Synthetic Roofing Slate Asbestos

Synthetic Roofing Slate Asbestos

Do manufactured / synthetic slates contain asbestos?

- POST a QUESTION or COMMENT about buying roofing slate & slate roofing tools

Here we discuss the presence of asbestos in some but not all synthetic slate roofing products.

This article series describes procedures for evaluating the condition of slate roofing. How to inspect, identify defects, and estimate remaining life of slate roofs are addressed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Is There Asbestos in Manufactured / Synthetic Roofing Slate?

Question: should I be concerned about asbestos in this roofing slate?

Question: should I be concerned about asbestos in this roofing slate?

... this particular tile (see enclosed pictures and below) looked to me like natural slate, but when I looked closer at the broken edge, I could see fibrous material embedded therein.

Could this be asbestos-containing fiber cement, do you think, and if so, what would you recommend doing with this broken slate?

Is it ok just to double-bag it and throw it away - is it considered a risk if left where it is?

Any suggestion or explanation would be much appreciated.

- Anonymous, Dorset, UK, by private email 2018/08/27

Reply: yes in some older products, not all

You're right that the slate roofing product in your photos is man-made, not a natural true-slate material - slate would be apparent as a layered material;

In most but not all natural or quarried slate you can see the layers that comprise the slate, as it was mined from a slate quarry, in this photo from our article SLATE ROOF LIFE EXPECTANCY

You can see the fine layers visible in the edge of any natural slate material.

Watch out: some slate, depending on its quarry of origin, may be more stone-like and may not show layering. Below is a natural slate from the Quarry Armadilla. Benuza (León) Spain and distributed also in New Zealand (cited below).

In your fiber-cement or synethtic slate product shown earlier and and in a closeup just below, I too, see the homogenous, solidified, particulate-based material with some fibers in the broken edge of your product - to be expected in a manufactured slate product, though there is at least one polymer-based synthetic roofing slate that also has a layered-look to the product's edge (described below).

That does not mean you'd assume the slate contains asbestos as fibers could be fiberglass, cellulose, or something else. In any event it's not a friable material.

If you know the country and city of origin of the material and its manufacture date that will place it in or out of the era when asbestos might have been used.

Furthermore, even if the manufactured-slate does contain asbestos that's no reason to be frightened of it.

Unless you're grinding or sawing the material it's doubtful that there is a detectable particle release in the air around the broken slate. You should be able to dispose of a broken slate as construction debris.

Test for Asbestos in a 28-year old Omaru New Zealand Roof

Above, the Heritage Court Motor Lodge, Omaru, New Zealand sports buildings using an older synthetic "slate" that was, at the time of our inspection, quite worn and deteriorating. We wanted to know if these building roofs contain asbestos.

These contemporary fibre cement products use filler and reinforcement that does not include asbestos, commonly fibreglass. What about the shingles shown just above?

They were installed in 1986 and were photographed (above) in 2014, making them 28 years old. We were told by a tenant that the building owner received a settlement on this roof but has not replaced it. Lab samples of this roof cladding were tested, and results are now available.

Above: preparing our synthetic slate sample for mailing to a certified asbestos test lab.

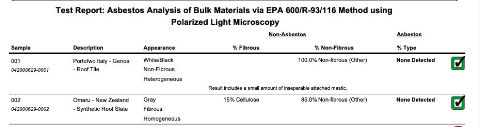

Below: lab test results, using PLM, asbestos was not detected. [Click to Enlarge Any Image]

This roof is also discussed at ASBESTOS & FIBER CEMENT ROOFING

- ASBESTOS TEST RESULTS SUMMARY [PDF] 2020/01-18-20, Test Report: Asbestos Analysis of Bulk Materials via EPA 600/R-93/116 Method using Polarized Light Microscopy EMSL Ord No. 042000629 2019-12-26 for samples No. 001-005 and 008-015.

For samples 001-005, and 008-014

Sample No. 01: see details at TEST of CEMENT ASBESTOS ROOF SHINGLE for ASBESTOS - Portofino Italy, fiber cement roof

Sample No. 02: see details at MANUFACTURED / SYNTHETIC SLATE ASBESTOS CONTENT - Omaru New Zealand, synthetic slate roof - ASBESTOS TEST REPORT: Asbestos Analysis of Non-Friable Organically Bound Materials by TEM via EPA/600/R-93/116 Section 2.5.5.1 [PDF] 2020/01/22 Test Report: Asbestos Analysis of Non-Friable Organically Bound Materials by TEM via EPA/600/R-93/116 Section 2.5.5.1

For samples 001, 010, 011 - Contact: EMSL Analytical, Inc., 200 Route 130 North, Cinnaminson, NJ 08077 USA, Tel: 856-303-2500 - Fax: 856-786-5974 - Toll Free: 800-220-3675

Lab Hours: Mon-Friday 7AM-10PM, Saturday 8AM-5PM, Sunday On-Call. - ASBESTOS TEST LABS in the USA - EXAMPLE REPORTS - provides fourteen example asbestos test results from EMSL

History of Use of Asbestos in Manufactured or Artificial-stone slabs, Shingles, Plates and Roofing Slates: 1900 - 2018

Asbestos was used in fiber cement products including both roofing and siding materials - as we detail

Asbestos was used in fiber cement products including both roofing and siding materials - as we detail

at ASBESTOS & FIBER CEMENT ROOFING.

