Coloring or Staining Concrete

Coloring or Staining Concrete

Concrete surface color, stain & polishing Methods & Concrete Color Troubleshooting

- POST a QUESTION or COMMENT about concrete staining, coloring or polishing methods

Concrete surface stains & colors or polishing methods:

How to obtain a colored, polished, or stained concrete finish on concrete floors, tables, countertops or other surfaces Concrete stain products & product sources are also provided.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Concrete Surface Finishes, Colors, Stains & Polishes

Deliberate stains or colors & finishes can be applied to concrete floor slabs, countertops, tables, or other concrete surfaces as a finish treatment using acid treatments or paint-on stain colours.

Deliberate stains or colors & finishes can be applied to concrete floor slabs, countertops, tables, or other concrete surfaces as a finish treatment using acid treatments or paint-on stain colours.

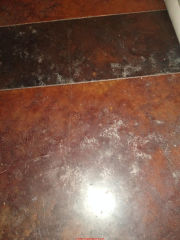

At left we see brown rectangular stains that are an artifact of a previously-installed vinyl asbestos or asphalt asbestos tile floor that has been removed, the surface cleaned, polished, and then sealed.

Color and finish methods for concrete surfaces include at least the following approaches.

Concrete Coloring & Staining Methods: dyes, stains, paints

- Clean & polish raw concrete

or old concrete from which other flooring has been removed. Unless a clear top sealant is applied, normal concrete will not usually polish up to a glossy surface but the finish may be adequate for many applications. - Polish new concrete formulated to accept a gloss finish

by using necessary concrete additives or formulation but without application of a colorizing or staining agent.

At below left the variations in gray color of the interior hard-finished floor are within normal occurrence on a hard-finished concrete floor slab of this Tivoli, New York home.

At below is a much more rough concrete surface with voids caused by air entrainment.

This concrete, discussed at CONCRETE STAINS: ID & REMOVAL, would not take a high gloss polish.

Polishing a new concrete mix formulated to accept a gloss finish, typically by adding marble dust, and that may have deliberate inclusions such as pebbles, stone, or even glass fragments.

Above and below are two concrete-cast tables whose finish surface used this technique. The same method may be used on interior or exterior floors.

The addition of marble dust to the concrete permits polishing to a hard glossy finish such as the concrete table shown at below left.

A second polished concrete table constructed by the same owners and workers is shown at below right where glass inclusions from bottle fragments form a dramatic but smooth-surface.

Here is a CLOSE-UP of the polished edge of this table whose composition includes concrete, marble dust and bottle glass inclusions. - Thanks to DP & LM in Guanajuato.

In some approaches a layer of formulated concrete (with marble dust for example) may be poured atop a thicker layer of standard concrete mix before the first pour has fully set and cured. The top layer permits the desired polishing while the standard concrete mix used for most of the thickness reduces the installation cost.

Colored finish surfaces on concrete floors are applied using one of these methods

- Concrete dyes

a coloring agent penetrates the concrete using an ultra-fine coloring agent that penetrates the concrete leaving less surface residue than some other methods. Most often used for interior polished concrete floors.

Concrete dyes are permanent (and so will be almost impossible to remove) and are sold in water soluble as well as solvent-based formulas.

Concrete color dyes work by actually penetrating the concrete surrace. Technically a true dye is a colored chemical or liquid, while paints and stains achieve their color by the use of pigments (particles) suspended in a lliquid vehicle. Concrete dye application can be expected to be a bit faster than concrete stain application - discussed below in this list.

Shown above and below are sections of colored concrete flooring in the Hacienda Las Trancas, Dolores Hidalgo, Guanajuato, Mexico.

This floor was constructed in 1932 and remains in superb condition (like the author) for its age.

Dyes that can be applied to concrete include both surface-applied coloring agents applied to rougher concrete surfaces and also polishing dyes that use fine pigment particles to penetrate and color interior concrete floor surfaces including coloring of polished concrete.

