Relief Valve Discharge Tube Codes & Hazards

Relief Valve Discharge Tube Codes & Hazards

Installation, inspection, & specifications for discharge tubes on TPR valves used on boilers, calorifiers, geysers, & water heaters

- POST a QUESTION or COMMENT about TPR valve or temperature/pressure relief valve drain line piping

T&P valve discharge tubes:

This article describes the requirements for a discharge tube or drain line on temperature & pressure relief valves used on any appliance that heats water. These include hydronic heating boilers (hot water boilers), steam boilers, and all types of water heaters, both those that use a water storage tank or cylinder and those that heat water on demand such as tankless water heaters.

Here we describe the installation specifications for TPR valve drain line piping and we include an extensive list of discharge tube installation or condition defects, most of which are unsafe. All of them are improper.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Temperature/Pressure Relief Valve Discharge Tubes & Drain Lines & Their Piping

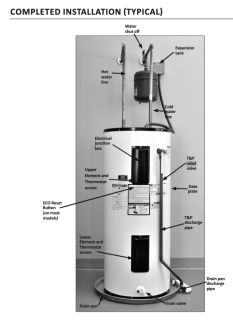

The Temperature & Pressure Relief Valve or TPR Valve on any heated appliance that contains water, such as a heating boiler, hot water tank, water heater, water cylinder, must have a drain line or discharge tube properly installed, routed, and made of proper materials. The purpose of this drain line is to discharge potentially hot scalding water to a safe location so that a bystander is not scalded.

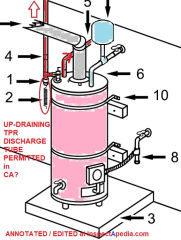

At left we see a typical TPR valve installation (by the author) including the vertical 3/4" copper drain piping that will discharge any T&P valve spillage to the floor.

[Click to enlarge any image]

An unsafe TPR drain line installation is shown at the top of this page. Only a complete fool would do what we found on this boiler. To "stop" an annoying boiler drip at the pressure temperature relief valve, the mechanic installed a short length of pipe capped by a drain valve which he could simply shut.

This might have been installed on a system for other reasons, such as connecting a hose to permit easy draining of pressure off of the boiler through the TP valve.

But it is in all events dangerous, illegal, and plain stupid to ever install a shutoff valve or any other sort of "cap" on a pressure/temperature relief valve.

But how dangerous is it to omit a discharge drain tube on a TPR valve? The possibility of a scalding burn is obvious but do these accidents actually happen?

Noticing that a TPR discharge tube was missing on a heating boiler during a home inspection I [DF] pointed out this safety hazard to my client while the real estate agent nearby frowned at my "old maid" trouble-making personality.

My client burst into tears. Sobbing she told me that she was grateful that inspectors would routinely point-out this hazard. Her son, playing with friends in the basement, lost an eye when he and a pal opened the discharge lever on a heating boiler, scalding his face and ruining his left eye forever.

Less dramatic but scary, at a different inspection I found that a string tied through a small hole in the end of the TPR valve's test lever. The string was routed up towards the ceiling, over a horizontal plumbing line and back down to a termination in a nice knot a few feet above the floor.

This interesting TPR test lever addition was explained by the building owner. His son and friends liked to play steam boat. It was fun to pull the string, pretending it was a steam boat whistle, and to see the burst of steamy hot water emerge from the end of the discharge line.

TPR Valve Discharge Tube Inspection: Signs of Trouble, Unsafe Installation, Safety Hazards

Watch out: While it is possible to "open" a boiler TP relief valve by lifting its "test" lever, unless you are a trained heating service technician or plumber, and unless you have a spare TP valve of the proper size in your hand, we advise against "testing" a TP relief valve by opening this lever.

Watch out: While it is possible to "open" a boiler TP relief valve by lifting its "test" lever, unless you are a trained heating service technician or plumber, and unless you have a spare TP valve of the proper size in your hand, we advise against "testing" a TP relief valve by opening this lever.

- TPR Valve Discharge tube is installed:

Check that the Temperature/Pressure relief valve has a discharge tube properly installed. The drain line must be connected to the discharge outlet of the T&P valve to "avoid water damage and scalding injury." (Watts 2011)

Our photo (left) shows an oil fired water heater with a T&P valve that has no discharge tube installed. There are of course other operating problems with this water heater as the photo makes clear. - TPR Valve Discharge tube blocked:

Check that the discharge is not blocked by anything whatsoever. Our page top photo shows a shutoff drain valve installed at the end of a short T&P valve discharge line. - TPR Valve Discharge Tube Corrosion:

any leak or corrosion stains around the mouth of the valve indicates that the T&P valve has been leaking.

The risk is that the valve is no longer leaking not because a proper repair has been made, but because the valve has become clogged and blocked by mineral salts left behind by the evaporating hot water - leaving the installation dangerous and risking a BLEVE - explosion.

...

- TPR Valve Discharge Tube Covered:

the tube end or termination cannot be covered such as by add-on water heater insulation.

In our photo at left, the relief valve on this water heater has been covered by owner-installed water heater insulation.This is an unsafe condition as the operation of the temperature or pressure relief valve may be interfered with by the insulation and also because the valve cannot be inspected for evidence of leaks or failure.

Similarly, discharging a relief valve leakage or drip to a location where the leak or drip cannot be observed is a dangerous practice because the leak can go unnoticed, causing failure to recognize an unsafe condition.

When a relief valve continues to leak it may become damaged and then fail to operate when an unsafe pressure or temperature occurs.

- TPR Valve Discharge Tube Piped "UP":

the drain line must never be piped upwards in any of its course. The hazard is that the drain can become blocked or that a small drip, representing an unsafe condition at the T&P valve, may be hidden as the water simply accumulates in the bend of the trap or upwards piped section.

See TPR DISCHARGE DRAIN PIPED UP - TPR Valve Discharge Drain Line Traps:

the T&P valve drain line may never be trapped for the same reasons that the drain line cannot be piped upwards.

Photo above: This photograph, courtesy of Kingston N.Y. building inspector Arlene Puentes, shows an unsafe temperature/pressure relief valve installation in an apartment building in Watertown, New York.

[Click to enlarge any image]

The

water heater relief valve discharge tube installed with its outlet touching the floor (and thus blocked). This is an unsafe installation that could prevent adequate relief of water and pressure, risking a BLEVE explosion.

- TPR Valve Discharge Tube Crimped, Plugged, or Reduced

the relief valve drain line may not be bent, crimped, nor plugged by any material. Our example above shows the relief valve tube tight against the floor - unsafe.

The diameter of the drain line may not be reduced to a size smaller than the opening of the T&P valve that it serves. Some jurisdictions may limit the number of elbows or bends permitted in the piping.

The photos above illustrates this unsafe installation practice: a 1/2" copper tube has been installed through a reducing fitting into the mouth or piping of a 3/4" diameter TPR valve.

Below the reducer from 3/4" to 1/2" was installed at the TPR valve opening. At above right a reducing elbow was used to shrink the 3/4" horizontal T&P drain line (from the TPR valve mouth) to 1/2" for the vertical run to the floor. Both of these installations are improper and unsafe.

...

- TPR Valve Discharge Tube Active Leaking:

above we show a wet floor area as well as the corroded end of the T&P discharge tube in our first photo: this relief valve is actively leaking. In this case investigation showed that the valve itself had failed - we replaced it. - TPR Valve Drain line Drip Marks:

any drip stains on the floor below the valve discharge tube (second photo above ) also indicate a history of leaks at the T&P valve. Without further investigation we don't know if this problem has been repaired or if it is simply intermittent. - TPR Valve Discharge Tube Opening is Wet:

If there is corrosion on the end of the discharge tube or if you see drip stains on the floor below the drain pipe, even if the floor is dry you should always test for active or recent spillage at the relief valve. It's possible that water on the floor has dried (on its own or with some help before a building inspection).

But if there has been recent spillage at the TPR valve the interior of the end of the discharge tube can confirm that. Using your finger, feel the inside of the tip of the discharge tube and check for water - it should be dry.

As the two photos show below, even though the floor was dry below this T&P drain line, the interior of the drain was wet - there was active leaking (or someone had recently opened the valve).

