Cut Nail Nail Age, History, Identification

Cut Nail Nail Age, History, Identification

Key to age & types of old & modern cut nails

- POST a QUESTION or COMMENT about hand-cut or machine-cut nail age, properties, uses, types, useful also in determining building age by examining its hardware

How to identify antique & modern reproductions of cut nails.

This article includes an identification key to specific types & dimensions of cut nails, followed with examples and description of hand-wrought heads, derived from Nelson and other historical researchers of nails and fasteners and using additional nail identification key photos based on Tremont Nail Co.'s., History of Cut Nails in America, cited in detail here.

This article series describes and illustrates antique & modern hardware: door knobs, latches, hinges, window latches, hardware, nails & screws can help determine a building's age by noting how those parts were fabricated: by hand, by machine, by later generations of machine.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Antique & Reproduction Nail Identification Key

On this page we illustrate and help identify cut nails of various types. The use of nails and their features are also factors in guessing their age.

What is a "Cut Nail"?

Cut nails are metal nails, usually iron, occasionally brass or bronze, that were "cut" from a large flat rectangular metal plate by using a huge slicing blade that could cut red hot metal. By "wiggling" the nail plate from side to side as it was fed into the shear or cutting tool the result was a tapered nail blank that virtually eliminated the need for hand-forged nail pointing.

The earliest cut nails cut from blanks were made using a hand operated cutting machine and the nail heads then forged by hand.

Later inventions included a heading die that could form the head on a cut nail by an additional machine step.

Modern cut nails are made by powered machines that produce cut nails at much larger volume and greater speed.

Is it a Cut Nail & How Old Is It?

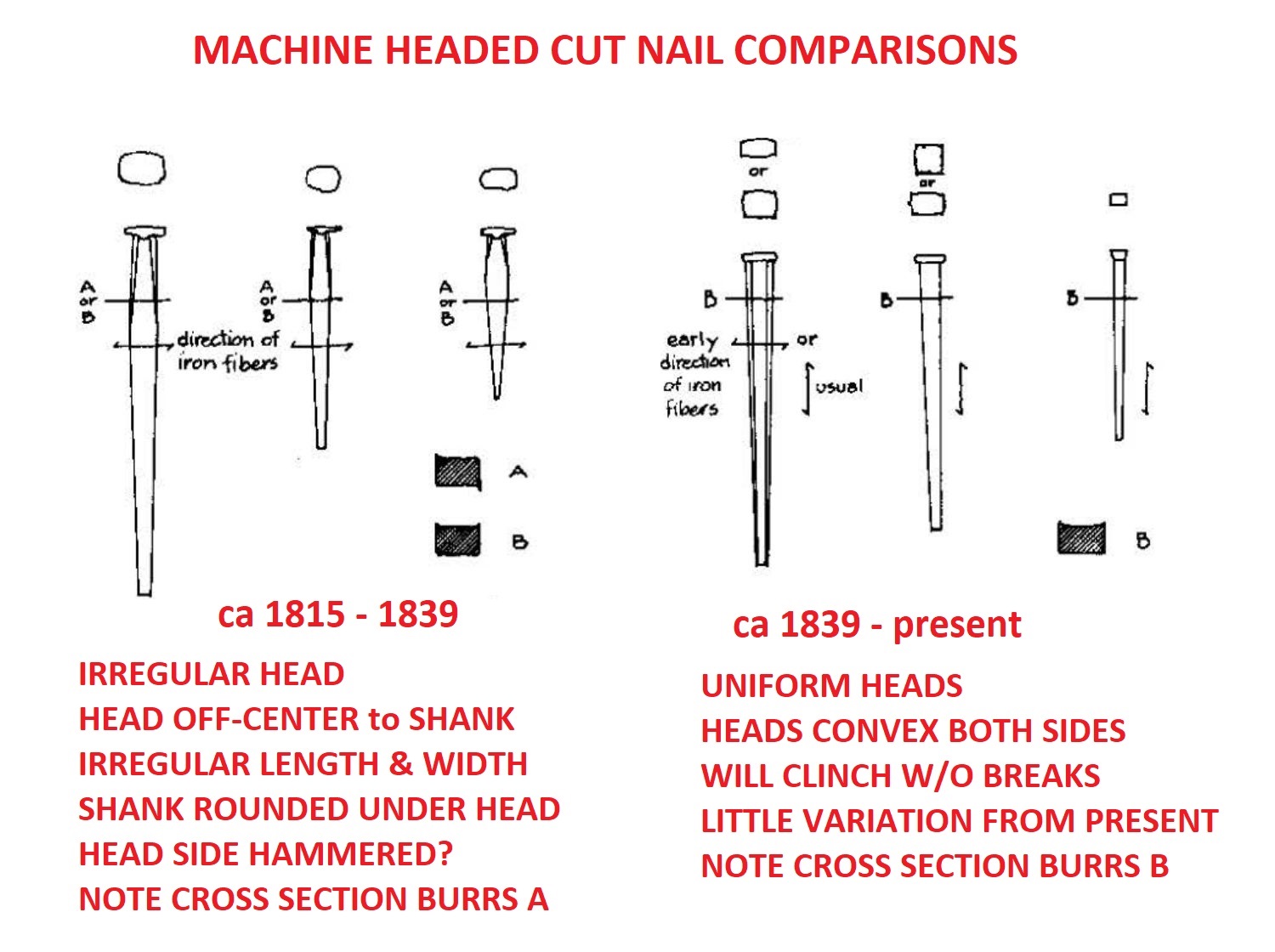

- The shape of a nail shank can help distinguish just how it was cut - a fact that helps determine its age as we will explain in more detail.

- The location of burrs on edges of the cut nail shanks tell us how it was cut and on what type of machine - additional factors in understanding the nail's age.

- The shape and type of head on the cut nail and the presence or absence of grip-marks on the nail shank below the head can also help define the nail's production methods and age.

