Gas Burner Chugging / Rumbling Noise, Diagnosis & Repair

Gas Burner Chugging / Rumbling Noise, Diagnosis & Repair

- POST a QUESTION or COMMENT about gas burner noises

Gas burner operating defects & noises:

Here we describe the diagnosis and repair of gas burner rumbling or chugging at a natural gas fired tankless heater.

We discuss the discovery of the problem, steps taken to diagnose the cause, and the process of repair using an actual homeowner incident involving gas burner noise and smell.

This article includes an example of gas appliance inspection for a residential gas fired appliance used for heating the home through its in-floor radiant heat system and its hot water supply.

Immediate LP or natural gas safety hazards: if there is evidence of an LP or natural gas leak at a building, gas odors, for example, you should:

- Do not do anything that is likely to cause a gas explosion, such as lighting a match, operating an electrical switch, or even using a telephone in the building

- Leave the building immediately and keep a safe distance away - 100 feet or more.

- Notify other building occupants of the safety concern

- Contact the local gas company and/or fire department

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Gas Heater Rumbling Chugging Noise Incident

During a spell of subzero temperatures ( -15F,) the homeowner of a new home construction in northern Minnesota heard her gas fired furnace kick in one evening, an Instinct Combi 155 by Triangle Tube (page top image).

During a spell of subzero temperatures ( -15F,) the homeowner of a new home construction in northern Minnesota heard her gas fired furnace kick in one evening, an Instinct Combi 155 by Triangle Tube (page top image).

A few moments later, she realized she was hearing an unusual ‘chugging’ or ‘rumbling’ sound not heard during previous subzero spells.

When investigating the source of the noise in the mechanical room, upon opening the door, she also smelled gas, although not overpoweringly so. Her husband concurred with the noise and the smell.

The unusual odor might have been a natural gas leak or a leak or defect in the venting of combustion gases.

[Click to enlarge any image]

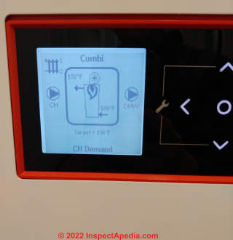

At that time, she recorded a video of the noise and the control panel showing what furnace operations were taking place at the time of the noise. In this case, it was calling for the central heat to turn on, which it did, but with the accompanying noise.

Temporary safety measures in response to gas heater noise & odor

Watch out: because a gas leak can lead to an explosion and because any abnormal behavior of a gas burner could risk dangerous or even fatal carbon monoxide poisoning, and out of concern for a possible leak in the gas supply system, the homeowners took a couple safety precautions:

- cracking open two windows for some fresh air exchange,

- turning down the thermostat so the gas fueled heater would turn off and not have to start again for a while.

Had the symptoms been more extreme and had outdoor temperatures not been well below freezing, the owners would simply have turned off the system entirely, both gas supply and power to the heater, while they waited for repair. .

Instead, after debating the safety of remaining or leaving the home (including using light switches that could create a spark, possibly not waking up from gas exposure, or the possibility of explosion), they opted to stay elsewhere for the night.

Inspection &Tests by City Gas Service Technician: Chugging Instinct Combi 155 Heater continues

In the morning, after calling the city gas department, the homeowner met the city employee at the house. Using his gas leak detection meter, he said it was safe to enter and to turn on lights since he registered next to no gas detected.

The furnace was still chugging away however.

(Note: they also found out that there is a 24 hour on call number for the city that could have been called the night before vs. waiting until the morning.)

At the Instinct Combi 155 boiler itself, with the detection meter right up next to a seam, he said it read slightly higher but still not much at all.

He then removed the cover of the furnace and again tested for gas, which again registered very little. (Photo above on this page).

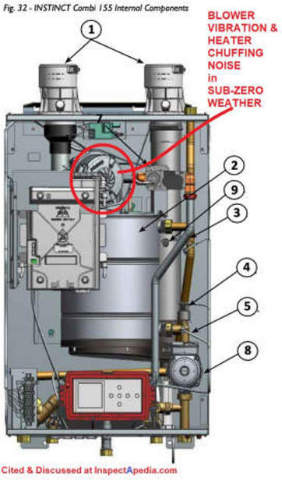

With the cover off, in addition to the noise, the blower assembly atop the heat exchanger [see illustration below] was visibly vibrating as the furnace ran and the "chugging" or "chuffing" noise continued.

