Code for Holes or Notches in Joists, Studs, Rafters

Code for Holes or Notches in Joists, Studs, Rafters

Permissible hole size & location in wood framing

- POST a QUESTION or COMMENT about permissible holes or openings cut into wood framing joist, studs, or rafters in residential construction

Where is it acceptable to cut holes or notches into wood framing members like joists or studs or rafters? Where can those cuts be located and where are they prohibited? How big or deep can we drill, saw, or notch a wood framing member?

This article answers those questions and includes citations to model and adopted building codes that guide builders in drilling or notching these wood framing members.

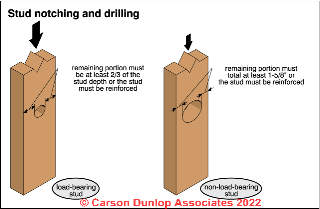

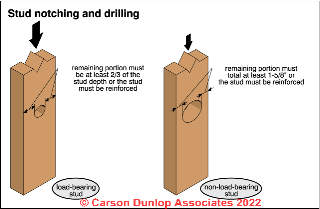

Page top illustration showing the basic rules for cutting holes in a load-bearing vs. non-load-bearing wood framed wall stud is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, report writing, & education company.

This article series describes wood framing construction, inspection, troubleshooting & repair, including both dimensional lumber (2x's) and also engineered lumber and beams.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Cutting Holes in or Notching Joists, Rafters, Studs, or the Web of Wood I-Joists

Here we discuss guidelines, codes, rules for notching or boring or sawing holes in wood joists.

Best construction practices plan pipe, wiring and duct runs to avoid notching or boring holes in wood framing, particularly in joists and rafters. Our photo shows how one builder did that, by routing ductwork either between or below these web trusses supporting a building floor.

But where such cuts can not be avoided, there are guidelines for the hole or notch location and its size.

If those hole or notch size and location guidelines can't be followed, typically additional framing or reinforcement will be required, ranging from something as simple as doubling a wall stud or ceiling or floor joist to more-complex framing and reinforcement workarounds.

Is It OK to Cut Holes in Floor Joists?

It is oK to cut a hole through the center of a floor joist, provided the hole diameter isn't too large for the depth of the framing member. We give specific hole size rules just below.

First two general rules

Holes or notches in wood framing have rules for size & location

Holes should be in the center of the wood framing member. Notches are allowed in the top or bottom edge of wood joists or rafters, but both of these types of cuts are limited by location in the member and by their size in diameter (for holes) or width and depth (for notches).

Use the actual, not nominal lumber dimensional depth or "D"

Watch out: the D or Depth of wood framing members like joists or rafters, as it should be used in these calculations of allowable hole diameter or notch dimensions, is the actual depth, not the nominal depth.

Example: a nominal 2x10 floor joist is actually 1 1/2 thick and 9 1/4" deep. So the "D" or "Depth" of this member is 9 1/4" (not 10").

As you'll read below, the maximum notch width in a floor joist is D / 3 so for a 2x10 that width is NOT 10/3 or 3.33" but rather it is 9.25 / 3 = 3.08" or as a practical matter, 3 inches, NOT 3 1/3 inches.

See details at DIMENSIONAL LUMBER SIZES

Hole Cutting Locations & Sizes in Wood Studs

In order to preserve the structural capacity of building framing, model codes such as the International Building Code IBC Section 2308 and the International Residential Code, Article R502.8 limit the size and location of holes cut in wood joists. Here is typical wording:

As Carson Dunlop's illustration shows above, re-states this rule and illustrates it: when cutting or drilling holes in wood studs to pass wires or plumbing, the hole should be centered, and the remaining portion of the wood must be at least 2/3 of the stud depth. If openings larger than this must be cut, the stud will require reinforcement.