Focusing more-specifically on artificial slate or artificial stone such as synthetic slate we cite below some research on asbestos-slates and patents describing products that used asbestos in artificial slate or stone beginning in North America as early as 1917 and by 1978 was widely used in manufactured slate and stone products including roofing materials.

By 1979 most countries had stopped producing asbestos-based artificial slates or roof tiles.

For example New Zealand had banned the use of asbestos in such materials in 1979.

MacMillan (2018), a New Zealand slate roofing company, notes that in that country "asbestos slates" or "artificial slates" had been used from the early 1900s until 1979, followed by fibre cement artificial slates (ca 1980-1988) that did not perform well, failing after just a few years.

You can see that performance in the New Zealand synthetic slate photos shown above on this page.

Reconstituted slate tiles, or composite slate, also referred to as "man made slate" may use recycled "slate spoil" - old slates removed from buildings, mixed with a binder - were produced in New Zealand from about 1985 to 1995 when those products, too, showed early product failures leading to their withdrawal from the marketplace.

McMillan says that the resins in these manmade slates were found to be broken down by UV light exposure.

By 1997 and probably earlier, US patent disclosures for synthetic slates did not include asbestos. Resins and plastics, reinforced with fiberglass or other non-asbestos fibers were common.

At MANUFACTURED / SYNTHETIC SLATE we list current man-made slate producers and indicate what those manufacturers say about the composition of their current product lines.

Is it slate, manmade slate, asbestos slate, fiber cement slate, or something else?

Watch out: because of looseness with which people use the terms shingle, roof tile, roof slate, some discussions of asbestos-cement "Slates" may refer to other asbestos cement roofing products that look nothing like slate.

Those non-slate products are discussed separately

at ASBESTOS & FIBER CEMENT ROOFING - home

In the U.S. asbestos-based artificial slate or cement asbestos roof tile production based on the use of asbestos-cement as the primary material was winding down by the 1980s. Asbestos cement roofing shingles, tiles, or "slates" performed well for decades.

Watch out: a number of non-asbestos manufactured or synthetic slates or fiber-cement roof shingles, slate, tiles that were produced when manufacturers stopped using asbestos were made using wood fibers or other materials. A number of these products, promising a life of 50 years or longer, were found to fail early in their life in the 1990s. Just about all of these products are no longer sold (in 2018).

See details at FIBERBOARD ROOFING & FIBER-WOOD ROOFING.

Research on Manmade Slate History

Below we cite research articles and patents that help track the earliest and latest uses of asbestos in manufactured / synthetic roof slates.

- ASBESTOS & FIBER CEMENT ROOFING - home - see citations and references in each of the articles in that article series.

- Fukuwatari, Tadashi, Kiyotaka Mishima, Hiroshi Ichimura, and Hideaki Kurihara. "Fiber reinforced cementitious substrate." U.S. Patent 4,085,001, issued April 18, 1978.

- Gualtieri, A. F., C. Cavenati, I. Zanatto, M. Meloni, G. Elmi, and M. Lassinantti Gualtieri. "The transformation sequence of cement–asbestos slates up to 1200 C and safe recycling of the reaction product in stoneware tile mixtures." Journal of hazardous materials 152, no. 2 (2008): 563-570.

Abstract:

Cement–asbestos is the main asbestos containing material still found in most of the European countries such as Italy. Man- and weathering-induced degradation of the cement–asbestos slates makes them a source of dispersion of asbestos fibres and represents a priority cause of concern.

This concern is the main prompt for the actual policy of abatement and disposal of asbestos containing materials in controlled wastes. An alternative solution to the disposal in dumping sites is the direct temperature-induced transformation of the cement–asbestos slates into non-hazardous mineral phases.

This patented process avoids the stage of mechanical milling of the material before the treatment, which improves the reactivity of the materials but may be critical for the dispersion of asbestos fibres in working and life environment. For the first time, this paper reports the description of the reaction path taking place during the firing of cement–asbestos slates up to the complete transformation temperature, 1200 °C.

The reaction sequence was investigated using different experimental techniques such as optical and electron microscopy, in situ and ex situ quali-quantitative X-ray powder diffraction. The understanding of the complex reaction path is of basic importance for the optimization of industrial heating processes leading to a safe recycling of the transformed product.