He could not determine any obvious reason for this however.

Above: Our red circles in the photo and in the parts illustration indicates the location of the blower located atop the heat exchanger. This blower was visibly vibrating as the heater made the noises described on this page, when operating in sub-zero temperatures. The vibration and noise appeared to stop after a gas pressure adjustment by the gas supplier.

[Click to enlarge any image]

illustration adapted from the Triangle Tube, INSTINCT SOLO 11 0 -15 5 -199 & COMBI 155 -199 INSTALLATION & MAINTENANCE MANUAL [PDF] (2019) Triangle Tube - 1240 Forest Parkway, Suite 100, West Deptford NJ 08066 USA, Tel: (856) 228 8881 - Fax: (856) 228 3584 - E-mail: info@triangletube.com

Make the Heater Run & Check Burners

The city gas service technician adjusted the thermostat temperature in order to call for more heat and also ran the hot water in order to place calls for both to the furnace.

He also checked all the stovetop burners on the gas range which showed good and appropriate gas flames.

Check Gas Heater Combustion Air Supply & Exhaust Vent

The next steps involved going outside to check that both of the vents, combustion and fresh air intake, were clear of any obstruction such as snow and ice, and they were. In looking at the gas meter, he, at first, thought that the gas meter was the wrong size needed but then realized that in fact, it had only been mislabeled and was correct.

Check Gas Supply Pressure vs Appliance Requirement

Inside again, in reading the label on the side of the furnace, he saw that the minimum gas pressure required for it was 5 inches wc (Water Column, a common residential gas pressure measurement scale).

So he went back outside and adjusted the gas meter to be between 6-7 inches wc, thinking that the sound may have been due to the furnace trying to run but not having enough gas to do so properly. But the chugging noise was heard yet again. The gas meter outside read satisfactory levels.

See GAS PRESSURES LP vs NATURAL GAS for a discussion of normal gas pressures expected at a home.

Replace Suspect Gas Regulator at Meter

His final action was to completely replace the regulator on the outside gas meter (see photo). He stated that there are so many parts inside the regulator that even a small piece of dirt could throw it off.

His final action was to completely replace the regulator on the outside gas meter (see photo). He stated that there are so many parts inside the regulator that even a small piece of dirt could throw it off.

Unfortunately, even after the gas pressure adjustment and the regulator replacement, he was able to reenact the same sequence that resulted in the noise once again.

Call the Installing Plumber

At that point, he felt that the plumber who installed the system needed to be called to correct the problem.

The homeowner then contacted the home builder who sent their plumbing installer up to investigate.

After playing the sound recording for them to hear, filling them in on what the city gas employee had done, and despite adjusting the controls to recreate the sequence that had been recorded the night before, the noise did not reoccur during their hour or more spent at the home.

Gas Burner Noise Disappears?

They, too, checked the gas pressure settings and even called the main furnace contact person who said to leave the adjusted pressure as is, and there was no need to call the city gas department again.

Check for Mechanical Noise Source

They did find that one of the wall brackets had not been secured to the wall so fixed that. Since there was nothing else for them to do, they left, leaving their phone number to call if the noise started again. It has not.

Check the Heater IO Manual for Boiler Noise Advice

At heater repair school, we learn that when all else fails, read the instructions and perhaps give a call to the heater manufacturer's technical support line.

The IO Manual for this heater (cited below), the Instinct Combi 155 manufactured by Triangle Tube Co., mentions the word "noise" just twice:

- [Electrical wiring] Line and Low Voltage wiring should be separated to prevent possible electrical noise on the low voltage circuits. - p. 41

- [Boiler piping] Purge any remaining air from the system. Air in the system will interfere with circulation, creating heat distribution problems and noise. - p. 63

Contact the Manufacturer's Technical Support Team

If this abnormal heater behavior occurs again I would contact Triangle Tube for technical support at:

- Phone: Tech Support 856-228-8881 ext: 575

- Email: techsupport@triangletube.com

Temporary Conclusion: Cause & Cure of Chugging Rumbling Noises at an Instinct Combi 155 Heater

We suspect that gas pressure was inadequate, causing un-even heater burner operation, perhaps fuel-starved, in turn causing rumbling noises that showed up when the heater was under very heavy load due to extremely-cold weather conditions. Why this noise did not occur during the first subzero weather conditions remains a mystery.

