Age of Horseshoe Nails & Horseshoes

Age of Horseshoe Nails & Horseshoes

Context, Head, Shank, Details Help Guess Age of Horseshoes & Nails

- POST a QUESTION or COMMENT about determining the age & history of horseshoe-nails & shoes

Easy questions help form a guess at the plausible age of horseshoes and horseshoe nails.

This article series describes antique and modern cut nails focusing on tree nails, wrought nails, and cut nails used in wood frame construction or interior finishing or carpentry work. It includes useful dates for the manufacture of different nail types.

The shoes worn by the horse shown above were nailed in place in June, 1956. The author, Daniel Friedman, was introduced to horse shoeing at the Tumbleweed Guest Ranch in Westkill, New York where older, more-experienced farriers and horse breakers, hailing from the west, were employed by the ranch owner.

Watch out: on the first day of horse shoeing back in 1958 I saw the farrier lose his grip on the foot of a rambunctious cow pony who yanked his foot through the farrier's legs before the horse shoe nails had been snipped and crimped down. The sharp points ripped right through heavy leather chaps and into the farrier's thigh.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Age of Horseshoe Nails & Horseshoes

Determine the age of horseshoes & horseshoe nail history

Determine the age of horseshoes & horseshoe nail history

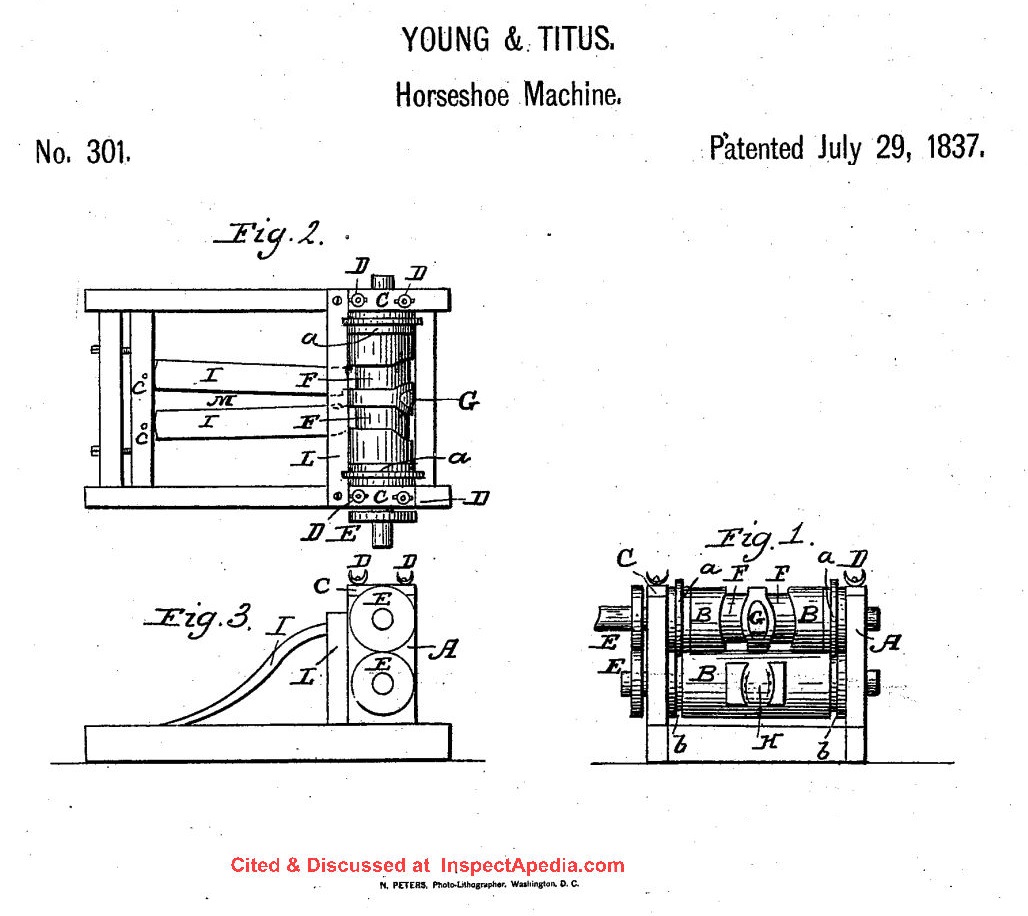

Illustration: Young & Titus horseshoe making machine patented in the U.S. in 1877, U.S. Patent No. 301. This machine was for making horseshoes, not horseshoe nails and was one of the earliest patents issued by the then new U.S. patent office.