Examples of concrete dye and polishing dye products and sources are given below on this page.

Concrete polishing dyes, often translucent, are specifically for use on ploished concrete surfaces while other concrete dyes can be sued on rougher concrete surfaces such as slabs or walks or un-polished concrete floors.

- Concrete acid or water-based stains - reactive concrete stains

usually an concrete coloring process that uses an acid-based coloring agent that works by chemical reaction with the CaOH (Calcium hydroxide) in the concrete.

A typical acid used in concrete stains is hydrochloric acid combined with a color source that varies by color, such as copper chloride for a jade-like color.

Using an acid stain to add color to concrete can give any of several color ranges such as the examples shown here.

Water based penetrating concrete stains can be sued to change the concrete surface to a darker color, matching or obscuring dark stains on the existing concrete surface.

To achieve color variations and patterns other than a rather solid or monotone on a concrete surface, concrete acid stains can be applied using either "wet on dry" or "wet on wet" methods.

" Wet on dry" acid stain method means that the first acid stain color, the lighter colored agent, is applied to some areas of the concrete surface and then allowed to dry for five hours or more before the second, darker acid stain color is applied (usually by spraying) more-sparingly (so as not to completely color the adjoinging surfaces with the darker stain). Wet-on-dry concrete staining produces more definite edges where colored areas meet.

"Wet on wet" concrete acid stain application produces more blended-edges between colored areas, as the second, darker color is applied while the first concrete acid stained areas are still wet.

See also, Concrete dyes above in this list. Compared with a concrete dye, a concrete stain may leave more surface residue on the concrete surface. But a concrete stain may be a bit more durable than a concrete dye.

Examples of concrete stain products and their sources are given below on this page.

- Concrete integral color method

Intergal coloring of concrete means that a color pigment, such as iron oxide in dry powdered form, is mixed thoroughly into the wet concrete while still in the mixer or truck, that is, before the concrete is placed or "poured" at the site.

Examples of concrete integral coloring products include Brickform's powdered color for concrete (shown above and cited in detail below on this page) and also the same companyh's Brickform Ultra-Mix, both using iron oxide as a coloring agent for cast-in-place concrete such as driveways or floors.

Concrete integral color products should comply with ASTM C979 “Pigments for Integrally Colored Concrete”.

Watch out: don't try using concrete integral color products as an add-on surface-applied dye or stain. Integral colors for concrete are intended only to be used as an additive to the concrete while it is being mixed. These products don't carry their own binder, so if added later to a concrete surface the treatment will not endure.

- Concrete microtopping color method

For indoor concrete floors suffering from cosmetic stainig, an expert can apply a very thin cement-based microtopping, in essence a skim coat of concrete combined with a bonding agent, to give a new colored surface.

(We're doubtful that microtopping is suitable for the heavier wear and tear that an outdoor concrete surface such as a driveway must endure.) - Concrete paints

paints (including epoxy paints) formulated to bond well with concrete surfaces, imparting a hard traffic-resistant surface.

Another, non-epoxy example of a concrete paint sometimes using "stain" in the product name is tinted acrylic concrete stain products. These are a translucent topical or surface coating applied to concrete that, like many painted-on surface coatings, can eventually wear or peel. - Concrete surface polishing (no dyes or coloring agents)

concrete may also be left in its natural color and color variations, polished to a hard finish, possibly coated with a clear sealant with no coloring agents applied. - Concrete sealers - try a tinted concrete sealer:

indoor concrete floors as well as outdoor concrete floors that have been stained or colored are usually protected using one of several sealants.- Indoor concrete surface sealants include

- Acrylic sealants

- Epoxy sealants or coatings

- Urethane sealants or coatings

- Exterior concrete surface sealants include

- Acrylic sealants (recommended as they don't trap moisture below the coating), requires re-coating periodically, as often as every two years

- Silicone sealants (short lived, surface penetrating)

- Indoor concrete surface sealants include

Watch out: be sure to consult your concrete coloring agent, stain, or dye manufacturer to assure that the sealant you select is recommended as compatible with the concrete coloring agent you used. Also be sure the surface has adequately cured, dried, and has been cleaned before applying any stain or sealant product.