Holes Bored in Studs

- Holes in the studs of a bearing wall can not be more than 40% of the stud width

- Holes in the studs of a non-load-bearing wall can not be more than 60% of the stud's width

- Notches in the studs of a bearing wall can not be more than 25% of the stud's width

- Notches in studs of a non-load-bearing wall can not be more than 40% of the stud's width

- The edges of holes drilled in studs must be at least 5/8" from the stud surface (this is to avoid a nail or screw penetrating a wire or pipe - see our note here about nail stop plates.)

Hole Cutting Locations & Sizes in Floor Joists & Flat Roof Rafters

Maximum hole size cut in a floor joist:

No structural member should be seriously weakened cutting or notching the member or by otherwise altering the framing member. The Carson Dunlop illustration shows that typical-allowed hole size in a load-bearing wall stud must leave 2/3 of the wood member's depth - or reinforce the member.

Holes Bored in Joists

- Holes bored in joists

shall not be within 2 inches (51 mm) of the top or bottom of the joist, and the diameter of any such hole shall not exceed one-third the depth of the joist. - Notches in the top or bottom of joists

shall not exceed one-sixth the depth and shall not be located in the middle third of the span.

Unusual Slots, cuts, holes, notches in joists or beams

Photo: a slot cut into a floor joist to clear the edge of a steel Lally column top plate tell us to be on the lookout for other strange, possibly improper cuts and notches in building framing in this home. Photo courtesy of home inspector DovBer Khan, cited below.

Mr. Kahn writes:

It appears that the beam was cut to support the columns, a construction detail that I've never seen before.

Nor have we.

Our opinion is that if this notch is in the left or right 1/3 of the beam it's probably oK, but as this is a non-standard beam or joist "hole" or slot, its analysis would require help from a licensed structural or civil engineer.

Minimum Hole Size in Studs or Joists

- When drilling a hole to pass an electrical wire through a stud or joist the hole should be 1/2" larger than the diameter of the wire.

Notch Locations & Size Restrictions in Wood Joists & Flat Roof Rafters

Notches have similar restrictions as the round holes we illustrated just above, with some additional detail that we recap here.

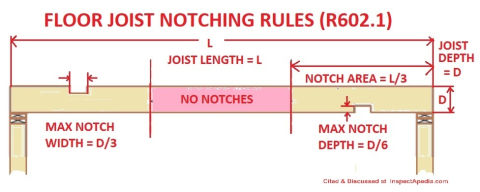

In the illlustration above, and referring to the U.S. R502.1.11 [IRC 502.8] Cutting, Drilling and Notching, note that the maximum notch depth is D/6 for members that are less than 4" in nominal dimension.

The notch must be in the 1/3 of ends of the member not in its middle third, and

the maximum notch width is D/3.

Floor Joist Notch Rules

- No notches are permitted at all in the center third of a horizontal joist, because cuts there will significantly-weaken the framing member(s).

- Notches may be cut in the 1/3 of the horizontal joist length at either end (or both ends) provided that:

- The notch horizontal width W is no more than 1/3 of the depth D of the framing member and that:

- The notch vertical depth is no greater than 1/6 of the depth D of the framing member

Floor Joist End Notch Rules

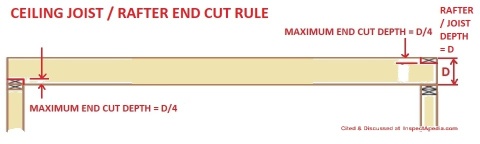

- Notches cut into a floor joist at its top or bottom either to recess a sill plate above or part of a top plate above, can be no greater in depth than 1/4 the depth D of the framing member.

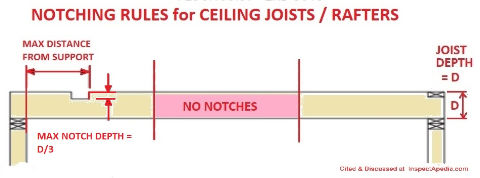

Ceiling Joists & Flat Roof Rafter Notch Rules

- No notches are permitted in the center third of a horizontal ceiling joist or roof rafter

- R 802.7.1 also gives the maximum allowed horizontal distance from a supporting wall or beam, typically 1/6 of the ceiling joist or flat roof rafter length.

