Wind Problems with Direct / Side Wall Vent Chimneys & Flues

Wind Problems with Direct / Side Wall Vent Chimneys & Flues

Diagnose & fix loss of heat blamed on wind at a direct vent exhaust

- POST a QUESTION or COMMENT about the installation or diagnosis of sidewall vent or direct vent chimney or flue exhaust systems for heating appliances: oil, gas, other fuels firing heating appliances & fireplaces

Wind problems at direct vent chimneys.

How to diagnose and fix complaints of loss of heat blamed on wind blowing at direct-vent or side-wall vent chimneys or exhaust systems for gas or oil fired boilers and furnaces. The article includes both manufacturer's advice regarding wind problems at direct vent systems and a ten-point checklist of things to explore when diagnosing an repairing wind-related loss of heat at a building.

This article series describes side wall vent systems for conventional & mid-range-efficiency heating boilers, furnaces & water heaters. We include for comparison, low temperature side wall vent systems used by high efficiency or condensing boilers, furnaces & water heaters.

We explain the difference between side wall or direct venting for conventional/mid-range efficiency oil or gas burning heaters and side wall vented high efficiency condensing heating appliances.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Direct Vent or Side-Wall Vent Chimneys & Flues

Direct-venting or side wall vent chimney and flue systems are a method of venting the exhaust gases from a heating appliance directly out through the side wall of a building while eliminating the need for a vertical chimney of any sort. This article discusses the diagnosis of wind-related problems at direct-vent systems.

[Click to enlarge any image]

Reader Question: oil fired furnace cycles on and off - blamed on wind

I have an oil burning, direct vent Benjamin furnace. The furnace goes off and comes on several times when it needs to create heat. This is caused by the wind gusting at our location (usually from the north). Is there some kind of vent shield to help reduce the wind around the vent.

This is a common problem in this area and, according to an expert, there is no such thing, but if there was, the inventor could get rich as this is a common problem.

Thank - Anon [by private email] 11 Nov 2015

Reply:

Your service tech has more nerve that I do. I wouldn't have the temerity to claim "there's no such thing" about very much as for just about every problem, somebody has come up against it before and somebody has figured out something to do. We've certainly reviewed other wind and venting questions around direct-vent heaters, though I suspect the issue has arisen more for gas-fired heaters than oil fired units, that's because I think oil fired direct vent exhaust uses a stronger fan.

At a conventional (natural draft) chimney, a properly designed and listed chimney cap + a review of chimney height is enough to stop venting problems but with a direct-vent or power-vented horizontally-run unit that's a different matter.

The manufacturer thinks they designed the power vent to be strong enough to not suffer from wind fighting the vent or its blower though we will cite some exceptions for gas fired vents.

Wind trouble with oil fired direct vent units: example advice

Tjernlund describes their Sideshot® direct vent models SS1 & SS2 and SS1C used with oil fired heating equipment in documents found at the company's website given at the end of this article.

In the instructions for the Tjernlund Model SS1 or SS2 you'll see this note referring to wind problems:

For SideShot Series SS1 Models: The Pre-Cycle Prover Status Check is deactivated from the factory on the SS1 Series. Because of the low set point of the SS1 Fan Prover (as low as .03" w.c.) cross winds may cause the Fan Prover to close prior to a call for heat.

Activating the Prover Status Check on the SS1 may cause nuisance lockouts. Important: Deactivate the Pre-Cycle Prover status check if installing this board on a new or existing SS1 installation by pushing the #9 dip switch up or “ON” to disable.

For Draft Inducers with the UC1: Natural draft or winds may be sufficient to close the fan prover switch contacts prior to a call for heat when using the PS1505 fan prover with a draft inducer. Keeping the Pre-Cycle Prover Status Check activated may cause nuisance lockouts.

Important: Deactivate the Pre-Cycle Prover status check if installing this board on a new or existing draft inducer installation by pushing the #9 dip switch up or “ON” to disable. - Tjernlund, "Model SS2 Installation Instructions", [PDF], retrieved 11 Nov 2015 original source: http://www.tjernlund.com/Tjernlund_8504105C.PDF

The company also suggests possible sources of heater operating problems that might include wind and a venting system issue and offers these suggestions in response to LED#5 blinking 3, 4, or 5 times on the direct vent controller:

Investigate cause of Fan Prover short cycling such as; Firing burner at capacities or temperatures exceeding Venter limits, excessive vent pipe runs, elbows directly on venter discharge, high winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover switch.