- TPR Valve Discharge Tube Materials:

the drain line material requirements vary by jurisdiction; some areas permit both plastic as well as copper or galvanized steel piping. But where plastic drain line materials are used, the temperature rating of the plastic must be above the highest temperature that might be produced by the heating appliance to which the T&P valve is connected. - TPR Valve Discharge Tube Shut-off Valves:

no shutoff valve can be installed anywhere in the discharge piping of a T&P valve - TPR Valve Discharge Tube Termination Fittings:

the end of the discharge or drain line tube should not be threaded nor fitted with any device that would permit attachment of a cap, plug, or valve that could close off the line. - TPR Valve Discharge Tube Termination Location:

The water that may be discharged from a T&P valve must be conducted to a safe place of disposal. This may be a floor drain (recommended by Watts) or in some jurisdictions another location may be permitted.

Some jurisdictions do not permit the discharge drain destination to be hidden from view, on the theory that you won't see a drip or leak and won't thus detect an unsafe condition.

Other jurisdictions, such as in the U.K., permit the TPR valve drain line to be piped to a hidden location but require the installation of a tundish in the drain line at a suitable visible location.

The Tundish will allow the occupants to see that the TPR valve is leaking, and its air gap provides other plumbing sanitation and blockage protection features.

See TUNDISH used in PLUMBING

Outdoor terminations of a T&P valve drain line

may be permitted in some jurisdictions, even required, to avoid water damage inside the building. However unless a tundish device is properly included such installations are unsafe. And piping a T&P drain line outside in freezing climates is unsafe because a dripping line may freeze and become blocked.

IRC Mechanical Code Section 70.5 WATER HEATER RELIEF VALVES. Section 608.5 UPC 2009

Relief valves located inside a building shall be provided with a drain, not smaller than the relief valve outlet, of galvanized steel, hard-drawn copper piping and fittings, CPVC, or listed relief valve drain tube with fittings which will not reduce the internal bore of the pipe or tubing (straight lengths as opposed to coils) and shall extend from the valve to the outside of the building with the end of the pipe not more than two (2) feet (610 mm) nor less than six (6) inches ) (152 mm) above the ground or the flood level of the area receiving the discharge and pointing downward.

Such drains may terminate at other approved locations.

Relief valves shall not terminate in a building’s crawl space. No part of such drain pipe shall be trapped or subject to freezing. The terminal end of the drain pipe shall not be threaded.Original source:

- Stevens WA, COMMONLY USED RESIDENTIAL BUILDING CODES, IRC 2009, [PDF] retrieved 2019/05/08 original source: http://www.co.stevens.wa.us/landservices/documents/MECHANICALSECTION.pdf

- Other sections of this mechanical code are given

at CHIMNEY HEIGHT & CLEARANCE CODE

- TPR Valve Mounting Leaks:

Check for leaks around the valve where it is mounted on the boiler or boiler piping. This is a TPR valve defect, not a TPR discharge tube defect, but depending on the valve position and location, a leak around the TRP valve mount may send water (or corrosion or mineral salts) down the outside of the discharge tube, offering a valuable visual clue and possibly being mistaken for a defect in the tube itself

Why We Don't Pipe the T&P Valve Drain Line Upwards from the Valve Mouth

Reader Question: explain the concern for a water heater discharge line above the TPR valve - why can't we pipe a TP valve discharge tube "up"

Reader Question: explain the concern for a water heater discharge line above the TPR valve - why can't we pipe a TP valve discharge tube "up"

I am ... in the process of selling a condo I own. I got this request for repairs for the hot water heater with a picture of the heater. On the picture it shows the that the discharge line is above the TPR valve, and that this is a problem (see description on attachment). This doesn't make any sense to me. Can you help me decide what the best action would be? thanks. - R.N. 7/11/2013

Quoting from the inspection report:

The overflow line is higher than the Temperature and Pressure Relief (T & P) valve. The over flow line should always allow to water to drain to a point lower than the valve without backing up to the valve.

Water trapped in the discharge line may cause the T & P valve to corrode and malfunction. (The concern is if the water overheats and turns to steam, and the temperature control valve fails to function, the over pressure may cause the heater to burst or explode.)

Lowering of the discharge line to a point below the valve and replacement of the valve should solve the problem.

Reply:

The photo is a bit difficult to read but if you look closely where the two flexible copper lines enter the wall behind the water heater, you'll see that the smaller leftmost flexible tube, connected back to the water heater TP valve, enters the wall at a height above the valve outlet opening. What the home inspector said was perfectly correct and represents a safety hazard.

Perhaps if I explain the concern in my own words it will be more clear:

The temperature/pressure relief valve on a water heater is connected to a drain line so that if the valve opens someone nearby is not shot in the face with hot water. The discharge drain extension is typically taken to just a few inches above the floor or in some jurisdictions it may be directed outdoors - a solution that I think is risky because IF the valve should be leaking, dripping, etc., one wants to notice that and fix it to keep the system safe.

The inspector's report makes a valid point: we should never route the discharge tube "up" from the actual outlet opening of the TP valve. That's because if the valve should develop a small leak or be discharged on occasion, the up-routed discharge tube will keep water and debris remaining in the tube at the valve outlet where debris or mineral accumulation clog the valve or interfere with its operating spring.

The result over time could be that the valve becomes clogged and would then fail to open in a true emergency - risking, ultimately a dangerous BLEVE or water heater explosion.

Watch out: ALSO, I suspect from the photo that your water heater has a discharge tube that directs the valve outlet into a wall and going to who knows where. If the other end of that line is not already readily visible and in a location where it would be noticed, that too would be unsafe and improper.

The FIX for this unsafe condition is usually trivial: the discharge tube must be routed only "downwards" from the TP valve outlet opening, and the end of the discharge tube must be in a readily accessible, visible, and safe location. You'd probably find these same instructions in the installation manual for the water heater.

The COST for this repair should be no more than a simple plumbing service call and perhaps a few piping connections. What would make sense to me and what would be most economical would be to combine this repair with any other plumbing repairs that are needed at the home.

The TIME to fix this problem is as soon as possible, without handling it as an extra-cost "immediate-emergency" plumbing repair. That means, call a plumber and schedule the work for as soon as possible and practical, but not sounding so scared that the plumber gouges the customer with extra fees.

TPR / Relief Valve Discharge Tube Plumbing Code Requirements

This except [adapted for clarity] from the Uniform Plumbing Code is excerpted from the U.S. state of Utah's adoption of the code:

P2804.6.1 Requirements for TPR [Temperature Pressure Relief Valve] Discharge Pipe

The [TPR valve] discharge piping serving a pressure-relief valve, temperature-relief valve or combination valve shall:

1. Not be directly connected to the drainage system.

2. Discharge through an air gap located in the same room as the water heater.

3. Not be smaller than the diameter of the outlet of the valve served and shall discharge full size to the air gap.

4. Serve a single relief device and shall not connect to piping serving any other relief device or equipment.

5. Discharge to the floor, to the pan serving the water heater or storage tank, to a waste receptor or to the outdoors.

6. Discharge in a manner that does not cause personal injury or structural damage.

7. Discharge to a termination point that is readily observable by the building occupants.

8. Not be trapped.

9. Be installed to flow by gravity.

10. Terminate not more than 6 inches (152 mm) and not less than two times the discharge pipe diameter above the floor or waste receptor flood level rim.

11. Not have a threaded connection at the end of the piping.

12. Not have valves or tee fittings.

13. Be constructed of those materials indicated in Section P2906.5 or materials tested, rated and approved for such use in accordance with ASME A112.4.1.

14. Be one nominal size larger than the size of the relief-valve outlet, where the relief-valve discharge piping is constructed of PEX or PE-RT tubing. The outlet end of such tubing shall be fastened in place.

From the same source we also have

504.6 Requirements for Water Heater TPR Valve Discharge Piping

The discharge piping serving a pressure relief valve, temperature relief valve or combination thereof shall:

1. Not be directly connected to the drainage system.

2. Discharge through an air gap located in the same room as the water heater.

3. Not be smaller than the diameter of the outlet of the valve served and shall discharge full size to the air gap.

4. Serve a single relief device and shall not connect to piping serving any other relief device or equipment.

5. Discharge to the floor, to the pan serving the water heater or storage tank, to a waste receptor or to the outdoors.

6. Discharge in a manner that does not cause personal injury or structural damage.

7. Discharge to a termination point that is readily observable by the building occupants.

8. Not be trapped.

9. Be installed so as to flow by gravity.

10. Terminate not more than 6 inches (152 mm) above and not less than two times the discharge pipe diameter above the floor or flood level rim of the waste receptor.