Watch out: several sources we reviewed including attributed to SolCrete (below) warn that rubber-backed carpet padding or throw rugs may trap moisture, leaving a white stain on the sealed floor.

Failures & Disappointments in Concrete Stain Finishes

Below the concrete floor was "stained" using an acid treatment. The light patches in the left of the photo indicate foot-traffic wear through the acid-treated concrete surface . (Rigby 2006).

Wear on a stained concrete floor will be increased by any of the following

- Foot traffic, especially if there is grit tracked onto or present on the stained concrete floor surface

- Wear caused by hard wheels on office chairs, library carts, trolleys, or other rolling equipment

- Moisture penetrating the concrete floor from below

- Moisture left atop the sealed floor

- Spills of solvents or acids that damage the protective coating

- Poor original concrete mix or placement or excessive water in the pour that yields a soft, spalling surface

- Irregularities in the concrete surface. For example if a walked-on concrete floor surface was not smooth, if raised surface areas were left as ridges or elevated particles, the added abrasion on those surfaces is likely to wear off or through the acid washed or painted-on concrete surface leaving surrounding areas intact.

- Poor surface cleaning and preparation before the concrete was treated.

White Bloom On or Under Finished Concrete Surfaces

White blooming under a clear or coloured finish on a concrete surface may be caused by application of the clear coat over moisture or by the movement of moisture through the concrete from an outside water source such as groundwater under a floor slab or from plumbing leaks.

White blooming under a clear or coloured finish on a concrete surface may be caused by application of the clear coat over moisture or by the movement of moisture through the concrete from an outside water source such as groundwater under a floor slab or from plumbing leaks.

See these diagnostic articles on mineral efflorescence that can ultimately show up on finished concrete surfaces as white discoloration below a clear or translucent coating or that may appear as a crystalline or powdery deposit on the concrete surface.

Research & Sources of Concrete Coloring Products, Stains, Washes, & Finishes

- 21st Century Concrete, P.O. Box 171

Watervliet, NY 12189 USA, Web: 21centuryconcrete.com Dyed-Colored Concrete,

CHROMIX G & L ADMIXTURES for COLOR-CONDITIONED CONCRETE [PDF]

Excerpt: Dyed-Colored Concrete has many different forms and compositions that can be used in both residential and commercial concrete applications, including sound/retaining walls, bridges, countertops, floors, etc. - Ameripolish, 120 Commercial Ave, Lowell, AR 72745 USA, Web: ameripolish.com Tel: 800.592.9320 Email: customerservice@ameripolish.com

INTEGRAL COLOR for CEMENTIOUS OVERLAY COLOR CHART [PDF] Concrete Color Dye products.

Excerpt:s

Ameripolish® Classic / Surelock / Dye-n-Seal - offers 24 stock colors covering the most common color choices seen in floors today. Custom colors are available upon request, but are made to order. The colors listed are only a representation of the Ameripolish® Concrete Dyes. Change in concrete slab colors will affect the apperance of the dye. Color results cannot be guaranteed. Actual colors may vary.