In-Forcer model’s intake screen and prefilter, if applicable, should be cleaned if necessary. - Tjernlund, "SideShot® Model SS1 Installation Instruction", [PDF] retrieved 11 Nov 2015, original source: http://www.tjernlund.com/Tjernlund_8504102D.pdf

Gas fired driect vent units: example advice

As with the oil-fired direct vent systems described above, some gas fired heater side wall vent product instuctions also address possible wind issues and offer a solution. Tjernlund's Gas power vent installation instructions for the SideShot Series SS1 and Side Wall Vent Systems for natural gas, LP, oil, Models HSJ, HS1, HS2 in the owners' instructions include the following:

SideShot Series SS1 Models: The Pre-Cycle Prover Status Check is deactivated from the factory on the SS1 Series. Because of the low set point of the SS1 Fan Prover (as low as .03" w.c.) cross winds may cause the Fan Prover to close prior to a call for heat. Activating the Prover Status Check on the SS1 may cause nuisance lockouts.

Important: Deactivate the Pre-Cycle Prover status check if installing this board on a new or existing SS1 installation by pushing the #9 dip switch up or “ON” to disable.

For Draft Inducers with the UC1: Natural draft or winds may be sufficient to close the fan prover switch contacts prior to a call for heat when using the PS1505 fan prover with a draft inducer. Keeping the Pre-Cycle Prover Status Check activated may cause nuisance lockouts.

Important: Deactivate the Pre-Cycle Prover status check if installing this board on a new or existing draft inducer installation by pushing the #9 dip switch up or “ON” to disable. - Tjernlund, "Side Wall Vent Systems for Natural Gas, LP, or Oil, Models HSJ HS1 HS2, Owners Instructions - includes UC1 universal control" - retrieved 11/11/2015 original source: http://www.tjernlund.com/Tjernlund_8504106C.PDF

And as with the oil fired vents, these instructions include this note in responding to an LED fault indicator light #4 blinking 3, 4, or 5 times:

Investigate causes of Fan Prover not making, i.e; Firing burner at capacities or temperatures exceeding Venter limits, excessive vent pipe runs, elbows directly on venter discharge, high winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover.

However wind-operating issues are not addressed for every direct vent product. Tjernlund, in this example installation guide for a gas fired direct vent system:

http://www.tjernlund.com/Tjernlund_VP-2F_VP-3F_8504140.pdf

never mentions the word "wind".

So in my opinion, reading the manufacturers' instructions is where to start. Some techs just used the instructions to kneel upon while working on the equipment.

Watch out: here is an important safety warning from Tjernlund found on the direct vent instructions we cite in this article:

These instructions are intended as an aid to qualified, licensed service personnel for proper installation, adjustment and operation oOf this unit. Read these instructions thoroughly before attempting installation or operation.

Failure to follow these Instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, carbon monoxide poisoning, explosion, or personal injury or property damage.

Look for These Ten Problems with Power Vent Systems When Diagnosing a Wind Issue

Something less obvious could be at fault with a power vent system too. The wall leaks and ice shown around a direct vent termination in our photo above are discussed

at DIRECT VENT INSTALLATION, SNAFUS & SPECS.

You'll see in my comments below that I think it's a dangerous mistake to slap on a "repair" before we know exactly what is the cause of the trouble. For that reason I'd not jump to try to build a wind block before some further investigation. Maybe you've covered all of those bases but I"ll list some suggestions below.

If your service guy has not checked all of these then either he found an apparent issue (and was wrong) or he's a lot more experienced and a lot smarter than I.

Watch out: with any gas fired appliance and some oil ones there is a risk of fatal carbon monoxide poisoning if the system is not properly installed or not working properly. Be sure your CO detectors are correctly located, installed and working.

Next: tell me the fuel (oil or gas direct vents are different), the manufacturer, data tag data such as model of the direct vent unit and the model and serial of your Benjamin furnace (is it really a furnace - hot air not hot water boiler ?) and we can see what the manufacturers think we ought to do.

Meanwhile don't try building something over the vent as you might create a fire hazard.

And also meanwhile here are some things to check:

- Proper direct vent model?

Be sure that the direct vent system is the one the manufacturer of your furnace accepts for their unit - wrong model could = inadequate draft. - Proper direct vent controls?

Has your service tech checked that the fan prover switch is the correct one, correctly located and functioning properly? If the problem really is a response to wind, this could be the trouble. - Proper direct vent control settings?