- The regularity of cut nails will be greater in any group found than hand-forged nails, as they're made using machinery. However the oldest cut nails, cut by hand from blanks, may vary in width and shank angle as the fabricator may not have shifted the blank an identical amount during each individual nail cutting operation. The shank lengths, however will be very similar, varying only insofar as hand-forged heads on cut nails may vary.

- Distinguish from cut nails: of course your nail sample might not even be a cut nail. If it's hand-forged it may be considerably older, though there are also modern reproductions of hand-forged nails.

Our separate discussion of hand-forged nails

at NAIL ID & AGE: HAND FORGED NAILS can help you further distinguish between cut-nails and their older ancestors that were forged by hand - hand-forged nails.

If your question is just about the age of an old nail or spike, see the key found

at NAIL AGE DETERMINATION KEY but remember that knowing the type of nail also helps identify its historic context or use and thus is also a clue to its age.

For a chronological history of types of nails from earliest time

Article Contents

- TYPES of CUT NAILS

- FIRST NAIL MAKING MACHINES

- REPRODUCTIONS of ANTIQUE CUT NAILS

- TREMONT CUT NAIL EXAMPLES

What are the Types of Cut Nails?

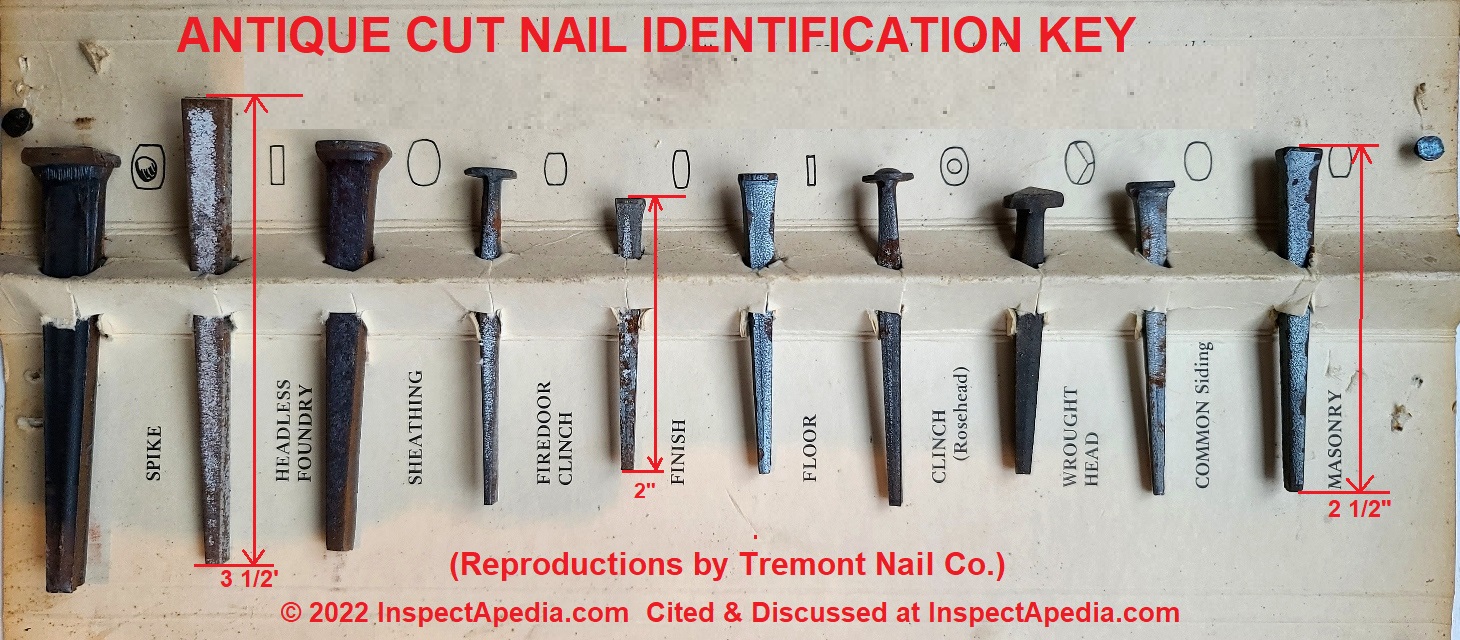

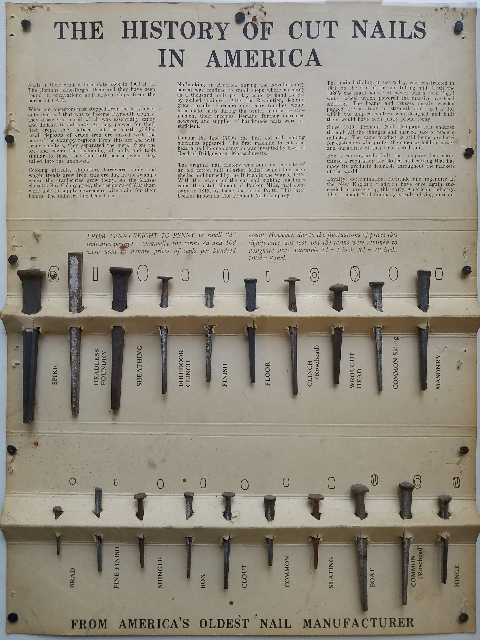

Above, excerpted and annotated from Tremont's panel of antique cut nails produced in America, we include some example cut nail dimensions.

[Click to enlarge any image]

Above the Tremont company illustrates, in order left to right, cut nails identified as

- Spike (3 1/4")

- Headless Foundry nail (3 1/2")

- Sheathing nail (3 1/16")

- Firedoor Clinch nail (2 1/2")

- Finish nail (2")

- Flooring nail (2 1/4")

- Clinch nail with rosebud head (2 1/2")

- Wrought Head nail (2 1/4")

- Common siding nail (2 1/2")

- Masonry nail (2 1/2" to 2 5/8")

You can obtain the lengths of other nails in this key by comparing the others with those whose lengths we've indicated.