11. Not have a threaded connection at the end of such piping.

12. Not have valves or tee fittings.

13. Be constructed of those materials listed in Section 605.4 or materials tested, rated and approved for such use in accordance with ASME A112.4.1.

Example of Plumbing Code Prohibiting Remote Termination of TPR Valve Discharge Tube

Some model and adopted building and plumbing codes expressly prohibit discharging the TPR valve out of the room containing the heating appliance that it is intended to protect.

The reasoning is simple: discharging the TPR tube end in a more-remote location increases the risk that a leak goes un-attended and the system becomes unsafe.

Example: here is an excerpt from Wisconsin's Plumbing Code ( WI Comm 82.40 (5) (d) (1) and (2) 1-5 (a-f))

(d) Safety devices: Water heaters shall be equipped with safety devices as specified in this paragraph.

1. All pressurized storage-type water heaters and unfired hot water storage tanks shall be equipped with one or more combination temperature and pressure relief valves. The temperature steam rating of a combination temperature and pressure relief valve or valves shall equal or exceed the energy input rating in BTU per hour of the water heater. No shut off valve or other restricting device may be installed between the water heater or storage tank and the combination temperature and pressure relief valve.

2. All pressurized non-storage type water heaters shall be provided with a pressure relief valve installed at the hot water outlet with no shut off valve between the heater and the relief valve.

3. Temperature and pressure relief valves shall be installed so that the sensing element of the valve extends into the heater tank and monitors the temperature in the top 6 inches of the heater or tank.

5. Every relief valve which is designed to discharge water or steam shall be connected to a discharge pipe.

5 (a) The discharge pipe and fittings shall be made of a material acceptable for water distribution piping in accordance with s.Comm 84.30 (4) (e) 1.

5 (b) The discharge pipe and fittings shall have a diameter not less than the diameter of the relief valve outlet.

5 (c) The discharge pipe may not be trapped.

5 (d) No valve may be installed in the discharge pipe.

5 (e) The discharge pipe shall be installed to drain by gravity flow to a floor served by a floor drain or to a receptor in accordance with s. Comm 82.33 (8).

The outlet of the discharge pipe shall terminate within 6 inches over the floor or receptor, but not less than a distance equal to twice the diameter of the outlet pipe. The discharge pipe may not be threaded.

5 (f) The discharge pipe for a water heater shall terminate within the same room or enclosure within which the water heater or hot water storage tank is located.

and ...

SPS 382.33 8.(d)

4. The local waste piping serving a water heater temperature and pressure relief valve, water treatment device, cross connection control device or assembly, humidifier, sterilizer, or a furnace or air conditioner may discharge into the riser of a floor drain when installed in accordance with sub. (7) (b).

5. The indirect or local waste piping serving a water heater temperature and pressure relief valve, water treatment device, cross connection control device or assembly, or a furnace or air conditioner may discharge to a floor served by a floor drain so as not to create a health or safety hazard.

6. The indirect or local waste piping serving a water heater temperature and pressure relief valve or water treatment device may discharge through the cover of a clear water sump so as not to adversely affect floats by means of a fixed air gap installed in accordance with subs. (7) (a) 2. and (8).

Here is the complete text:

- WISCONSIN PLUMBING CODE, Chapter SPS 382, DESIGN, CONSTRUCTION, INSTALLATION, SUPERVISION, MAINTENANCE AND INSPECTION OF PLUMBING [PDF] (2016) retrieved 2019/11/13 original source: https://docs.legis.wisconsin.gov/code/admin_code/sps/safety_and_buildings_and_environment/380_387/382.pdf

see our complete collection of plumbing codes and PDF downloads at

California Plumbing Code Permits Up-Routed TPR Drain IF a Pigtail Drain is Provided

Special thanks to reader Bryce Nesbitt for bringing to our attention the spiral tubing described as a copper pigtail that we'd describe as a pigtail drain for up-routed pressure relief valve discharge drain lines.

Special thanks to reader Bryce Nesbitt for bringing to our attention the spiral tubing described as a copper pigtail that we'd describe as a pigtail drain for up-routed pressure relief valve discharge drain lines.

Illustrated here in a photo and sketch you can see that the relief valve drain line can, where local codes approve, be routed "up" to carry discharge across a ceiling and then down to an approved drain discharge location provided that a special draining device, shown as a spiral-wound small-diameter copper tube is attached to drain the residue water in the vertical section of the drain line after a discharge.

In our original discussion the role and nature of that small diameter copper pigtail shown in the photo was not explained. It looked like a thermocouple as might be found on a temperature sensor and its bottom was cut-off in the photo so we couldn't see its final connection.

Later explanation from Mr. Nesbitt clarified that the copper pigtail is a small diameter "drain" intended to remove water from the vertical portion of the relief valve up-piped drain line after the valve has discharged water during an over-pressure or over-temperature or test condition.

It's not a control nor thermocouple, it's simply a small diameter drain. The small diameter and flow resistance of the coiled tubing causes any significant volume of TPR valve discharge to be routed up through the vertical TPR valve drain line from the tee, and the combination of tee and short copper nipple connected to the wound copper tubing are probably intended to prevent standing water or debris accumulation at the mouth of the TPR valve itself.

Watch out: in our OPINION this installation may not be safe nor reliable in all water heater installations.

The pigtail drain may appear to work perfectly to drain the residing water in the vertical section of the discharge line for the relief valve at initial installation and testing, experience suggests to us that debris, especially mineral scale, is epidemic at water heater relief valves, especially if the leak at the valve is a slow drip.

Such scale might easily clog the small-diameter copper pigtail "drain" tubing itself, leading to a relief valve malfunction.

Details of our discussion with Mr. Nesbitt are given below.

Reader Comment: California plumbing code permits up-piped TPR drain installations

For your TPR pages, my local AJH having dealt with too many botched basement TPR's under the California Plumbing Code, has adopted this - Bryce Nesbitt

For your TPR pages, my local AJH having dealt with too many botched basement TPR's under the California Plumbing Code, has adopted this - Bryce Nesbitt

[Photo and sketch shown above]

[relief valve that drains upwards and uses a "pigtail", presumably a temperature sensor shutoff control, at its base - Ed.]

Moderator reply:

Thanks again for the head's up on the up-pigtailed TPR.

Really? I can't say that I understand it nor what that pigtail is doing as shown in the illustration (though I make some guesses) - what is it? A temperature sensor or something else?

if you are an inspector or plumber who wants to be credited as a technical contributor I can add your contact info there.

Some details including the design, the pigtail connection (presumably to a shutoff control) and research supporting this up-draining valve would be helpful.

In my opinion it's unreliable as shown and could be unsafe and as I opine with comments in the articles I cite:

RELIEF VALVE DISCHARGE TUBE - you are on this page

It would be useful to know what research was done to support accepting this up-draining TPR design, presumably using a temperature sensor that shuts down the boiler if hot water is found at the bottom of that tee at the TPR valve outlet.

In our OPINION that is an unsafe and questionable relief valve design in that any TPR that drains "up" is at risk of ultimately depositing mineral salts that can lead to the valve refusing to open in response to an over-temperature or over-pressure condition in the boiler, risking a catastrophic BLEVE explosion.

A slow drip type leak at this pressure relief valve may never provide enough heat to shut off the equipment but might clog the valve, and

worse, draining the valve "up" as shown, means that a slow drip or leak won't be discovered by visual inspection until it has leaked so long as to fill that up-sloping TPR drain that, we hope, ultimately empties at a visible location.

In our OPINION the design you show violates CA §608.5 Discharge Piping 608.5 Discharge Piping - The discharge piping serving a temperature relief valve, pressure relief valve, or combination of both shall have no valves, obstructions, or means of isolation and be provided with the following: Equal to the size of the valve outlet and shall discharge full size to the flood level of the area receiving the discharge and pointing down.