Ameripolish® OS Integral Color is a concentrated liquid dispersion of mineral oxide pigment particles formulated to color concrete and is available in a broad range of hues. OS Integral Color meets ASTM C979, Standard Specification for Pigments for Integrally Colored Concrete and is approved by the manufacturer of Rapid Set® TRU™, a leading cementitious self-leveling polishable overlay. - Arizona Polymer Flooring Color Fuse,

Art-Crete Faux brick concrete stain,

Butterfield Color Perma-cast Sierra Stain,

Engrav-A-Crete, - Arnold, Phillip J. "Getting ahead with colored concrete." Concrete Construction (1988): 853-

- Behr Concrete Stains, Website: behr.com, Tel: USA: 800-854-0133 Ext 2; Tel Canada: 1-800-661-1591

Behr's concrete stains & dyes include solid color concrete stains, semi-transparent concrete stains, and a decorative concrete dye as well as floor sealer products. - Butterfield Color (a Sika brand) 625 West Illinois Avenue

Aurora, IL 60506 USA, Email:

decorativeconcrete.orders@us.sika.com

INTEGRAL CONCRETE COLORS PDF] ackaged in pre-measured repulpable bags for accurate and convenient coloring of concrete. 11 standard base colors provide 44 color options by varying the number of bags per cubic yard.

Excerpt:

Integral color is added to the concrete mix before installation begins, providing consistent color throughout the entire thickness of the concrete. Adding color, with only a common broom or troweled finish, provides a dramatic beautification to plain concrete. In addition, integral color is also used with a colored release agent, to create a stamped concrete finish that rivals any natural stone, brick, hardwood, or tile look, but has all of the benefits of concrete.

Uni-Mix Liquid Integral Concrete Colorant, Integral Concrete Colorants in a pre-dispersed liquid form.

- Brickform, BLUSH-TONE ACID STAIN TECHNICAL INFORMATION SHEET [PDF] (2022) Brickform is a division of Solomon Colors, Inc., 4050 Color Plant Road, Springfield, IL 62702 USA Tel: 800-483.9628 Web: brickform.com - retrieved 2023/08/17, original source: brickform.com/wp-content/uploads/2022/07/Blush-Tone-Acid-Stain-TIS.pdf

Excerpts:

Brickform Blush-Tone Acid Stain is a reactive stain that uses mineral salts to chemically react with the free lime at the surface of the slab to produce a permanent color change. The colors produced are unique and captivating with multicolored intensities that simulate the natural shadings of aged stone, concrete and masonry.

Use Blush-Tone Acid Stain to create natural color variations on un-colored concrete, integrally colored concrete, color hardened concrete, and overlays. Blush-Tone Acid Stain, when properly maintained, is durable enough for use in both residential and commercial applications and can be applied to horizontal and vertical concrete surfaces.

The effect is random depending on the composition of the concrete. Even more interesting shades and colors can be obtained by using Blush-Tone Acid Stain over integrally colored concrete,

Brickform BLUSH TONE ACID STAIN COLOR CARD [PDF] (2017) - retrieved 2023/08/17, original source: brickform.com/wp-content/uploads/2022/07/Blush-Tone-Acid-Stain-Color-Card.pdf

BRICKFORM Blush-Tone Acid Stains color concrete surfaces with a beautiful, variegated and mottled appearance. Reacting with the minerals that exist in new or existing concrete, acid stain transforms ordinary concrete into the rich look of granite or marble.

Brickform Bluish-Tone Acid Stain, "reacts with minerals in newly-cured or existing concrete, penetrates top layer with color "(coloring effects vary) -

Brickform CONCRETE INTEGRAL COLOR POWDER COLOR CARD [PDF] (2021)

Excerpt: Packaging: 12 base colors deliver 44 separate (distinct) concrete color shades.

- DecoCrete Supply, 133 North Kohler Road

Orrville, Ohio 44667

(330) 682-5678 Web: deco-cretesupply.com (shown above)

DecoCrete CONCRETE POLISHING DYE DATA SHEET [PDF]

Excerpts:

Polishing Dye is a translucent, formulated using very fine particles of color designed to penetrate and color interior cementitious surfaces, including polished concrete. Polishing Dye creates a unique, multi-colored translucent color scheme that unlike paints, will not crack, chip or peel.

...

Polishing Dye is recommended for most cured, unsealed interior concrete substrates. Do not apply to a floor that has been sealed prior until all sealer has been completely removed.

