-265-5774

US Contact: Applied Membranes, Inc., 2450 Business Park Dr., Vista, CA 92081 USA, Tel: (760) 727-3711 (760) 727-4427 Web: www.appliedmembranes.com Email: sales@appliedmembranes.com

Note: viqua.com auto-forwards to https://www.trojantechnologies.com/en/products/residential

The UV disinfection lamp systems below are powered by Sterilight. - TROJAN UVMAX UV WATER PURIFICATION SYSTEM MANUAL [PDF] Basic Models A, B4, C4, D4, E4, F4 Plus Models D4 Plus, E4 Plus, F4 Plus,

- VIQUA Sterilight UV LAMP BALLAST Re-Set Instructions - retrieved 2022/05/12, original source: https://www.uvo3.co.uk/how-to-reset-an-r-cansterilight-ballast/

Excerpt:

1. Turn off your UV ballast from the power.

2. Hold down the reset button on the side, keep it held down.

3. Now turn the main power back on.

4. Continue holding the reset button held - Wait for the RSET display and the single beep - after about a second

5. Release the reset button - VIQUA Hi-Flo UV LAMP & QUARTZ SLEEVE REPLACEMENT INSTRUCTIONS [PDF] Model: Hi-Flo

- VIQUA D-E-F-Series OWNER'S MANUAL UV Disinfectant Light [PDF] Model: D4 Premium, E4, F4 + Models: D4+, E4+, F4+, E4-50+, F4-50+ Validated Models: E4-V, F4-V D4-V+, E4-V+, F4-V+

- VIQUA D-E-F-Series INSTRUCTIONS + Discontinued Models [PDF] Models: D4, E4, F4, D4 Premium, Plus Models

Discontinued Models: A, B, C, D, E, F, B4, C4

Instructions for VIQUA lamp and quartz sleeve replacement. - VIQUA H, K, PRO UV MAX WATER PURIFIER MANUAL [PDF] Models: H, K Plus Models: H+, K+ PRO Models: PRO10, PRO20, PRO30, PRO50

- VIQUA S-Series OWNER'S MANUAL UV DISINFECTANT LIGHT [PDF] Models: S1Q-PA, S2Q-PA, S5Q-PA, S8Q-PA, S2Q-P/12VDC, S5Q-P/12VDC NSF Standard 55 Class B Validated Models: SV5Q-PA, SV8Q-PA

- VIQUA SQ-SS Sterilight Silver OWNER'S MANUAL [PDF] (2009) Models: D4, E4, F4, D4 Premium, Plus Models Discontinued Models: A, B, C, D, E, F, B4, C4

- VIQUA Tap, Home, Professional UV LAMP & QUARTZ SLEEVE REPLACEMENT [PDF] Models: Tap, Tap Plus, Home, Home Plus, Professional, Professional Plus (Excluding, D4,

E4, F4, and Plus and Monitored versions)

Distributed in the U.S. by Applied Membranes, Inc., 2450 Business Park Dr., Vista, CA 92081 USA, Tel: (760) 727-3711 (760) 727-4427 Web: www.appliedmembranes.com Email: sales@appliedmembranes.com

Excerpts:

Overview

UV Lamp replacement:

The amount of UV light created by the UV lamp decreases over time, requiring that the UV lamp be replaced. The system will automatically notify you when it is time to replace the UV lamp.

Quartz Sleeve replacement/maintenance:

Minerals in the water slowly form a coating on the quartz sleeve. This coating must be removed because it reduces the amount of UV light reaching the water, thereby reducing disinfection performance. If the quartz sleeve can not be cleaned, it must be replaced. - VIQUA UVMAX OPERATING MANUAL [PDF] Model: IHS22-E4 (see Applied Membranes contact information above.)

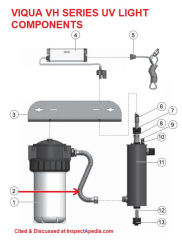

- VIQUA VH-SERIES OWNERS MANUAL UV LAMP [PDF] Models: VH200-F10, VH410-F20 425 Clair Rd. W, Guelph, Ontario, Canada N1L 1R1 t. (+1) 519.763.1032 • tf. (+1) 800.265.7246 (US and Canada only) t. (+31) 73 747 0144 (Europe only) • f. (+1) 519.763.5069 e-mail: info@viqua.com www.viqua.com

- VIQUA VT-SERIES UV WATER PURIFIER MANUAL [PDF] Models:

VT1, VT1/2, VT1/2A, VT1/2B, VT1/12

VT4, VT4/2, VT4/2A, VT4/2B, VT4/12

Note that the IO manual for this UV system shows use of a stainless steel flexible hose between a water sediment filter and the lamp's input port. [Red arrow in illustration excepted from the manual cited above]

This use may be simply a matter or connection convenience within a small working space.

