Woodstove Combustion Air Requirements

Woodstove Combustion Air Requirements

- POST a QUESTION or COMMENT about combustion air requirements and safety hazards for oil and gas fired heating appliances

Combustion air defects & hazards at woodstoves:

This article explains how to recognize and fix combustion air defects at a wood burning stove and and answers basic questions such as how much combustion air does a woodstove need and how should it be supplied.

This article series explains how to recognize and fix combustion air defects on heating appliances.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Combustion Air for Woodstoves - How is It Provided?

The question-and-answer article below paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Article Contents

- HOW to PROVIDE COMBUSTION AIR for a WOOD STOVE?

- HOW MANY CFM of AIR DO I NEED for my WOOD STOVE?

- REDUCED INITIAL DRAFT at a WOOD STOVE - CAUSES

- NEED for DEDICATED AIR DUCTS to a WOOD STOVE - is it really OK to run a woodstove with the door ajar?

...

How do I provide combustion air for a woodstove?

I've often read about the necessity of providing combustion air to a woodstove, but there's usually not much explanation of how it's done. Is it just a pipe that ends near the stove inlet? - Chris Rich, New Castle VA

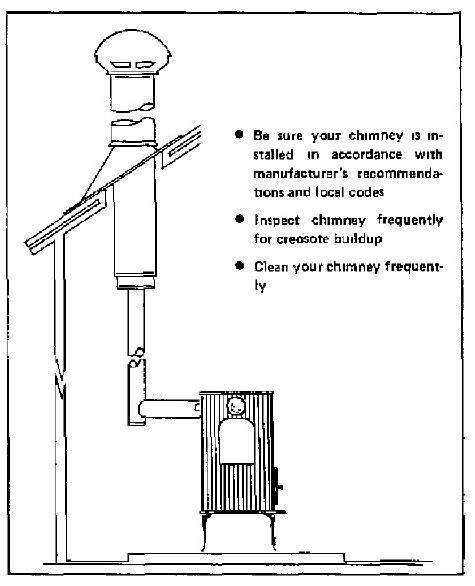

Answer: hard-ducted outside combustion air required for some woodstoves - in manufactured housing

Many wood-stove manufacturers provide a special line of stoves intended for manufactured housing. These woodstoves must have an external combustion-air inlet hard-ducted directly into the stove.

Often the combustion air supply duct comes up through the floor under the woodstove (or coal stove or airtight wood-burning fireplace), making it almost invisible from inside the room where the woodstove is located.

This makes it attractive for the homeowner, and easy for the builder to install.

...

How many cubic feet of make up air do I need for my wood stove combustion?

My stove has been installed for 13 years but, in the last couple years I have noticed trouble with it establishing an initial draft and under a high fire condition it does not heat as much.

For example I used to be able to get the top to glow slightly if I was not careful but, now I can't get it any near that hot, even if I try.

The flue and chimney are cleaned and inspected every year and they are tight. We have installed new windows over the last five years and we had the house weatherized this last spring of 2019.

The weatherization team insulated the attic and air sealed the attic at all of the penetrations and drywall seams. They also sealed all of the band boards in the basement and installed a zipper tent on the attic door and all new weather strips on the exterior doors.

Our 1956 home went from 7 air changes an hour to 3 air changes an hour. The inspector estimated we were probably at 12 -15 air changes an hour at the time the stove was first installed, before we installed new windows and fan fold insulation under our siding.

How do I determine how many cubic feet of make up air I need for my wood stove combustion? I know I have a combustion air problem and I need to install a fresh air intake. I just need to determine what the correct amount of CFM I need so I can install the proper size.

I have a 75kbtu wood stove and an 85kbtu oil burner I have an electric dryer. Kitchen fan, and two bath fans. With none of them running I have trouble with the wood stove drafting on low and high fire. With a window open it works fine if all are running.

