Wood Roof Shingle & Wood Shake Roof

Wood Roof Shingle & Wood Shake Roof

Installation Specifications: exposure, layout, nailing, stapling

- POST a QUESTION or COMMENT about wood shingle and wood shake roofs: installation, inspection, troubleshooting, maintenance, & replacement

Wood shingle & wood shake roof installation specifications:

This wood roof article describes the slope and exposure requirements for wood shake or wood shingle roofs, and provides detailed instructions on how and where to nail or fasten wood shingles/shakes on roofs.

We discuss the following: Nailing schedule for wood shingles/shakes. What types of nails or staples are used with wood shakes or wood shingles? What is the proper nailing pattern for wood shingle or wood shake roofs. Wood shingle exposure length table. Notes on side-lap wood shingle roofs.

Our page top sketch of wood shingle roof installation details is provided courtesy of Carson Dunlop Associates.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Slope and Exposure Tables & Nailing Details for Wood Shake & Shingle Roofs

As discussed in BEST ROOFING PRACTICES,

Recommended exposures for shakes and shingles on roofs are shown in Tables 2-13 and 2-14.

- Minimum slopes. The minimum recommended slope for standard installation of shingles is 3:12, and 4:12 for shakes.

- Low slopes. On lower slopes, shingles or shakes may be installed over a fully waterproof built-up roof (BUR) or membrane roof. Over the membrane, install vertical 2x4 battens lined up with the rafters, then spaced sheathing as described below.

- Climate factors. In warm, high-moisture climates, lowslope

wood roofs need extra maintenance, particularly

in areas with overhanging trees.

If pine needles, leaves, or other organic debris is allowed to accumulate on a shaded section of the roof, moss, lichen, and algae will grow and retain moisture. This, in turn, will lead to premature curling, splitting, and decay of the shakes or shingles.

Periodic wood roof cleaning, as well as chemical treatment, helps to avoid these problems

See WOOD ROOF MAINTENANCE or see page 93 in the printed text Best Practices Guide to Residential Construction). Pressure-treated shakes or shingles are recommended in these conditions.

- Adapted/paraphrased with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter on BEST ROOFING PRACTICES:

Wood shingle head lap in a good installation exposes no more than 1/3 of the shingle to the weather. The head laps are 6", 7", or 9" respectively for 16", 18" or 24" long shingles respectively. More details are

at WOOD ROOF INSPECTION GUIDE.

Wood Roof Shingle Exposure Specifications

Shingle exposures for wood roofs: the maximum weather exposure for wood shakes or wood shingles depends on the shingle size and the slope or pitch of the roof.

Allowable shingle exposure may also vary by the shingle grade - something that you might infer by visual inspection of the shingles, matching against wood shingle grade definitions, or if a shingle identification label can be located.

| Roof Slope or Pitch | Maximum Wood Shingle Exposure on Roofs |

||||||||

| 16" | 18" | 24" | 16" | 18" | 24" | 16" | 18" | 24" | |

| 3/12 - 4/12 | 3 3/4" | 4 1/4" | 5 3/4" | 3 1/2" | 4" | 5 1/2" | 3" | 3 1/2" | 5" |

| 4/12 & steeper | 5" | 5 1/2" | 7 1/2" | 4" | 4 1/2" | 6 1/2" | 3 1/2" | 4" | 5 1/2" |

Exposure specifications for wood shakes are detailed

at WOOD ROOF SHAKES INSTALLATION.

Wood Roofing Shingle Specifications & How are Wood Shingles Nailed onto a Roof?

Wood roof shingles are typically 16", 18" or 24" in length and up to 13" in width (but limited to 8" in width in some building codes).

Wood roof shingles are typically 16", 18" or 24" in length and up to 13" in width (but limited to 8" in width in some building codes).

Carson Dunlop Associates' sketch (left) illustrates the typical wood roof shingle application pattern.

The shingles are 4/10" to 1/2" in thickness, and wood shingles are installed with a 5" exposure (16" shingle length), 5 1/2" exposure (18" shingle length), or 7 1/2" exposure (24" wood shingle length).