And although the noise has not re-occurred since the plumber and gas technician service call visits ended, the fact remains that it did re-occur once after the gas pressure was adjusted while the city gas technician was still there. So that leaves us without a completely clear diagnosis.

Really? It is un-settling for a noise or any improper heater operation to simply disappear without a clear diagnosis. The owners remain on alert for any future signs of heater malfunction such as noises, odors, or heat delivery questions.

Low fuel supply or lowered fuel delivery pressure for both natural gas and LP gas can occur during extremely-cold weather, but in a northern Minnesota gas-fueled heater installation we'd expect the installers to be aware of and to provide for this potential issue.

Other Combi-Heater Gas Burner Noise Source Possibilities

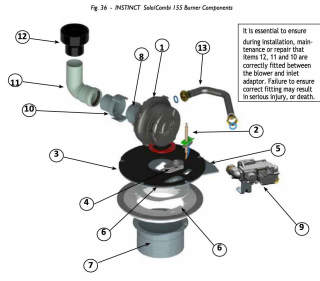

Illustration: adapted/excerpted from the IO Manual for the Instinct Solo/Combi 155 heater installation manual cited below, showing the burner components. Click the image to see a larger image containing the names of each of the components shown.

Watch out: This page in the IO manual warns that

It is essential during installation or repair that items 12,11 and 10 are correctly fitted between the blower and inlet adapter. Failure to ensure correct fitting may result in serious injury or death.

- Control device adjustment or installation defect: see details of the CTRL MAX used with this heater. See the Triangle Tube CTRL MAX supplement [PDF] link provided below.

- Gas supply flow rate & pressure-adequacy: the gas regulator was replaced and gas supply pressure checked and increased at the rumbling chugging gas heater described above on this page.

- Gas-Air Fuel Mixture SNAFU?: If the gas-air fuel mixture in the gas-fired heater is not correct, the result can be burner noises including humming or rumbling. A service tech might use a combustion analyzer to double-check that the unit is operating properly.

- Improper installation of the heater? the installation & operating manual for this heater, cited below, warns the installer that certain connections and adjustments are critical for proper heater operation.

- Outdoor temperature effects on gas heater operation: we don't know if other controls on the heater could cause chattering or oscillation in a control that in turn might affect heater operation and heater noises but we notice that the heater also uses an outdoor temperature sensor about which the manufacturer warns (without detailing the effects):

Ensure the outdoor sensor is shielded from direct sunlight or the effects of heat or cold from other sources (exhaust fans, appliance vents...) to prevent false temperature readings. - p. 67

Gas fuel flow at very cold temperatures is more of a concern for propane users but also can affect natural gas fuel supplies in some communities. See

Mitchell, Francis, KEEPING YOUR HOUSE OPERATING DURING A COLD ALASKAN WINTER OVERCOMING UTILITY FREEZEUP PROBLEMS [PDF] City of Unalaska, 43 Raven Way - P.O. Box 610, Unalaska, Alaska 99685 USA Tel: (907) 581 1251 - retrieved 2021/12/31 original source: www.ci.unalaska.ak.us/sites/default/files/fileattachments/Public%20Utilities/page/531/keeping_your_house_operating_during_cold_alaskan_winters.pdf - Pump noises? some owners of this boiler report a rumbling noise that some plumbers opined was a failing circulating pump. Try using a mechanic's stethoscope (or even a screwdriver against your ear) to touch pumps or other boiler parts to pinpoint the noise source.

(Watch out not to touch live electrical parts.)

In our OPINION a failing pump is more-likely to show up as a bearing failure resulting in a screaming or screeching noise, not rumbling or roaring.

Air in any water piping system can also cause a variety of noises including gurgling and rumbling. - Mineral Scale in any hot water system can cause loud rumbling noises at the burner, though in the case above, the equipment was brand new, so scale was not suspected as a noise source.

