Rust & Corrosion in Electrical Panels

Rust & Corrosion in Electrical Panels

- POST a QUESTION or COMMENT about the causes & frequency of occurrence of dangerous leaks or moisture in electrical panels.

Rust in electrical panels, sources of water leaks into electrical panels:

A Study and Report on Frequency and Causes of Rust & Corrosion inside of residential electrical panels. Field observations of residential service panel connections and components discovered significant occurrences of rust, corrosion, and damage to electrical equipment, risking failure to trip on overcurrent and thus risking building fires.

These observations led to a study of the frequency and cause of water damage, rust, corrosion, or other moisture-related unsafe conditions in residential electrical panels. This report by Daniel Friedman was presented to the electrical engineering community at the IEEE Holm Conference on Electrical Contacts.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Rust and Corrosion in Electrical Panels - Field Observations of Residential Service Panel Connections and Components

Introduction to the Electrical Panel Corrosion Study

IEEE Holm Conference on Electrical Contacts, Daniel Friedman, Poughkeepsie, NY, October 19, 1992, updated 12 March 2015

[Click to enlarge any image]

ABSTRACT: Visual examination of the electrical service panel is an important element of the procedure followed by professional home inspectors, whose observations are most often made at the time of sale of a used residence. T

he inspectors' observations can provide a data base on field performance of residential electrical system components that may be valuable toward the development of improvements in both the components and their associated qualification standards.

The observations noted in this paper are derived from a set of more than 1,500 detailed inspection reports by the paper's author and from a survey of members of the American Society of Home Inspectors (ASHI).

Professional home inspectors offer a unique perspective of field failures: in performing a comprehensive survey of a building's systems and components, an inspector may discover common external or interactive causes of damage or deterioration. Home inspectors regularly observe field deterioration in progress before hazards or malfunctions are so obvious as to come to the attention of the occupants.

The reported observations in electric panels include corroded, burned, and damaged connections and corroded and malfunctioning circuit breakers. Causative factors noted in the service environment include presence of moisture, damage from overcurrent, and poor installation practices.

Suggested improvements, including the need for greater resistance to corrosion and other field and environmental conditions, are discussed. -- This material was first presented at the October 1991 IEEE-Holm Conference on Electrical Contacts. Original text expanded by the author for this online publication 20 February-March 2006.

Rust and corrosion in residential electrical panels is more than a theoretical safety concern. Our friend and contributor to this InspectAPedia.com Steven Bliss reported:

In a heavy rain, water was gushing through my main service panel and subpanel, flowing through the circuit breakers like a waterfall. Very disturbing. The electrician and Burlington Electric both thought water was coming through cracks in the exterior main service entry cable that has very old cloth sheathing.

However, I caulked the hell out of the top of the electrical meter where the wire goes enters the meterbox and also at the wall where the SEC passes into the house, and the problem appears to be solved.

One circuit breaker had frozen solid from corrosion and had to be replaced. I don’t know how long this has been going on. I only discovered it when I tripped a breaker with a power tool.

Watch out: for electrical services, panels, breakers, fuses that have been flooded or wet, to avoid dangerous or fatal electrical shock

see HOW TO TURN OFF ELECTRICITY in a building that has been wet or flooded

Visual examination of the electrical service equipment

is an important element of the procedure followed by professional home inspectors, whose observations are most often made at the time of sale of a used residence.

These observations can provide a data base of field performance of residential electrical system components that may be valuable for the development of improvements in both the components and their associated qualification standards.

Professional home inspectors offer a unique perspective on field failures:

in performing a comprehensive survey of a building's systems and components,

an inspector may discover common external or interactive causes of

damage or deterioration.

Professional home inspectors offer a unique perspective on field failures:

in performing a comprehensive survey of a building's systems and components,

an inspector may discover common external or interactive causes of

damage or deterioration.

Inspectors see in-service field conditions, often before failures occur, and before failing conditions are so obvious as to come to the attention of the occupants.

Other studies of connector/component failures in service panels have focused on defects discovered after rather than before actual failures and have not considered corrosion/damage diagnosis based on a comprehensive examination of the entire structure and site for causal factors. (1)(2)(3)(4)

1052 Electric Service Panels were examined in the field, in conditions of actual use.

Examination revealed frequent occurrences of corroded, burned, and damaged connections and corroded and malfunctioning circuit breakers. Significant, reportable corrosion/related defects in the panels were observed in 12% of cases - a frequency significantly greater than that anticipated by the electrical industry.