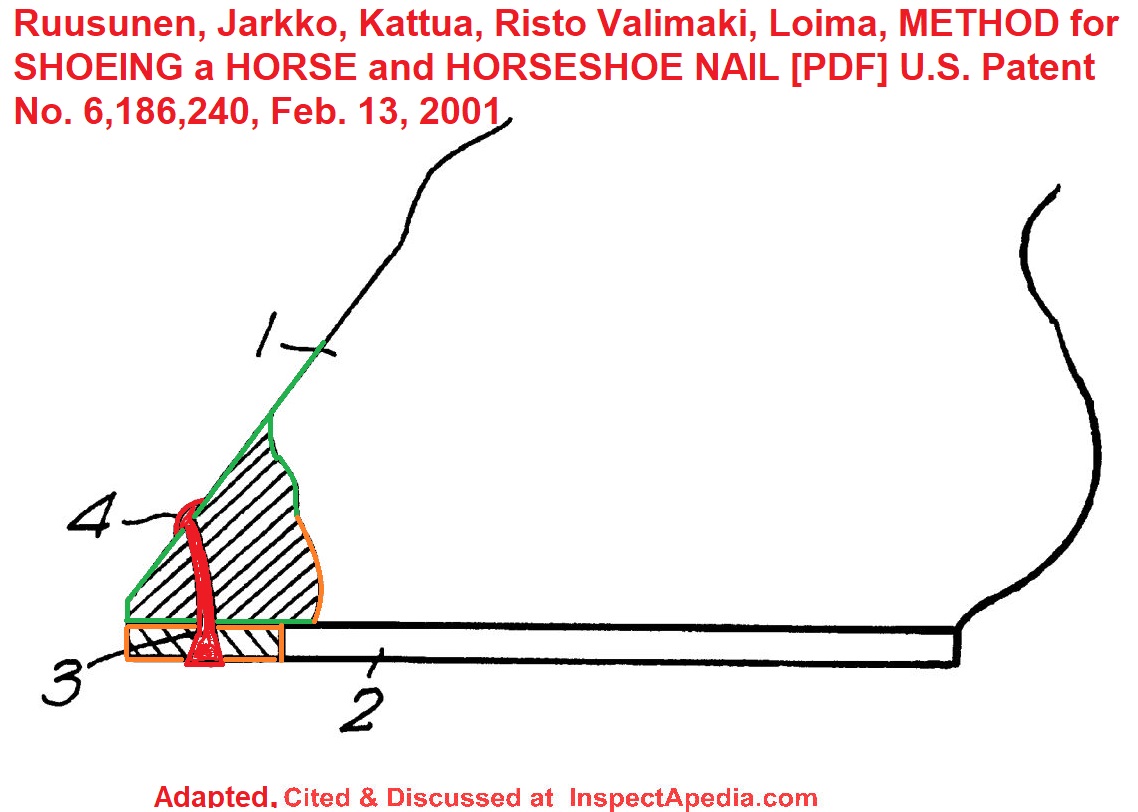

Excerpt:

The design and technique of horseshoes and shoe nails

have developed only a little. The basic technology has been

the same throughout the history, the shoes and nails are in

general of iron.

Nails of the horseshoes have always been made by forging

or drawing of iron, nowadays mechanically.

Due to the form

of the nails, their production is slow and the price relatively

high compared with wire nails made of the same material by drawing, used e.g. by the construction industry.

Attempts have been made to improve the industrial manufacturing process of the horseshoe nails e.g. by press cutting

and other methods.

The process of forging, however, provides the metal at the sharp point portion of the nail with

hard but at the same time with required tensile characteristics.

The nail is a sharp edged, thick headed Spike narrowing

evenly and with a length of about 4 to 6 cm. Evenly thick or

round nails cannot be used as nails for horseshoes. - (Ruusunen et als 2001)

The nail

penetrating the hoof in the most preferable way must have

the traditional form with a rectangular cross section.

When shoeing a horse, the nails are hit via the nail holes

in the horseshoe through the keratin hoof of the horse so that

the sharp point of the nail comes out from the side of the

hoof.

This visible part of the nail will be shortened by cutting, and bent downwards against the Surface of the hoof.

Thus, the nails form durable tight hooks fastening the Shoe

to the hoof of the horse.

This procedure for Securing and

fastening the nail is called clenching. [or "Clinching" - Ed. ]

Means, equipment, parts and methods made of materials

of new technologies have been invented within other fields

in order to develop these fields.

Nothing essentially new has

been developed for shoeing horses.

In the U.S. in the 1960s, at least when the author [DF] participated in shoeing horse, more common was a pattern of dots or a grid across the sides of the nail head. The shoes and horse shoe nails on the pinto above can be definitely dated as May 1956.

Pretty much all modern horseshoe nails will have an embossed pattern on both sides of the nail head, as shown below.

Above: modern horseshoe nails, 45mm or 1.77 inches long, from Victory. Website excerpt:

The Victory Horseshoe Nails are perfectly matched for use with the Victory Racing Horseshoes. These quality nails are straight driving and have a smooth finish. They are designed to feel smooth(no burrs or rough edges) and for the user to be able to feel the nail and be able to place it without having to look at it.

The sleek design makes driving the nails very easy. Each nail is individually inspected. - https://www.allvetsupply.com/victory-horseshoe-nails.html

On 2022-07-11 by Tferencik - S marking on head of a horseshoe nail - hoof nails.

Wondering if anyone might know where and when this nail might have been made?

It has a "S" on the edge of the long side of the head. Thank you

On 2022-07-11 by InspectApedia (mod) - @Tferencik,

Our best and most complete advice for guessing the age of a nail or spike are in the steps given

However, the general shape of that nail and its size suggest it could be a horseshoe nail.

In essence, as you’ll read above, when estimating the age, properties, use, and history of a metal fastener like a nail, spike, or screw, and particularly for guessing the age of a horseshoe nail, we look at

- The item itself for clues

about how it was made, of what materials, and in some cases iron fibre direction that can bracket age of manufacture - The shape of the horseshoe nail head

and the presence/absence of hand-forging tool marks - The horseshoe nail head and shank for grip marks

left by a machine that won't be present on hand-forged horseshoe nails. Even the earliest horseshoe-making machine (Young & Titus 1837) used - The thickness of the horseshoe nail shank -

thinner probably means machine made - Where the horseshoe itself is found

observe the following:

the shape and features of the shoe, as outlined by Ahalt - cited in detail below and also

the number of nail holes in the shoe

the curve in or out of the heel of the shoe

rim-horseshoes that include a groove along the middle of the shoe (used for traction and for sporting and racing horses (and was on all of the shoes we saw in NY in the 1950s- Ed.)

presence of calkins or calks - projections at the heel of the shoe (1869 - Ahalt & Fleming 2019)

presence of a toe clip (post 1850)

horse shoe metallurgy (aluminum horse shoes are a recent "modern" innovation) - Contextual clues:

what we know from surrounding materials, location, history of the area, etc. - Local history

including changes in the volume of production of horseshoe nails can give a clue to the age of found horseshoe nails in a given area. (Dunbabin 1993)

Most historians think they were introduced around 500 or 600 B.C. and came into common use around 1,000 A.D. At first they were probably used in war, rather than in agriculture.

Historians differ on who the originators were. Some think they were the Romans, others think they were the Mongolians. (Berningstall 1998)

The earliest horseshoes and horseshoe nails that were present in North America would have been brought by the Spanish. (Cossins 2018) Of course the history of and types of horseshoe nails varies by country and even location within country. The first horseshoe nails made in New Zealand, for example, appeared in 1880. (Isaacs 2009)

The earliest horseshoe making machinery patented in the U.S. dates from at least as early as 1837 (Young & Titus 1837) as we cite below, pre-dating Berningstall's estimate of 1855 and probably the first horseshoe machine that was patented in the U.S. as the patent number is U.S. Patent No. 307!