On 2022-05-11 Fernando Garcia - Brand & Model Info for UV disinfectant system

@Inspectapedia Com Moderator, thanks for all your information; I’m attaching the pictures of the tags in the lamp and the ballast; I used leftover PVC pipes from the house construction and definitely they weren’t schedule 40.

In my next trip there I will bring some better means of conexión to prevent any leaks. I’m glad some of us are learning something new

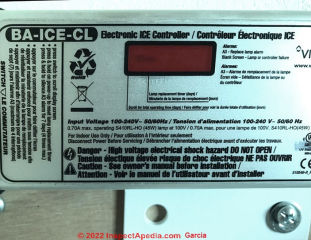

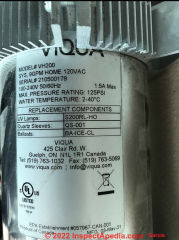

Above: the Sterilight UV ballast used with the VIQUA UV water purifier discussed here. Below: the data tag on Mr. Garcia's VIQUA VH200 UV Light system.

On 2022-05-11 by Inspectapedia (mod) - intense UV light from a water sterilizer shines right through white PVC water pipe

@Fernando Garcia,

@Fernando Garcia,

Mil gracias por su repuesta. Continuamos:

Thank you for the follow-up.

PVC piping can be affected by UV light exposure though just how serious is the effect depends on several conditions that we'll discuss here.

What we have not found reported before is your example of white PVC water piping being rendered transparent to intense UV light generated by the UV lamp in a water sterilizer system. .

A concern that might occur to one is that intense UV light exposure could make the piping a bit more fragile, giving rise to risk of a leak.

Research and opinions on the effects of UV light on PVC piping vary considerably depending on whose research we read and more-so on the UV light source.

1. Effects of sunlight exposure on PVC or CPVC piping

The sources that we reviewed all assert that there is little effect on the pipe by UV in sunlight other than a small decrease in impact resistance and possibly discoloration. Reduced impact resistance is not associated with a reduced ability of the pipe to withstand water pressure.

But those sources usually also recommend protecting PVC or CPVC used outdoors from sunlight exposure by various means (painting, shading, covering). A second type of PVC pipe, “furniture grade PVC pipe” , is said not to be harmed by sunlight.

1.a. Effects of fluorescent lighting on plastic pipe

The effects on PVC or CPVC of building lighting using fluorescent lamps is negligible.

Eight hours of exposure of PVC pipe to fluorescent light is equivalent to about one minute of exposure to sunlight. (XXX 1993)

2. Effect on PVC or CPVC pipe caused by exposure to UV light from a UV water disinfection or sterilizer system

More-difficult to find in research citations, nevertheless a reading of advice from companies who market UV disinfection systems for water treatment provides a strong warning that that much-more intense exposure to UV light may indeed weaken PVC or CPVC piping sufficiently to risk breakage and leaks.

At least some vendors of UV sterilizers for water systems specifically advise against direct-connection of PVC piping to the UV light itself. For example cleanwaterstore.com recommends and sells the Falcon stainless steel flexline, a water connector that should be connected to the UV light itself.

That can give 18” to 24” of stainless steel between the UV lamp and the PVC water piping. A shorter length may be adequate, depending on the piping routing and arrangement.

Shown here is a John Guest(tm) Push-to-Connect 3/4” x 18” stainless steel connector # PTC-PTC34-18 from Flacon Stainless, Inc., There are plenty of these stainless (or copper) flex-connectors available as they have been widely used on other water treatment equipment such as water heaters and water softeners for a long time.

(For example, to avoid heat damage, we don’t connect PEX tubing directly to a water heater.)

Above on this page you’ll see our use of green PVC pipe on a UV water treatment system installed in Central Mexico. Green PVC or CPVC is also made from PVC resin but is more flexible than standard PVC.

It can withstand higher temperatures than white PVC piping. We don’t yet know its resistance to UV light.

JM Eagle says that glue, green, or purple pipe will “sun-bleach.