The typical life of a wood shingle roof is 30-40 years, but life expectancy varies considerably depending on how the shingles were installed as well as on the pitch of the roof (its slope), and its sun and weather exposure. (Too much sun dries out the shingles leading to splitting, and too much shade may keep the shingles too damp, leading to rot.)

Shingle quality and shingle treatments (for example with preservatives or with protection against photoxidation) are important life factors as well. Wood shingles are installed on roofs with a slope of 6" in 12" for best performance but may be on a slope as low as 4/12.

Wood shingle nails need to be long enough to penetrate 1/2" (3/4" for the UBC) into the roof wood decking or nailing boards.

The diamond-shaped nail tip itself has no holding power, just the roofing nail shank. So if you see shingle nails protruding through a plywood roof deck, that is not an error.

Nails or Staples for Wood Shingles

Nail specifications for wood shingles may vary by wood species; using western red cedar as an example, nails are to be corrosion resistant hot dipped galvanized, stainless steel, aluminum, or copper

In dry climates, good quality electrogalvanized staples, conforming to ASTM A641, are satisfactory according to the Cedar Shake and Shingle Bureau, but from our field experience we prefer nails.

Also see additional warnings about using roof shingle staples in asphalt shingle roof jobs

at ASPHALT SHINGLE STAPLE vs NAIL.

Do not use blued steel or copper fasteners with cedar shakes or cedar shingles.

Wood shingle nailing pattern:

in most applications only two nails are used per shingle, in order to permit movement without splitting as the shingle expands and contracts during changes in its moisture level.

Keep nails about 3/4" to 1" (1" is for the U.B. Code), away from the side edges of the shingles and 1 1/2" (2" for UBC) above the butt line of the following course.

According to the Cedar Shake and Shingle Bureau, fasteners should be driven flush with the shake or shingle top surface, but no so deeply that the head crushes the wood.

For added details about proper wood shingle or wood shake roof installation,

perhaps the most authoritative source of wood shingle and wood shake information is from the Western Red Cedar Shingle & Shake Bureau (now the Cedar and Shake Shingle Bureau, since not only western red cedar is used for roof shingles).

Eaves Flashing Details for Wood Shingle & Shake Roofs

As stated in Best Practices Guide to Residential Construction (printed text) chapter BEST ROOFING PRACTICES:

Apply eaves flashing to either spaced or solid sheathing in regions with an average daily temperature of less than 25°F (under the IRC) or in other areas prone to ice and snow buildup.

The eaves flashing should extend up the roof to a point 24 inches inside the building. Where eaves flashing is required with spaced sheathing, install solid sheathing along the bottom section of the roof to support the eaves flashing.

Wood Shingle & Shake Nailing Guidelines

Continuing from from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

Continuing from from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

Fastener Specifications for Wood Shingle & Shake Roofs: Nails, Staples

All nails should be either stainless steel (type 304 or 316), hot-dipped galvanized, or aluminum. Staples should be either stainless steel or aluminum. Galvanized staples will not last the life of the roof.

Table at left - Best Practices Guide to Residential Construction

[Click to enlarge any image]

Treated wood roof shingles may require stainless steel or other special fasteners. Consult with the treatment company for recommendations. Stainless steel is also the first choice in coastal environments.

- Nails used with wood shingles or shakes should be box type and penetrate the sheathing by 3/4 inch (Table 2-15 above/left)

- Staples used on wood shingles or shakes should be of stainless steel and have crowns between 7/16 and 3/4 inch wide and penetrate the sheathing by 3/4 inch.

- Drive wood shingle nails flush. Do not drive nail heads or staple crowns below the surface of the shingle. Underdriving or overdriving weakens the shingle attachment.

- Placement of wood shingle nails.

Each shake or shingle should receive only two nails. Place one fastener 3/4 inch in from each edge and about 1 1/2 inches above the exposure line (Figure 2-50 below).

Stapling Schedule for Wood Shingles

The Cedar Shake & Shingle Bureau prefers ® the use of nails, however if you choose to use staples they must be stainless steel Type 316 in locations within fifteen (15) miles of salt water.

For locations outside of the salt water zone stainless steel Type 304 or Type 316 must be used. Each Certi-label shake or ® shingle shall be applied with two (2) staples.