In our OPINION the design you show also violates CA §761. (3) The discharge pipe cannot be readily plugged or otherwise obstructed.

You offered no California code source or citation that clarifies the pigtail installation - if you can offer that it would be most helpful.

See

- CALIFORNIA §608.3 EXPANSION TANKS, AND COMBINATION TEMPERATURE AND PRESSURE-RELIEF VALVES - retrieved 2021/11/19 original source: up.codes/viewer/california/ca-plumbing-code-2016/chapter/6/water-supply-and-distribution#608.0

- CALIFORNIA §608.4 PRESSURE RELIEF VALVES retrieved 2021/11/19 original source: up.codes/viewer/california/ca-plumbing-code-2016/chapter/6/water-supply-and-distribution#608.0

Quoted entirely below

CA 608.3 Expansion Tanks, and Combination Temperature and Pressure-Relief Valves

A water system provided with a check valve, backflow preventer, or other normally closed device that prevents dissipation of building pressure back into the water main, independent of the type of water heater used, shall be provided with an approved, listed, and adequately sized expansion tank or other approved device having a similar function to control thermal expansion.

Such expansion tank or other approved device shall be installed on the building side of the check valve, backflow preventer, or other device and shall be sized and installed in accordance with the manufacturer's installation instructions.

A water system containing storage water heating equipment shall be provided with an approved, listed, adequately sized combination temperature and pressure-relief valve, except for listed nonstorage instantaneous heaters having an inside diameter of not more than 3 inches (80 mm).

Each such approved combination temperature and pressure-relief valve shall be installed on the water-heating device in an approved location based on its listing requirements and the manufacturer's installation instructions. Each such combination temperature and pressure-relief valve shall be provided with a drain in accordance with Section 608.5.

608.4 Pressure Relief Valves

Each pressure relief valve shall be an approved automatic type with drain, and each such relief valve shall be set at a pressure of not more than 150 psi (1034 kPa). No shutoff valve shall be installed between the relief valve and the system.

608.5 Discharge Piping

The discharge piping serving a temperature relief valve, pressure relief valve, or combination of both shall have no valves, obstructions, or means of isolation and be provided with the following:

Equal to the size of the valve outlet and shall discharge full size to the flood level of the area receiving the discharge and pointing down.

Materials shall be rated at not less than the operating temperature of the system and approved for such use.

Discharge pipe shall discharge independently by gravity through an air gap into the drainage system or outside of the building with the end of the pipe not exceeding 2 feet (610 mm) and not less than 6 inches (152 mm) above the ground and pointing downwards.

Discharge in such a manner that does not cause personal injury or structural damage.

No part of such discharge pipe shall be trapped or subject to freezing.

The terminal end of the pipe shall not be threaded.

Discharge from a relief valve into a water heater pan shall be prohibited.

608.6 Water-Heating Devices

A water-heating device connected to a separate storage tank and having valves between said heater and tank shall be provided with an approved water pressure relief valve.

608.7 Vacuum Relief Valves

Where a hot-water storage tank or an indirect water heater is located at an elevation above the fixture outlets in the hot-water system, a vacuum relief valve that is in accordance with CSA Z21.22 shall be installed on the storage tank or heater.

Also see

- CALIFORNIA §761. SAFETY VALVES AND PRESSURE RELIEVING DEVICES, BOILERS [PDF] retrieved 2021/11/19 original source: https://www.dir.ca.gov/title8/761.html

Excerpted below

CALIFORNIA §761 Subchapter 2. Boiler and Fired Pressure Vessel Safety Orders Article 4. Installation

(a) Each power boiler, nuclear boiler, and high temperature water boiler shall have safety valves or pressure relieving devices constructed, stamped and installed in accordance with the applicable section of the Code, except:

(1) For existing installations the stamping required by the Code at the time of original installation may be accepted until the valves are replaced.

(2) Upon written request by the employer, the Division may permit three-way two-port valves to be installed under two safety valves, each with the required relieving capacity, provided they are so installed that both safety valves cannot be closed off from the boiler at the same time and provided the three-way valve will permit at least full flow to the safety valve in service at all time.

(b) The user shall maintain all pressure relieving devices in good operating condition. Where the valves cannot be tested in service, the user shall maintain and make available to the inspector records showing the test dates and set pressure for such valves.

(c) Pressure relieving devices with open discharge installations shall have piping and supports designed for pressure relief reaction forces in accordance with Appendix II of ANSI B 31.1.

The discharge from pressure relieving devices shall be piped to a safe location where:

(1) The discharge of steam or hot water will not present a hazard to employees.

(2) The discharge of steam or water will not be detrimental to any electrical or other machinery or equipment.

(3) The discharge pipe cannot be readily plugged or otherwise obstructed.

Reader follow-up:

I've tested this setup several times, though only with 140F water, not hotter water - B.N. 2022/01/11

I've tested this setup several times, though only with 140F water, not hotter water - B.N. 2022/01/11

See

- WATER HEATER INSTALLATION INFORMATION, Bulletin 293 [PDF] (2020) City of San Jose, Planning, Building & Code Enforcement, Development Services

Permit Center

San José City Hall

200 E. Santa Clara St.

San José, CA 95113

408-535-3555

www.sanjoseca.gov/permitcenter

Excerpt:

WATER HEATER INSTALLATION IN A BASEMENT - REQUIREMENTS

Follow these specifications outlined and illustrated below when installing a water heater in a basement:

1. 3/4” tee with 1/8” reducer

2. 1/8” tubing, drip coil with slightly crimped end

...

7. Terminate not less than 6” and not more than 24” at exterior

... additional specifications are in the document cited above - Ed.

Moderator reply:

I appreciate the significant convenience of being able to route a TPR valve discharge line up and thence horizontally and then "down" to a more-convenient discharge location, and now that we've got your added detail I understand the theory of a copper pigtail drain on the down-end of a Tee into which the water heater or boiler TPR valve is discharging.

I'm still nervous about the long term safety of this design.

It would be helpful to see the actual California plumbing code text on this detail and also useful to know what long-term testing and field experience have shown about the safety and reliability of this approach.

OPINION: If the small diameter pigtail drain clogs the homeowner will never know it. In normal water heater operation there should be no discharge from its TPR valve, so if later a slow drip at the valve leads to a clogged pigtail drain that condition may be indistinguishable from a perfectly functional installation.

You might detect a clogged pigtail drain on an upwards-piped relief valve drain during an annual test of the TPR valve: the valve is opened to discharge and then closed; afterwards you should see a small volume of water exiting from the pigtail drain as the remaining water in the up-piped larger diameter TPR discharge tube drains out through the pigtail.

Really? While TPR valves may come with an instruction to test the valve annually, in five decades of building inspections of thousands of buildings we have not found more than a handful of building owners who ever test a relief valve nor even know of that requirement.

I much appreciate the discussion and polite well-intended argument. Working together may make us smarter.

Overall I am sometimes concerned that someone comes up with what seems like a great idea without considering pitfalls or hazards that are well-known to others who have more depth or breadth or time of experience in the same field. You don't know what you don't know. You don't even know you don't know it.

In my opinion the fundamental error in ANY up-piping of ANY TPR valve is that the design is unsafe because of the possibility of accumulation of scale or other debris in that water reservoir leading to blocking of the valve's operation when needed.

It's a similar hazard to the one that occurs even in a down-piped TPR valve when the valve is constantly dripping or leaking. That passage of water leaves scale that ultimately blocks the valve.

Just how fast that unsafe condition occurs depends on variables including

- water hardness

- water temperature

- water leak rate

TPR Copper Pigtail is a Drain Not a Sensor

I inferred from the product design in your photo that an engineer or someone had added a temperature sensor intended to detect spillage as heat and thus to act as a different method of shutting off an unsafe hot water heating appliance.

I now understand from our correspondence that this is not a temperature sensor, it's a flow-resistive drain.

Your earlier photos were incomplete in that detail . We still have no product name, description, manufacturer, installation instructions, nor building or plumbing code approval data. Those would be most helpful.

Simpler Safety Controls are Safer

In my opinion, the safest design, especially where we're avoiding a very dangerous catastrophe (BLEVE) is the simplest one with fewest parts that need to work to protect the building and its occupants.