End cuts are limited in the allowable depth to joist/rafter depth / 4 as illustrated below.

Watch out: protection for pipes, wires, or other components routed through notches in some cases through holes in wood framing will usually require extra protection from penetration by nails or screws.

Our photos below show a nail stop plate and nail stops installed to protect condensate drain and refrigerant piping in a wood framed wall where the installer drilled holes through the wall studs to pass those lines.

See details at NAIL STOPS to PROTECT WIRES

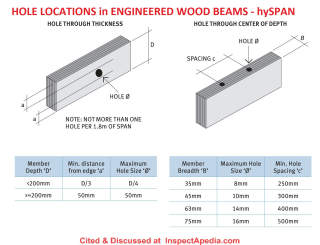

Hole Locations & Sizes in Engineered Wood Beams

Notches, cuts and holes in beams, bearers, joists and rafter members specified within this brochure may have penetrations and notches performed in accordance with AS1684.2, Clause 4.1.6 and the figure below from HySpan, cited below.

OK to cut holes in the Web of I-Joists

Generally it is permitted to cut round holes in the center of the web of a wood I-joist, depending on the specific guidelines of the I-joist manufacturer.

You should never cut nor notch the top or bottom chord.

The rules for allowable hole size depend on the I-joist dimensions and also on where in the run of the wood I-joist the hole is to be cut. For example, no holes may be permitted near the ends of wood I-joists.

Watch Out: common construction defects involving wood I-Joists include improper size or placement of holes cut in the I-joist web to permit installation of wiring, plumbing, or ductwork.

Improper location or size of holes, notches, or even removal of the center web can cause substantial weakening of the structure and are violations of both the manufacturer's instructions and building codes.

See STRUCTURE, ROOF DEFECTS LIST for details.

Below our photos of I-joists used to support a building floor illustrate how the builder avoided most cuts in the i-joist webs: flex duct and plumbing were laid out to move between I-joists rather than through them, and where an HVAC duct trunk line had to run at right angles to the I-joists the builder suspended it below the I-joists.

This was a much better solution than we found at a different job where the builder removed entire sections of I-joist web to run large rectangular HVAC ducts!

Research & References on Lumber Holes & Notching Codes & Rules

- Dindas, HySPAN® ENGINEERED WOOD PRODUCTS SPAN GUIDE for RESIDENTIAL FRAMING [PDF] hySPAN, CarterHolt Harvey Woodproducts, Australia, Dindas Australia, Dindas Victoria, Victoria 58 Whiteside Road, Clayton, Dindas New South Wales, New South Wales 138 Dunheved Circuit, St Marys, Didas Queensland Queensland 433 Wondall Road, Tingalpa Website: http://www.dindas.com.au/Tel: 1-800-808-131 VIC: (03) 8540 0500 NSW: (02) 9673 8000 QLD: (07) 3249 9888 retrieved 2020/03/04 original source: http://www.dindas.com.au/f.ashx/pdf/dindas-hyspan-span-tables-oct13.pdf

- FL, R502.1.11 [IRC 502.8] Cutting, Drilling and Notching [PDF] Florida Building COde 2014, adopting IRC 502.8 (given again below), authoritative source 2023/01/27 https://up.codes/s/irc-502-8-cutting-drilling-and-notching

Excerpt

R502.1.11.1 [IRC 502.8.1] Sawn lumber.

Notches in solid lumber joists, rafters and beams shall not exceed one-sixth of the depth of the member, shall not be longer than one-third of the depth of the member and shall not be located in the middle one-third of the span. Notches at the ends of the member shall not exceed one-fourth the depth of the member.