I did measure the air inlet on the stove which is approximately a 2.5 square inches (.0174 sqft) with my anemometer and it read 250ft/min. With all items running except the wood stove (which was cold and the air flow was coming out of the inlet of the stove). If my math is correct I have approximately a 4.34 cuft/min deficit without the stove running.

How much additional make up air should I plan for the wood stove?

I would assume,

4.34 Cuft + (wood stove usage) + (safety cushion).

I could find "rule of thumb" for gas and oil but none specific for wood. Are they the same? 2019-11-30 by loven

Moderator reply: Key variables in woodstove air supply CFM needed are combustion air, fuel and draft

I very much appreciate such a thoughtful an interesting question. I'm going to need to read it again and give your topic some thought before replying in more detail.

Meanwhile you can certainly do some empirical experiments by temporarily cracking a window to see what difference it makes to the behavior of the stove.

The other thing you would do would be a careful inspection when the stove is fully cool and cleaned, taking a look at all of this gaskets and seals to make sure that air is only entering where it's intended.

After all the key variables are combustion air and fuel and draft.Reader follow up:

@danjoefriedman, I replaced the door gasket and the glass gasket a year ago and I do the "Dollar test on the door gasket every year and the "rattle" test on the glass gasket as well every year. They are both tight.

I also replaced the door handle last year as it was bent from age and heat causing it to come to its stop without actually tightening the gasket.

A little background on myself I am a home improvement contractor. I also have a background in HVAC, gas fitting, and commercial cooking equipment.I am very familiar with venting and makeup air, but I could not find any hard figures on wood combustion air requirements. Thank you for your timely response.

Reply: Depends on the leakage rate of your building

I've found research on combustion air for wood-burning appliances and will list some of the stronger articles below.

I suspect that a truly accurate answer to your question

"How do I determine how many cubic feet of make up air I need for my wood stove combustion? " will depend on the leakage rate of your building - how tight it is or isn't; in turn that would require a blower-door test -BLOWER DOORS & AIR INFILTRATION

What I'm saying is that a theoretical answer is interesting but an empirical answer that fits the specific building is what's needed.

Most installers use a simple rule of thumb. For example an oil burner needs about 1 sq.in. of unshuttered air intake opening per thousand BTUS of burner input BTUh.

Such a nice number is far more tricky for wood burning stoves; in addition to individual stove parameters, stove intake air adjustment, building air change rate or air infiltration rate, square feet of open space around the woodstove - all standard parameters, we also would need to know the specific wood species, wood moisture content or dryness, possibly even wood dimensions and flame area.

Here are some sources ofWood burning stoves and air requirements theory

- Roy, Murari Mohon, and Kenny W. Corscadden. "An experimental study of combustion and emissions of biomass briquettes in a domestic wood stove." Applied Energy 99 (2012): 206-212.

- Schmidl, Christoph, Iain L. Marr, Alexandre Caseiro, Petra Kotianová, Axel Berner, Heidi Bauer, Anne Kasper-Giebl, and Hans Puxbaum. "Chemical characterisation of fine particle emissions from wood stove combustion of common woods growing in mid-European Alpine regions." Atmospheric Environment 42, no. 1 (2008): 126-141.

- Strehler, A. "Technologies of wood combustion." Ecological Engineering 16 (2000): 25-40.

- Kalla, Smail, Hugo Marcoux, and Alen deChamplain. "CFD approach for modeling high and low combustion in a natural draft residential wood log stove." International Journal of Heat and Technology 33, no. 1 (2015): 33-38.

...

Causes of reduced initial draft at a woodstove

While an onsite expert would certainly find more or perhaps more-important contributors to your initial woodstove draft question, here are some suggestions I can infer from your description of the problem.

I also recommend starting with a review of our article

CHIMNEY DRAFT & PERFORMANCE - causes of inadequate chimney draft, puffing, smoking, fireplace or heater malfunctions

1. You say the chimney is "tight" and has been cleaned annually, but a second look could be worthwhile.

Examples of chimney changes I've come across that could drastically affect draft include discovery that the ash pit cleanout door has been left open or that the chimney cap has been squashed, damaged, or even blown off.