Back in 2016, Justin Phillips at AICHE, something similar: " “The most effective and efficient mitigation or elimination of risk is achieved at the earliest juncture and at the most fundamental level,” “The most effective and efficient mitigation or elimination of risk is achieved at the earliest juncture and at the most fundamental level,” (Justin 2016)

- Phillips, Justin, AVOIDING PRESSURE RELIEF SYSTEM PITFALLS [PDF] AICHE, (2016) original source https://www.aiche.org/sbe/resources/publications/cep/2016/july/avoid-pressure-relief-system-pitfalls

Werner Sölken offers a nice explanation of these concerns. The company points out that ANY backpressure on a conventional pressure relief valve of the type commonly used on residential water heaters (disc and spring type design) will see a reduction of its opening response if there is any backpressure on the valve, such as from debris, or even from standing water in a discharge tube piped upwards (though I suspect the pressure difference in most buildings would be small).

- Werner Sölken, TPR BASIC OPERATIONS [PDF] retrieved 2022/01/11 original source: https://www.wermac.org/valves/valves_pressure_relief.html,

Excerpt: A conventional safety Relief Valve is a pressure Relief Valve which has its spring housing vented to the discharge side of the Valve. The operational characteristics (opening pressure, closing pressure, and relieving capacity) are directly affected by changes of the back pressure on the Valve."

Allied Valve raises another objection that may pertain to your up-piped relief valve discharge piping: possible loading on the valve body itself if the piping does not support its own weight.

- Allied Valve, 3 THINGS TO AVOID WHEN INSTALLING & OPERATING SAFETY VALVES [PDF] Allied Valve, 4119 State St., Riverdale IA, 52722 Tel: 800-827-1197 Web: alliedvalveinc.com - retrieved 2022/01/12 original source: https://alliedvalveinc.com/the-valve-expert/3-things-avoid-installing-operating-safety-valves/

Excerpt: "Stress from Improperly-supported discharge piping" Discharge piping must be installed so that it supports its own weight and does not put any weight or strain on the valve itself. According to the National Board of Boiler and Pressure Vessel Inspectors, improperly supported discharge piping is one of the top problems that can prevent valves from operating normally.

Discharge piping connected to the device must be supported so as not to impart any loadings on the body of the device. These loadings could affect or prevent the proper operation of the device including proper reclosure after operating

Most descriptions of safe and proper TPR valve discharge piping presume that there is no copper pigtail drain and will specify

"The discharge piping should be sloped from the outlet to facilitate drainage." (Hellemans 2009)

- Hellemans, Marc. THE SAFETY RELIEF VALVE HANDBOOK: DESIGN AND USE OF PROCESS SAFETY VALVES TO ASME AND INTERNATIONAL CODES AND STANDARDS [PDF] Elsevier, 2009. [copy provided by https://www.daboosanat.com ]

In sum, a relief valve discharge tube that is not pointing downwards may become unsafe. I agree that the worst does not always happen; if it did there would be no doubters. But the risk of a BLEVE explosion and the results of such a blast are so serious as to be considered carefully.

Reader follow-up:

When I spoke to the lead inspector in Berkeley CA they said they copied from San Jose CA.

They consider it legal under the California Plumbing Code, and thus not an AMMR, just an accepted method.

Pigtail uprouted TPR for below grade basements (PUTPRfbGB)?

It's way better than the method of putting a manual drain valve there, which of course will be left in the wrong position. - B.N. 2022/01/12

Clog with scale sure, but only if there's water in the pipe, which there should not be.

Maybe insects though could clog it up.

I like the pigtail approach because it offers a better chance for the owner to notice if there's a drip drip leak

from the TPR. With the TPR going outside a drip drip could go unnoticed a very long time.

The other solution to this same problem would be TPR's rated for two way immersion.

That would mostly eliminate the need to dry the pipe out, or at least reduce the consequence.

Moderator reply:

OPINION: Not quite:

TPR valves drip far more often than they flow at volume. Slow drips easily leave scale that can clog a 1/8" diameter spiral tube with crimped end pretty quickly.

This looks to me like a "good idea" that has not yet seen long-term testing in real-world conditions.

Photo Credits:

- Arlene Puentes [Website: www.octoberhome.com ] , an ASHI member and a licensed home inspector in Kingston, NY, holds five International Code Council Certifications, New York State DOS Certified Code Enforcement Official, ASHI Member 210232, NYS Home Inspector License No. 16000095212and has served on ASHI national committees (Bylaws, Standards), as well as HVASHI Chapter President. Ms. Puentes can be contacted at ap@octoberhome.com She is a frequent technical contributor to InspectApedia.com.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-03-03 by InspectApedia Publisher - effects of corrugated tubing or pipes on water flow

@Richard,

Continuing on the effects of corrugated tubing or pipes on water flow

A lot of research has focused on heat transfer comparisons between smooth and corrugated piping or tubing - more turbulence may improve the heat transfer.

Studies discuss the effect on the Reynolds number for corrugated vs smooth tubing or pipes.

pipeflow.com defines this factor, important in engineering studies of flow.

The Reynolds number (Re) of a flowing fluid is calculated by multiplying the fluid velocity by the internal pipe diameter (to obtain the inertia force of the fluid) and then dividing the result by the kinematic viscosity (viscous force per unit length).

- op cit

where the higher the Reynolds number the more turbulent is the flow within the pipe.

And quite a few studies discuss problems of pipe noise or whistling pipes where corrugated piping is in use - all speaking to the effect on flow of corrugated tubing and pipes.

A Google scholar search for "pressure relief valve corrugated discharge tube"

finds similar articles on pressure drop, but I have not yet found studies that specifically focus on the question of the effect of use of corrugated tubing on a pressure relief valve's rated discharge and safety.

Fortunately, it is almost never the case that a pressure/temperature relief valve will be installed on a boiler or water heater such that the valve's rated pressure/temperature relief capacity is anywhere close to the input BTUH of the heater itself.

PRVs are, luckily, usually chosen with a relief capacity that is significantly greater than the input energy of the heater that they protect. So we may have enough of a safety margin that the code writers felt that corrugated discharge tubes themselves were not a significant worry.

That does NOT, however, excuse having to avoid bends and elbows in discharge piping - as we discuss above on this page and in this article series.

On 2023-03-03 by InspectApedia Publisher - corrugation and elbows might have a significant effect in the flow rate or flow resistance in piping

@Richard,

Thank you so much for your interesting and helpful comment. We agree with you that both corrugation and elbows might have a significant effect in the flow rate or flow resistance in piping (as well as in flues and exhaust vents and other mechanical systems).

This is an old question discussed in the U.S. at least since the 1930s.

We've published some general notes on this in our articles on water flow rates (effect of pipe diameter and bends on "water pressure" ) and dryer exhausts and chimneys and flues. Indeed some installation manuals such as for clothes dryers recognize the problem (there are potential fire hazards in that case).

https://inspectapedia.com/water/Water_Flow_Rate_Measurement.php

is one example

I did a quick search for research articles on the effects of corrugated pipes or tubing on flow rates - that has certainly been studied. We'd both need to take this question to the present code-writing committee who concern themselves with pressure relief valve discharge tube codes to see what they have researched and decided in permitting corrugated tubing on PRV discharge lines.

Examples of helpful research on the effect of corrugation on both flow rate and heat transfer are below. Be sure to note Hermsmeier, 1970 - it's not a new question.

Cao, Yan, Phong Thanh Nguyen, Kittisak Jermsittiparsert, Hafedh Belmabrouk, and Sayer O. Alharbi. "Thermal characteristics of air-water two-phase flow in a vertical annularly corrugated tube." Journal of Energy Storage 31 (2020): 101605.

Crawford, Frank S. "Singing corrugated pipes." American Journal of Physics 42, no. 4 (1974): 278-288.

Dodson, A. G., P. Townsend, and K. Walters. "On the flow of Newtonian and non-Newtonian liquids through corrugated pipes." Rheologica Acta 10 (1971): 508-516.

Abstract:

Consideration is given to the flow of Newtonian and non-Newtonian liquids through a “corrugated” pipe of circular cross section whose radius sinusoidally along its longitudinal axis. The flow is produced by a constant pressure gradient. The theory predicts that in the Newtonian case, the corrugated wall of the pipe causes a reduction in flow rate when compared with the value expected on the basis of a straight pipe of the same mean radius. This prediction is confirmed by experiment.