Causative factors noted in the service environment included presence of moisture, damage from overcurrent, and poor installation practices. Suggested improvements, including the need for greater resistance to corrosion and other field and environmental conditions, are discussed.

This information was first presented to industry experts at the 1992 Philadelphia IEEE Holm Conference on Electrical Contacts to suggest that the moisture and corrosion resistance characteristics of electrical panels and their contents should be increased.

Information about the common causes and sources of water entry was also of importance to home inspectors who need to be alert for these conditions and for the damage and risks they may cause.

Article Contents

- ELECTRICAL PANEL RUST STUDY PROCEDURE

- ELECTRICAL PANEL RUST STUDY RESULTS - frequency of occurrence of corrosion

- ELECTRICAL PANEL CORROSION LOCATIONS

- ELECTRICAL PANEL MOISTURE / WATER SOURCES - separate page

- ELECTRICAL PANEL AGES VS FAILURE RATES

- ELECTRICAL PANEL CORROSION-RELATED FAILURE EVIDENCE

- ELECTRICAL PANEL CORROSION FAILURE CONCLUSIONS & RECOMMENDATIONS

- ELECTRICAL PANEL CORROSION FAILURE PHOTOS LIST

- ELECTRICAL PANEL RUST & CORROSION RESEARCH / BIBLIOGRAPHY - separate page

PANEL RUST STUDY PROCEDURE - for Electrical Panel Corrosion

Comprehensive visual inspections for building defects were performed on 1052 private homes between 1987 and 1991.

The overhead service drop, service entrance conductors, electric meter, and raceway or cable from the electric meter to the service panel were examined, as were the service panel and all components therein.

Inspection was visual, did not normally involve use of test equipment, and followed well established guidelines for professional home inspectors.(5)(6)(7).

Field notes were recorded indicating any defects in each panel. Site conditions which might be a related cause were also noted.

Every "defect" was severe enough to merit a report to the building owner or buyer as a safety concern.

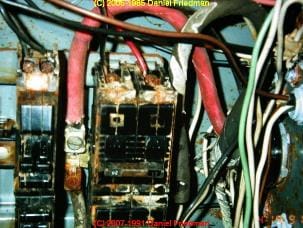

Visible damage or other conditions which might indicate malfunction or unsafe conditions included: significant rust or corrosion on any component; signs of overheating [Such as [Fig-3 above] overheated electrical ground and neutral wires at a corroded panel bus, ...

and [Fig-15, a below] verheated electrical branch circuit wires which may or may not be due to a corroded circuit breaker which failed to trip], or other damage at connections of the service entrance wires, at wiring connections on circuit breaker terminals or individual fuse terminals, at neutral or ground bus bars or connectors; or rust at the base of the panel enclosure itself.

Light surface rust on the exterior of the panel or minor corrosion in the panel interior were not reported if there were no other indications of malfunction such as evidence of overheating or of past repair work.

The field data were tabulated: estimated year of equipment installation, system ampacity, panel type (breaker, fuse, antiquated), presence of knob-and-tube wiring, presence of rust or corrosion on four common locations in the panel, apparent source of moisture related to corrosion, and other defects (mis-wired device, burned connectors, etc.).

PANEL RUST STUDY RESULTS - for Electrical Panel Corrosion

Frequency of Corrosion in Electric Panels

| Table 1. Year of Electrical Equipment Installation and Number of Electrical Panels Studied | ||||||

| '90-'87 | '87-'76 | '75-'65 | '64-'59 | '58-'37 | Pre-'37 | Total |

| 60 | 244 | 308 | 145 | 201 | 94 | 1052 |

An examination of field notes from more than a thousand private home inspections performed between 1987 and 1991 reveals rust and corrosion of various electrical components in 126 of 1052 service panels. More than one in ten service panels showed sufficient corrosion to merit, in the opinion of the inspector, report to the client of a possible safety or functional concern with the equipment.