See CHIMNEY CLEANOUT DOOR

and CHIMNEY CAP / CROWN CONSTRUCTION

Have you done the basic experiment of simply opening a nearby window when the stove was having trouble firing-up, then observing any difference in how the stove behaves?

2. Steps you've taken to weatherize and tighten the home against air leaks are well-known to create combustion air supply problems for woodstoves and fireplaces. While I would not go so far as to recommend a blower door test, we describe these concerns at

BLOWER DOORS & AIR INFILTRATION https://inspectapedia.com/Energy/Blower_Door_Test_Procedure.php

Your notes suggest that you may have already done this, as you describe the fresh air intake rate measured in ACH (Air Changes per Hour) falling from 12-15 (very high) down to 7, down to 3 (very tight).

I don't have any details about your specific woodstove's air supply requirements in CFM but the rang I see in various woodstove manuals and government publications ranges from about 10-40 CFM for a small and tight woodstove up to over 140 CFM depending on stove type and design.

While sources such as woodheat.org discuss woodstove air supply requirements and state "The average air consumption of a modern wood heater is in the range of 10-25 cfm" (and claim that the natural leakage rate of most houses will provide plenty of air, my own field experience and preference is to look for objective data when solving a specific woodstove installation.

You've done that to a degree: you already observe that your stove is "air starved" at least before it benefits from the stronger draft created after the fire has been well-established.

3. General guidelines on woodstove BTUH ratings vs air supply in cfm: here are some rules of thumb:

A generic standard is provided by the International Fuel Gas Code (IFGC) : "Combustion appliances need 50 cubic feet of air per 1,000 BTUs per hour."

When I installed and inspected oil burners heating homes in the northeastern U.S. we used a rule of thumb that we needed 1 square inch of open (unscreened) outdoor air supply per 1000 BTUs of heater rating.

4. Make a very close inspection of the wood stove itself as well as the flue vent connector, any stove dampers in the stove or in the flue, for air leaks or air flow blockages. In my first point where I mentioned the chimney cleanout door ajar problem, a gas boiler service company in northern Minnesota told our client that they needed a new gas boiler because the unit was spilling flue gases at its draft hood.

By luck I simply looked behind the boiler and found the cleanout door had been left open about 2 inches - that was enough to subvert the draft at the boiler itself.

I'm unclear about the accuracy of your anemometer reading (kudos for giving it a shot though); but your measurement sure tells us that the building is air-starved: you were running other air-consuming devices enough to create a backdraft of "250 ft/min" drawing air backwards, down the chimney and OUT of your woodstove's air inlet.

5. If all of your re-inspection convinces you that the stove is not leaking air where it shouldn't be and that there are no operable controls that are not working such as a damper that you thought was open that was sooted or stuck shut by creosote, then considering the increase in air tightness you've described, I'd be looking for a passive air supply inlet to feed the woodstove.

If it were my project I'd provide a passive air supply giving me at least 10 cfm air flow to the woodstove, and I'd provide for an adjustable air inlet so that I could experiment, closing it down to the point to stop excess draft (by observation at the woodstove).

More diagnostics for you are at

Thank you for the discussion

Daniel

Woodstoves also regulate the wood fire and thus stove temperature by adjusting the combustion air intake to the woodstove at the fire door.

The orange circle in my photo above surrounds the woodstove air inlet draft control.

Above is a beautiful Jotul woodstove that I (DF) traded to Paul Galow for a fancy wristwatch.

...

Are Dedicated Combustion Air Ducts Needed for Woodstoves?

@loven, I have read a new article recently that says that wood stoves with dedicated make up air ducts are not effective or necessary because leaving the door open does NOT draw very much indoor heated air up the flue.

