Electrical Wire Routing & Protection

Electrical Wire Routing & Protection

How to route & locate wires for an electrical plug outlet or wall plug

- POST a QUESTION or COMMENT about how to install and wire electrical outlets or receptacles in buildings.

How & where to route electrical wires when hooking up an electrical receptacle or wall plug or electrical outlet.

This article series describes how to choose, locate, and wire an electrical receptacle in a home.

Electrical receptacles (also called electrical outlets or "plugs" or "sockets") are simple devices that are easy to install, but there are details to get right if you want to be safe.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Electrical Wire Routing & Protection Requirements

Article Contents

- ELECTRICAL WIRE ROUTING & PROTECTION - Clearances from the nailing face of studs, joists, etc.

- NAIL STOPS / PLATES to PROTECT ELECTRICAL WIRE

- ELECTRICAL WIRE CLEARANCE DISTANCE from DUCTS or PIPES

- ELECTRICAL WIRE PROTECTION in METAL STUDS

- ELECTRICAL WIRE PROTECTION in METAL STUDS - CODE

- SOURCES of WIRE PROTECTION PLATES, BUSHINGS, GROMMETS etc

- ELECTRICAL WIRE PROTECTION & ROUTING REFERENCES / CODES

...

Routing, Securing & Protecting Electrical Wires

The electrical circuit wire must be properly routed and secured between the electrical panel and the receptacle location, and must be properly secured at the junction box that is to hold the electrical receptacle.

If the hole drilled through a stud or joist is within 1 1/4" of the stud or joist face then a nail plate is required. That's to assure that a drywall or paneling nail or screw won't penetrate the wire, causing damage or a short circuit or even a fire.

We secure wires at intervals specified by the electrical code so that it doesn't sag, hang, pull on itself, and become damaged or unsafe.

The sketches at page top and just above, courtesy of Carson Dunlop Associates, show examples of routing electrical circuit wires through a wood stud wall and through a wall supported by metal studs. Carson Dunlop Associates is a Toronto home inspection, report writing tool, and education company. More CDA sketches are below on this page.

The electrical circuit wire must be protected from damage.

We don't route electrical wires where they can be punctured by someone driving a nail into a wall to hang a picture.

...

Use Nail Stops to Protect Wiring & Pipes in Walls

Wires running in walls anywhere from floor level to seven feet above the floor (U.S.) or five feet above the floor (Canada) must be protected from nails driven through walls. Our photo (left) illustrates a 6-inch NS-2 Nail Stop produced by Simpson Strong-Tie. Simpson Strong-Tie describes these as Protecting Shield Plate Nail Stoppers.

We are showing the side of the nail-stop that will be in contact with the stud surface when it it tapped into place, providing 5 3/8" of 16-gauge steel that will protect electrical wiring (or plumbing pipes) from punctures by nails or screws driven into the wall when this nail stop has been placed on a wall stud over the point through which an electrical wire (or pipe -

see CONDENSATE DRAINS, CODES) has been passed.

Nail stops by Simpson Strong-Tie are made of 16-gauge steel, include sharpened protrusions that allow the plate to be tapped into place on stud surfaces, and are sold in 1 1/2" or 5-inch widths and in lengths ranging from 2 1'2" to 16 5/16". The most commonly-seen nail stop we encounter is the NS1 3-inch model.

Nail stops prevent penetration of fasteners into wiring or piping.

They are 16 gauge steel to meet the protection requirements of the code and feature a galvanized coating. Install with prongs or 8d common nails.[6]

Simpson Strong-Tie provides a Code Compliant Repair and Protection Guide that describes the company's range of protective and reinforcing steel devices to comply with the various building code requirements to protect wiring and plumbing from nail and screw fastener damage.

...

Electrical Wire Clearances from Ducts & Pipes

We also don't route wires too close to places where the wires can be damaged by heat from a heating appliance or chimney, flooded, etc. as you'll see depicted in the two Carson Dunlop Associates sketches below.

Watch out: We also recommend the same protection where pipes run through studs or joists. Or friend Ed Nisley recounted the messy wall leak that occurred when he was hanging a picture in a new home. The picture nail penetrated a copper water pipe. He heard a hissing noise. Then, Ed said, he made a bigger mistake: he pulled out the nail.

...

Routing Electrical Wiring Through Metal Studs

Reader Question: NMC cable pulled through metal studs without proper protection

Having a hard time with seller who framed the basement with metal studs, and pulled ROMEX through with no grommets or bushings.