...

Polishing Dye is packaged only in a powder form which needs to be mixed with acetone ... - Dupont, Methocel, hydroxypropyl methylcellulose (HPMC) cellulose ethers concrete additive to improve concrete durability & strength. Web: industrialcellulosics.com Tel: 844.925.3308

- Enduracoat Concrete Stains, Acid Stain Kits, Website: enduracoat.net, Tel: 888-246-9614 (USA) Email: info@EnduraCoat.net

- H&C Semi-Transparent Concrete Stain,

Kathy Ireland Concrete Stain

Kemiko Stone Tone Stain,

Lithochrome Tintura from L.M. Schofield, - Heritage acid stain, reactive concrete acid stain product,

- Home made concrete stains: stainedfloor.com/

- Kemiko Specialty Coatings, concrete floor stains, epoxies, urethane coatings, polyaspartics, Website: http://www.kemiko.com/,

- Kubanick, James E., and PENNSYLVANIA SOUDERTON. "Protective and decorative coatings. An updated catalog." CONCR CONSTR. 35, no. 4 (1990): 6. [Includes discussion of concrete stain products]

- Quikrete Etching Stains, Website: quikrete.com

Quikrete 1317-00 LIQUID CEMENT COLOR DATA SHEET [PDF] (2021)

Excerpt:

QUIKRETE Cement Color (No. 1317) is a liquid additive for adding color to concrete, mortar, sand mix, stucco and other gray cement-based mixes.

- Renaissance concrete chemical stain,

Sim-Stain, from L&M Industries,

Smith's color floor,

Smith Paints (Braxton-Bragg Co.), - Rigsby, S. "Decorative Concrete Floors With acid-based stains, you can add an attractive, low-maintenance finish to ordinary concrete floors." FINE HOMEBUILDING 178 (2006): 83.

- Rodgers, Randy. "Successful colored flatwork." Concrete international 26, no. 6 (2004). [Chemical stains, tints, toppings, sealers used for creating colored concrete]

- SolCrete, LLC, Dallas, TX (Denton), USA, Tel: 940-594-9257, Email: info@solcrete.com

acid stain projects for concrete floors, Website: solcrete.com - Super-Krete S9500,

Super Stone's Chlor-Stain

- Surface Koatings, Inc., 134 Davis St. Portland, TN 37148

USA, Email: info@surfkoat.com Tel: 615.323.9461 Web: surfkoat.com/

Surfkoat HERITAGE REACTIVE ACID CONCRETE STAIN DATA SHEET [PDF] (shown above)

Excerpt:

HERITAGE Reactive concrete stain is an All Natural, Organic colored acid concrete stain. No other products process can produce the superb marble and antique patina style finishes of HERITAGE. This process reacts chemically with the mineral content of the concrete for a uniquely beautiful, deep penetrating, permanent stain. Most stains are UV stable when sealed. Used for interior or exterior. Green and blue color acid stains should be used interior only.

Surfkoat Aqualon: Polishing Kolour Dye, a powdered concentrate mixed with acetone

- Surfkoat: Exterior Kolour Dye, also mixed with acetone.

Surfkoat also produces other concrete color dye products including a penetratingmottling agent and a series of color packs - acyrlic tint coloring agents, and Metallic FX to providfe metallic colors.

- Triple-S Concrete Acid Stains

Concrete Discoloration or Stain Identification & Removal

See CONCRETE STAINS: ID & REMOVAL - Stains on Concrete Identification of types & sources of stains on concrete surfaces, accidental or deliberate concrete staining & stain application or stain removal

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-06-25 - by (mod) - colored concrete patio stained brown, turned green!

Wow, Mark, that's sure not a dark brown stain any more.

Wow, Mark, that's sure not a dark brown stain any more.

A concrete stain that's actually in the concrete and based on chemical treatment isn't going to wash off, I agree.