Above we quoted notes from Tjernlund about proper dip switch settings on the direct vent control board, including deactivating The Pre-Cycle Prover Status Check in some circumstances. - Damaged direct vent fan:

Has the fan itself been checked for damage, loose or bent blades, loose wiring? - Damaged direct vent blower motor:

Has the blower motor been checked for proper operation, speed, output? (If the motor is very hot to the touch it could be failing or it could be seeing low voltage) - Flame igniter (gas units) defects:

While your tech is at it, have the igniter module checked: a weak spark can also be mistaken for a wind issue. - Improper driect vent termination cover:

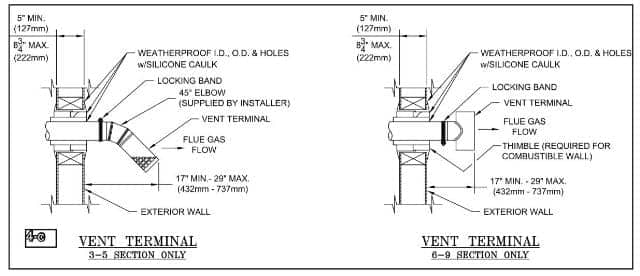

Check that the termination or cover on the direct vent - the outdoor components are exactly what the manufacturer specified. I've seen some dangerous installations and some misbehaving ones at which the installer invented their own termination, violating even the simple sketches given by the manufacturer.

One reason this occurs is that some direct vent kits do not include a factory-made termination. While you're at it, check all parts of the venting system: the vent pipe material, diameter, connectors, and the outside wall terminating cover. - Air Leaks:

check that there are no air leaks in any of the connections of the whole direct venting system from outside termination to connections at the heater. - Vent Blockage:

If you live in a freezing climate, look for signs of ice blockage in an improperly-draining vent: that can not only shut down the system, it can make it dangerous (if gas fuel, a CO risk). An inadequately supported, sagging or wrong-sloped vent can pool condensate and can freeze-up. Even in a climate where freezing does not occur, pooling condensate may interfere with venting. - Combustion air:

Check the combustion air supply; a partly blocked or inadequate air intake can cause the system to shut down as you describe.

Provide us with field data specifics to help diagnose the trouble: Describe the conditions at the outside wall where the vent terminates - in preparation for discussing with the manufacturers air redirection baffles or other site-specific solutions.

Tell us where you live and what the range of wind speeds and wind directions (vs. direction your vent wall faces) are.

Does snow cover ever cover the vent?

How high off the ground is the vent?

Has the vent been checked for partial blockage by a birds nest or insect nest?

Send me photos of the heater, vent from inside, vent from outside, and a more distant view showing that side of the home.

Finally, yes I have read claims (though not confirmed) that sometimes a manufacturer will recommend a wind-shield around the termination vent of a direct-vent heating system; if so we'll want to see that the measurements and materials are manufacturer-specified so as not to cause a heat or other dangerous problem at the building.

Reader follow-Up: blocking wind works as a temp-fix for this oil fired heater:

Here are 3 photos. After putting the board up it is working better. Before the board, the furnace would start and restart 15 times. - B.S. 2015/12/15 [Canada]

References for Direct Vent Product Sources & Installation Guides

- TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

- Tjernlund direct vent systems for oil fired heaters: http://www.tjernlund.com/oilsidewall.htm

Abstract:

The SideShot® models SS1 and SS2 SideWall Vent Systems include the UC1 Universal Control for increased safety, performance and reliability. Designed for oil fired heating equipment or a deluxe gas vent system.

Patented vent termination propels flue gases at high velocities away from the building exterior, a necessity when venting oil fired equipment. Both models can be installed with zero clearance to combustible materials and have stainless steel construction in critical areas.

Factory wired safety and operating controls allow simple interlock with any burner. The new model SS2 features a self-cleaning stainless steel, backward inclined impeller and sealed ball bearing motor for virtually maintenance free installations.

Ultra-fine draft adjustment and slide-out access to all internal components. Easy multiple appliance interlocks with our MAC Series multiple appliance controls. - Tjernlund direct vent systems for gas fired heaters: http://www.tjernlund.com/gassidewall.htm

- Tjernlund direct vent systems for oil fired heaters: http://www.tjernlund.com/oilsidewall.htm

- For a complete list see SUPPLIERS of Side Wall or Through Wall Vent Chimney Systems & Equipment - where to buy it

...