Watch out: while UV lights are often used as a water disinfectant in lieu of injecting chlorine into the water supply, if your water supply does have higher chlorine levels, the combination of chlorine and UV light exposure may work together to weaken or damage the PVC piping.

Bottom line:

Effect of UV Treatment Light on PVC piping:

Where there is far-more intense exposure to UV, sufficient to actually shine right through the PVC pipe in your photo, the jury is out on the effect of that UV exposure on PVC piping right at the UV lamp itself but there are suggestions from industry that suggest using a metal section of pipe between the UV lamp and the PVC piping would be wise to reduce the risk of future leaks.

Recommendation:

use a short length of copper or stainless steel between your UV water sterilizer light and the PVC piping that connects to it. That should be able to eliminate the risk of PVC pipe damage and leaks due to UV lamp effects.

(Clear PVC pipe is described as UV-resistant. )

PPR Water Pipe UV-Resistance

A possible alternative is to use water pipe that is rated as UV-resistant, such as PPR Tuboplus Pipes produced in Mexico by Tubos Monterrey, by Rotoplas in Distrito Federal, Mexico, illustrated below.

A possible alternative is to use water pipe that is rated as UV-resistant, such as PPR Tuboplus Pipes produced in Mexico by Tubos Monterrey, by Rotoplas in Distrito Federal, Mexico, illustrated below.

PPR pipe is a rigid pipe made from Polypropylene Random Copolymer plastic, manufactured using a continuous extrusion process.

You can see in our photo that the pipe we used has a white interior tube that is protected by a UV-resistant green exterior sheathing.

In areas including ours in Central Mexico where it's common to install plastic piping outdoors, exposed to strong sunlight, this is a popular product.

PPR pipe connections are made by fusing fittings and pipe together using a hot-melt technique that has proven very reliable.

This green PPR piping is what we used at our UV disinfectant light system installed in Mexico illustrated above on this page. See details

at PPR PIPING GUIDE

Request:

Help our research by giving me the missing details of your UV light brand and model (and a photo of its data tag or logo) and photos showing clearly the brand and grade of the white PVC piping in your installation (one photo per comment).

Effects on PVC or CPVC pipe caused by exposure to UV light from sun or from UV water treatment equipment

A study by Uni Bell, a PVX pipe association, found that "... impact strength did not drop below that of most other pipe materials." - a bit of in my OPINION careful phrasing.

See

- Uni-Bell, EFFECTS of UV RADIATION on PVC PIPE [PDF] Uni-Bell PVC Pipe Association, 201 E. John Carpenter Freeway, Suite 750, Irving, TX 75062 USA

Tel: 972.243.3902 Email: info@uni-bell.org- retrieved 2022/05/11 original sourcewww.uni-bell.org/Portals/0/ResourceFile/the_effects_of_ultraviolet_radiation_on_pvc_pipe_.pdf - Uni-Bell, UV EXPOSURE HAS NO PRACTICAL EFFECTS ON PVC PIPE PERFORMANCE [PDF] Uni-Bell, Op. Cit., - original source: www.uni-bell.org/Portals/0/ResourceFile/uv-exposure-has-no-practical-effects-on-pvc-pipe-performance.pdf

We note that for much of the discussion of the effect of UV light on PVC piping, the source is not a disinterested party and we emphasize that none of these research papers have addressed the far-more intense exposure to UV light that occurs when PVC piping is connected directly to a strong UV light source such as that in your installation.

I note that the exposure to UV light from sunlight would be extremely small compared with the exposure of PVC piping to UV light immediately adjacent to an intense UV bulb's output in a UV water treatment system.

It's quite interesting that many sources state that UV light can not pass through PVC piping. But again I'm not sure they're considering intense UV light sources such as that of your installation.

In my next citation you'll see that there is some caution about the effects of UV on PVC piping, and again that the discussion and advice appear to focus on the much-lower exposure to UV from the exposure of PVC piping to sunlight.

- IS PVC and CPVC pipe UV RESISTANT? [PDF] (2007 - 2018) United States Plastic Corp.®, 1390 Neubrecht Rd., Lima, OH 45801 USA Tel: 800-809-4217retrieved 2022/05/11 original source: www.usplastic.com/knowledgebase/article.aspx?contentkey=774

Quoting in entirety:

Testing and past field experience studies have concluded that when conventional Type I, Grade I (Cell Class 12454) rigid PVC pipe is exposed to UV radiation from sunlight the following conditions have been noted.