Watch out: the lengths of nails, both hand wrought and cut, may indeed vary from these examples depending on who made them, where the nail was produced, and its exact production method.

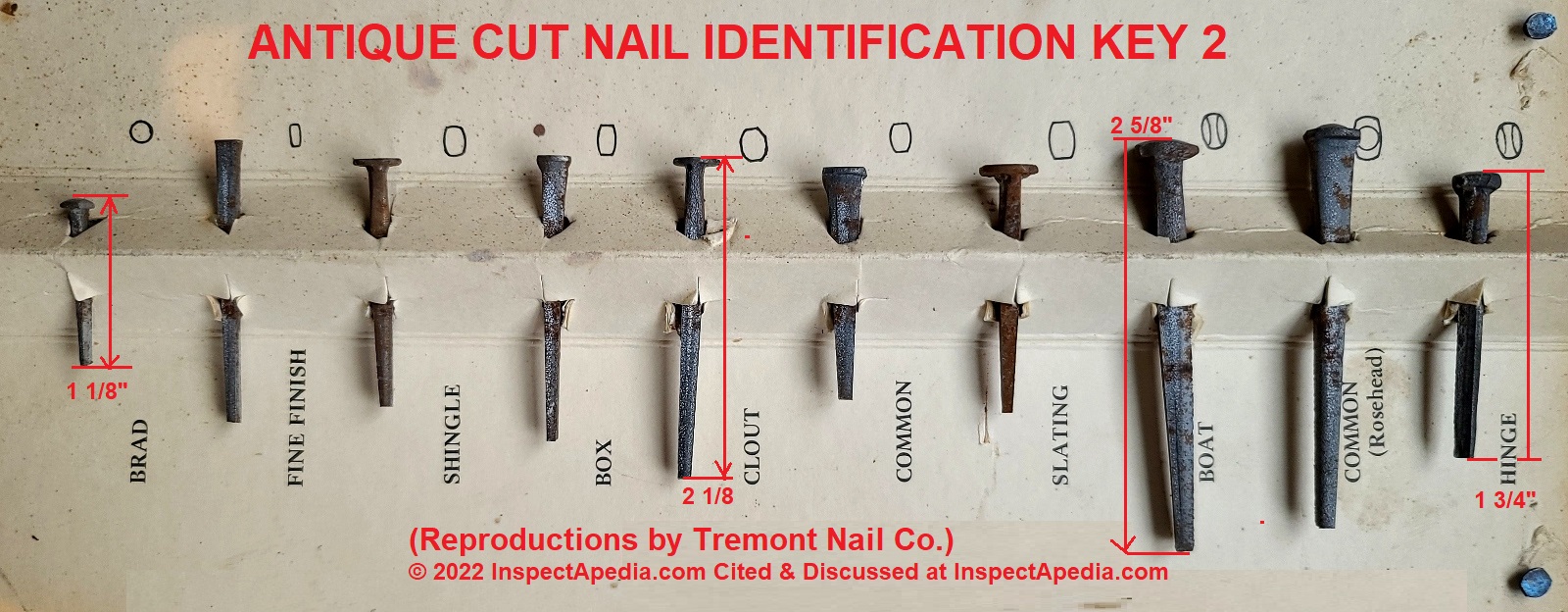

Below, Tremont illustrates cut nails from left to right:

- Brad (1 1/8")

- Fine finishing nail (1 7/8")

- Shingle nail (1 5/8")

- Box nail (1 7/8")

- Clout nail (2 1/8")

- Common nail (1 1/2")

- Slating nail (1 5/8)

- Boat nail (2 5/8")

- Common nail with rosebud head (2 5/8")

- Hinge nail (1 3/4")

Tremont supplies restoration contractors and others working on historic buildings and for historians, Tremont offers a reference set of modern reproductions of old nails fasteners, shown above and below.

- Contact: Tremont Nail Company, P.O. Box 31, Mansfield, MA 02048, Tel: 800-835-0121, 508-339-4500 Website: http://www.tremontnail.com/

First Nail Making Machines in North America - 1790 "Cut Nails"

1772 - 1820: In North America early machine cut nails

Dating from 1590 in England, as the earliest report of nail production, the earliest reported cut nails in America are reported to have been cut, essentially by-hand, by Darrow in 1772 (Federal Writers Project 2013) with other authors crediting the Wilkinson brothers somewhat later, ca. 1783 (Benedict 1883).

Dating from 1590 in England, as the earliest report of nail production, the earliest reported cut nails in America are reported to have been cut, essentially by-hand, by Darrow in 1772 (Federal Writers Project 2013) with other authors crediting the Wilkinson brothers somewhat later, ca. 1783 (Benedict 1883).

The Wilkinson's realized that if the flat iron plate were simply shifted back and forth on an angle as each successive nail was cut from the blank, the nails would already be tapered and pointed, greatly speeding the process of making usable nails.

Nelson notes the first generation of cut nail manufacturing involved cutting all nails from common sides with heads hammered on as a separate production step.

The first nail making machines in North America appeared during the late 1700's - earlier than one might have guessed.

The slitting mill, introduced to England in 1590, simplified the production of nail rods, but the real first efforts to merchandise the nail-making process itself occurred between 1790 and 1820, initially in the United States and England, when various machines were invented to automate and speed up the process of making nails from bars of wrought iron.

These nails were known as cut nails or square nails because of their roughly rectangular cross section.