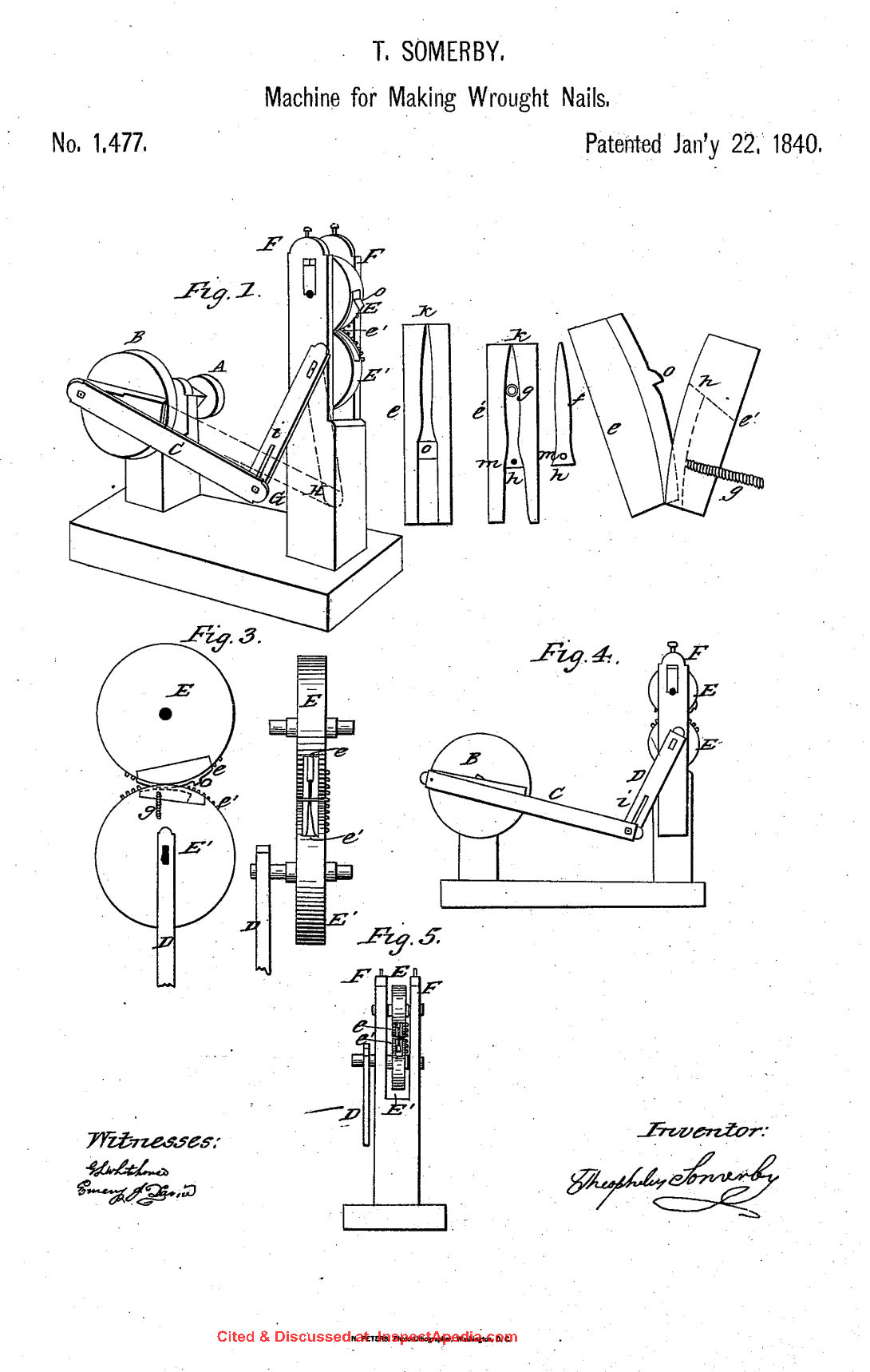

The earliest U.S. patent we found for a machine to make horseshoe-nails themselves was by Maine inventor Theophilus Somerby in 1840 - cited below. Even that patent suggests by its language that there were earlier horseshoe or wrought iron nail making machines in use.

But indeed a patent search finds an explosion in horseshoe nail making equipment beginning in 1858.

In the mid-1800s Mr. Daniel Dodge, Mr. Silas Putnam, and Mr. George Capewell all patented nail-making machines to mass produce horseshoe nails. (Berningstall 1998)

Index to Modern Horseshoe Nail Brands & Markings

[Click the link names below for example illustrations of each horseshoe nail brand]

- KEY LOGO HORSESHOE NAIL (Brand Identification Needed) - courtesy of reader Nicholls - illustrated above

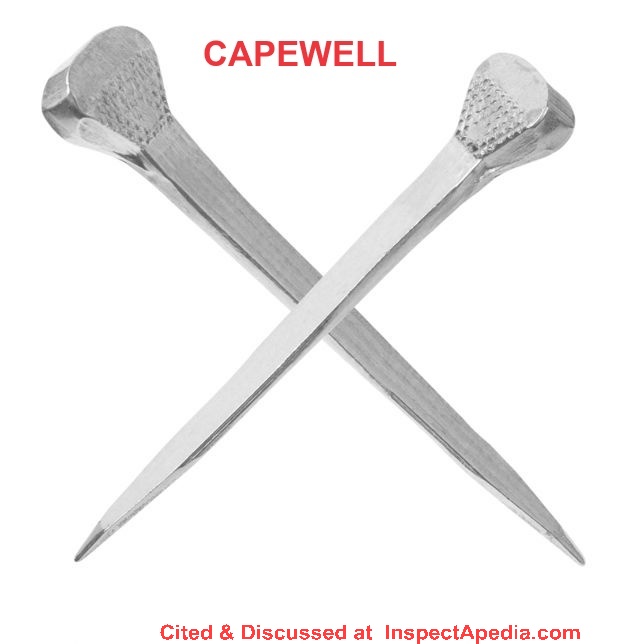

- CAPEWELL HORSESHOE NAIL

- CAPEWELL HORSESHOE NAIL - closer look at the nail head

- DELTA CITY HORSESHOE NAIL - two views with the "D" logo and with Delta's traingular Greek "Delta" logo