Tried to explain that that Metal studs are SHARP and will eventually cut through the romex and short it (POW !), or make the studs live (ouch) I will trade pictures with you if you have some that will go with these.

These photographs are from the inspection. - B.S., Professional home inspector, 7/27/2014

Reply by Friedman (mod):

You are correct that wiring passing through metal studs require protection against damage.

You are correct that wiring passing through metal studs require protection against damage.

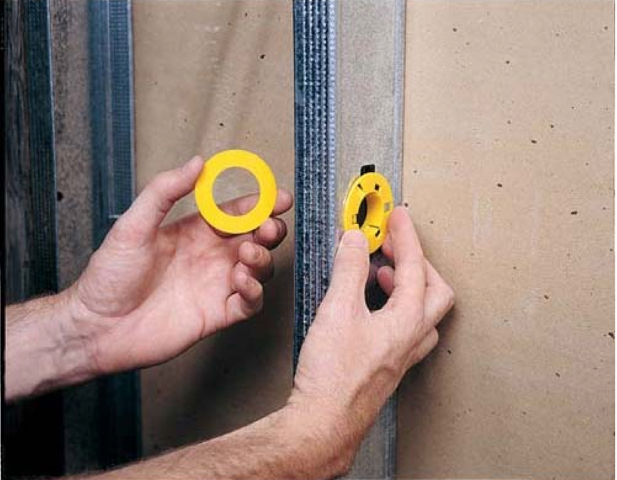

There are simple plastic snap-in wiring grommets or "bushings" that offer that protection and that would have been easy to install at the time of wiring and that can doubtless be retrofit now though if the installer has to cut the bushings to insert them around the existing wiring s/he will need to check with the acceptability of that bushing modification by callling the local electrical inspector for the jurisdiction.

Carson Dunlop Associates sketch of wiring passing through a metal stud (image, used with permision) just above in this article discusses this very topic.

The photo at left, courtesy Greenlee Corporation (www.greenlee.com) illustrates a plastic bushing PN 712A-1000 designed to protect wiring where it passes through metal studs.

Wiring through metal studs is a very common procedure as we know. In addition to using the larger holes shown in your photos, there is a punching tool (a metal stud punch) and plastic grommets to fit the punched holes so that wires can be run exactly where needed.

I'll post your photos along with images of the proper plastic bushings and send you the link.

...

U.S. Electrical Code for Wiring NMC through Metal Studs

Meanwhile, if we are reduced to having to cite code to tell some goofus what she or he ought to have known and done in the first place, see these NEC sections:

NEC 334.17 Through or Parallel to Framing Members.

Types NM, NMC, or NMS cable shall be protected in accordance with 300.4 where installed through or parallel to framing members.

Grommets used as required in 300.4(B)(1) shall remain in place and be listed for the purpose of cable protection.

and see

NEC 300.4(B) Nonmetallic-Sheathed Cables and Electrical Nonmetallic Tubing Through Metal Framing Members.

(1) Nonmetallic-Sheathed Cable. In both exposed and concealed locations where nonmetallic-sheathed cables pass through either factory- or field-punched, cut, or drilled slots or holes in metal members, the cable shall be protected by listed bushings or listed grommets covering all metal edges that are securely fastened in the opening prior to installation of the cable.

Canadian Electrical Code for Wiring NMC through Metal Studs

Canadian Inspectors needing code citations for protection of non-metallic-sheathed wiring will want to see the 12-19-11 Ontario Electrical Safety Code Bulletin

- BULLETIN 12-19-11 NON-METALLIC-SHEATHED CABLES (NMSC) WIRING METHODS, [PDF] Rules 2-034, 2-200, 4-004, 12-500 to 12-526, 12-3012 and 12-3022(3)", May 2012, (cited again below)

It is interesting that Rule 12-520 does not permit cables to be fished where metal joists, metal top or bottom plates, or metal studs are used.

Rule 12-516(2) permits the use of non-metallic-sheathed cable with metal stud construction.

Where NMSC is used in metal stud construction the following are installation requirements:

- Approved inserts (grommets) to protect the cable where it passes through the metal stud. The inserts referred to in Rule 12-516(2)(b) must be approved for the purpose and adequately secured in place.

- Round inserts are approved for a given size opening in a steel stud. If inserts are loose fitting or can be easily removed, they are not adequate for that installation and shall be replaced or installed in properly sized holes.