Staples must be 16 gauge with crowns 7/16" minimum horizontal, maximum 3/4" horizontal to the Certi-label® shake or shingle butt.

...

Fasteners, two (2) per shake or shingle, shall be applied approximately 3/4" from the edge and approximately 1 1/2" above the exposure line.

Fasteners shall be long enough to penetrate into the sheathing at least 3/4" or all the way through.

Minimum nail lengths are shown in the fastener chart. Nails and staples must be driven flush with the surface of the Certi-label shake or shingle. ®

Overdriving the fastener can split and/or distort the Certi-label shake or shingle. - Cedar Shake & Shingle Bureau (2000) cited in detail cited below.

[Do not use electrogalvanized (EG) fasteners. ]

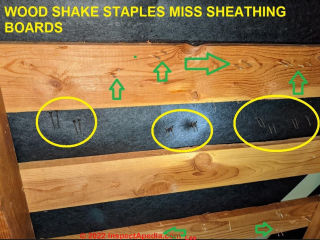

Question: effect of too many staples & staples that missed the roof skip-sheathing boards

Hope I can get an answer with a “current install”. Please see pics below.

Hope I can get an answer with a “current install”. Please see pics below.

- #1 Cedar Shakes, 24”, installed with existing skip sheeting and #30 tarpaper (pretty standard install).

- However, the roofers have “missed staples” in the skip sheeting in some localized areas (but these areas are NOT adjacent metal flashing/valleys.

- As a result, they have obviously put in way more than just “2” staples per cedar shake installed.

My question is, will these “staples that missed the skip sheeting” be a:

- Potential Leak Issue(s) over the life of the shake(s)?

- Does it weaken the integrity of the newly installed shake, with e.g. 4 staples (2 ‘landing on the skip sheeting, as 2 staples that are just piercing the tarpaper – effectively doing nothing to secure the shake. - Anonymous by private email 2022/07/04

[Click to enlarge any image]

Moderator reply: wood shingle or shake staples completely miss the skip-sheathing boards below - "staples" are just into roofing felt in some areas

1. For clarity: are we talking about sawn wood shingles or split wood shakes?

2. While I'm nervous about using staples in roofing, the worst staple problems occurred on asphalt shingles - discussed at https://inspectapedia.com/roof/Staple-vs-Nail-Asphalt-Shingles.php

3. What kind of staples were used? 1/2" stainless steel staples are permitted for wood shingle/shake installatin

In SIDING installations Aluminum or stainless-steel staples with 7/16-inch to 3/4 -inch crowns are also an option for red cedar shingles if accepted by local codes.

In wood shingle or shake roofing, typical instructions such as from Wasaka state

Materials:

Only corrosion resistant nails or staples shall be used in applying Eastern White Cedar shingles, hip and ridge units and starters.

Stainless steel (Type 304 or 316), aluminum, or hot-dipped zinc-coated steel nails and stainless steel staples have proven to give good service.

Bright or blued steel and electro-galvanized nails and staples are not recommended.

I agree that you raise a perfectly valid question. If too many Staples are shot through a wood product the danger is that it could split and ultimately therefore the roof could leak.

It would be very worthwhile for you to make a thorough inspection of the roof to see if you see any splits where it has extra Staples driven through.

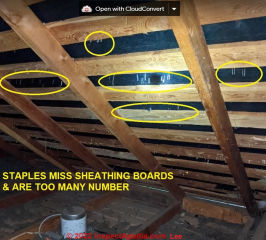

Reader follow-up: stapling details for ½” x 24” resaws, number 1 grade premium

Thank you for the reply, and your questions…

They are red cedar shakes, ½” x 24” resaws, number 1 grade premium. Attached pic.

The staple (box) indicates they are using “A11 Series Tacker staples” 3/8” Length. There is another set of numbers:

A1138

69x53x108

70. 5x54. 5x110. 5

Thanks for the tip on “inspection”

. Right now, the shakes are brand new install (and I see no evidence of them “splitting”, but seeing how they are sawn only ½” thick, I am worried that “blasting e.g. 4 staples” into them, is going to weaken their integrity, and perhaps leak as quickly as 3 to 4 years from now, with occasional walking on them, to clean the roof, as well as weathering.