Anybody care to comment? 2025-02-07 by Steve

Mod reply: dangers of running a woodstove with the door ajar

@Steve,

My opinion is that there will be no single correct answer to your question, but thanks for asking as it's an interesting and useful one.

In the U.S., every wood stove installed in a residential home constructed after 2008 in the UK and some other jurisdictions at other dates will, to comply with model codes, require either an air vent or external air intake.

But that does not mean that every woodstove benefits from one.

Your statement "wood stoves with dedicated make up air ducts are not effective or necessary" is, as I just explained, incorrect in at least some circumstances (stoves without an air feed)

Your statement continues: " because leaving the door open does NOT draw very much indoor heated air up the flue" is completely contrary to my experience and contrary to my field measurements of drafts and heat loss in buildings.

Direct Stoves, a U.K. wood stove vendor at https://www.directstoves.com/our-blog/what-is-an-external-air-kit-for-a-wood-burning-stove/ gives a nice summary of cases where an external air vent is effective, needed, or useful:

1. if there is no permanently-open external air supply vent feeding the stove or the room where it's located (so a window that can be closed doesn 't count)

2. if your home is built to standards (such as the UK PassiveHouse standard) that construct a tight building with managed fresh air ventilation to a balanced level (the woodstove will throw that way off)

3. similar to point 2, if your home uses a balanced heat recovery ventilation system - see our explanation of HRVs - Heat Recovery Ventilators at VENTILATION, BALANCED https://inspectapedia.com/BestPractices/Balanced_Ventilation_Systems.php

4. your stove is installed in a building or area where the existing ventilation system can create negative pressure (the stove will be air-starvedf)

Watch out: leaving a wood stove with the door partly ajar or "cracked open" - as we sometimes do to get a fire going, is very dangerous and can cause the stove to overheat and might even contribute to a chimney fire.

Watch out: operating a woodstove with the door wide open and *without* an outdoor air supply fed directly to the stove will almost certainly operate at a net heat loss for the building as it draws outdoor air through various air leak points into the home to supply the fire.Older leakier homes will lose more heat. Newer more air-tight homes may lose less heat but the woodstove may operate poorly if it's air starved.

Watch out: very similar to my warning immediately above, even *closing* the door to a woodstove can lead to dangerous overheating if the door gaskets are missing or worn and leaky, for the same reason I just described.You can usually see if you have this problem because with the stove door shut tightly you may, if there is view of the fire, see a a blowtorch effect on part of the fire where air streams through the door gaps, or even without looking you may hear a rushing sound.

Watch out: a roaring sound can indicate a very dangerous chimney fire. If in doubt, close off all dampers and flues feeding air to the fire and also in the flue vent too. And call your fire department from a safe location out of the building.

My friend Nancy, trying to save on home heating costs in an older but renovated New York home, runs her woodstove through the winter.But she insists on using it in "fireplace" mode. Sure the area around the stove warms up from the stove's radiant heat, but the rest of the home, or at least the first floor of the home where the stove is located, is colder than it would be if she used the woodstove as an airtight woodstove.

Daniel

The original Q&A article in PDF form immediately below has been replaced by the expanded/updated online version of this article found above on this page.

- Q&A on OUTSIDE COMBUSTION AIR FOR WOODSTOVES - PDF version, use your browser's back button to return to this page. Original article, Solar Age Magazine, November, 1985, adapted and updated for InspectAPedia.com December 2010 - March 2025.

...

...