The effects of exposure to UV radiation results in a color change to the product, slight increase in tensile strength, slight increase in modulus of elasticity, and a slight decrease in impact strength.

UV degradation occurs only in the plastic material directly exposed to UV radiation and to extremely shallow penetration depths (frequently less the 0.01”).

UV degradation does not continue when exposure to UV is terminated.

UV radiation will not penetrate even thin shields such as paint coatings, clothing, or wrapping.

Based on these studies, Harvel Plastic, Inc. recommends that PVC and CPVC piping products (i.e. pipe, duct, & shapes) exposed to the direct effects of UV radiation be painted with a light colored acrylic or latex paint that is chemically compatible with the PVC/CPVC products.

Compatibility information should be confirmed with the paint manufacturer. The use of oil based paints is not recommended.

When painting the effects of exposure to sunlight are significantly reduced, however, consideration should be given to the effects of expansion/contraction of the system caused by heat absorption in outdoor applications.

The use of light colored, reflective paint coating will reduce this affect, however, the system must also be designed and installed in such a manner to reduce the effects of movement due to thermal expansion.

It should be noted that Harvel’s standard formulation of PVC compound (H707) used in the manufacture of our rigid pipe contains 1-1/2% titanium dioxide (Ti02), a natural UV inhibitor. Harvel’s Corzan compounds used in the manufacture of rigid CPVC pipe contains at least 2% Titanium Dioxide (Ti02).

Harvel’s Clear PVC piping products do not contain UV inhibitors and should not be exposed to UV radiation.

One of several sources and research papers citing the observation that eight hours of UV exposure from indoor flourescent lighting is about equivalent to a minute of UV exposure to sunlight when outdoors.

- Klein, Rachel S., Robert M. Sayre, John C. Dowdy, and Victoria P. Werth. RISK of UV RADIATION fro INDOOR LAMPS [PDF] - original title "The risk of ultraviolet radiation exposure from indoor lamps in lupus erythematosus." Autoimmunity reviews 8, no. 4 (2009): 320-324. Copy below from NIH www.ncbi.nlm.nih.gov/pmc/articles/PMC2829662/pdf/nihms80064.pdf

Below: an Example of a stainless connector usable between the UV disinfectant lamp and PVC water supply piping - discussed above

- Falcon, CORRUGATED STAINLESS STEEL CONNECTOR [PDF], Falcon Stainless, Inc., 43153 Business Park Dr. Temecula, CA 92590 USA, Email: info@falconstainless.com Web: falconstainless.com Tel: 800-814-8444, push-to-connect tubing used with water softeners, water heaters, UV water treatment lamps,

On 2022-05-11 by Fernando Garcia

@Inspectapedia Com Moderator, hi. I will found more about the brand if the lamp; is in Costa Rica and is not a clear plastic pipe; I did the installation myself and we didn’t notice until the house caretaker took a night picture. Some how it’s glowing through the pvc. Thanks for your response

On 2022-05-10 by Inspectapedia Com Moderator (mod)

@Fernando G,

Please tell us the brand & model of your UV water treatment device and the country/city of location.

On 2022-05-10 by Inspectapedia Com Moderator (mod) - green glow from UV water disinfectant system penetrates PVC pipe

@Fernando G,

Are you sure that green light is new?

Is it possible that we are seeing a clear plastic pipe section below your UV lamp, intended to let the homeowner know that the light is on.

If you're asking about the color of your green UV light, indeed there are green UV light water treatment systems, sold as products that are reported to use less energy.

The difference in the UV light color is its wavelength:

- UV-Violet: 380–450 nm

- UV-Blue: 450–495 nm.

- UV-Green: 495–570 nm.

You can see that green UV isn't that far off from violet UV light - as little as 45 nm.

All of these disinfectant UV light frequencies are considered together in the ranges shown below.

(source cited just below. )

- IES Committee Report: GERMICIDAL ULTRAVIOLET (GUV) – Frequently Asked Questions IES CR-2-20-V1 [PDF] (2020) Illuminating Engineering Society,

120 Wall Street, 17th Floor, New York, NY 10005-4001 USA, Tel: +1 212-248-5000 Web: https://www.ies.org/ - original source: media.ies.org/docs/standards/IES-CR-2-20-V1-6d.pdf

ASTM Standard for PVC Plastic Pipe

I see from partial reading of the black print on your white PVC water pipe that it's compliant with US ASTM D1785. That helps identify your piping.

- Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120, ASTM, website: astm.org, retrieved 2022/05/11, original source: https://www.astm.org/d1785-12.html

Abstract

This specification covers poly(vinyl chloride) (PVC) plastic pipe, schedules 40, 80, and 120 for use with the distribution of pressurized liquids only.

This specification also includes classification criteria, nomenclature system, test methods, requirements, workmanship, dimensions, sustained pressure, burst pressure, flattening, extrusion quality, finish, appearance, and marking methods for PVC plastic pipe.

PVC pipe covered are marked with one of six type/grade/design stress designation and defined by four hydrostatic design stresses. PVC plastics are categorized by short-term and long term-strength tests.|

1.1 This specification covers poly(vinyl chloride) (PVC) pipe made in Schedule 40, 80, and 120 sizes and pressure-rated for water (see Appendix X1). Included are criteria for classifying PVC plastic pipe materials and PVC plastic pipe, a system of nomenclature for PVC plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, flattening, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials.

Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

On 2022-05-10 by Fernando G - Green glow penetrates PVC pipe in 3-month-old UV system

Is this normal in a system that is less than 3 months old? The green glow penetrates the PVC pipes

On 2021-06-26 by inspectapedia.com.moderator (mod)

@Don Chester,

Even with "new" water entering your tank (from a source you've not named) and even though you're treating it with a UV (light - not a "filter),

I wouldn't assume that the water storage you described is now nor remains free of contaminants, including bacteria; it'd make sense to include a disinfection system, including one like those described above.

On 2021-06-26 by Don Chester

Hi,

The house has a large tank in the loft (about 40 galls ) that feeds everything, this tank is fed by a pressurised system that goes through a UV filter; can we say how long this water remains safe to drink, the family only come down two or three times a year?

Regards,

On 2021-05-14 by danjoefriedman (mod) - where to buy 12V and 24VDC UV water treatment disinfectant light systems

@Michael.,

Thank you for asking a helpful question about the availability of 12V and 24VDC UV water treatment disinfectant light systems.

Certainly, you can find both 12V and 24V UV water treatment equipment from quite a few manufacturers. Below I paste in an example showing UV lights from MiniPure, MIghtyPure, and Sanitron. (There are others)

I clipped this shot from a third party vendor, https://purestfilters.com/, who distributes UV treatment systems from a slew of sources.

(to be clear: InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information for the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website. )

On 2021-05-14 by Michael.

We get our water supply from the fellside via a break tank.we are considering putting in a solar panel system for an electric supply which will be 12or 24 volts,

is it possible to run a u.v. System to treat our incoming water supply on either of these voltages.

On 2020-07-11 by danjoefriedman (mod)

Aaron

In general, any suspended particles or contaminants (such as iron) that cloud the water so as block or diffuse or refract light can interfere with UV treatment.

Phosphates, if over 100 ppb, can encourage algal growth that in turn can cloud the water.

On 2020-07-11 by Aaron Bond

What might be in my pool water that would drop its transmittanve to 93 percent as it passes through the UV filter chamber?

Do phosphates block UV light from penetrating through the water column?

On 2020-05-30 by danjoefriedman (mod) - cost to install an uv system to get rid of chemical contaminants?

Carol

A UV system will have no useful effect on chemical contaminants in water.

You will need to install a water treatment system specifically designed to remove chemical contaminants, such as reverse osmosis combined with charcoal filtration.

On 2020-05-29 by Carol

How much does it cost to install an uv system for a 4 bedroom house, 41 years old,

water constantly being compromised from round up, prodiamine, glyphosate, ethyl cyanide, lawn service products to keep up appearances where human/animal life is at risk.

Having all this contamination would an ultraviolet light be a good remedy?

On 2018-04-24 by danjoefriedman (mod)

Yes, for the ones that I have seen. I suspect your bulb is burned out. Of Course it also makes sense to check with the manufacturer.

On 2018-04-24 by Larry

Do uv lamps lite up the full length of the tube? Mine does not. Just on the ends.

...