To be frank, that’s the kind of concern I was hoping to get from unbiased-pros, (like yourself), that “experience” tells us, that it is “OK” or it is “NOT OK”?

Note that I contacted 5 local roofing companies today (here in the greater Seattle area) and 2 of the 5 actually talked to me over the phone, (the other 3 businesses ignored my request).

The 2 companies essentially said that “as long as the staples were not put in the keyways, you’ll be OK, shouldn’t leak”.

Again, I’m just very cautious (as the project is very expensive) and I’m still worried that the integrity of the “4 staple cedar shakes” are not going to last even a decade (but again, I don’t have any info to back this concern up with.

Yes, that would be great if you send the links, and I will study-up, to get as educated as I can on the subject matter.

Moderator Reply:

I see from label details in your third photo that these are Island Cedar Products Co. Red Cedar shakes, 1/2" x 24" ReSaws No. 1 Grade (Premium Select) Western Red Cedar .

1. Staple length:

As your shingles are 1/2 inch thick (13mm) an installer couldn't have been shooting through them with 3/8 long staples, (3/8" < 1/2") so something's wrong with your example data.

In your photos we see some staples that penetrate the skip-sheathing boards; those boards are typically 3/4" thick.

As your"sawn shakes" are 1/2" thick that means that to see the staple protruding through the sheating board the staples must be at least 1 1/4" long plus the length of exposed staple ends seen in the attic.

The staples shown through the felt and missing the sheathing boards are a long, (probabl 1 1/2" or so ) narrow-crown staple suitable and permitted by at least some wood shingle/shake suppliers.

But experts use no more than 2 staples per shingle or shake, regardless of shingle or shake width, and the staples that an experienced wood roofer might use would be stainless steel, 1 1/2" long x 1/2" wide (narrow-crown) 18-gauge.

FYI 18-gauge is just 1.024mm or 0.040 inches (1/20 ") in staple diameter.

Other staple dimensions

are the crown width and the gauge of the staple wire itself. The thin wire gaue

The staple fastener box in your photo above, stating that the A-11 Tacker Staples are 3/8" long could not describe the staples used on your roof.

More likely those 3/8" staples would have been used to staple down the roofing felt underlayment we see in your photos.

A Grip-Rite "slap hammer" tacker stapler like the one we show below uses A-11 / T-50 staples and is commonly used to staple down roofing felt.

2. On-Roof Examination Needed:

I don't think you can determine whether or not Staples are shot in the keyways OR gaps or side butt joints between the wood shingles without inspecting from the roof exterior surface. So we don't know where the staples are actually located.

The concern would be damaged to shingles such as shingles that have been split by an excessive number of staples. That's something you might be able to see by inspecting from the interior. If there are no splits, and considering how small and actual diameter of the arms of those staples are, it's not likely that the staple itself is going to be a leak point.

3. Watch out: When I see a roofing product that is flagrantly in disregard of the manufacturers installation instructions

I worry that the installer or one or more of the people on the crew were inexperienced, untrained, unsupervised.

There are a great many other possible errors that could have been made in installing a wood shingle roof, some possibly far more significant than the one that brought itself to your attention. That's why you need an expert roof inspection.

None of these is a reason to panic nor start calling lawyers, but it is a reason to have a more careful inspection of your roof.

Keep in mind that you may not get much help from the roof shingle manufacturer or supplier. Contrary to what you may think, they don't view you as their customer. The view roofer is their customer and they are understandably inclined to protect that company. .

Wood Shingle Installation Specifications

Whether installed over solid sheathing or spaced sheathing, follow these guidelines:

- For the starter course, double or triple the shingles in the first row.

- Each shingle gets two nails about 3/4 -inch in from each end, and 1 1/2 inches above the butt line of the overlaying shingle.

- The first course should overhang the fascia by 1 1/2 inches. All courses should overhang the rake by about 1 inch.

- Leave a gap of 1//4 to 38 inch between adjacent shingles for expansion when wet.

- Offset joints in successive courses by at least 1 1/2 inches (Figure 2-50 shown just above). Also, no more than 10% of joints should line up with joints in alternate courses (two courses away).

- Flat-grain shingles wider than 8 inches should be split into two shingles before installing.