Continue reading at DIRECT VENT INSTALLATION, SNAFUS & SPECS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see DIRECT VENT WIND PROBLEM FAQs - questions & answers posted originally on this page

Or see these

Recommended Articles

- DIRECT VENTS / SIDE WALL VENTS - home

- GAS APPLIANCE / HEATER DIRECT VENT CLEARANCES

- GAS BURNER RUMBLING CHUGGING NOISES

- WALL-MOUNTED FURNACES

Suggested citation for this web page

DIRECT VENT WIND PROBLEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [2] Carrier Model BW9 Gas-Fired Condensing Boiler - Gas Fired Direct Vent Condensing Boiler - Example Installation & Operating Manual

- [3] "Instructions for Installing FIELD Type AF Barometric Draft Controls," Form No. 31 DC 30666, Field Corporation, Mendota, IL 61342, web search 04/02/2011, original source: http://www.fieldcontrols.com/pdfs/04592700.pdf, Field Controls, Kingston, North Carolina 28501, Tel: 919-522-3031

- [4] Tjernlund Draft Controls, A Series (single action for oil, solid fuel, and fan-assisted gas burners) and B Series (double action for gas heating appliances), web search 04/02/1011, original source: http://www.tjernlund.com/Tjernlund_8500490.pdf , Tjernlund Products, Inc., 1601 Ninth Street, White Bear Lake MN 55110-6794, Tel: 651-426-2993 or 800-255-4208 website: www.tjernlund.com Email: fanmail@tjfans.com

- [5] "Gas Side Wall Power Venters", Tjernlund Corporation, 1601 9th Street

White Bear Lake, MN 55110-6794 Tel: 800-255-4208, Website: tjernlund.com/gassidewall.htm, Quoting:

Side Wall Vent Systems save time and money and are excellent for electric to gas/oil, renovations, new construction or for replacing deteriorated chimneys. Side wall venting saves costly materials and labor on two, three or more story runs. It also increases living space by cutting out interior chases. Proven safety interlocks assure proper exhaust, a feature conventional chimneys do not offer in today's homes and buildings. - [6] "Oil Side Wall Vent Systems", Tjernlund Corporation, 1601 9th Street

White Bear Lake, MN 55110-6794 Tel: 800-255-4208, provides SS2 SideShot Wall Vent System. Website: .tjernlund.com/oilsidewall.htm Quoting:

The SideShot® models SS1 and SS2 SideWall Vent Systems include the UC1 Universal Control ... [ and are ] designed for oil fired heating equipment or a deluxe gas vent system. Factory wired safety and operating controls allow simple interlock with any burner. ... SS2 features a self-cleaning stainless steel, backward inclined impeller and sealed ball bearing motor for virtually maintenance free installations.- Tjernlund Corporation also provides a Sidewall Venting sizing tool for oil fired heating equipment (www.tjernlund.com/Sizing/Oil.htm) and a separate tool for gas fired heating equipment (www.tjernlund.com/Sizing/gas.htm).

- [7] Bradford White Sidewall Power Venter Kit, Field Controls, Tel: 252-522-3031, Website: www.fieldcontrols.com

- [8] National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- [9] "Tankless water heater side wall vent termination", Rheem Corporation, Website: http://www.rheem.com/products/tankless_water_heaters/

how_to_install/side_wall_vent_termination_10/ - [10] "Gold™ CGs Gas-Fired Water Boilers Venting Supplement: sidewall direct exhaust, vertical direct exhaust, sidewall direct vent, vertical direct vent models

- [11] "Mighty Venter Power Vent System", Laars Models MV2, MV2, MV4, MV5 for Mighty Therm 5009-1825. Bradford White Corporation, U.S. 20 Industrial Way, Rochester, NH 03867 • 603.335.6300, Canada, 1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100, Website: www.Laars.com

- [12] "Be Alert, Keep Sidewall Vents Clear", Vermont Gas Corporation, P.O. Box 467, Burlington VT 05402 Delivery: 85 Swift St, South Burlington VT 05403. Phone: 802.863.4511. Email: CustomerService@VermontGas.com, web search 4/1/2012, original source: vermontgas.com/winter/vents.html

- [13] "Power Venting, SWG/CV Power Venter, ComboVent Power Venter, Field Controls, FIELD CONTROLS, LLC 2630 Airport Road Kinston, NC 28504 Tel: 252.522.3031 Email: sales@fieldcontrols.com

- [15] "Gas Fired High Efficiency Furnace Down Flow & Direct Vent (Sealed Combustion) Thermo Pride Model CMA1-50N & CMA2-75N Installation and Service Manual", Thermo Pride, Thermo Products LLC, PO Box 217, North Judson, IN 46366, Tel: 574-896-2133, retrieved 12/30/2012, original source: www.thermopride.com/pdf/mg-508.pdf, copy on file as Thermo_Pride_CMA1-50N_CMA2-75N_Installation_mg-508.pdf

- Lennox Pulse Furnace Safety Inspection/Warranty Program: Carbon Monoxide Warning

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.