- The improperly installed inserts can lead to cable insulation failures. Installation of NMSC in steel stud construction will not be accepted where the standards of workmanship or the type of inserts used results in the inserts not staying in place.

- The cable must have adequate mechanical protection. Protection plates are required in all loca- tions where NMSC is within 32 mm from the edge of steel studs in accordance with Rule 12-516(1).

Thanks to Mike Holt for help with this topic. https://forums.mikeholt.com/

...

Sources of wiring protection, grommets, bushings for metal studs

Shown here: red plastic metal bushings or grommets for wiring through metal studs, provided by Clark Dietrich Co. cited below.

[Click to enlarge any image]

- Clark Dietrich www.clarkdietrich.com, plastic grommets for metal studs, as shown above.

- Greenlee, Website: https://www.greenlee.com/us/en/metal-stud-bushings Email: orders@greenlee.textron.com

techsupport@greenlee.textron.com, Tel: Canada: 800-435-0786, U.S.: 800-435-0786

Eample: Greenlee 712A100 Bushing for Metal Stud Punch, sold in bags of 1000, shown above,

GREENLEE GL-712A100 Bushings for Metal Studs are constructed of PVC (Poly Vinyl Chloride) which is fire and water resistant. The PVC bushings have a smooth finish all around allowing for quick and easy installation of all your cables without inflicting any damage.

Not only does the triple lock mechanism keep these bushings locked to 12 or 24 gauge metal studs but also prevents damage or abrasion from happening when bundling up to 10 electrical cables at once. These insulation rings are UL listed, CSA Certified and come with a 1 year warranty.

Illustration: red round and square plastic grommets for use in routing electrical wiring through metal studs, provided by Tyco, cited below.

- Tyco Electronics Corporation, TE Connectivity, Metal Stud Bushings Part # CPGI-ETD-RSS-BG-25 (bag of25 stud bushings) shown at left, also sold in other quantities and packaging.

Metal Stud Bushings fit existing round or square shaped holes in metal studs. Website: http://www.te.com, Tyco Quoting:

Can be used with any type of wire. Use these bushings to comply with paragraph 300-4b(1) of the 2005 NEC code.

...

Electrical Wiring Routing & Protection References

Illustration: Nail plates, guards, reinforcements in wood framing, from Simpson Strong-Tie's 2020 Code Compliant Repair & Protection Guide [PDF] cited below. [Click to enlarge any image]

Illustration: Nail plates, guards, reinforcements in wood framing, from Simpson Strong-Tie's 2020 Code Compliant Repair & Protection Guide [PDF] cited below. [Click to enlarge any image]

- BULLETIN 12-19-11 NON-METALLIC-SHEATHED CABLES (NMSC) WIRING METHODS, [PDF] Rules 2-034, 2-200, 4-004, 12-500 to 12-526, 12-3012 and 12-3022(3)", May 2012, - retrieved 7/27/14, original source http://www.esasafe.com/assets/files/esasafe/pdf/Sample_Bulletins/12-19-11.pdf.

- [3] NFPA - the National Fire Protection Association can be found online at www.nfpa.org

- [4] The 2008 NEC National Electrical Code (ISBN 978-0877657903) Online Access LINK https://catalog.nfpa.org/ (you'll need to sign in as a professional or as a visitor)

- [5] Special thanks to our reader Steve who pointed out prior errors in our illustrations.

- Simpson Strong-tie 2020 CODE-COMPLIANT REPAIR & PROTECTION GUIDE for the INSTALLATION of UTILITIES in WOOD FRAME CONSTRUCTION [PDF] (2020) Recommendations for the construction of building-code-compliant decks, Simpson Strong Tie®, retrieved 2020/11/23, original source: https://www2.strongtie.com/catalog_order.asp?site=SST where you can download any of a large collection of reference documents, catalogs, and product guides from Simpson Strong-Tie.

- [6] Simpson Strong-Tie, 2012 CODE COMPLIANT REPAIR AND PROTECTION GUIDE FOR THE INSTALLATION OF UTILITIES IN WOOD FRAME CONSTRUCTION [PDF] (2012) retrieved 5/21/12, original source strongtie.com/ftp/fliers/F-REPRPROTECT09.pdf,

Excerpt: The information in this guide is a summary of requirements from the 2003, 2006 and 2009 International Residential Code (IRC), International Building Code (IBC), International Plumbing Code (IPC), International Mechanical Code (IMC), 2006 Uniform Plumbing Code (UPC) and the 2005 National Electrical Code. - "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- "Basic Housing Inspection," US DHEW, S352.75 U48, p.144, out of print, but is available in most state libraries.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: ok to notch an electrical wire into the plaster wall surface?