- Treat knots, similar defects, and centerline of heart as if they were joints between shingles, and locate the defect 1 1/2 inches from joints in the row above or below.

Wood Shake Roof Installation Specifications: Felt Interlay or Felt Underlayment

Details for installing wood shake roofs are

at WOOD ROOF SHAKES INSTALLATION.

Details about felt underlayment requirements and wood shingle or shake course interlayment are provided

at WOOD ROOF SHEATHING, UNDERLAYMENT.

- Adapted/paraphrased with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter on BEST ROOFING PRACTICES:

Side-lap Wood Shingle Roofs

See

- Houston James & John N. Fugelso. FABRICATING AND INSTALLING SIDE-LAP ROOF SHINGLES IN EASTERN PENNSYLVANIA [PDF] APT bulletin, 33-41.

Quoting from that article:

In order to restore some of Pennsylvania’s historic buildings, the authors are recovering a lost trade practice.

Over the past decade of working on side-lap-shingle roofs, the authors have observed many earlier attempts by others to make the process of replicating these roofs faster and less expensive.

These attempts have included substituting materials, sawing and planing shingles rather than riving them to speed the manufacturing process, and adding other materials between courses to reinforce the roofing system.

All of these attempts have saved money and time in the short term but have failed to perform long enough to realize the savings.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-05-28 by InspectApedia-911 (mod) - effect on roof life of converting a Class-B wood shingle roof to Class A Fire Rating - blocked venting

@Ann,

Thank you for a helpful question.

Although doing so may be permitted by local codes, when you install wood shingles or shakes over any form of solid, un-vented support (for example by covering the venting provided by spaced nailers), you can expect a shorter wood shingle or shake roof life.

Some roofers install wood shingles on nailers or battens that are placed parallel to the eaves and ridge, on the theory that the space under the wood shingles permits some drying and longer roof life. That may be so, though I've not found research supporting that claim.

In my OPINION, giving up ventilation under wood shakes or shingles, particularly shingles (that lie more-flat and more-sealed on the roof) reduces the roof life.

- Moisture effects: Because air movement works not just by wind but by convection, horizontal battens block air flow under such a roof: the benefit of the 3/4" air space offered by the nailing battens may be minimal.

- Heat effects: Because of the blocked or reduced air movement through the wood shingle or shake layer the wood roofing also suffers more from heat gain during temperature extremes, also reducing shingle lif and causing cracks and bends

I'm researching the question further. Meanwhile see

- Bonura, Tony. Installation, care, and maintenance of wood shake and shingle roofs. Vol. 201. US Department of Agriculture, Forest Service, Forest Products Laboratory, 2011.

- Niemiec, S.S.; Brown, T.D. 1988. Care and maintenance of wood shingle and shake roofs. Corvallis, OR: Oregon State University Extension Service. EC 1271. (September).

- US FPL, WOOD HANDBOOK [PDF] U.S. Forest Products Laboratory, (2010) retrieved 2021/06/19 original source: https://www.fpl.fs.fed.us/documnts/fplgtr/fpl_gtr190.pdf

- Simpson, William, TenWolde, Anton, "Physical Properties and Moisture Relations of Wood", [PDF] from U.S. FPL, Forest Products Laboratory, Wood Handbook - Wood as an engineering material", 1999, Gen. Tech. Rep. FPL-GTR-113, Madison WI, U.S. Department of Agriculture (USDA) Forest Service, FPL. - retrieved 12/20/2014, original source: http://www.woodweb.com/Resources/wood_eng_handbook/Ch03.pdf

Read this text as Chapter 3 in the US FPL Wood Handbook cited above.

Watch out: without more-complete information, don't assume that your roof has been properly classified & approved as Class-A fire rated based only on the use of a Class A underlayment.

See details at

WOOD ROOF COATINGS & FIRE RATINGS https://inspectapedia.com/roof/Wood_Roof_Fire_Coatings.php

and at

FIRE RATINGS for ROOF SURFACES https://inspectapedia.com/roof/Shingle_Fire_Ratings.php

On 2022-05-28 by Ann

Does putting a Class A cap sheet under the class B treated wood shingles to achieve a Class A fire rated roof negate the needed ventilation for the wood shingles to last their expected lifespan? If yes, are there any workarounds? Thank you

On 2021-01-01 by (mod) - fix exposed nails on wood shingle roof?