The tension side of members 4 inches (102 mm) or greater in nominal thickness shall not be notched except at the ends of the members. The diameter of holes bored or cut into members shall not exceed one-third the depth of the member. Holes shall not be closer than 2 inches (51 mm) to the top or bottom of the member, or to any other hole located in the member.

Where the member is also notched, the hole shall not be closer than 2 inches (51 mm) to the notch.

R502.1.11.2 [IRC 502.8.2] Engineered wood products.

Cuts, notches and holes bored in trusses, structural composite lumber, structural glue-laminated members or I-joists are prohibited except where permitted by the manufacturer's recommendations or where the effects of such alterations are specifically considered in the design of the member by a registered design professional.

- RC, CO, NOTCHING & BORING - IBC Section 2308 & IRC R502.8 - R802.7.2 Joists, Studs, Rafters, and Beams [PDF] Routt County, Colorado 522 Lincoln Avenue

Suite #30

Steamboat Springs, CO 80487

USA, Tel: 970-879-0108, Routt County building code as adoption of nthe International Building Code IBC, & the International Residential Code IRC - retrieved 2023/01/28, original source: http://www.co.routt.co.us/DocumentCenter/View/61/Notching-and-Boring-Allowances-for-Lumber?

Excerpts:

IBC 2308.8.2 Framing details.

Joists shall be supported laterally at the ends and at each support by solid blocking except where the ends of the joists are nailed to a header, band or rim joist or to an adjoining stud or by other means.

Solid blocking shall not be less than 2 inches (51mm) in thickness and the full depth of the joist. Notches on the ends of joists shall not exceed one-fourth the joist depth. Holes bored in joists shall not be within 2 inches (51 mm) of the top or bottom of the joist, and the diameter of any such hole shall not exceed one-third the depth of the joist.

Notches in the top or bottom of joists shall not exceed one-sixth the depth and shall not be located in the middle third of the span.

R502.8 Drilling and notching.

Structural floor members shall not be cut, bored or notched in excess of the limitations specified in this section. See Figure R502.8. R502.8.1 Sawn lumber.

Notches in solid lumber joists, rafters and beams shall not exceed one-sixth of the depth of the member, shall not be longer than one-third of the depth of the member and shall not be located in the middle one-third of the span.

Notches at the ends of the member shall not exceed one-fourth the depth of the member.

The tension side of members 4 inches (102 mm) or greater in nominal thickness shall not be notched except at the ends of the members.

The diameter of holes bored or cut into members shall not exceed one-third the depth of the member. Holes shall not be closer than 2 inches (51 mm) to the top or bottom of the member, or to any other hole located in the member. Where the member is also notched, the hole shall not be closer than 2 inches (51 mm) to the notch. R502.8.2 Engineered wood products.

Cuts, notches and holes bored in trusses, laminated veneer lumber, gluelaminated members or I-joists are not permitted unless the effects of such penetrations are specifically considered in the design of the member.

R602.6 Drilling and notching - studs.

Any stud in an exterior wall or bearing partition may be cut or notched to a depth not exceeding 25 percent of its width. Studs in nonbearing partitions may be notched to a depth not to exceed 40 percent of a single stud width.

Any stud may be bored or drilled, provided that the diameter of the resulting hole is no greater than 40 percent of the stud width, the edge of the hole is no closer than 5/8 inch (15.9 mm) to the edge of the stud, and the hole is not located in the same section as a cut or notch. See Figures R602.6(1) and R602.6(2).

Exceptions: 1.

A stud may be bored to a diameter not exceeding 60 percent of its width, provided that such studs located in exterior walls or bearing partitions are doubled and that not more than two successive studs are bored.