- DELTA HORSESHOE NAIL - racing

- DIAMOND FARRIER HORSEHOE NAIL

- LIBERTY HORSESHOE NAIL - No. 8, regular head

- LIBERTY HORSESHOE NAIL - hybrid

- MUSTAD HORSESHOE NAIL

- MUSTAD HORSESHOE NAIL - Regular

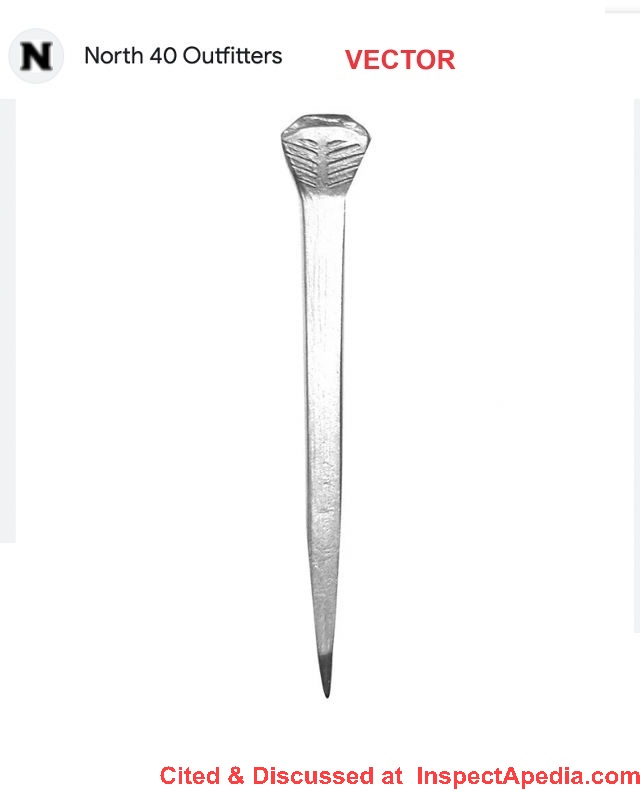

- VECTOR HORSESHOE NAIL - example 1

- VECTOR HORSESHOE NAIL - example 2

- VECTOR HORSESHOE NAIL, CITY head

- VICTORY HORSESHOE NAIL - copper-coated racing

Index to Modern Horseshoe Brands (North America)

[Click the link names below for illustrations of each horseshoe brand]