2020/04/15

I have a new TV that I'm framing, so I can't have the wires exposed.

The problem is that I have a plaster and lath wall that doesn't really have any space for me to run cables behind it. In fact, the wall between my apartment and my neighbor's is a mere 2.5" thick.

So I had an idea. I would simply cut a 1" deep channel in the wall as a recess area for a square raceway, this would house the media and power cable till it gets to the media cabinet only 1.5 ft below it.

It'll be a short race, but is that up to code? - Anonymous by private email

Reply: Don't bury electrical wire hidden in a wall surface. Here is a better approach

No, not in my opinion, not unless you either provide a nail-proof metal shield over the entire passage or use steel conduit to keep someone from punching a nail through the wiring in the future.

Aside from violating electrial codes, in a more lay-person explanation, if you bury an elecrical wire just below the surface in a channel notched into plaster or drywall, then smooth it over so the wall looks nice again, the risk is that someone else, in the future, hangs a photo or something else on the wall by driving a nail or screw right through the wire. The risk then is fire or shock or worse.

But before you go to that trouble I'd consider snaking a wire through the wall cavity. Working on older plaster-lath homes I found that was pretty easy, especially on interior partition walls that are not blocked by insulation. For a case like yours, bringing power to a recessed wall cavity, you have to cut the wall open at that location anyhow.

So I might try snaking a wire down to the bottom of the wall.

There I pull off the wall-floor baseboard trim, open the wall as needed to route my power wire to a source, then put back the baseboard.

I've then avoided cutting and fooling with the plaster and my wire is safely inside the wall cavity where it is not so much at risk of a puncture by some future nail or screw driven innocently into the wall.

An alternative would be to route steel conduit in the wall surface and plaster over that, provided your electrical inspector will approve that installation.

Question: where to buy smaller 1 5/8-inch grommets for metal stud wiring?

I'm looking for grommets that will fit 1-5/8 metal framing stud. Anyone know of a website I can find smaller gromments? (Oct 7, 2017) E

Reply:

E:

Snap-in plastic grommets for use in metal studs and that will fit a 1 5/8" opening in the stud are widely available from electrical suppliers.

Shown here are red plastic 1 5/8" metal stud grommets made by Clark Dietrich www.clarkdietrich.com

Question: where to get square grommets for metal studs

When searching for Greenlee 712A100, I can only find the circular grommets. Is there a separate part number, specifically for the square grommets?

thanks in advance, (July 17, 2017) Kevin W

Reply: Greenlee, Tyco and other grommets or stud bushings for metal stud wiring safety

Kevin,

On the page above you will see square grommets for wiring through metal studs, produced by Tyco (and others).

All of the Greenlee grommets (plastic metal stud bushings) I found as well as grommet opening punches for use on metal studs (to run wiring) were round in shape.

I was unable to find the exact part you specified.

If you can send me photos of it and any packaging I'll research further. Use the page bottom CONTACT link

...

Continue reading at NAIL STOPS to PROTECT WIRES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ELECTRICAL RECEPTCALE WIRE CLEARANCE DISTANCES

- ELECTRICAL WIRE CLEARANCE FROM DUCTS & PIPES

- ELECTRICAL WIRE ROUTING SECURING & PROTECTION

- NAIL STOPS to PROTECT WIRES

Suggested citation for this web page

ELECTRICAL WIRE ROUTING SECURING & PROTECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Timothy Hemm has provided photographs of various electrical defects used at the InspectAPedia TM Website. Mr. Hemm is a professional electrical inspector in Yucala, CA.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- Thanks to InspectApedia reader Steve for pointing out erroneous illustration link details, now fixed.

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Simpson Strong-Tie, "Code Compliant Repair and Protection Guide for the Installation of Utilities in Wood Frame Construction", web search 5/21/12, original source strongtie.com/ftp/fliers/F-REPRPROTECT09.pdf, [copy on file as /Structures/Framing/Simpson_Framing_Protectors.pdf ]. "The information in this guide is a summary of requirements from the 2003, 2006 and 2009 International Residential Code (IRC), International Building Code (IBC), International Plumbing Code (IPC), International Mechanical Code (IMC), 2006 Uniform Plumbing Code (UPC) and the 2005 National Electrical Code."

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.