See details at WATER HEATER SCALE DE-LIMING PROCEDURE

Triangle Tube Combination Heater Manuals & Support Contact

More about the Instinct Combi 155 heater:

- Triangle Tube, INSTINCT SOLO 11 0 -15 5 -199 & COMBI 155 -199 INSTALLATION & MAINTENANCE MANUAL [PDF] (2019) Triangle Tube - 1240 Forest Parkway, Suite 100, West Deptford NJ 08066 USA,

Tel: (856) 228 8881 - Fax: (856) 228 3584 - E-mail: info@triangletube.com

Technical support: Triangle Tube at 856-228-8881 extension 575 / Email: techsupport@triangletube.com

For installation professionals: See Triangle Tube's excellent videos at https://triangletube.com/support/help-videos - Triangle Tube, SOLO 110-155-199 & COMBI 155-199 OWNER/USER MANUAL [PDF] (2019)

- Triangle Tube, Instinct SOLO 110-155-199 & COMBI 155-199 APPLICATION GUIDE [PDF] (2020)

- Triangle Tube, Instinct SOLO 110-155-199 & COMBI 155-199 SUPPLEMENT [PDF] (2019)

- Triangle Tube CTRL MAX SUPPLEMENT [PDF] (2019)

Natural Gas pressures are described in detail at

Triangle Tube Combi 155 Heater Chugging Noise Technical Support Update

2022/01/31 We sent a request for help and for technical review of this article to Triangle Tube's technical support at techsupport@triangletube.com and will report the company's advice here.

2022/02/03 update:

Triangle Tube has not responded to our request for technical support.

Fuel-Air Mix Adjustment Needed: the local installing plumber re-visited the installation with a new, calibrated gas analyzer and found that the heater's fuel-air mixture was incorrect.

When the technician tested the heater with a functioning tool, it did, in fact, read that it was a combustion issue and that the 'mix' of CO2 and O2 was incorrect.

The tech concluded that a malfunctioning fuel analyzer caused this problem to be missed at earlier installation and service calls. So they went through a number of 'calibrations' with the analyzer attached to the furnace, checking levels and adjusting as necessary, and adjusting the home thermostats in order to create calls for heat as part of the testing process.

The technician said the O2 was at 5.8 and it should be at 4.5 so it seemed that there was too much oxygen in the natural-gas fuel-air 'mix'.

Excess oxygen readings mean that enough oxygen isn't being consumed during combustion, suggesting there wasn't enough gas in the mix. The heater was working/chugging as the flame and combustion process surged during operation.

The technician added the municipal gas supply pressure itself was fine.

So he feels that now that the properly functioning analyzer has allowed them to correct the blend, it should be fine. The gas burner chugging, rumbling noise should stop.

Wind a factor in gas burner operating trouble?

The service technician recalled that when the un-even burner performance and noises occurred, conditions were very windy. He speculated that high wind gusts blowing into the fresh air vent were pushing excess air into the combustion chamber. He said that if it happens again, now that the combustion mixture is corrected, they may need to think about the wind flow question.

He also finished off the outside exhaust and combustion air intake terminations. He lengthened the 'exhaust' vent with a coupling, adding the bird screen at the coupling inside the pipe to protect against birds, etc. He also shortened the 'fresh air' vent, adding the same bird screen to the slight elbow piece he added, which turns down.

See also DIRECT VENT WIND PROBLEMS

Check the gas flame appearance?

The technician pointed out the gas burner observation window on top of the Triangle Tube Combi 155 heater unit that you can look into and see the flame. For some homeowners, this may be hard to see due to the height of the unit.

See also BLUE vs YELLOW COMBUSTION FLAMES

...

Continue reading at GAS BURNER FLAME & NOISE DEFECTS - home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BANGING HEATING SYSTEM NOISES

- BLUE vs YELLOW COMBUSTION FLAMES

- DIRECT VENT WIND PROBLEMS

- GAS BURNER FLAME & NOISE DEFECTS - home

- GAS BURNER POPPING NOISES

- GAS BURNER RUMBLING CHUGGING NOISES

- GAS DETECTION INSTRUMENTS

- GAS LEAK DETECTION, LP / NG

- GAS LP & NATURAL GAS PRESSURES

- GAS PRESSURE FLOW INADEQUATE

- GAS REGULATOR NOISES - buzzing, humming, and other noises at gas appliance regulators

- LPG PROPANE TANK PRESSURES

- NOISE / SOUND DIAGNOSIS & CURE - home

- RUMBLING WATER HEATER

- TANKLESS WATER HEATER WHISTLE

- WATER HEATER SCALE DE-LIMING PROCEDURE - rumbling popping noises

Suggested citation for this web page

GAS BURNER RUMBLING CHUGGING NOISES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS APPLIANCES, PIPING, CONTROLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about gas burner operating problems: flame defects, noises, safety hazards.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.