I don't know but I suspect that there was either an error in the chemistry and mixing of the stain additive or a chemical reaction between the stain and something in or on the concrete.

[Click to enlarge any image]

I see some mottling and inconsistency but the green is pretty much all over; is there any correlation of the pattern with any other information about the patio?

Can you answer these

Concrete Coloring or Stain Process Troubleshooting Questions

- The country and city of location where this colored concrete is installed

- The weather just before, at the time of stain application and immediately afterwards

- The age of the concrete at time that the stain was applied

- Was a neutralizer used?

- Was a surface sealer applied?

- The type of concrete coloring agent or stain (water based, acid, other) brand and product ID or number of the stain that was used (this is most-important)

- When the original concrete colorant was applied (4 years ago in your case)

- When the discoloration or concrete stain color shift began and at what rate it occurred

as with that information we can do some research on the cause.

As for remedies for

Color-Shifted Colored or Stained Concrete Remedies

I am very doubtful that we can simply remove the green color in the concrete that was supposed to have been stained brown

- I've not tried it but I've read some claims that paint thinner can lighten a bad concrete stain application but I'm doubtful as the stain is a chemical change in the top few mm of concrete, not a painted-on coating.

Other concrete re-stain remedies:

- Clean, dry, etch and use an exterior paint rated for concrete - not an approach I would recommend for several reasons: durability, inconsistency, and a possible slip hazard.

- You might be able to apply a dark gray-brown acid-based solid-color stain atop to see if you can change the hue. This might give moderate improvement. Because the concrete is already mostly green with some gray, you'll want to test the new stain first on a small area, as in cases where the concrete was "stained" previously the new color is not entirely predictable.

- A water-based stain will change a concrete color less dramatically and I suspect won't be sufficient in the case of the concrete patio in your photo.

The last "repair" option for a concrete stain treatment that has gone awry is more onerous: a new layer of concrete, thick enough to remain stable, is added atop the existing surface and is stained anew - this time, with great care to follow the staining agent manufacturer's instructions.

On 2020-06-25 by Mark

I have an exterior patio that was decorated and stained dark brown 4 years ago. It turned to neon green. It can't be washed, even with straight sulfuric acid. Nothing phases it. Any ideas?

[See photo above]

On 2020-05-13 - by (mod) - white spots on colored concrete

Misty

What is the floor: colored concrete? If so I think you're seeing efflorescence under the floor's top seal or surface.

That may be due to spills, leaks from below, or improper treatment of the surface.

On 2020-05-11 by Misty - What are these white spots from on the stained concrete floors?

We just moved into a new home and the floors are a mess. I think these wide spots are from bleach but I'm not sure and there's little scratches everywhere and some cracks in the concrete

can you tell me if bleach can make these light marks or what could have possibly done this and why the floor so many scratches and is very easily scratched now. I'm trying to figure out if the floors just weren't properly sealed or if they just need to be resealed and what can cause these light spots all over the floor in just a couple of areas. Thanks

I'm trying to figure out if these floors weren't properly sealed or if it's just time to reseal them and what could cause them to be very easily scratched like little bitty scratches all over and big scratches very easily plus some cracks in the concrete and these light colored bleach looking spots.

I know dust and dart can cause scratches butt these floors seem unbelievably easy to scratch and I really want to figure out what could cause these light looking spots. Thanks

On 2018-05-22 - by (mod) - how to put a pattern on a melamine concrete countertop?

I'm not aware of anything that you would apply to melamine that would then result in providing a pattern or color to concrete poured on top of that surface.

Melamine is a plastic, so we need some clarification of your question before we proceed.

It is possible to use melamine-coated hardboard or sheets of melamine as a concrete form and possibly to use melamine-coated patterning forms to impress a pattern into a concrete countertop surface. Both melamine and plexiglass will release from concrete without having to be coated with a releasing agent.

That is generally not the case for other concrete forms such as wood or rubber.