Cut nails were one of the important factors in the increase in balloon framing beginning in the 1830s and thus the decline of timber framing with wooden joints. (Kirby 1956)

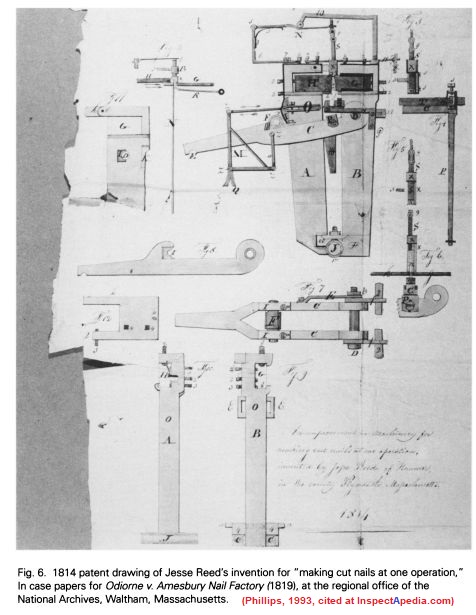

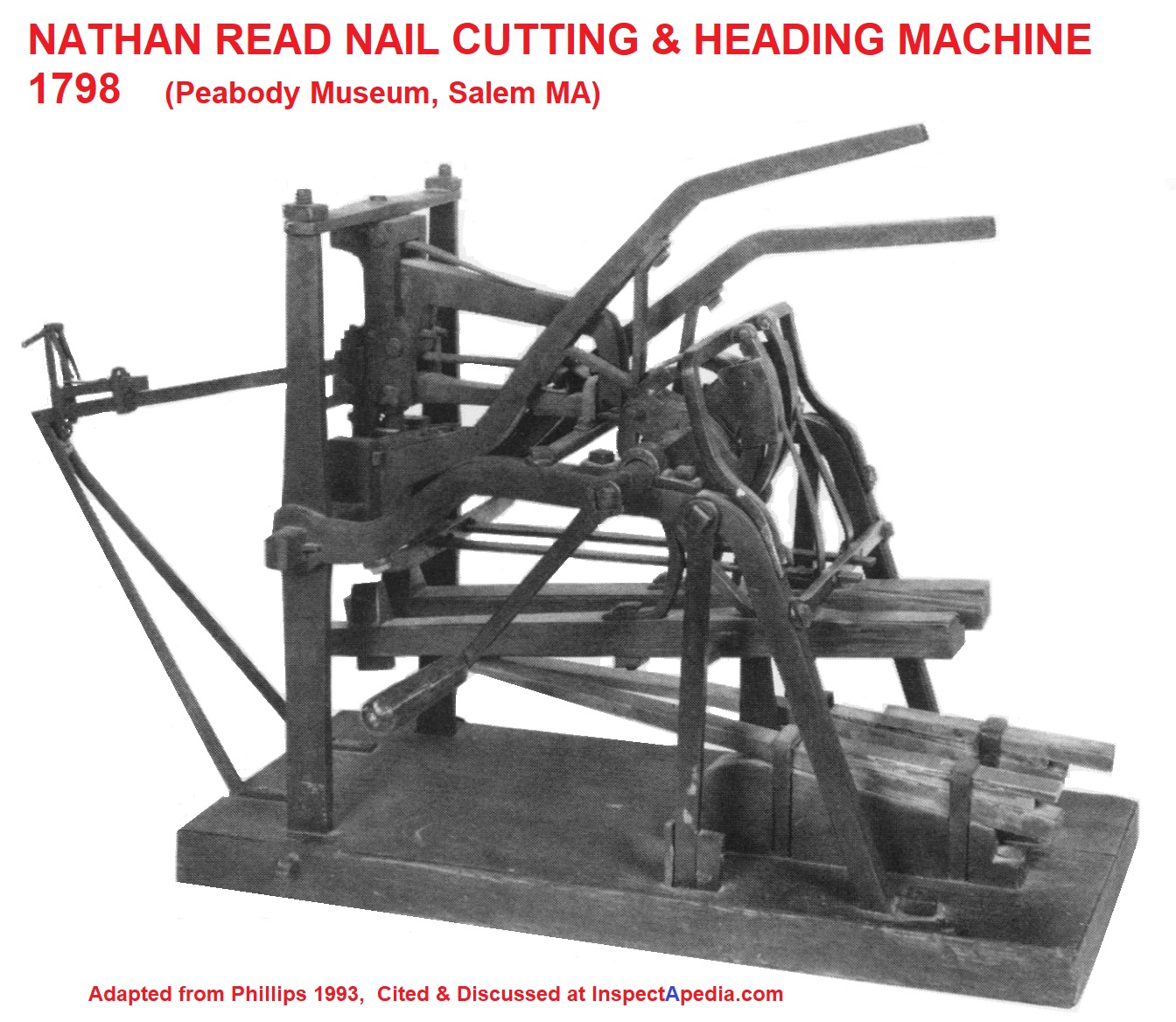

Illustration above: a Read nail cutting machine. Nathan Read produced cut nails at their Salem Iron Factory beginning in 1798. Ezekiel Reed (un-related to Nathan) is credited with inventing the one-operation nail cutting machine in 1807. (Phillips 1993).

Jacob Perkins, inventor of a water-powered nail-cutting machine, began producing machine-made cut nails in 1794 and in 1795 received the first U.S. nail-cutting machine patent. His production combined an Ostrich nail cutting engine and a Vulcan nail-heading machine. (Phillips, 1993). The machinery skewed or "wiggled" the nail plate stock from side-to-side between cutting strokes, thus producting the tapered nail shanks that avoided having to hand-forge nail points or tapers.

Perkins' cut nails were formed to have a nail shank that is rectangular in cross setion with two tapering sides with burrs from the cutting blade appearing on diagonally-opposite edges. The nail head was flat, thin, irregular, and eccentric to the shank, and the nail shank just under the head was rounded and thinner than the rest of the shank - the effect of the vise that gripped the nail during the heading step. (Phillips, 1993).

A key contributions to nail production credited to Perkins was the production of nail plate stock that was sized big enough to permit cutting nails whose iron fibre or grain was longitudinal to the nail shank.