In the case of elastico-viscous liquids, the theoretical analysis for a certain fluid model indicates that the reduction in flow rate may be amplified or reduced by the non-Newtonian properties of the liquid depending on the precise flow conditions.The qualitative predictions are again confirmed by experiment. The possible practical implications of the work are outlined.

Dong, Yang, Li Huixiong, and Chen Tingkuan. "Pressure drop, heat transfer and performance of single-phase turbulent flow in spirally corrugated tubes." Experimental Thermal and Fluid Science 24, no. 3-4 (2001): 131-138.

Hermsmeier, Lee F., and Lyman S. Willardson. "Friction factors for corrugated plastic tubing." Journal of the Irrigation and Drainage Division 96, no. 3 (1970): 265-271.

Abstract:

Hydraulic tests on corrugated plastic drain tubing were conducted at the Southwestern Irrigation Field Station of the Agricultural Research Service, Brawley, CA. Manning&s n and Darcy-Weisback f were determined for commercially available tubing from 1.375 to 4-in. nominal diameter.

An average design value of Manning's n of 0.016 is recommended for 2-in. through 3-in. diam. corrugated plastic tubing for grades over 0.001. For lower grades with these diameters an average design value of Manning's n of 0.017 is recommended. For corrugated plastic tubing less than 2 inches in diameter and average design value of Manning's n of 0.018 is recommended. Humps and depressional variations up to two diameters fro ma uniform grade do not increase head losses in full-flowing lines.

-

Note: see also the discussion of this article given at this ASCE link https://ascelibrary.org/doi/abs/10.1061/JRCEA4.0000728

Jin, Zhi-jiang, Bu-zhan Liu, Fu-qiang Chen, Zhi-xin Gao, Xiao-fei Gao, and Jin-yuan Qian. "CFD analysis on flow resistance characteristics of six-start spirally corrugated tube." International Journal of Heat and Mass Transfer 103 (2016): 1198-1207.

Laohalertdecha, Suriyan, and Somchai Wongwises. "The effects of corrugation pitch on the condensation heat transfer coefficient and pressure drop of R-134a inside horizontal corrugated tube." International Journal of Heat and Mass Transfer 53, no. 13-14 (2010): 2924-2931.

Mohammad, Fawzi S., and R. Wayne Skaggs. "Drain tube opening effects on drain inflow." Journal of irrigation and drainage engineering 109, no. 4 (1983): 393-404.

Abstract:

Laboratory tests were conducted to determine the effects of total opening area, location of openings and gravel envelope on radial flow to 100 mm (4 in.) diam corrugated plastic drains. Radial flow theory was used to evaluate the effective drain tube radius, [Math Processing Error]

and the drainage transfer coefficient for the corrugated tubes.

The effective radius increased with total perforation area as expected, but the location of the drain tube perforation had little effect on [Math Processing Error] The greatest increase of effective radius for an increase in perforation area occurred between areas of [Math Processing Error] where [Math Processing Error] increased from 5 mm to about 21 mm.

Use of a 50 mm thick gravel envelope resulted in an increase in the effective drain radius for a 100 mm diam pipe from 5–36 mm. Experimental results for the effective radius were compared to theoretical values obtained from an earlier solution for circumferential openings. The experimental results were in close agreement with predicted values for a 1.0 mm opening width.

Nakiboğlu, G., S. P. C. Belfroid, J. Golliard, and Avraham Hirschberg. "On the whistling of corrugated pipes: effect of pipe length and flow profile." Journal of Fluid Mechanics 672 (2011): 78-108.

On 2023-03-03 by Richard

I was a National Board of Boiler and Pressure Vessel Inspectors Authorized Inspector Supervisor back in the day. In addition to all of the potential issues detailed above, and related to ensuring that flow from a relief valve was not restricted/impeded, it was never precisely 'enough' that the diameter of the discharge piping be no smaller than the outlet. It included concerns about pressure drop.

Restrictions on the number of elbows and total lengths were required to ensure that back pressure could not develop to the point of restricting flow rate. Back then, all pipe was smooth walled pipe, even if it were to be bent. Every elbow takes a toll on pressure drop because of the sudden change in direction.

A smoothly bent pipe with smooth walled interior performs better, but would generally still count as a full elbow in terms of maintaining a safety margin unless one wanted to do the pressure drop calculations. Regardless, one thing that could be even more devastating than the big pressure drops at elbows, was non-smooth-walled piping.

I see installations utilizing the newer corrugated copper flex-pipe and I cringe. In fluid dynamics terms, these amount to being turbulence generators and performance cannot be predicted using the mathematical technologies currently available to humans.

We can predict when turbulence will arise and we know that when it does, the back-pressure skyrockets.

I am a bit surprised that this potential issue arising from use of these corrugated pipes has not been a forefront concern in the discussions above.

I do not know if anyone has conducted testing, etc. and unless someone can find such to justify the use of this material for discharge piping, my recommendation would be to avoid it altogether and consider it dangerous until proven otherwise. I certainly would be interested in any additional information anyone has come across.

On 2023-01-23 by InspectApedia Publisher - proper relief valve drain system makes it possible for you to see if the valve is dripping or discharging

@Anonymous,

Unless I'm missing something in your question that's a perfectly acceptable solution.

As a side note, it's important that the Relief valve drain system make it possible for you to see if the valve is dripping or discharging.

On 2023-01-23 by Anonymous

Re: "TPR Valve Discharge Tube Termination Location: The water that may be discharged from a T&P valve must be conducted to a safe place of disposal. This may be a floor drain (recommended by Watts) or in some jurisdictions another location may be permitted."

Is it acceptable to use the drain pan as the TPR Valve Discharge Tube Termination Location when the drain pan has drain tube that terminates in a floor drain?

On 2022-01-02 by Inspectapedia Com Moderator

@Mattenzie,

We are glad to assist, working together makes us smarter. Do keep me posted.

On 2022-01-02 by Mattenzie

@Inspectapedia Com Moderator, thank you, I was just looking at that as well and am going to check it against our local codes. I really appreciate your help!

On 2022-01-02 by Inspectapedia Com Moderator

@Mattenzie,

Use the on Page search box or look in the index to related articles to read about the

tundish

for an alternative approach

On 2022-01-02 by Mattenzie

@Inspectapedia Com Moderator, thank you very much for the feedback.

Hopefully the discharge disappearing into the subfloor does so to a hidden drain and not into the plumbing system. Though I will need to correct for visibility if a drain is there. Perhaps I could do a proper TPR run to a drain pan which could then route to the possible hidden drain, which would also allow for drainage in the case of a full heater failure and drainage (separate from TPR drainage).

If it does tap into the plumbing system, I'll disconnect and cap that line to keep the TPR discharge free and visible.

I will still be caught with no drainage though due to initial construction.

On 2022-01-02 by Inspectapedia Com Moderator - not acceptable to route discharge into the plumbing system

@Mattenzie,

It would not be possible to discharge a TPR valve into a water supply line - you'd simply have backpressure on the safety valve and it could never work

That would be very dangerous, risking a BLEVE explosion.

Also a TPR valve discharge end MUST be VISIBLE so that occupants can see that it's leaking - a dangerous condition - OR a special device like a "tundish" - search InspectApedia.com for details - must be installed.

The problem with discharging into a bucket - other than during service - is that you can't see if there is active leaking from the valve - unless the bucket is normally empty.

On 2022-01-02 by Mattenzie

Prior installation routes TPR discharge line, via copper, into hole cut in sub-floor. I need to examine closer once I remove water heater to be replaced, but since this same hole also provides routing for a copper supply line elsewhere in the home, I am concerned that the discharge is routed into the active plumbing system.

1. Is it acceptable to route discharge into the plumbing system?

2. Assuming it is NOT, is it acceptable for me to cap the prior connection at the plumb line, NOT the discharge line, and route the new discharge properly down only, into a plastic 5 gallon bucket? There is no floor drain in this location.

Wouldn't tapping into a pressurized line violate the gravity requirement for discharge?

On 2021-09-13 by inspectapedia.com.moderator - You can NOT install a pressure relief valve into a tee

@Sam,

I answered this earlier, but I don't see it. Perhaps it was on another page.