Continue reading at WOOD STOVE OPERATION & SAFETY or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CHIMNEY FIRE ACTION / PREVENTION

- COMBUSTION AIR REQUIREMENTS - home

- WOOD STOVE OPERATION & SAFETY - home

- COMBUSTION AIR for WOODSTOVES

- DEFECTS LIST - HEAT, WOOD APPLIANCE

- FIRE CLEARANCES, WOOD COAL & PELLET STOVES

- FIREPLACE INSERTS INSTALL, INSPECT, REPAIR

- HEAT SHIELD SPECIFICATIONS for WOOD STOVES & PELLET STOVES

- PELLET STOVE CLEARANCE DISTANCES

- PELLET STOVE DRAFT CONTROL

- PELLET STOVE MANUALS

- WOOD FURNACE FAN LIMIT CONTROL

- WOODSTOVE DRAFT CONTROL

- WOOD STOVE DRAFT TEST

- WOOD STOVES, CATALYTIC PUFF-BACKS

- WOOD STOVE INSTALL CONVERT

- WOOD STOVE INSPECTION CHECKLIST [PDF]

- WOOD STOVE MANUALS

Suggested citation for this web page

COMBUSTION AIR for WOODSTOVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to FIREPLACES COAL & WOODSTOVES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about combustion air requirements and safety hazards for oil and gas fired heating appliances

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Handbook - Fundamentals, 1993, Chapter 15, page 15.9 Air For Combustion.

- ASME CSD-1- Controls and Safety Devices for Automatically Fired Boilers, 1992 with addendum 1a 1993. section CG-260 Combustion Air.

- BOCA - National Mechanical Code, 1990, article 10, Combustion Air.

- NFPA 31 - Installation of Oil Burning Equipment, 1992, section 1-5 Air for Combustion and Ventilation.

- NFPA 54: National Fuel Gas Code (2015), addresses heating appliance combstion air ventilation specifications. NFPA 54, ANSI Z223.1 provides minimum safety requirements for the design and installation of fuel gas piping systems in homes and other buildings.

- NFPA 85: Boiler and Combustion Systems Hazards Code: NFPA 85 contributes to operating safety and prevents explosions and implosions in boilers with greater than 12.5 MMBTUH, pulverized fuel systems, and heat recovery steam generators.

- NFPA 87: Recommended Practice for Fluid Heaters, This recommended practice provides safety guidance for fluid heaters and related equipment to minimize fire and explosion hazards that can endanger the fluid heater, the building, or personnel

- SBCCI- Standard Mechanical Code, 1991, section 305 Combustion and Ventilation Air.

- Axtman, William H., "Combustion Air Requirements: The Forgotten Element in Boiler Rooms", Grayh Gull Associates, retired executive director of the American Boiler Manufacturers Association, National Board Technical Series, Winter 1995 National Board Bulletin. Retrieved 26 January 2015, original source: http://www.nationalboard.org/index.aspx?pageID=164&ID=191

Excerpt:

Several safety codes such as the National Fire Protection Association's standards, NFPA 54 - National Fuel Gas code, NFPA 31 - Installation of Oil Burning Equipment, and the American Society of Mechanical Engineers (ASME) CSD-l Controls and Safety Devices for Automatically Fired Boilers have sections covering the requirements for combustion air intakes. In addition, building codes such as the Building Officials and Code Administrators International (BOCA) National Mechanical Code and the Standard Mechanical Code published by the Southern Building Code Congress International (SBCCI) have air requirements for combustion.

Editor's note: Some ASME Boiler and Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual experience. The reader is cautioned to refer to the latest edition and addenda of the ASME Boiler and Pressure Vessel Code for current requirements. - Nussbaumer, Thomas. "Combustion and co-combustion of biomass: fundamentals, technologies, and primary measures for emission reduction." Energy & fuels 17, no. 6 (2003): 1510-1521.

- Utiskul, Yunyong P., Wu, Neil P., Biteau, Hubert, "Combstion Air Requirements for Power Burner Appliances, Final Report", The Fire Protection Research Foundation, The Fire Protection Research Foundation

One Batterymarch Park

Quincy, MA, USA 02169-7471

Email: foundation@nfpa.org

http://www.nfpa.org/foundation, retrieved 25 Jan 2015, original source: http://www.nfpa.org/~/media/files/research/research%20foundation/rfcombustionairrequirements.ashx, Executive Summary:

Gas-fired appliances require combustion air to properly function. Adequate air is necessary for

supporting combustion of the appliance burner, dilution of flue gas, and proper ventilation of the

space where the appliance is installed. Current standards and model codes outline requirements

and methods to supply the combustion air. One method is to provide outdoor combustion air

through openings or air ducts communicating with the outdoors through natural ventilation.