[B]ut in order to provide for this quality, also, in my said cut nails, when it is intended to make cut nails that is required to be clenched, I have the iron or other metal rolled into plates as wide as they can conveniently be made, and then have these plates slit or divided transversely into strips or plates, and the nails cut from these strips or plates will have their strata or fibres of the metal disposed longitudinally or lengthwise of the nails, which will render them as flex- ible as those which are wrought from nail rods, and equally susceptible of being clenched. (Phillips, 1993 citing English Patent No. 3365, application dated July 26, 1810; specifications filed January 26, 1811.)

Shown below are nails used to secure accordion lath - a plaster base found in a rural U.S. post-and-beam home in Wyoming County, New York.

More about the accordion wood lath in this building and our estimate of the building age are

Below: our green arrow points to the characteristic edge ridge that illustrates a machine made cut-nail.

The red arrow points to a split in the cut nail, characteristic of the effort to align the fibres of iron running down the length of the nail - discussed in our description of nails made after 1830 - below. .

These photos of antique cut-nails were provided by an InspectApedia.com reader June 2018.

As I mentioned about a different nail in photos on this page, the fact that the delaminating or split in this nail run lengthwise (parallel to the nail shank) suggest that the nail was of iron whose fibers ran lengthwise, making the nail one probably made after the late 1830s.

For these nails, because it appears that the two cutting/stamping burrs appear on the same side of the nail suggest the nail may have been made after 1840.

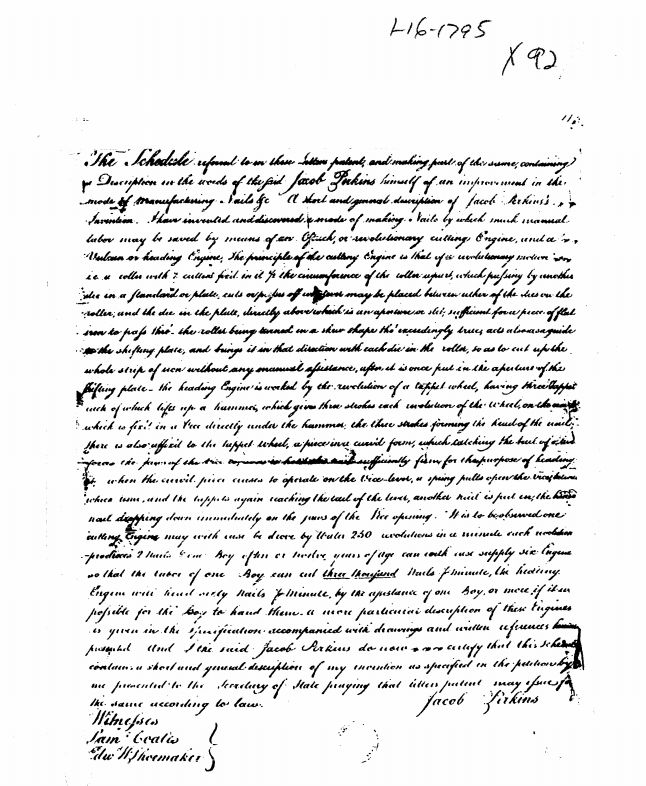

Below: Jacob Perkins' 1795 Nail Production Machine Patent. Perkins was a polymath described as an inventor, mechanical engineer, and physicist [Wikipedia] who held 12 American patents and another nineteen English patents. His machine for cutting and heading nails was issued when Perkins was just 24 years old. His nail factory was powered by water from the Powwow river in Amesbury Massachusetts.

Though still used for historical renovations, and for heavy-duty applications, such as attaching boards to masonry walls, cut nails are much less common today than wire nails. - source: https://en.wikipedia.org/wiki/Nail_(fastener) retrieved 2018/06/15

The cut-nail process was patented in America by Jacob Perkins in 1795 and in England by Joseph Dyer, who set up machinery in Birmingham. The process was designed to cut nails from sheets of iron, while making sure that the fibres of the iron ran down the nails.

Also see Pitt (2003) cited below.

Jacob Perkins' NAILING MACHINE PATENT No X-92 [PDF] was granted Jan. 16, 1795, to Jacob Perkins, Newburyport, MA, witnessed by Sam Coates and Edward W. Shoemaker.

Regrettably all of the drawings are missing from the patent scan.

Here we reproduce the photographic copy of Perkins' nail machine patent; the photo itself was made from the original on 3 March 1911.

Note: the first U.S. patent was issued in 1790, and in 1795 the U.S. issued just 12 patents.

See our separate guide to cut nails at

NAIL ID & AGE: CUT NAILS - photos of types of cut nails and details about determining their age.

Who made the first cut nails in America?

An inspectapedia reader asked:

According to “The WPA Guide to Connecticut: The Constitution State”, By the Federal Writers Project.

The first cut nails produced in America were produced by Edmund Darrow in 1722. It says:

“Early industry did not attain any importance until 1772 when a Bean Hill blacksmith, Edmund Darrow, produced from barrel hooping the first cut nails in America”.

- books.google.com/books?id=E07pCAAAQBAJ&pg=PT324&lpg=PT324&dq=Edmund+Darrow+1772&source=bl&ots=D6v851C38P&sig=ACfU3U3CziUWfa8g5zLnoFOeE62bQF-oWg&hl=en&sa=X&ved=2ahUKEwiuz6yx4-bpAhWQT98KHYZEBIwQ6AEwAHoECAYQAQ#v=onepage&q&f=false

There is another reference: “Reminiscences of Bean Hill, Norwich” page 297, written in 1897 by Burrell W. Hyde that states the same thing.

- play.google.com/books/reader?id=Wv8aAAAAYAAJ&hl=en&pg=GBS.PA297

Your website states that the first cut nails were made in 1790 (18 years later than 1772).

Can you tell me who is correct? I’m doing a research project and am wondering which reference is correct.