- ANVIL HORSESHOES

- DELTA TS7 HORSESHOE

- DIAMOND CLASSIC HORSESHOE - plain

- DOUBLE S HORSESHOE - slider, unclipped

- EDSS Avanti HORSESHOE - unclipped PLR

- EDSS Avanti HORSESHOE - top, bottom, side views

- EDSS Centaur HORSESHOE - Natural Balance, centre fit, un-clipped

- EPONA COMPOSIT HORSE SHOE, PONY

- KAHN HORSESHOE, Certifier - quarter-clipped

- KERCKHAERT HORSESHOE, STANDARD - lilght, unclipped

- MUSTAD EQUI-LIBRIUM HORSESHOE

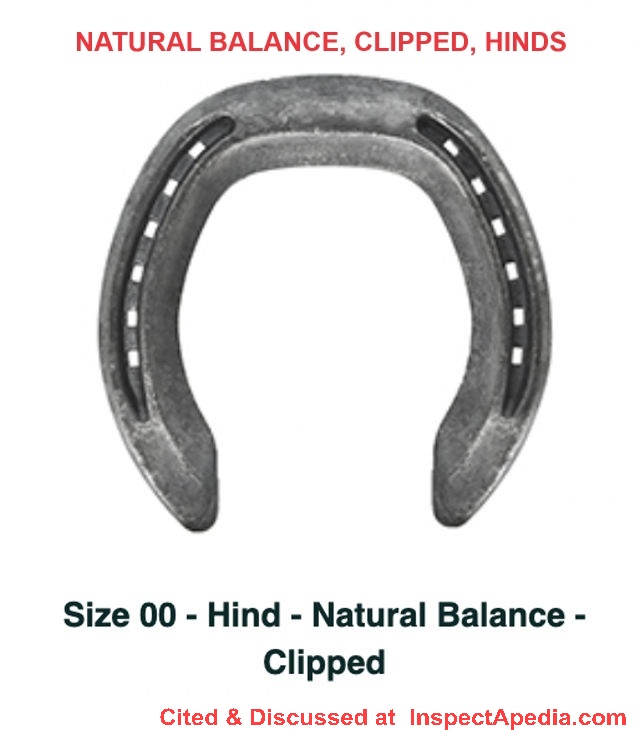

- NATURAL BALANCE HORSE SHOES - clipped hind feet

- KERCKHAERT DRAFT HORSE HORSESHOE - toe clipped

- St. CROIX PONY SHOES

- WERKMAN Warrior HORSESHOES

Research References on the History of Horseshoe Nails

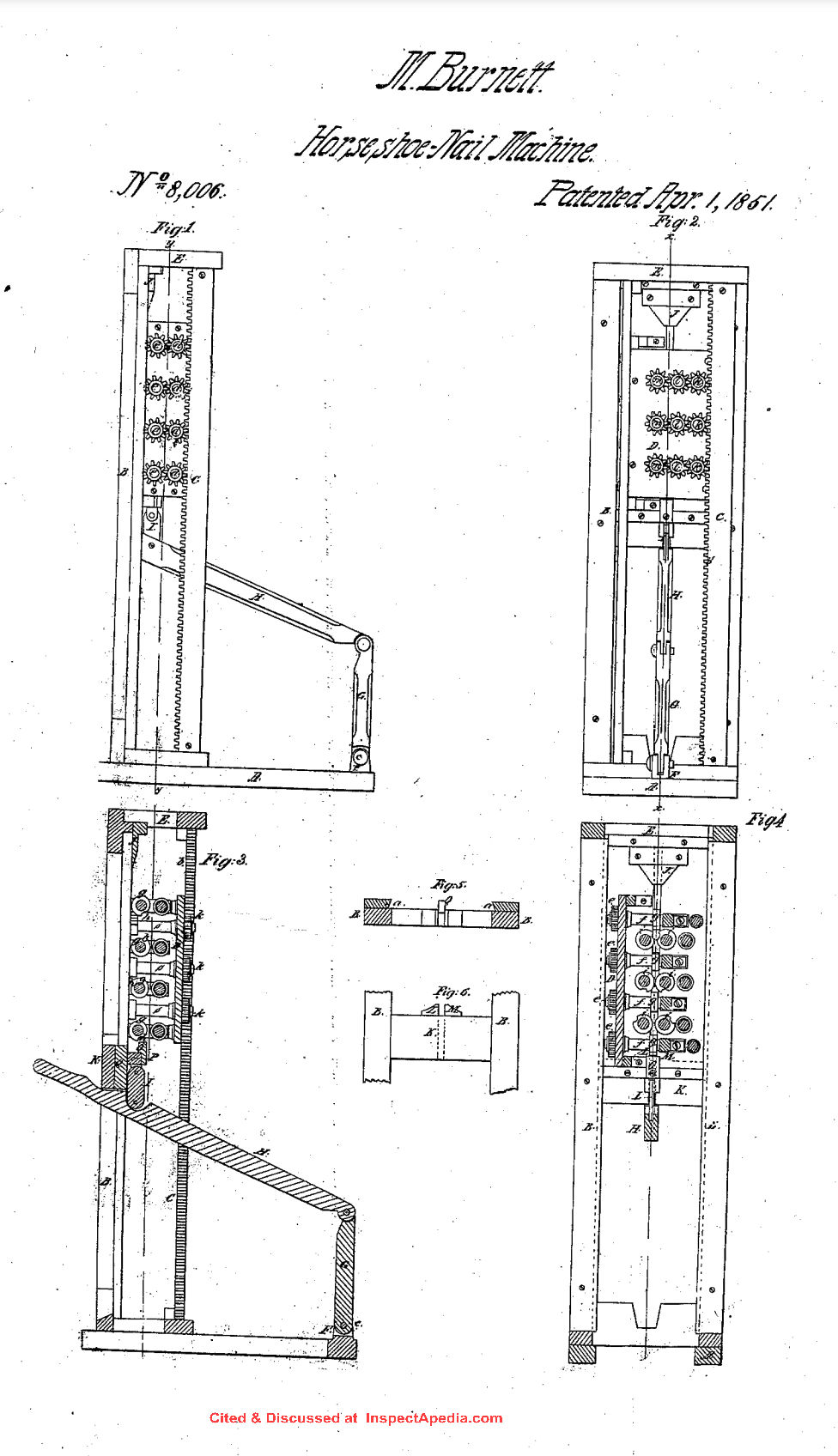

Above: the Burnett horseshoe nail making machine patented in 1851 and cited in detail below. The fact that Burnett describes his patent as an "improvement" - this was not the first horseshoe nail machine used in North America. We think that honor was held by Young and Titus who patented a horseshoe-nail making machine in 1837 - cited below.

Above: the Burnett horseshoe nail making machine patented in 1851 and cited in detail below. The fact that Burnett describes his patent as an "improvement" - this was not the first horseshoe nail machine used in North America. We think that honor was held by Young and Titus who patented a horseshoe-nail making machine in 1837 - cited below.

Among our horseshoe nail history research citations below we include all of the earliest U.S. patents of horseshoe-nail making machines as well as other of the earliest machines patented for making nails, rivets, and railroad spikes, dating from the 1830's.

- Ahalt, Daphne, HISTORY and the HORSESHOE [PDF] (2019) C.A.R.T. Archeology, Archaeology & Collection Branch, Fairfax County Park Authority, Fairfac County VA, retrieved 2022/11/05 original source: https://cartarchaeology.wordpress.com/2019/11/01/history-and-the-horseshoe/

Excerpts:

Horseshoes are often found during archaeological excavations and are considered a common artifact on both colonial and post-colonial sites.

Being able to identify the parts that make up a horseshoe, and the different forms horseshoes have taken through time, can facilitate functional analysis and period-dating of the artifact when enough of the shoe has been recovered.

Domestication of the horse exposed the animal’s hooves to environmental conditions that caused excessive wear and breakage.

When a horse is “employed on hard roads, broken ground, and in a humid climate”, such as Virginia, “to carry and draw heavy loads at different degrees of velocity, and forced to stand on stony pavements during resting hours, (hooves) are unable to meet the many severe demands imposed upon them.” (Fleming, 1875)

To counteract and prevent the damage, shoes were applied, and their form and function evolved over time.

Parts of a horseshoe include the branches, the foot, the margin, the fuller, and the heel.

The branches are the curved sides of the shoe, while the wider, flat section of a branch is called the foot or ground surface.

Margins are the edges of the shoe and are where the indented channel containing nail holes, called the fuller, is located.

At the open end of each branch is the heel. If the heel is thicker and turned down it is considered a calkin, or calk.

The tab, when found at the junction of the branches, is called a toe clip.

According to Ivor Noel Hume (1969), fullered shoes appear in a Virginia context dating to no later than 1660.

He also states that seventeenth-century shoes have “either three nail holes in each branch or three in one and four in the other.”

Shoes made during the early seventeenth-century tended to have heels that turned inward, the turn inward becoming so prominent in the late-1600s as to have a “keyhole appearance”.

This shape continued through the early eighteenth-century but is rarely seen in post-1740 contexts. - AllenTimothy, IMPROVEMENT in MACHINES for MAKING COOPERS and OTHER RIVETS [PDF] U.S. Patent Reissue No. 43, February 28, 1833, Reissue Dated July 8, 1842. 7448X related document.

- Ballard, Edwin C. FOR WANT OF A NAIL: AN ANALYSIS OF THE FUNCTION OF SOME HORSESHOE OR" U"-SHAPED STONE STRUCTURES [PDF] (1999) Massachusetts Archaeological Society (1999): 38.

- Berningstall, Tom, HORSESHOE NAILS [PDF] Rural Heritage, Winter 1998 - retrieve 2022/11/05, original source: https://www.ruralheritage.com/

- Brasher, Nugent. "The Chichilticale Camp of Francisco Vásquez de Coronado: The Search for the Red House." New Mexico Historical Review 82, no. 4 (2007): 2.

Excerpt: Hopefully we will find metal artifacts like caret-head horseshoe nails ... - Brucker, Gene A. "“The horseshoe nail”: structure and contingency in medieval and renaissance Italy." Renaissance Quarterly 54, no. 1 (2001): 1-19.

- Buchwald, Vagn Fabritius. Iron and steel in ancient times. Vol. 29. [PDF] Kgl. Danske Videnskabernes Selskab, 2005. [Visible online as a Google soft-copy book, available in some libraries]

Excerpts:

In about 1500 A.D. the test in Copenhagen to qualify as a master smith was to forge a horseshoe with matching nails from three osmund bars. [p. 340]

... table 12.8, line 6, Nos. 9-11 aer three iron objects found on furnace siges at Dokkflovann and dated to 1000-1300 A.D. Two horseshoe nails appear now for the first time in the material, although we met horseshoes already in Table 12.5.

Editor's note: Table 12.5 SEM-EDAX analysis of Viking Age objects from Denmark, p 307. - Burnett, Marshall HORSESHOE-NAIL MACHINE [PDF] U.S. Patent No. 8,006, April 1, 1851

Excerpt: Beit known that I, Marshall Burnett, of Boston, in the county of Suffolk and State of Massachusetts, have invented a new and useful Improvement in Machines for Making Horseshoe-Nails.