On 2018-05-22 by Ken

What brand and material can I use for giving pattern to a new concrete countertop. This would be applied to melamine surface prior to adding concrete

...

Continue reading at STAINS on CONCRETE - un-wanted discolorations, markings, that you didn't ask for, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CONCRETE COLORING & POLISHING

- CONCRETE DELIVERY & MIXING

- CONCRETE FOUNDATION, WALL, SLAB DEFECTS

- CONTROL JOINT CRACKS in CONCRETE

- CONCRETE ROOFING

- CONCRETE STAINS: ID & REMOVAL

- FLOOR, CONCRETE SLAB CHOICES

- FLOOR, CONCRETE SLAB POURED FINISH

- FLOOR TILE INSTALL on CONCRETE

- RADIANT SLAB FLOORING CHOICES

- STAINS on CONCRETE - un-wanted discoloration, defects, stains

- STAINS on INDOOR SURFACES, PHOTO GUIDE

- STAMPED CONCRETE CLEANING

Suggested citation for this web page

CONCRETE COLORING & POLISHING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Baragary, Chance, and Hani A. Salim. "Effects of cold joints in blast resistant structural concrete [abstract]." In 2007 Undergraduate Research and Creative Achievements Forum (MU). University of Missouri--Columbia. Office of Undergraduate Research, 2007.

- Biel, Timothy D., and Hosin Lee. "Performance study of portland cement concrete pavement joint sealants." Journal of transportation engineering 123, no. 5 (1997): 398-404.

- Bussell, M. N., and R. Cather. Design and construction of joints in concrete structures. Vol. 146. Thomas Telford, 1995.

- Collepardi, M., R. Khurana, and M. Valente. "Construction of a dry dock using tremie superplasticized concrete." ACI Special Publication 119 (1989).

- Den Entwurf, Neue Deutsche Richtlinie Für, Zur Rückhaltung Von Wassergefährdenden Von Betonbauten, Nouvelle Directive Allemande Sur La Conception, R. E. T. E. N. T. I. O. N. De Produits, And Dangereux Pour L'eau. "New German Guideline For Design Of Concrete Structures For The Containment Of Hazardous Materials." Otto-graf-journal 17 (2006): 9.

- Erickson, Scott. "Pervious concrete durability testing." In Proceedings of the 2006 Concrete Technology Forum. 2006.

- Fowler, T. J. "Lessons Learned from Refractory Concrete Failures." ACI Special Publication 57 (1978).

- McCurrich, L. H., and N. R. Cook. "Airfield and road pavement use in the UK of high performance coal tar pitch PVC joint sealants, and a comparison of UK and ASTM standards." ACI Special Publication 70 (1981).

- Odum-Ewuakye, Brigitte, and Nii Attoh-Okine. "Sealing system selection for jointed concrete pavements–a review." Construction and Building Materials 20, no. 8 (2006): 591-602.

- Ribeiro, AC Bettencourt, J. Díez-Cascón, and A. F. Gonçalves. "Roller compacted concrete-tensile strength of horizontal joints." Materials and Structures 34, no. 7 (2001): 413-417.

- Sarsam, K. F., and M. E. Phipps. "The shear design of in situ reinforced concrete beam–column joints subjected to monotonic loading." Magazine of Concrete Research 37, no. 130 (1985): 16-28.

- Soliman, Haithem, Ahmed Shalaby, and Leonnie Kavanagh. "Performance evaluation of joint and crack sealants in cold climates using DSR and BBR tests." Journal of Materials in Civil Engineering 20, no. 7 (2008): 470-477.

- Yan, Shangyao, and Weishen Lai. "An optimal scheduling model for ready mixed concrete supply with overtime considerations." Automation in Construction 16, no. 6 (2007): 734-744.

- Yildirim, Yetkin, Yusuf Yurttas, and Ilker Boz. "Service Life of Crack Sealants." In First International Conference on Pavement Preservation. 2010.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.