Thanks very much. Bob Dees 2020/06/04

Moderator reply:

Thanks for the discussion, Bob. I think that for clarity we should distinguish between actual production of "cut nails" that included manual cutting of nails out of existing sheet iron (like a barrell hoop), and nail making machines that in turn could produce large volumes of nails.

Thanks for the discussion, Bob. I think that for clarity we should distinguish between actual production of "cut nails" that included manual cutting of nails out of existing sheet iron (like a barrell hoop), and nail making machines that in turn could produce large volumes of nails.

My favorite source, often cited, for the history of nail making is Nelson, but the article above and also the references at the end of this page cite several sources.

Above, from Nelson, we note that nail making machinery dates back to 1590 - in England.

The slitting mill, introduced to England in 1590, simplified the production of nail rods, but the real first efforts to merchandise the nail-making process itself occurred between 1790 and 1820, initially in the United States and England, when various machines were invented to automate and speed up the process of making nails from bars of wrought iron.

To get back to your original comment, citing

- Benedict, W. Charles, History of the Town of Sutton, Massachusetts, from 1704 to 1876: Including Grafton Until 1735; Millbury Until 1813; and Parts of Northbridge, Upton and Auburn. town, 1878.

We have on page 279 this by the author:

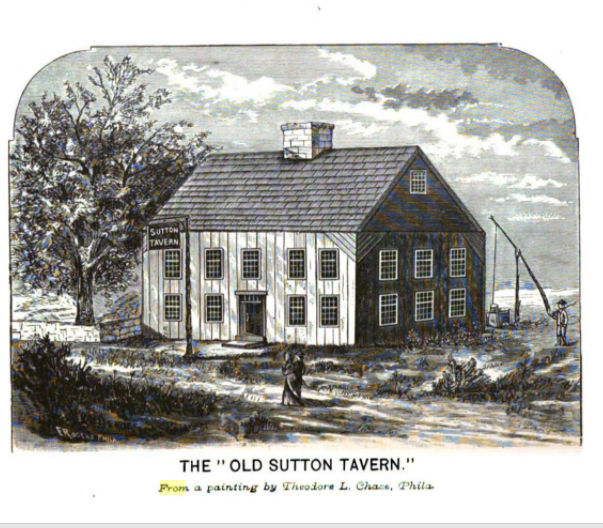

The author was discussing, in history of Sutton MA, the "Old Sutton Tavern", (an engraving is shown in the book) and writes about hand wrought nails used in construction of the tavern:

"As will be seen by the engraving, that represents it as it originally appeared, the siding consists of thick oak planks nailed perpendicularly to the frame, and at each of the upper corners the planing is placed diagonally, for the purpose of giving additional strenth in bracing the building.

The clapboards were not added until a later period. They were cloven by hand and fastened by hand-made nails, * cut nails being then unknown.

* About the time of the close of the revolutionary war two brothers of the name Wilkinson, who had ironw orks in Cumberland, R.I., cut a lot of nails from some old barrel hoops, "Spanish hoops," as they were called, and these are supposed to have been the first cut nails ever made.

The first cut nails produced in America were produced by Edmund Darrow in 1772. (Federal Writers' Project 2013) cited by you

Excerpt: “Early industry did not attain any importance until 1772 when a Bean Hill blacksmith, Edmund Darrow, produced from barrel hooping the first cut nails in America”.

And a similar but less explicit date crediting the Wilkinson brothers in Cumberland R.I., ca 1783 (as the American revolutionary war is dated as April 19, 1775 - September 3, 1783) - (Benedict 1878)

Benedict was writing a bit under 100 years after the end of the revolutionary war so was closer in time to the event of interest, but on the other hand the very recent (2013) Federal Writers' project may benefit from more extensively-available resources.

In sum I'd like to duck the trouble of who made the first cut nails by describing the history as

Dating from 1590 in England, as the earliest report of nail production, the earliest reported cut nails in America are reported to have been cut, essentially by-hand, by Darrow in 1772 (Federal Writers Project 2013) with other authors crediting the Wilkinson brothers somewhat later, ca. 1783 (Benedict 1883).

Also in

James Campbell, Nicholas Bill, Karey Draper, Patrick Fleming, Yiting Pan, Wendy Andrews, Proceedings of the First Conference of the Construction History Society

(2015)

[This volume collects together the papers delivered at the first annual conference of the Construction History Society, held in Queens' College, Cambridge in 2014. Papers cover a wide range of topics all on the common theme of the history of construction, from the ancient world to the present day.]

The volume includes discussion of American cut nails and also of the British cut clasp nail, beginning on p. 233

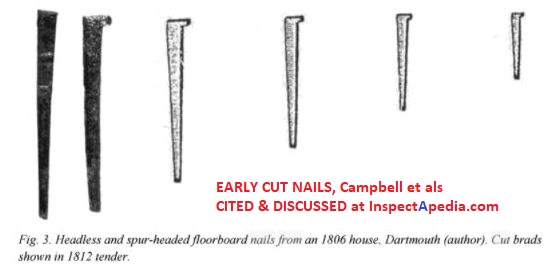

In the illustration above those offset-headed nails were referred to by the author as spur-headed nails. Other sources (Nelson, NPS) identify these heads as used on sprigs and brads (finish nails) while the larger T-headed nails and rose-headed nails were used in framing and also in smaller form for holding wood lath onto framing as a plaster base.

American cut nails

With some justification, the Americans claim that machine production of cut nails was an American invention. From a simple beginning, the lever-operated guillotine machine patented by the prolific Jacob Perkins in 1795 was developed by various independent inventors into a series of efficient cut nail fabrication devices. [21]

By 1810 water powered nail machines had been developed, although American nail making predominantly relied on manual machines.