Continue reading at UV ULTRAVIOLET LIGHT WATER TREATMENT REPAIR - troubleshoot and fix your UV light water treatment system, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see UV ULTRAVIOLET LIGHT WATER TREATMENT FAQs - questions & answers posted originally on this page

Or see these

Relate Articles

- FILTERS for DRINKING WATER PURIFICATION

- UV LIGHT BLACK LIGHT USES

- UV WATER DISINFECTION, PORTABLE for emergency or camping use

- DISINFECTION SYSTEMS, SEPTIC EFFLUENT where UV is also used

- TDS & TSS SOLIDS in DRINKING WATER - cloudy water is hard to disinfect by UV

- WATER QUALITY & QUANTITY San Miguel de Allende

- WATER TREATMENT EQUIPMENT DISINFECTION

- WATER TREATMENT EQUIPMENT CHOICES - home

Suggested citation for this web page

UV ULTRAVIOLET LIGHT WATER TREATMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER TREATMENT SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about choosing, installing, & maintaining or repairing UV light water treatment systems or "water purifiers"

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Aqua Pure is a 3M Company. CUNO Incorporated, 400 Research Pkwy, Meridien CT 06540 800-222-7880 or www.aquapure.com / www.cuno.com

- Siemens Ultraviolet Water Disinfection System, Sunburst - SBH series, 80 Commerce Drive, Allendale NJ 07401, 201-760-0364 or Siemens Headquarters, Water Technologies Group, 1901 West Garden Road, Vineland, NJ 08360

- Thanks to an anonymous reader for discussing water testing procedures following a UV light installation - 11 Sept 2009

- Hoff, John C., and Elmer W. Akin. "Microbial resistance to disinfectants: mechanisms and significance." Environmental Health Perspectives 69 (1986): 7.

- Qualls, Robert G., Michael P. Flynn, and J. Donald Johnson. "The role of suspended particles in ultraviolet disinfection." Journal (Water Pollution Control Federation) (1983): 1280-1285.

- Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- Principles and Practice of Disinfection, Preservation and Sterilization (Hardcover)

by A. D. Russell (Editor), W. B. Hugo (Editor), G. A. J. Ayliffe (Editor), Blackwell Science, 2004. ISBN-10: 1405101997, ISBN-13: 978-1405101998. - Handbook of Disinfectants and Antiseptics, Joseph M. Ascenzi (Editor), CRC, 1995, ISBN-10: 0824795245 ISBN-13: 978-0824795245 "The evaluation of chemical germicides predates the golden age of microbiology..." -

- When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues even when the public tap water is still flowing". Mr. Stein's website is www.whentechfails.com/

Water Supply & Drain Piping, Wells, Pumps, Water Supply Equipment

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Crystal Clear Supply provides portable ceramic water filter purifiers and portable reverse osmosis water treatment equipment - see http://www.crystalclearsupply.com/category_s/7.htm

- Handbook of Disinfectants and Antiseptics, Joseph M. Ascenzi (Editor), CRC, 1995, ISBN-10: 0824795245 ISBN-13: 978-0824795245 "The evaluation of chemical germicides predates the golden age of microbiology..." -

This well-focused, up-to-date reference details the current medical uses of antiseptics and disinfectants -- particularly in the control of hospital-acquired infections -- presenting methods for evaluating products to obtain regulatory approval and examining chemical, physical, and microbiological properties as well as the toxicology of the most widely used commercial chemicals. - Potable Aqua® emergency drinking water germicidal tablets are produced by the Wisconsin Pharmacal Co., Jackson WI 53037. 800-558-6614 pharmacalway.com

- Principles and Practice of Disinfection, Preservation and Sterilization (Hardcover)

by A. D. Russell (Editor), W. B. Hugo (Editor), G. A. J. Ayliffe (Editor), Blackwell Science, 2004. ISBN-10: 1405101997, ISBN-13: 978-1405101998. - U.S. Army Field Manual 21-10, Field Hygiene and Sanitation, 1988, web search 07/02/2010, original source: http://www.enlisted.info/field-manuals/fm-21-10-field-hygiene-and-sanitation.shtml

The purpose of this manual is to assist individual soldiers, unit commanders, leaders and field sanitation teams in preventing disease and environmental injuries. The manual provides information on preventive medicine measures (PMM) to the individual soldier as well as essential information for the unit commander, unit leaders, and the unit field sanitation team on applying unit level PMM. - When Technology Fails, Matthew Stein, Chelsea Green Publisher, 2008,493 pages. ISBN-10: 1933392452 ISBN-13: 978-1933392455, "... how to find and sterilize water in the face of utility failure, as well as practical information for dealing with water-quality issues even when the public tap water is still flowing". Mr. Stein's website is www.whentechfails.com/

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.