2. Approved stud shoes may be used when installed in accordance with the manufacturers recommendation. r

602.6.1 Drilling and notching of top plate.

When piping or ductwork is placed in or partly in an exterior wall or interior load-bearingwall, necessitating cutting, drilling or notching of the top plate by more than 50 percent of its width, a galvanized metal tie of not less than 0.054 inches thick (1.37mm) (16ga) and 11/2 inches (38mm) wide shall be fastened to each plate across and to each side of the opening with not less than eight 16d nails at each side or equivalent. See Figure R602.6.1.

Exception: When the entire side of the wall with the notch or cut is covered by wood structural panel sheathing

R802.7 Cutting and notching.

Structural roof members shall not be cut, bored or notched in excess of the limitations specified in this section. r

802.7.1 Sawn lumber.

Notches in solid lumber joists, rafters and beams shall not exceed one-sixth of the depth of the member, shall not be longer than one-third of the depth of the member and shall not be located in the middle one-third of the span. Notches at the ends of the member shall not exceed one-fourth the depth of the member.

The tension side of members 4 inches (102 mm) or greater in nominal thickness shall not be notched except at the ends of the members. The diameter of the holes bored or cut into members shall not exceed one-third the depth of the member.

Holes shall not be closer than 2 inches (51mm) to the top or bottom of the member, or to any other hole located in the member. Where the member is also notched, the hole shall not be closer than inches (51 mm) to the notch.

Exception: Notches on cantilevered portions of rafters are permitted provided the dimension of the remaining portion of the rafter is not less than 4-inch nominal 102 mm) and the length of the cantilever does not exceed 24 inches (610 mm).

R802.7.2 Engineered wood products.

Cuts, notches and holes bored in trusses, structural composite lumber, structural glue-laminated members or I-joists are prohibited except where permitted by the manufacturer’s recommendations or where the effects of such alterations are specifically considered in the design of the member by a registered design professional.

- IPC International Plumbing Code (2018), Appendix C, Structural Safety, Section C101, CUTTING, NOTCHING and BORING in WOOD MEMBERS [PDF] - retrieved 2023/01/28, original source: https://codes.iccsafe.org/content/IPC2018P5/appendix-c-structural-safety

- LVL LAMINATED VENEER LUMBER BEAMS [Web article]

- Dov Ber Kahn, a home inspector in Rockland County, NY has contributed photographs of various building features to InspectApedia. Mr. Kahn is a licensed home inspector in New York and New Jersey, and can be reached at Website: Kahnbhomeinspectors, Tel: 845-445-8234, Email: kdovber@googlemail.com

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2017-03-23 - by (mod) - running air vent ducts requires really big holes cut into joists

James:

Yep as Bernie Campbalik used to say as he'd make a sucking noise thorough his teeth, "They had guys like that back then too."

The return air ducting is particularly critical in that if the air handler is return-air starved the whole system will always be under-performing and operating at unnecessarily-high cost.

Depending on where you live, yes it's common and was permitted to use the space between floor joists as a return air passage - I'd want to be sure that space was clean of insulation, mold, insect debris, etc.

But I'm a little worried about a 4-inch hole through a typical floor joist - even cutting it at the center where it's doing the least harm.

Though it's a different product the concepts are the same as we discuss at CUTTING HOLES in WOOD I-JOIST WEBS [you are on this pagfe] - it's surprising to us beginners that the location of the hole means everything.

On 2017-03-23 by James Thornton

A part of the cold air return has not worked for 60 years. The first Forced Air Furnace ducting install put in, cut off the use of two cold air return vents. One of these vents is the cold air return vent from the second floor, living space.

To use the vents and connect the resulting vent to the rest of the Furnace Cold Air Return would require, say a 4inch hole in the center of the floor joist.

Continued for two joists. I figure I could sister 2 by 4's on the top and bottom and each side of the of the joists, glue and screws, to regain rigidness in the floor joist.

Is this allowed, and advisable. I want to use the joists to become the new extension to the cold air return that I never had.