Above: Anvil brand horseshoes as illustrated at Centaur Forge, cited below.

- Centaur Forge, 117 N. Spring Street, Burlington, WI 53105 USA Web: centaurforge.com/Race-Nails/products/497/ Email: info@centaurforge.com Tel: 262 763 9175 Centaur Forge -- accessed 2023/10/03

Centaur has one of the most-complete libraries of blacksmith equipment and supplies that we have found, including horseshoes and horseshoe nails. Some of the horseshoe nail and horseshoe shape and type illustrations on this page are frdom that source: - Cossins, Daniel. THE MISSING CITY on the PLAINS [PDF] New Scientist 240, no. 3206 (2018): 40-43.

Excerpt: For Blakeslee, the clincher came in the shape of an iron shot. He had taken a group of volunteers armed with metal detectors down to the rock-lined ravine he had identified as the spot where the battle took place.

Just as everyone was thinking about packing up, the landowner's son dug up an iron ball roughly the size of a marble. It was pockmarked in a way that has convinced Blakeslee it had been fired from a Spanish gun.

He has also found a Spanish horseshoe nail. “We have definitively found the site of the battle,” he says. - Dent, A. A., 1967. ‘The Early Horseshoe’, antiquity, 61–3.Google ScholarOpenURL query

- Dunbabin, John P. "The League of Nations' place in the international system." History 78, no. 254 (1993): 421-442.

- Edes, Oliver & Andrewe Holmes, MACHINERY for MAKING RIVETS [PDF] U.S. Patent No. 1,564, April 24, 1840

Excerpts: Be it known that, We, Oliver Edes and Andrew Holmes, of Braintree, county of Norfolk, and State of Massachusetts, have invented new and useful improwements in Machinery for Making Rivets. - Elvinge, F. "On the origin of the horseshoe. A preliminary report (author's transl)." Nordisk Veterinaermedicin 27, no. 7-8 (1975): 389-392.

Abstract:

The question of the origin of the horse-shoe is reconsidered and China is pointed out as the site of origin. The theory is put forward that the Mongolian people living north of China and having constant fights with the Chinese have learnt the horseshoes with nails from the Chinese and that the Huns on their travel westwards have brought this type of horseshoe to Europa.

The theory is substantiated from authoritative sources. The Chinese ministry of agriculture and forestry has given the information that horseshoes with nails have been used here for more than 2000 years.

The possibility exists -- however -- that the Mongolians having good knowledge of the treatment of various metals, have produced the first horseshoes and given the Chinese the knowledge of that procedure.

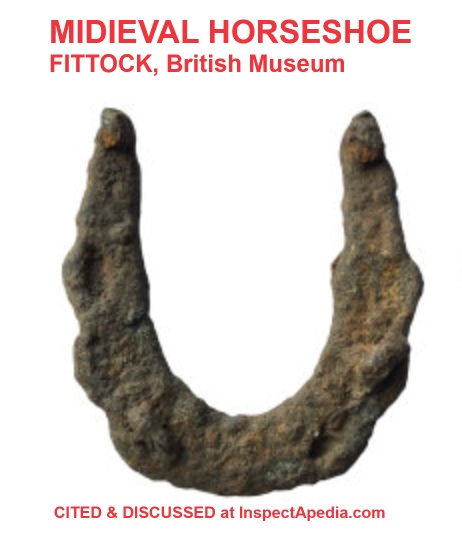

- Fittock, M (2021) BH-45EF89: A MEDIEVAL HORSESHOE British Museum, retrieved 2023/10/03, [illustrated above] original source: finds.org.uk/database/artefacts/record/id/1030624 [Accessed: Oct 3, 2023 3:36:19 PM]

Excerpt: A complete forged/wrought iron wavy rimmed horseshoe of Clark type 2B dating to the Medieval period (c. 1150-1300). - Fleming, George. 1869. Horse-shoes and Horse-shoeing: Their Origin, History, Uses, And Abuses. Chapman and Hall, London. Page 610. E-book accessed October 2019.

- Fleming, George. 1875. Practical Horseshoeing. D. Appleton and Company, New York. Page 57. E-book accessed October 2019.

- Green, Charles, 1966. ‘The Purpose of the Early Horseshoe’, antiquity, 305–8.Google ScholarOpenURL query

- HG Horseshoeing LLC. 2015. Hoof Care for Horse Owners: Common Types of Horseshoes. [dead link, october 2022 - Ed.]