Nails of a primitive sort could always be cut manually by a blacksmith from heated barrel hoop or other strip iron and several instances of this resort to basics are recorded in the 1788 colony at Botany Bay. [22]

Perkins' later machine took the process one step further and cut tapering shanks from a heated iron ribbon. In order to maintain a taper to the proto shank, the ribbon either had to be wiggled through a shallow horizontal arc or flipped over between each cut.

Perkins' machine was entirely manual, but recent research has shown that at "black heat" of around 500 degC, the shear force of a typical nail shank drops to roughly 300 kilograms. Using leverage. this is easily attainable. [23] The device significantly speeded uip the cutting of basic nail shanks.

These simple headless brads have been found in Britain both of iron and steel, and were usually used in flooring or specialist work. (Fig. 3, nail 1). In American they would be re-heated and headed separately with either conventional facetted heads or bulbous oval heads would be formed with a hand-held die. ...

Reader follow-up

Bob Dees said:

Thanks very much. If I can find a more definitive, more descriptive narrative of the 1772 Edmund Darrow cut nails of Norwich CT, I'll let you know. - 2020/06/04

Modern Reproductions of Antique Hand-Wrought Nails

[Click to enlarge any image]

Above, adapted from Nelson (NPS), we summarize some observations that can help separate early cut nails from later cut nails used in North America.

If your cut nail is irregular in shank width and has the "A" type side burrs, it's likely to have been made before the late 1830s.

Even most reproduction nails that simulate hand-wrought fasteners will show regularity: the same simulated-hand-hammered head will appear on every nail, and you may observe the straight--edged raised rib of die cut nails made by machine.

Below is a modern cut nail showing the uniformly convex head on both sides of the nail head. This is the head of a modern machine-made cut nail.

Tremont Nail Company continues to manufacture reproduction nails which in appearance are quite like those made by hand more than 100 years ago.

The original factory was established by Issac and Jared Pratt in 1819 on the site of an old cotton mill which had been shelled and burned by the British in the War of 1812.

Known originally as Parker Mills Nail Company, it later became known as the Tremont Nail Company. - Tremont Nail, http://www.tremontnail.com/about.htm

Above is a "hand wrought style" machine made cut nail, produced by Tremont.

Shown above is Tremont's standard Clout Nail: Similar in design to Shingle Nails, but made from lighter gauge steel, this nail was (and is) used for the application of thin siding and paneling.

It was and is also used for furniture repair, cabinet work, batten doors and counter tops. (Photo courtesy Tremont Nail Company).

The Mansfield, Massachusetts Tremont Nail company's historical notes indicate that nails have been made (by hand) dating back to 300 B.C.

Tremont further explains that in North America, nails were made by hand, often as a winter activity.

Tremont Cut Nail Detail Examples

Above and below, using a Tremont machine-made boat nail as an example we illustrate the sharp edge profile (below left) and the line left along the shank of the cut nail by the stamping machine (below ) that characterizes machine made "cut nails" appearing in widespread use as early as the 1830's in the Northeastern U.S. and appearing later in other locations.

More Images of Tremont's Modern Reproductions of Antique Nails

The ruled Tremont nail photo below is followed by four additional photographs of all four sides of this nail.

Below we show all four sides of this nail.

Below is a close-up of the head of the cut nail spike described just above.

This view is important since, if you are examining a completed structure, the nail head may be about all you can see of the fastener.

Research on Cut Nail History & Identification, Manufacture & Age

- Adams, W.H. Machine cut nails and wire nails: American production and use for dating 19th-century and early-20th-century sites, Hist Arch (2002) 36: 66. https://doi.org/10.1007/BF03374370

- Ferguson, Eugene S. "The Rise and Decline of the American Cut Nail Industry: A Study of the Interrelationships of Technology, Business Organization, and Management Techniques. By Amos J. LovedayJr.(Westport, Conn.: Greenwood Press, 1983. xx+ 160 pp. $29.95.)." Business History Review 58, no. 4 (1984): 610-611.

This is a review of Loveday's The rise and decline of the American cut nail industry cited below.

Excerpts:

In the 1880s, at the peak of production of machine-mae cut nails, Americans, used nearly ten pounds of nails per capita. That figure was nearly five times the per capita consumption in 1810, and the price per pound [for cut nails] in 1887 was only one fifth that of 1810. The machine-made cut nail was a significant American innovation of the nineteenth century, and anumber of nail-making centers arose. This book, despite its general title, is about the nail makers of Wheeling, West Virginia, one of those centers.

...

It was in the 1880s that the wire nail, a French innovation, was introduced in America, and the demand for cut nails rapidly dried up. The businessmen owners and cost-accounting operators disregarded the threat and made no effective attempt to make wire nails. By 1902, the American production of wire nails had surpassed that of cut nails. Ten years later, 92 percent of all nails made in America were wire nails.

Prospective purchasers should be warned that this book is an overpriced, lightly revised, and inadequately edited re-publication of a recent Ph.D. dissertation. Its limitations are suggested by the title of Loveday's dissertation: "The Cut Nail Industry 1776 - 1890; Techology, Cost Accounting and the Upper Ohio Valley." [also cited below - Ed.]

- Loveday, Amos J. The rise and decline of the American cut nail industry: A study of the interrelationships of technology, business organization, and management techniques. No. 53. Praeger, 1983. - and - Business Organization, and Management Techniques (Westport, CN: Greenwood Press, 1983)

- Loveday Jr, Amos John. THE CUT NAIL INDUSTRY 1776-1890; TECHNOLOGY, COST ACCOUNTING AND THE UPPER OHIO VALLEY [PDF] PhD diss., The Ohio State University, 1979.