You can NOT install a pressure relief valve into a tee for several reasons including

increasing its distance from the device it's supposed to protect,

affecting its ability to sense temperature correctly,

and possibly interfering with a temperature sensor probe

If the correct pressure relief valve is installed it can be mounted in either a vertical or horizontal position, of course with the mouth or opening facing out or down

On 2021-09-13 by Sam

My T&P valve on my gas boiler was installed horizontally so they could place an air eliminator valve in the vertical position. Is it safe to use a brass tee out of the boiler, place the T&P valve correctly (vertical) and apply a brass elbow off the tee so I can use a vertical air eliminator valve also?

On 2021-07-10 by H Brown

@inspectapedia.com.moderator, Thank you. That cold water pipe comes out of the bottom of the shut off. Someone wondered if it was to cool the hot water when being discharged...

or is it something that was added when the last homeowner put a recirc pump on and used one of those connections at the faurthest faucet. That was removed though. I see that for sure I'll have to get the discharge pipe lower.

On 2021-07-10 by inspectapedia.com.moderator - improper, illegal, and dangerous piping arrangement

@H Brown,

We don't know what the heck is going on with that piping in your photo, in that we don't know the sources or destinations of the extensions and connections to that relief valve extension pipe.

But for sure I can say

Watch out: this is an improper, illegal, and dangerous piping arrangement - in all events - because it the relief valve discharge has been piped down into a "U" and then UP and then horizontally out to - who-knows-where.

Piping a relief valve "up" means that if/when it drips or leaks the water held against the valve outlet by that up-piping invites corrosion, debris, blockage of the valve outlet that can result in a dangerous BLEVE EXPLOSION

I speculate that someone routed the discharge tube to a drain or to the outdoors but it's dangerous at the outset because of that up-piping, and possibly also dangerous if its ending cannot be observed (as no one will know that it's leaking so won't know of unsafe conditions at the water heater)

I speculate that that small diameter tubing connected by Tee to the improper relief valve discharge tube along its horizontal run may be draining A/C condensate - if so then we have additional unsafe, unsanitary, dangerous plumbing:

- algae, sediment, debris can add to clogging of the relief valve itself - again adding to the BLEVE danger

- wastewater discharged in that smaller tube can contain pathogens that as piped form a cross connection between wastewater and potable water in the building - also an improper plumbing detail that risks contaminating the building's water supply.

See details at CROSS CONNECTIONS, PLUMBING

Watch out: finally when we see plumbing like this in a building we know for sure that plumbing work has been done by someone who has, frankly, no idea of proper, safe, sanitary plumbing - so you should be alert for and have an inspection for other unsafe, improper, unsanitary plumbing work

Correct this immediately lest your water heater turn into a catastrophe. The cost should be minor, especially compared with the risks.

Just removing that "cold water line" into the TPR valve extension tee is nowhere near-enough.

On 2021-07-10 by H Brown

I have a cold water line coming from the bottom of the cold water shut for water heater to the discharge line of the T&P valve. I just replaced the valve because it was leaking or so I thought.

Now I think that the cold water line is what is constantly draining out. The discharge line goes into the wall and under the slab to the outside. Can I just remove that line?

Question: Unsafe relief valve on old Rheem water heater

I am a tenant who found this the other day on a 35 year old water heater: (see pics)

Then this and another pressure relief valve on a furnace boiler were overlooked for code violations in an official inspection--which I arranged--which took all of five minutes.

There are other things I might mention. I wish the water heater were red-tagged, but you know, I'm only a ten ant.

Who, besides a willing contractor/plumber (which tenants don't hire in this state) can (red tag)?

From what I understand, if it's still functioning, an ordinary inspector will give an appliance a passing grade and therefore the official "okay". (happened already).

They don't seem to care to look as closely at things like temperature and pressure relief valves as your inspection website does--but I wish.

Where could I have found such care and expertise in an inspector the first time? - Anonymous by private email 2021/05/04

Moderator reply: building landlord is responsible for safety of mechanical equipment

Watch out: as you already know this water heater is unsafe, risking a very dangerous

Watch out: as you already know this water heater is unsafe, risking a very dangerous

as your photos shows improper and dangerous modifications:

- The relief valve discharge tube is down-sized, smaller than the opening of the relief valve itself, reducing the valve's ability to release heat, pressure, energy, should the heater over-heat

- There is a drop of water at the discharge tube mouth that may be telling us that this valve leaks - which risks valve clogging by mineral scale and again risking that it cannot work safely if called-on to do so.

- I think your photo of the water heater shows rust at its bottom; an old water heater and especially a rusty one that has suffered leaks over its life is at greater risk of bursting - a BLEVE explosion risk.

- Some of the discharge tube is wrapped in foil and isn't visible so there may be other hazards.

- Incidentally, that water heater insulation is not required and in some installations can be itself unsafe, e.g. if it blocks view of or draining of a relief valve.

"Red tagging" is most-often done by a service technician. Others (building code inspector or home inspector) should write up the issue, and because it's a life-safety concern, ought to notify all parties concerned, including owners and occupants of the building - in writing and orally.

The cost to cure is trivial: a few dollars in plumbing parts and, of course, the plumbers labor charge.

It's worth noting to your landlord both orally and in writing immediately that

- There are immediate life-safety hazards at the property

- The cost to correct them might be trivial

More information is at RELIEF VALVE, WATER HEATER

Reader follow-up:

Thank you. You said: "the cost to cure is trivial..." Yes, but I'm thinking it might/should be a little more--based on the opinion of a couple of plumbers I've spoken with--and the tank's age

(you're right, though, still trivial--compared to the risk mentioned)--Neither one would be willing to touch it, but instead recommended replacement due to age.

concerning the heating element, it was suggested that it might be impossible to get a replacement part for that as well.

Moderator reply:

By "trivial" I mean that the cost of the correct-sized relief valve discharge tube in 3/4" copper (or even PVC) probably less than $10. U.S.

The plastic Reliance -brand T&P discharge pipe I show here is sold by plumbing suppliers locally and on-line for about $12. U.S.

An hour of plumber's time to install the tube costs $50. to $150 depending on where the building is located. (many handyman people could also do this job)

I've already cited the safety concern.

Details are at BLEVE EXPLOSIONS

None of this addresses a separate question of an old water heater that's shot.

by no means do I want to sound glib; and I know it's FAR too easy to sit in some distant spot and tell someone else to just spend money.

Maybe the water heater needs to be replaced: if it's leaking or badly-corroded, for example. No one can see that from your original question.

In fact you might want to check out the opinion at

OTHER PEOPLE's MONEY

On 2021-01-18 by (mod) - unsafe, improper TPR valve installation: wrong location, improper drain piping

No, Gina that is NOT a safe nor an approved installation.

No, Gina that is NOT a safe nor an approved installation.

The TPR valve needs to be installed in a tapping on the heater itself, near the top or on the top, as provided by the manufacturer; if you give the brand and model of water heater we may be able to find the installation manual that will show those exact details.

Watch out: a TPR valve not properly located risks failing to respond adequately to over-temperature or over-pressure in the water heater, risking a BLEVE explosion.

Finally: I'd like to see a photo of that TPR valve and another of its data tag.

Watch out: Looking again at your photo it looks to me as if the TPR valve is connected to a pipe that goes "up" to some unknown destination or "down" to a valve that is closed; this is an unsafe and dangerous and incorrect installation.

Safest would be to turn the heater OFF entirely until the plumbing is done correctly.

On 2021-01-18 by Gina

Is it okay/safe to install the TPR valve on the hot water outlet line coming off the top of the water heater? [ see photo above ]

On 2020-11-23 - by (mod) - How close Can a T and P discharge Pipe be to dry wall

Great question, RJ.

I have a practical answer and a legal answer.'

Practically, you have to have enough space that when replacement of the TPR valve is needed there is working space to unscrew and remove the old one and get the new one in place - that might be just an inch or two past the test lever; and separately, you don't want any dripping or discharge to wet the drywall lest you invite a mold contamination issue.

Practically - adding another messy detail, if your water heater sits in a drip or spill tray then the bottom of the discharge pipe will have to jog out and over and down to get past the outer edge of the drip tray, so the drip tray itself is going to space the heater and most of the discharge pipe a bit more-distant from the wall.