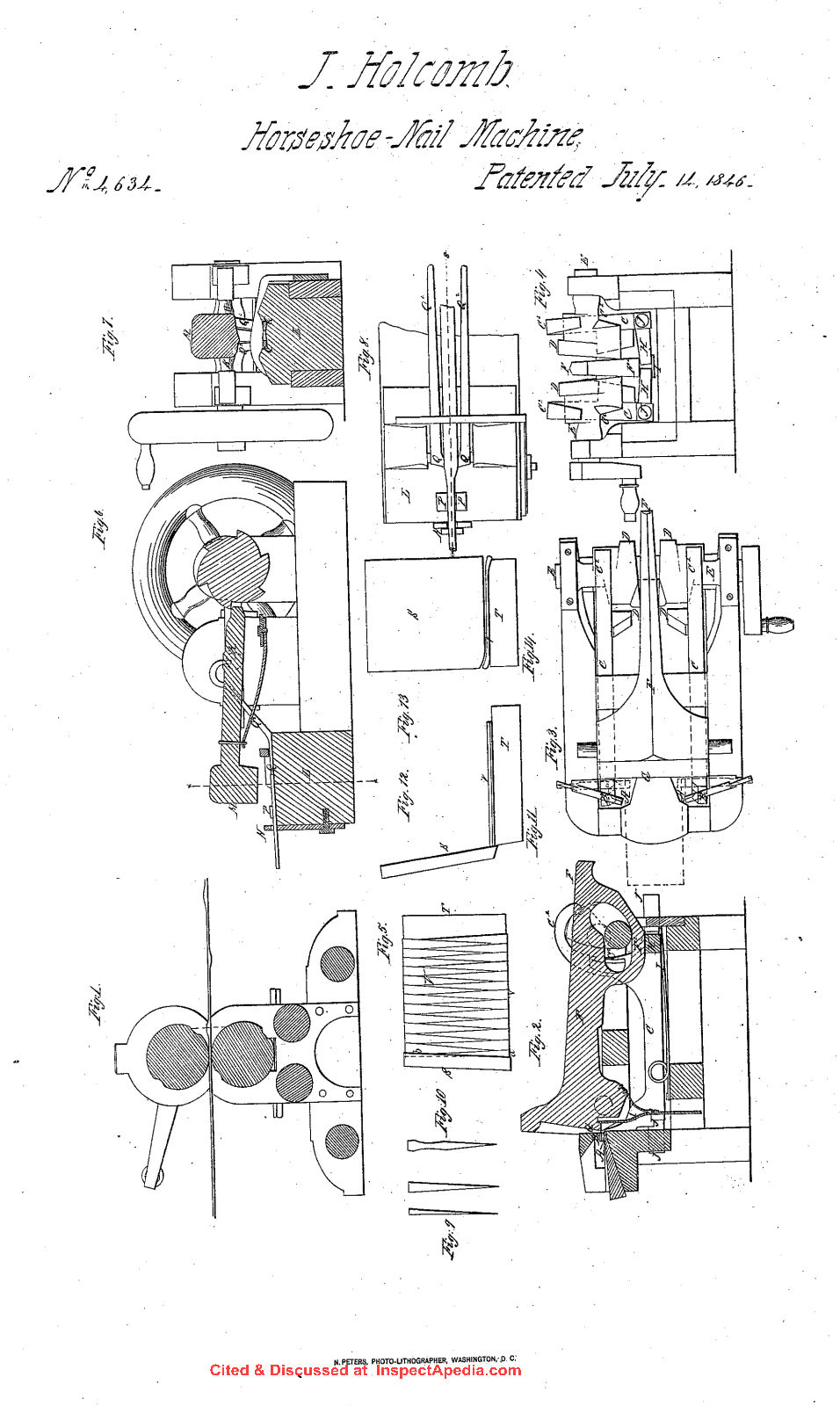

- Holcomb, Jedediah, NAIL MACHINERY [PDF] U.S. Patent No. 4,634, July 14, 1846

Excerpt: Be it known that I, JEDEDIAH. HoLCOMB, of the town of Brandon, in the county of Rutland and State of Vermont, have invented certain new and useful improvements in the mode of manufacturing Wrought-iron nails for shoeing horses, oxen, and for other uses, also wrought board-nails, which improvements are described as follows, refe ence being had to the annexed drawings of the same, making part of this specification. - Isaacs, Nigel. "Nails in New Zealand 1770 to 1910." Construction History 24 (2009): 83-101.

Excerpt: Forged horseshoe nails were being made in Christchurch in 1880. - Kleist, Bill, GENERAL PRODUCTION PROCESSES FOR HORSESHOE NAILS [PDF] Farrier products - retrieved 2022/11/05, original source: https://www.farrierproducts.com/farriery/NAArchives/featurearticles/feature4.html

Excerpts: Iron nails for holding horseshoes are found as early as 500 B.C. by the Celts in Britain.

In the 1700’s horseshoe nails were hand-made by Journeyman Nailers.

From the mid 1700’s to early 1800’s nails were produced in a variety of machinery. Typically all these machines used heated iron or steel in their production process.

The development of better steel wire in the late 1800’s eventually allowed the development of cold forging processes where the horseshoe nail could be produced without having to heat the base material before forming the nail.

The final product produced by these three different methods produce a product that is very similar in appearance, but field results and lab results show that the products are very distinct in their physical properties.

From the metallurgical point of view the rolling process produces the strongest nail of these three processes.

The reason for this is the shank of the nail is gradually drawn resulting in a much more uniform granular microstructure. This gradual drawing of the shank increases the tensile strength of the final product.

This can also be attested by the practical fact that rolled nails can be produced in very narrow shank sections and the resulting nail is still capable of holding the shoe to the horse’s feet. - Littauer, Mary Aiken, Early Horseshoe Problems Again,

Antiquity , Volume 42 , Issue 167 , September 1968 , pp. 221 - 225

DOI: https://doi.org/10.1017/S0003598X0011868X

Excerpt: Mr. Charles Green's note (1966) raised two pretty problems concerning the purpose of the early horseshoe and nail:

1. why, if the "fiddle key" nail was such an asset for traction in sort footing that the early British shoe was devised 'simply as a support for hobnails of a special kind', has such a nail not been in use in recent times in areas of going similar to that of parts of Roman and midieval Britian?

2. Why, on the other hand, if the studs did not serve this purpose did they occur at all, and why did they persist for so long? As Mr. A.A. Dent pointed out (1967, 62, 63), studs tend to raise the foot unnaturally and, as well as the bad effects he cited, there is the disadvantage that, with the frog no longer in contact with the ground a normal stimulus to circulation is removed. - Morris, Rick R. What the horse left behind: the archeological study of horseshoes. University of Nevada, Reno, 1988.

- National Museum of Horseshoeing Tools, Web: https://www.horseshoeingmuseum.com/

- Poe, Mike. 2010. Toe Clips: Explanation and Applications. Alpha Farrier Services.

- Rand, Oliver P., & Joseph Berry, MAKING CUT NAILS [PDF] U.S. Patent No. 155, March 30, 1837

Excerpts: Be it known that we, Oliver P. Rand, blackSmith, and Joseph Berry, carpenter, of Newmarket, in the county of Rockingham and State of New Hampshire, have invented, constructed, made and applied to use a new and useful improvement of machinery for cutting braids and nails of such various descriptions as may be manufac tured by the said machinery.

...

We are aware that the size, shape and ma terials of the several parts of the above machinery may be varied at pleasure, so as to answer the intended purpose of cutting brads, or Such other nails as may be manu factured by the same.

- Ruusunen, Jarkko, Kattua, Risto Valimaki, Loima, METHOD for SHOEING a HORSE and HORSESHOE NAIL [PDF] U.S. Patent No. 6,186,240, Feb. 13, 2001 - illustration above.