- Maddox, Lee R., LABELL IRON WORKS, PHOTOGRAPHS, DRAWINGS, DESCRIPTION of the Labelle Cut Nail Collection [PDF] National Park Service, Lee R. Maddex

Historian

Historic American

Engineering Record

August 1990. - retrieved 2022/04/28 original source: http://lcweb2.loc.gov/master/pnp/habshaer/wv/wv0300/wv0329/data/wv0329data.pdf

Excerpts (some paraphrasing)

The Labell Iron works (La Belle Cut Nail Works) was built in 1852 with additions circa 1870, 1890 and 1920, and is still in operation, currently owned by Wheeling-Pittsburgh Steel Corporation Wheeling, West Virginia.

La Belle is the largest American cut nail factory and one of two remaining United States cut nail manufacturers. La Belle has been in business for almost 140 years and still uses the same equipment and processes to make cut nails. La Belle helped make Wheeling the "Nail city" during the late 19th century. - Melchert, Ken, "The Humble Nail – A Key to Unlock the Past" [archived here as PDF] The Harp Gallery, 2495 Northern Road

Appleton, WI 54914

USA retrieved 2020/07/06 original source: https://www.harpgallery.com/library/nails.htm

Excerpts:

Archaeologists have found hand made bronze nails from as far back as 3000 BC. The Romans made many of their nails from iron, which was harder, but many ancient iron nails have rusted away since. The hand-forged nail changed little until well into the 1700's.

...

In Europe in the 1850's, steel wire was made into tiny nails known as “brads,” with only a very small widened head. These continue to be used to attach small moldings and trim. About 1880 in America and in Europe, the modern wire nail was developed. - Nelson, Lee H., NAIL CHRONOLOGY as an AID to DATING OLD BUILDINGS [PDF], Historic American Engineering Record

National Park Service

Department of the Interior

Washington, D.C. 20013-7127 , Technical Leaflet No. 48. retrieved 2019/01/08, original source: http://npshistory.com/publications/nail-chronology.pdf

Excerpt:

Dating old buildings from their nails is not a precise technique, but when used with discretion, it has proved generally reliable and useful, for example, in Independence Hall which has been subjected to a complex series of alterations from 1750 to the present time.

If a sufficient number of samples are taken from all parts of the building they can be a good indication that

( 1) the building was built entirely at a given time, or

( 2) the building has been subjected to additions, alterations, or simple maintenance measures.

Nails can help to define the extent of these changes. For this reason we believe it worthwhile to discuss briefly the various nail types that arc generally found in American buildings.

They are

( 1) hand-wrought nails,

( 2) cut nails, and

( 3) wire nails.

Within these major groups there is a surprising variety with subtle differences in type which enable us to use nails as dating tools with some certainty.'

- Phillips, Maureen K., MECHANIC GENIUSES AND DUCKIES, A REVISION OF NEW ENGLAND'S CUT NAIL CHRONOLOGY BEFORE 1820, [PDF] APT Bulletin Vol. XXV No. 3-4, (1993), pp. 4-16, Association for Preservation Technology (APT) Stable URL: https://www.jstor.org/stable/1504461

Excerpt from Introduction:

The standard accepted chronology of the manufacture of cut nails used in the field today is based on Henry Mercer's 1923 article "The Dating of Old Houses" and on Lee Nelson's 1968 pamplet "Nail Chronology as an Aid to Dating Old Buildings."

However, restoration work in the New England, New York, and the mid-Atlantic areas perfor4med since the 1970's has led preservationists to theorize that some types of early cut nails may have been manufactured several years earlier than had been postulated by Mercer and Nelson.

For example, during recent restorationwork at an historic structure in Newbury, Massachusetts, cut nails with characteristics thought to date to post-1815 were found in building fabric known to date before 1807. It was decided to test this thoery by documenting cut-nail manufacturing in New England in the late eighteenth and early nineteenth centuries.

Three areas were studied: the operation of nail factories around Boston during that period, the descriptions of early nail m achines those factories used, and dateable nail samples from New England structuers that machines may have been produced.

...

A catastrophic fire in the U.S. Patent Office in Washington, D.C. in 1836 destroyed most of the specifications and drawings of the patents filed to that date. While some records were recreated from copies of patent documentation existing in other repositories, these records are far from complete, and the missing documents created critical gaps in the record.

Fortunately some of these gaps were filled when copies of specifications and drawings for two important early nineteenth-century cut nail machine patents were found filed with the ase papers of an early nineteenth-century patent inufringement lawsuits in the regional office of the National Archives in Waltham, Massachusetts.

...

In addition, documentationfor a third important early nineteenth-century machine was found in the specifications and drawings of an 1810 English patent that was filed by an American inventor.

The newly-discovered material provided a tantalizing glimpse into the era of early cut-nail technology, and resulted in the development of a revised chronology for cut nails that relates specifically to New England construction for the years between 1790 and 1815.

- See our complete bibliography including more articles on the history & prodution of cut nails

at

NAILS & HARDWARE, AGE RESEARCH

...

...

Continue reading at NAILS, AGE & HISTORY - home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see NAIL ID & AGE: CUT NAILS-FAQs, diagnostic questions & answers posted originally at this page.

Or see these

Recommended Articles

- AGE of a BUILDING, HOW to DETERMINE - home

- DOOR HARDWARE AGE

- NAILS, AGE & HISTORY - home

- HORSESHOE & HORSESHOE NAIL AGE

- NAIL & HARDWARE, AGE RESEARCH

- NAIL & HARDWARE CLEAN-UP

- NAIL AGE DETERMINATION KEY - use this key to guess at the age of your nail or spike

- NAIL ID & AGE: CUT NAILS

- NAIL ID & AGE: HAND FORGED NAILS

- NAILS in BARTER & TRADE

- NAIL SPLITS & CRACKS vs AGE

- NAIL TYPE, ANTIQUE, IDENTIFICATION KEY

- RAILROAD SPIKES

- RAILROAD SPIKE AGE - CONTEXTUAL CLUES

- SAW & AXE CUTS, TOOL MARKS, AGE

- WINDOW HARDWARE AGE

Suggested citation for this web page

NAIL ID & AGE: CUT NAILS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING AGE

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.