For the recycling of asbestos containing materials, the Italian laws require that the product of the crystal chemical transformation of asbestos containing materials must be entirely asbestos-free, and should not contain more than 0.1 wt% fraction of the carcinogenic substances such as cristobalite.

Moreover, if fibrous phases other than asbestos (with length to diameter ratio >3) are found, they must have a geometrical diameter larger than 3 μm. We have demonstrated that using an interplay of different experimental techniques, it is possible to safely verify the complete transformation of asbestos minerals in this temperature-induced process.

The product of transformation of cement–asbestos (CATP) has a phase composition similar to that of a natural or a low temperature clinker with the exception of having a larger content of aluminium, iron and magnesium.

This product can be safely recycled for the production of stoneware tile mixtures. The addition of 3–5 mass% of CATP does not bear significant variations to the standard parameters of white porcelain tile mixtures. - Gualtieri, A. F., and G. Elmi, UNDERSTANDING THE HIGH TEMPERATURE REACTION SEQUENCE DURING THE THERMAL TREATMENT OF CEMENT-ASBESTOS SLATES [PDF]

In Proceedings of the European conference on asbestos risks and management ARAM, Rome, vol. 4. 2006.

Excerpts from conclusion:

The study of the transformation of cement-asbestos slates must consider the complexity of the system as the high temperature reactions taking place greatly differ from the reactions regarding the pure asbestos minerals. - Kim, Young-Chan, Byeung-Hun Son, Hye-Mi Kim, and Won-Hwa Hong. "A study on the distribution maps for asbestos cement slates using GIS." KIEAE Journal 11, no. 3 (2011): 57-62.

Abstract:

Asbestos have been used around the world because of reliable and cost-effective physicochemical characteristics. After incubation period about 15-40 years asbestos can cause various cancers, including malignant mesothelioma when inhaled into the air. These properties turned out, asbestos have been banned from using in developed countries. ...

Asbestos Cement slates which is Widely distributed throughout the country as roofing materials has much scattering potential compare with inside materials. ...

Minister of Environment or governor should do survey on the actual condition targeting rural buildings with slates and partly or fully fund to dissolve, remove asbestos slate which was used in each buildings.

Therefore, to solve these problems, database-building and necessity of management strategies have been continually arisen. So this study was performed. Its application value is very high in terms of its political, economic.

Asbestos Cement Slates database could build to collect national registered building data and then using GIS, asbestos cement Slates distribution map were constructed in each province's cities and counties of the country. And this map by Application, construction was to visualize by application, construction of year.

Through these results, information of Asbestos Cement Slates could visually inform to policy makers, asbestos dismantling and management contractor, and civilian and it would alleviate the gap of knowledge information. This is expected to be utilized by medium and long-term and effective plan for demolition and dismantling of asbestos cement Slates. - Kuipers, Charles, and Samuel Stoltzfus. "Artificial shingle." U.S. Patent 6,972,149, issued December 6, 2005.

- MacMillan Slaters Co., "Artificial slate roof tile History Interlocking slate roof tiles, Composite roofing slates, Man made slate NZ, Imitation slate, synthetic slate" - retrieved 2018/08/27, original source: http://macmillanslaters.co.nz/roofing-materials/artificial-slate-roof-tile-history/

- Maurer, Ronald L., and Frank C. Cosmas. "Synthetic slate roofing member." U.S. Patent 5,648,144, issued July 15, 1997.

The word "asbestos" does not appear in this patent disclosure. - Saenger, William. "Artificial-stone slab, shingle, and plate and composition for making same." U.S. Patent 1,223,834, issued April 24, 1917. Original Assignee Asbestos Slate Roofing Mfg. Company Inc.

Excerpt:

This invention has reference to a novel process of making artificial stone slabs, shingles, plates and the like. It pertains particularly to anovel process of producing slabs and shingles for roofing purposes of a composition consisting essentially of asbestos fiber, hydraulic binding cement and anhydrous silica or as it is scientifically called silicon dioxid or silicium dioxid, and some water.

Heretofore compositions of this kind have} been prepared from asbestos fiber and cements with additions of special watersilica which is mixed with Portland cement, etc. - Sorensen, Niels C., "Blackboard construction." U.S. Patent 2,025,833, issued December 31, 1935.

Excerpts:

The bulletin board ill is constructed of any suitable relatively soft material in which pins or tacks can be readily inserted and removed, for example, such as cork, paper board, wood, etc

....

The blackboard H5 is constructed of slate or of such composition boards as those embracing wood pulp, asphalt, concrete, asbestos or other materials suitable for the purpose.

...

Continue reading at MANUFACTURED / SYNTHETIC SLATE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SLATE ROOF INSPECTION & REPAIR - home

- SYNTHETIC STONE ASBESTOS

Suggested citation for this web page

MANUFACTURED / SYNTHETIC SLATE ASBESTOS CONTENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.