- Savery, Richard, MACHINE for MAKING WROUGHT SPIKES and NAILS [PDF] U.S. Patent No. 664, April 2, 1838

Excerpts:

Be it known that I, RICHARD SAVARY, of the city of Pittsburgh, in the county of Allegheny and State of Pennsylvania, have invented certain new and useful Improvements in Machines for Making Wrought Nails and Spikes;

In its general construction this machine resembles some others which have been previously constructed for the same, or a similar purpose, but it is distinguished from them by certain peculiarities particularly, in the manner of gripping the nails, or spikes in the dies, and also in the manner of forming the points. - Severance, Levi, MACHINE for MAKING RIVETS for RIVETING STEAM BOIELRS and OTHER ARTICLES - APPLICALBE to OTHER PURPOSES [PDF] U.S. Patent No. 268, July 11, 1837

Except: Be it known that I, LEVI SEVERANCE, of Pittsburgh, in the county of Allegheny and State of Pennsylvania, have invented a new and useful Machine for Making Rivets of Iron or other Metal, for Riveting Steam boilers or other articles, which machine

I also intend to apply to the manufacturing of railroad pins, spikes, and other rivets and pins in which a rounding-head is required or where it is desired that the shank should be larger immediately under the head than toward the point;

- Somerby, Theophilus, MACHINE for MAKING WOUGHT NAILS [PDF] U.S. Patent No. 1,477, January 22, 1840

Excerpts: Beit known that I, THEOPHILUS SOMERBY, of Wells, in the county of York and State of Maine, have invented a new and useful Improvement in the Making of Wrought Drawn Nails for Horseshoes or Any other Purpose;

Fig. 1 represents the machine in the posi tion to receive the rod, which is heated and placed between the dies when it is drawn or pressed in, pressing down the spring f, which fills the bottom of the space in the die.

The clipper o cuts off the rod at h, the wheel then recedes, the pressure is relieved from the spring f, the spiral g, operates, throws out the nail ready made and the dies are ready to receive the rod again.

Those parts of the machine that the size is not named are to be made and propor tioned of such size as will give sufficient motion to the dies.

What I claim as my invention and desire to Secure by Letters Patent is The shear or clipper which separates the nail from the rod in combination with the dies, and also the employment of the spiral Spring inserted in the female die for throw ing out the nail, all as described. - Speir, Thomas E. THE SPANISH MUSTANG: HISTORICAL AND ARCHEOLOGICAL IMPLICATIONS IN TEXAS [PDF] (1997) The Steward, Collected Papers on Texas Archeology, Texas Archeological Stewardship Networ, Office of the State Archeology, Texas Historical Commission,

Excerpt:

When analyzing horseshoes, consider first the size of the shoe to determine the likely size of the animal for which the shoe was made.

Second, consider the shape to help determine if the shoe was made for a horse or a mule, a front hoof or a rear hoof.

Wear patterns can determine not only which hoof wore the shoe, but how long the shoe had been worn prior to its being removed or lost.

As most horseshoes in the early historic period were hand made from bar stock, each shoe was customized for the specific hoof it was to be placed on.

Corrective shoeing techniques serve as indicators of the physical well-being of the animal at the time of shoeing and the tasks it was performing. - Ward, Gordon, 1941. ‘The Iron Age Horseshoe and its Derivatives’, Antiquaries Journal, XXL, 7–27.

- Ward-Perkins, J. B., 1941. ‘The Iron Age Horseshoe’, Antiquaries Journal, XXL, 144–9.

- Webley, Robert, HORSESHOES [PDF] Portable Antiquities Scheme, The British Museum, Web: finds.org.uk/ - retrieved 2023/10.03, original source: finds.org.uk/counties/findsrecordingguides/horseshoes/

Excerpts:

This guide follows Clark (2004). This itself supersedes the some of the content, but, most importantly, the classification terms used in his earlier FRG Datasheet 4 (Clark 1986); for convenience both are mentioned here. Of course many metal-detected examples or casual finds are likely to be incomplete, and so will be very difficult to date and classify even with the use of X-rays.

...

Horseshoes are formed of an iron plate with the toe at one end at the heel at the opposite end (see figure).

They were fixed to the hoof using ‘clenched’ nails, which were set in circular or rectangular nail-holes located in the branches and generally avoiding the toe. Medieval nails of the fiddle-key form have large semicircular heads.

Often the nail-head protruded for grip but was protected from undue wear by either separate countersinkings, in the late early-medieval and medieval period, or by a fuller (a more continuous groove near the edge), in the post-medieval period.

Further grip could be provided by calkins, projections at the heel, which could be formed by thickening or bending the heel (for different forms of calkin see Clark 1986, 1; fig. 2; 2004, 81; fig. 59). The toe-clip (not shown) is a post-medieval trait. - Wheeler, John E., & David B. Loring, IMPROVEMENT in MACHINES for FINISHING HORSESHOE NAILS [PDF] U.S. Patent No. .201727, July 13, 1877

Excerpt:

We claim and desire to secure by Letters Patent of the United States

1. In a horse-nail machine, the combination of one pair of revolving dies, shaped to com pletely form the head, and to somewhat thicken and lengthen the shank by a lateral pressure exerted upon the edges of a blank, another pair of revolving dies at right angles to and immediately below the first pair,

shaped to operate upon the face and back of the shank of the blank, either with or without means for indenting the end of the blank, and means for simultaneously operating said dies, whereby the head and shank of a cold blank are suc cessively completed by their joint adaptation and operation,

but one direct pressure suc cessively exerted upon the sides and edges of the blank, whereby substantially a uniform density is given the completed nail, substan tially as described.

2. The combination of the feed-tunnel M with the centering device described, the same consisting of reciprocating plate O and de tent W, all arranged to feed substantially as described, and for the purpose set forth,

- Young, Barzillai & Samuel Titus, MACHINE for MAKING HORSESHOES [PDF] US. Patent No. 301, July 28, 1837.

Excerpt:

Be it known that we, Barzillai Young, of Killingly, and Samuel Titus, of Brooklyn, in the county of Windham and State of Connecticut, have invented a new and useful Machine for Making Horseshoes;

...

...

Continue reading at NAIL ID & AGE: HAND FORGED NAILS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see HORSESHOE & HORSESHOE NAIL AGE FAQs, diagnostic questions & answers posted originally at this page.

Or see these

Recommended Articles

- AGE of a BUILDING, HOW to DETERMINE - home

- DOOR HARDWARE AGE

- HORSESHOE & HORSESHOE NAIL AGE

- NAILS, AGE & HISTORY - home

- HORSESHOE & HORSESHOE NAIL AGE

- NAIL AGE DETERMINATION KEY - use this key to guess at the age of your nail or spike

- NAIL ID & AGE: CUT NAILS

- NAIL ID & AGE: HAND FORGED NAILS

- NAILS in BARTER & TRADE

- NAIL & HARDWARE CLEAN-UP

- NAILS & HARDWARE, AGE RESEARCH

- RAILROAD SPIKES

- SAW & AXE CUTS, TOOL MARKS, AGE

- WINDOW HARDWARE AGE

Suggested citation for this web page

HORSESHOE & HORSESHOE NAIL AGE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING AGE

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.