Charlie:

They may not be an active leak but nail heads are generally a potential leak source where exposed to the weather; they belong under the shingle by an inch or more.

It's an easy fix mechanically: we slip a bit of flashing up under the shingles so that the nail head is covered. The flashing slides high enough to be under the lower edge of the next course of shingles above.

We use copper that will turn brown with weather exposure so as not to make shiny silver spots (aluminum flashing) that will spoil the look of the roof; or other colored flashing as appropriate.

Watch out: a few such exposed nails that are reached easily from a ladder at the roof edge would be a trivial repair. However; accessing, walking on an older wood shingle roof risks causing far more damage than the "maybe" problem that the inspector said should be "fixed. And the expense to work from padded supported ladders or scaffolding so as to protect the roof from damage could men spending a lot of money on a theoretical problem.

If that were my house I'd inspect in the attic very carefully to see if there are actually any leaks - from the exposed nails or from anything else.

If there are not leaks it would be better for you and frankly better for the new owner to keep people from walking on what may be a fragile roof surface.

The home inspect was right to point out that exposed nails are a *potential* leak source; she or he should have also cited any visual evidence that there are or have been leaks in the roof.

In my OPINION, except as I've explained above, I'd prefer to keep people off the roof, so I would not "fix" any "theoretical potential leaks" that have not shown any sign of becoming "an actual leak".

Calling for a "fix" for every possible problem that we find, may not have done the best job or sorting the important actionable findings from those to keep an eye upon.

Home inspectors, by training and experience, learn to pick up thousands of small clues that may (or may not) lead to important safety or cost concerns on buildings. Luckily not every single clue we find turns into a catastrophe. If the did we'd all be dead and Trump would be up for a second term.

A bit of caution and thoughtfulness at throwing your money at this observation might save you and the new owner aggravation and a large expense. That judgement would be, in my OPINION, the mark of a top notch inspector who earned their fee and more.

At OTHER PEOPLE's MONEY https://inspectapedia.com/home_inspection/Other_Peoples_Money.php

I explain the difficulty of giving the advice that is most-professional and, as part of the Rotary 4-way test, advice should be fair to all concerned.

On 2021-01-01 by Charlie

I have a rough saw cedar shake roof on my house that's 11 years old.

I'm trying to sell the house and a house inspector has seen some of the stainless steel nail heads between the shingles and is saying they should be "fixed," I have no leaks in my roof and wonder if these are a problem? Thanks

On 2020-08-20 by (mod)

Krys, in my OPINION, that's right, but roofing associations and standards and manufacturers indeed permit the installation of wood shingles on solid plywood roof decking.

Some procedures call for using furring strips to provide an air space.

In my field experience I certainly saw wood shingles nailed directly to solid plywood roof decks and I saw that invariably those roofs had a notably shorter life. Wood shingles and shakes will last better and longer if they can breathe.

On 2020-08-20 by Krys

I read that cedar shakes should not be put onto a plywood base roof because wood will not set and breathe.

Is this correct, and if so what are the options if I do not want to use the synthetic mesh some places sell as an underlayment.

On 2016-08-23 by (mod)

Good question, Ed. I don't know the answer and haven't come across a mixing specification. The cedar shingle bundles that I've opened were usually rather homogeneous in color, and I think we figured that on the roof shingles would weather to a more uniform color rather quickly.

Take a look at the wood shingle and shake installation guide from the Cedar Shake and Shingle Bureau (or use our page bottom CONTACT link and we can send you a copy) http://www.cedarbureau.org/

The word "mix" doesn't appear in that document, though the experts do discuss color:

Note: Cedar’s natural color varies as shown in these examples, yet without applying a paint or stain it will all weather to a beautiful gray

Mark:

In nailing roofing to a solid plywood roof deck roofing specifications assume you're using 1/2" CDX plywood sheathing and that the nails must protrude through the plywood at least past the entire point of the nail to the beginning of the shank. Otherwise you risk shingle blow-off.

You could use thicker plywood or you could install over thicker wood-furring.