Most standards require the outdoor opening(s) be prescriptively sized based on the total energy

input rating of the appliance. However, in the United States, the current standards contain no

separate provisions to address the opening size supplying the combustion air for

commercial/industrial sized appliances, which typically have a high energy input rating of

greater than 300 kBtu/hr and are equipped with a power burner unit. As a result, the opening(s)

can be excessively sized when determined based on the current standards.

This research project establishes minimum outdoor combustion air requirements specific to gasfired

appliances utilizing power burners with input ratings no greater than 12.5 MBtu/hr. A

review of the available literature, engineering guidelines, and current standards and model codes

related to combustion air requirements was performed. This report provides an understanding

of the technical basis for the existing provisions for combustion air and their applicability to

power burner appliances. This report also identifies the range of energy input ratings for gasfired

appliances equipped with power burners, and compares the combustion air requirements

specified by a range of appliance manufacturers. A theoretical model for air flow through

openings was developed and the modeling results, together with the data gathered through the

literature review, were used to provide a baseline to establish the theorized combustion air

requirements suitable for power burner appliances.

... - [1] Jeff Wilcox, "Evaluating Duct Work, How to Evaluate Furnace Duct Work & Cure Short Cycling or Inadequate Ductwork Problems" Vermont Department for Children and Families, Office of Economic Opportunity, - dcf.vermont.gov/sites/dcf/files/pdf/oeo/WAPManual/AppendixI.pdf retrieved 12/5/2013. Geoff Wilcox Vermont Office of Economic Opportunity Weatherization Assistance Program Waterbury, VT (802) 769-8376 Geoff.wilcox@state.vt.us Reference Material for the original article came from: 1. Saturn Mechanical Systems Field Guide 2. Bacharach (Rudy Leatherman)

- Field Controls provides instructions for the installation of LP and Natural Gas spill sensor switches, for example for their Gas Spillage Sensing Kit Model GSK-3, GSK-4, GSK-250M switches. Contact your heating service technician directly, or contact Field controls at fieldcontrols.com for more information. These switch models include a manual reset switch. Field Controls, Kingston NC 28504 - Tel 252-522-3031.

- Tjernlund Products provides instructions for the installation and use of their controls, including the WHKE Millivolt Interlock Kit for use with their UC1 Universal Control, MAC1E or MAC4E auxiliary controls for gas fired equipment. This document also describes Tjernlund's recommended combustion air safety check which we recommended in this article. Contact Tjernlund Products at tjernlund.com or at 800-255-4208.

- Bachrach Corporation, www.bachrach-training.com provides education for HVAC technicians. We found their web pages hanging during loading -01/2009. Readers may want to contact the company directly at: bacharach-inc.com or at 800-736-4666.

- R.E. Prescott Company, a producer of other REPCO™ residential and industrial products as well as a provider of design-build engineering services is at 10 Railroad Avenue, Exeter, NH 03833. Tel: 603-722-04321 or 888-786-7482. Trish O'Keefe from Prescott informed us (10/7/2009) that their company had nothing to do with the failed Repco heating boilers discussed at InspectAPedia.com. She wrote:

- Our company manufactures & distributes residential water treatment equipment, including our Repco line of conditioners. We have a plumbing & heating supply dept as well. We are mistaken for the Repco Boiler company on a regular basis, most frequently in Oct. and Nov.

- Any information you could give me on the other Repco company would be appreciated. We've assumed it is no longer in business, and we'd like to know that for sure. Many callers want to know where to get replacement parts and I would be glad to direct them if I knew...plus there's always a chance they might be interested in a Crown Boiler instead

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.