This Q&A were posted originally

The design and content found at InspectAPedia.com® are © Copyright protected, All Rights Reserved. Contents of this website may not be copied in any form. Our main website topics listed at page top or at the MORE READING links at the bottom of this article provide in-depth, un-biased, expert information on building defect inspection, diagnosis, & repair.

...

Continue reading at FRAMING CONNECTORS & JOIST HANGERS for a discussion of special fasteners used when framing with wood I-joists,or select a topic from closely-related articles below, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FRAMING BLOCKING & BRACING

- FRAMING DAMAGE, INSPECTION, REPAIR

- FRAMING AGE, SIZE, SPACING, TYPES

- FRAMING CONNECTORS & JOIST HANGERS

- FRAMING FASTENERS, NAILS, SCREWS, & HIDDEN

- FRAMING AGE, SIZE, SPACING, TYPES

- I-JOISTS, WOOD ROOF, FLOOR

- LVL LAMINATED VENEER LUMBER BEAMS

- STRUCTURAL INSPECTIONS & DEFECTS - home

- STRUCTURE, FLOOR DEFECTS LIST

- STRUCTURE, ROOF DEFECTS LIST

- STRUCTURE, WALL DEFECTS LIST

- TRUSSES, FLOOR & ROOF

- WOOD STRUCTURE ASSESSMENT

Suggested citation for this web page

CUTTING HOLES in WOOD I-JOIST WEBS, JOISTS, RAFTERS, STUDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about selecting, specifying, & constructing with & defect inspections of wood I-Joists for building floors & roofs.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- APA - The Engineered Wood Association [Website: www.pacificwoodlaminates.com ], 7011 So. 19th St., PO Box 11700, Tacoma WA 98411-0700, Tel: 253-565-7265. APA provides an HDO/MDO Plywood Product Guide that offers details about these products., provides an HDO/MDO Plywood Product Guide that offers details about these products. Product support help desk: 253-620-7400. Email the APA at help@apawood.org. Web search 09/13/2010, original source: http://www.pacificwoodlaminates.com/img/PDFs/PlywoodGuide.pdf

- Paul Galow [Website galowconsulting.com ] - technical consultant on networking, LAN design, applications support. Galow Consulting Services [Website galowconsulting.com ] , 914-204-1749, email: paulgalow@galowconsulting.com

- John Rudy, Advantage Home Inspections, Flemington N.J. 08822 home inspector, 908-806- 6364, Home, Radon & Termite Inspections, Central & Parts of North New Jersey, email: jonadvantage1@yahoo.com

- Laminated Veneer Lumber, Overview of the Product, Manufacturing, Market, Department of Forest Products Marketing, wood-Based Panels Technology, Finland [PDF] web search 09/14/2010, original source: http://www.hochstrate.de/micha/finnland/reports/replvl.html

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Design of Wood Structures - ASD, Donald E. Breyer, Kenneth Fridley, Kelly Cobeen, David Pollock, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328

This book is an update of a long-established text dating from at least 1988 (DJF); Quoting:

This book is gives a good grasp of seismic design for wood structures. Many of the examples especially near the end are good practice for the California PE Special Seismic Exam design questions. It gives a good grasp of how seismic forces move through a building and how to calculate those forces at various locations. THE CLASSIC TEXT ON WOOD DESIGN UPDATED TO INCLUDE THE LATEST CODES AND DATA. Reflects the most recent provisions of the 2003 International Building Code and 2001 National Design Specification for Wood Construction. Continuing the sterling standard set by earlier editions, this indispensable reference clearly explains the best wood design techniques for the safe handling of gravity and lateral loads. Carefully revised and updated to include the new 2003 International Building Code, ASCE 7-02 Minimum Design Loads for Buildings and Other Structures, the 2001 National Design Specification for Wood Construction, and the most recent Allowable Stress Design. - Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Guide to Domestic Building Surveys, Jack Bower, Butterworth Architecture, London, 1988, ISBN 0-408-50000 X

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.