Separately, wood shingles directly atop solid plywood, while permitted by the authorities, is not a great practice as the absence of ventilation on the shingle underside argues for a reduced roof life.

On 2016-08-23 by Ed

Mixing cedar shingles before they are installed to ensure color variation is evenly distributed--- is this commonly known as a requirement for cedar roofing practice?

On 2016-02-02 by Mark

In my previous question, I meant to say, so nails don't show through.

If I want to roof an open porch roof with cedar shingles, what thickness does the sheathing need to be so no nails show through.

The porch sheathing is the ceiling and gets painted. It is now beaded 1X6's but a lot of them need to be replaced, and I can if necessary, use 2X6's put a bead on one edge, and nail the shigles. Would that work?

Question: Is it okay to install a roof paper, then cedar breather when using shakes?

(Dec 7, 2012) Jarod said:

Is it okay to install a roof paper, then cedar breather when using shakes? I see details showing the felt underlay method. How time consuming.

(Apr 1, 2014) phil said:

Can I install red cedar shingles on roof with 1/2 plywood or should I add 1x6 strapping on plywood and then

install cedar shingles?

Reply:

Jarod and Phil,

From what I've learned of this topic, codes permit installing wood shingles atop solid plywood roof decking but in my field experience I see early failures where the roof is poorly vented. In my OPINION a better roof job uses strapping to allow airflow beneath the shingles.

...

Continue reading at WOOD ROOF FLASHING DETAILS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIRE RATINGS for ROOF SURFACES

- SIDING WOOD SHINGLE INSTALLATION - best practices

- WOOD ROOF COATINGS & FIRE RATINGS

- WOOD ROOF FLASHING DETAILS

- WOOD ROOF INSPECTION GUIDE

- WOOD ROOF INSTALLATION SPECS

- WOOD ROOF MAINTENANCE

- WOOD SHAKE & SHINGLE ROOFING - home

- WOOD ROOF SHAKES INSTALLATION

- WOOD ROOF SHEATHING, UNDERLAYMENT

- WOOD ROOF SHINGLE PROPERTIES

- WILDFIRE DAMAGE PREVENTION for HOMES

Suggested citation for this web page

WOOD ROOF INSTALLATION SPECS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Cedar Shake & Shingle Bureau, CSSB, U.S.: Sumas, WA 98295-1178, Tel: 604-820-7700, In Canada:

Cedar Shake and Shingle Bureau #2 - 7101 Horne Street, Mission, BC V2V 7A2 Tel: (604) 820-7700, E-mail: info@cedarbureau.com , website: http://www.cedarbureau.org/

CCSB offers wood shingle installation instructions in the form of a manual - cedarbureau.org/installation/wall_manual/introduction.htm - "Treatment of Cedar Shakes and Shingles," David Flickinger, RRO, Professional Roofing, October 1999, Rosemont IL.

- "Fabricating and Installing Side-Lap Roof Shingles in Eastern Pennsylvania", James Houston & John N. Fugelso, Web Search 07/12/2010

- "From Asbestos to Zinc, Roofing for Historic buildings, Metals-part IV, Wood", Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source:

http://www.nps.gov/history/hps/tps/roofingexhibit/slate.htm - Sharon C. Park, Preservation Brief 19: The Repair and Replacement of Historic Wooden Shingle Roofs (Washington, D.C.: U. S. Dept. of the Interior, 1989), 6.

- Johan Heinrich Jonas Gudehus, “Journey to America” (1829), trans. Larry M. Neff, re-printed in the Publications of The Pennsylvania German Society 14 (1980), 307. “The houses of the Americans as well as their farm buildings have wooden shingle roofs that are so thick and solid that a ray of light can come through nowhere. These roofs are painted red, brown or dark blue with oil color and on most of them is to be found a lightning rod…”

- Robert C. Bucher, “The Long Shingle,” Pennsylvania Folklife 18, no. 4 (summer 1969): 51–56. This article was the first study of side- lap shingles and the primary source of basic information for "Fabricating and Installing ... " above.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Wood Shingle Roofs, Care and Maintenance of wood shingle and shake roofs, (EC), Stanley S. Niemiec (out of print)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.