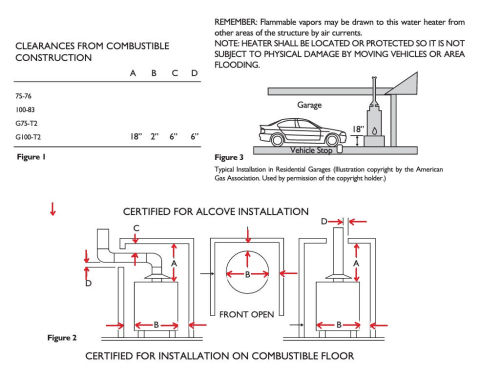

Legally: you have to respect the working clearance space or distances specified by the manufacturer or your specific water heater brand and model. That may be considerably more.

And depending on the kind of water heater and its fuel you will need to meet clearances from combustibles (that includes your wall).

For example this gas fueled American Standard water heater - just an EXAMPLE - your heater may differ, lets the heater itself be as close as 2 inches from a wall, but that does NOT consider space to get the TPR valve on and off.

Take a look at where the TPR valve is connected to your water heater; if it's on a side (near the top of course) then you need working space for the valve.

If the TPR valve is connected off of a tapping on the top of the water heater (as is on some models) then there's probably plenty of working space there and the discharge tube could be quite close to the wall - but considering the practical warnings I gave above.

Above is an illustration of an [American Standard] electric water heater installed with a drain pan - notice the relief valve discharge pipe routing.

On 2020-11-23 by R J - How close Can a T and P discharge Pipe be to dry wall

How close Can a T and P discharge Pipe be to dry wall

On 2020-07-15 by (mod) - can I just dump the T&P valve into a crawl space under a slab?

Even though the discharge of water into an area may not, in your opinion, cause damage to the building, the point of discharge must be visible so that someone can spot trouble (leaks) before a catastrophe occurs

OR

Your local building code inspector might indeed approve routing the relief valve discharge to a hidden and harmless location provided a Tundish is installed so that leaks can be detected.

See details at

On 2020-07-15 by Doug H - can I just dump the T&P valve into a crawl space under a slab?

This electric heat pump water heater is installed in a crawlspace (6" ceiling). The water heater is sitting on a reinforced 4" concrete slab.

Would it be acceptable to allow the T&P valve to simply dump into the crushed rock in the crawl space? Could the same be done with the condensate line?

Two alternatives:

1. Pipe the T&P and condensate lines to a sump with a float to pump outside. (Probably the appropriate approach but rather difficult given rocky soil condition and distance.)

2. The house's main sewer line is right next to the water heater but about 28" above the base of the water heater (ie not a floor drain). A "P" Trap could be installed about 10" under the T&P. (Probably not permitted because it is above floor height?)

Thanks

Doug

On 2020-02-21 by (mod)

Eleni

Eleni

I'd like to see photos of the relief valves that you mention and of their discharge tubes.

I am not aware of any temperature/pressure valve that itself is made of plastic.

It is common to see plastic discharge tubes on some PT valves and that's an accepted practice provided the tubing is properly rated for the temperatures involved.

"A substantial amount of money" worries me.

As you can see from the example I give below, a typical residential boiler relief valve costs less than $100. U.S. and a typical discharge tube of 3 or 4 feet or less costs less than $10. U.S.

Even if a plumber charged a minimum of an hour's labor to unscrew the old valve and screw in the new one and its discharge tube that ought not amount to a substantial total (where I read "substantial" as hundreds of dollars) unless there was something rather unusual and costly going on in your home.

On 2020-02-21 by Eleni - white plastic discharge tube not to code?

Recently we replaced our 14 year old Ultra 310 Boiler with a new Evergreen 399 Boiler. Our Ultra 310 boiler was professionally installed with a plastic PT valve a white plastic discharge tube. During a routine maintenance,

were told that the white plastic was not to code and should be replaced with copper.

At the time, we immediately requested the heating company to replace the plastic and paid a substantial amount of money to do this. |

We now have a new Evergreen Boiler and the copper was removed and replaced with a blue plastic discharge tube. So, which should it be? We are puzzled.

On 2019-11-11 by (mod) - is it ok for the TP valve to drip or leak?

Yes Joe

Watch out: you should be concerned - the system may be or may become unsafe.

The risk includes destructive, even fatal BLEVE EXPLOSIONS.

Please read RELIEF VALVE LEAKS for details and let me know if any questions remain.

On 2019-11-10 by Joe Alessi

In a plastic container I'm getting about 4oz of water from the TP valve discharge tube. Should I be concerned?

On 2016-06-15 by (mod) -

Either the end of the drain needs to be visible or if your local codes permit, you can install a Tundish - search InspectApedia for TUNDISH to read about use of that device

On 2016-06-14 by Michael

I have a T&P that is just inserted into a PVC drain line that goes to the outdoors. I looked through the code book (IRC) and can't find any where that states it must be mechanically attached. Should I have the plumber attach it or let it ride? Or where can I find it in writing?

On 2016-05-30 by (mod) -

A visible location, or if to a not-visible location, search Inspectapedia for TUNDISH and use one of those at the heater.

On 2016-05-18 by Alfred

Hi I would appreciate if you could advise where I should direct the relief valve pipe to.

The 45 litre electric hot water unit is installed under the kitchen bench inside the cupboard in a unit.

The kitchen under sink outlet pipes are higher than the relief valve pipe.

Your expert advice will be appreciated

On 2015-12-16 by (mod) -

Paul.

This condition is unsafe. At its extreme, a leaky relief valve can clog, leading to a BLEVE EXPLOSION.

(Search InspectApedia.com for that term)

Turn off the boiler to avoid damaging it.

the problem could be the valve but mire likely a boiler over pressure condition or a water feeder problem.

Diagnose the cause before replacing parts.

On 2015-12-16 by Paul

There is water FLOWING from the DISCHARGE TUBE on my Triangle Tube, indirect fired water heater. (I shut of the water supply off to the tank so it isn't spilling onto the floor.) Does this suggest that I need to replace the T&P relief valve?

On 2015-10-01 by Eddie

Hi there just wondering why my TPR doesn't discharge at all and i tested it by lifting the lever and it was flowing freely outside and stopped when i released it back?Is that normal?Thanks

Question: no discharge tube on TP valve, steam coming out; Wrong TP valve rating?

(Oct 8, 2012) Filipe Bernardino said:

I have a relief valve right on top of my steam boiler, it doesn't have a discharge outlet but it has openings right on top of it where i see some, if not too much steam coming out, it should be replaced or it is normal?

(Oct 8, 2012) raul said:

if the installation for my boiler said use 50psi and the tech put in 30psi relief valve. do you think that's the reason it keeps leaking.

Reply:

Anon

Possibly. But it's easy to check. Compare the actual boiler pressure when leaks are seen with the valve rating. Normally a hydronic heating boiler doesn't run over 30 psi

Fillip, the valve should not be leaking, but before replacing it you need to know why it's leaky, as the problem may not be the valve. Call your service company as this is va safety concern

Watch out: a discharge tube is required on TP valves to avoid scalding burn hazards.

Question: does the relief valve discharge tube have to be of copper? Is PVC ok?

Thanks for the information. Is there any requirement that the fitting and pipe extension is required to be made from copper? I came across a boiler where the fitting off the T&P and the extension to the floor is made of PVC. - Kevin 7/26/2011

Reply:

Kevin the relief valve would itself tap into a metal fitting on the boiler or on older installations on metal heating piping. But the discharge tube on many new installations is plastic; it's a pipe that rarely sees service and whose job is to divert hot water to the floor rather than onto a bystander. In that application most code officials accept PVC.

Question: Should TP Valve Discharge Lines be Trapped?

Does TP valve on residential water heater use a p-trap - Xavier

Reply:

No Xavier, the discharge from a TP valve should not be trapped it's discharge end should be visible

Question: handling TP valve discharge

(Nov 12, 2012) W Fisher said:

My new tankless water heater is in a place in my basement (finished) where there is no floor drain. A sump pit and pump exist in the area. Obviously if my relief valve activates, if it were to just be allowed to dump onto the floor, the water would travel through a finished part of my basement before reaching the drain.