The age of equipment varied from brand new to more than 50 years old. [Table 1 above]. Most of these were circuit-breaker type panels (835), with the remainder fused equipment (217). More than one in ten service panels showed sufficient corrosion to merit a report to the client of a concern.[Table 2 below].

| Table 2 - Frequency of Corrosion In Service Panels | |||

| Number of Defects | Percent of Cases | Percent of Total Panels | |

| Cases 1 | 126 | 100% | 11% |

| Panel Surfaces & Other Steel Components | 110 | 87% | 10% |

| Circuit Breaker Terminals | 97 | 76% | 9% |

| SEC Connectors | 46 | 36% | 4% |

| Bus Bar Connectors | 42 | 33% | 3% |

Notes to Table 2

1. 126 service panels examined had one or more reportable corrosion or corrosion related defects. Since some panels have more than one reported defect,, the number of defects will total more than the number of cases.

2. 1052 service panels were examined.

The criteria for reporting such damage in a given panel is subjective, not quantitative, and does not normally involve equipment tests. Two definitions of severity of damage are:

Light corrosion in an electrical panel:

Light corrosion in an electrical panel:

surface rust spots on panel enclosure parts or on other steel components in the panel. No visible evidence of failure, wet components, arcing, burning, history of repairs, or other clues suggesting, from external visual inspection, that safety components such as fuses or circuit breakers appear at likely risk of malfunction. Light corrosion instances were not tabulated in this study.

Serious corrosion in an electrical panel:

heavy rusting or other corrosion at connections of the service entrance wires (usually at terminals on a main fuse block or circuit breaker), at wiring connections on circuit breaker terminals or individual fuse terminals, at neutral or ground bus bars or connectors, or at the base of the panel enclosure itself.

Exfoliation on steel panel components, or other highly-suspect conditions are present in such cases.

Even if the inspector does not observe serious corrosion on wiring connections in a panel equipped with circuit breakers, the presence of heavy rust, exfoliation, or actual water in the panel enclosure is considered grounds for reporting a serious finding.

This conclusion is based on an untested opinion of many professional inspectors that the presence of sufficient moisture to cause such corrosion raises questions about the condition of hidden safety components such as circuit breaker internal parts or bus-bar components covered by breakers or fuses.

The natural collection point for moisture, the panel bottom, might be reached after droplets have passed over and in some cases through other electrical components and connectors.

Rust on steel service panel components

was by far the most common observation, occurring in 110 (10%) of the installations examined. [Fig-1 at left]

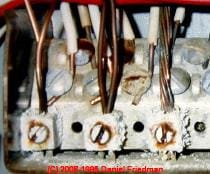

Rust on screw connectors on circuit breakers,

and less often on fuse terminals, was also common, occurring in 97 cases, slightly less than 10% of the systems examined.

In some cases corrosion was so severe that not only was the connection questionable, but the connector screws themselves were so corroded that the electrician had to cut the wire when preparing to install new breakers. [Fig-2 at left]

Corrosion at the connection of service entrance cable to main breakers

or fuse connectors was found in 46 cases.

It was common to see severe corrosion at this location when water was present.

Evidence of overheating (burned insulation and discolored wire and in some instances partially melted aluminum wire) was observed at those connectors in several instances.

Corrosion on neutral and grounding bus bars and connector screws was found in 42 cases.

Evidence of overheating was seen in two of these cases - the next two photographs shown below.

Where does Corrosion Occur in Electrical Panels?

Rust on steel service panel components is by far the most common observation,

occurring in 110 (10%) of the installations examined. [Table 2 above]

Rust on steel service panel components is by far the most common observation,

occurring in 110 (10%) of the installations examined. [Table 2 above]

Rust on screw connectors on circuit breakers, and less often on fuse terminals, was also common, occurring in 97 cases, slightly less than 10% of the systems examined.

In some cases corrosion was so severe that not only was the connection questionable, but the connector screws themselves were so corroded that the electrician had to cut the wire when preparing to install new breakers. When severe rust is present we report that the operation of the circuit breakers might be suspect.

Corrosion on neutral and grounding bus bars and connector screws was found in 42 cases.

However field data indicates that bus-bar connector corrosion so severe as to offer visual suggestion that the connection is highly questionable is rare. Evidence of overheating (possibly related to corrosion) was seen in only two of these cases, detected as discolored copper wires at the connector.

Corrosion at the connection of service entrance cable to main breakers or fuse connectors was found in 46 cases.

However this connection gives cause for greater concern, as it is not uncommon to see severe corrosion at this location when water is present. we have observed evidence of overheating such as burned insulation and discolored wire and in some instances partially melted aluminum wire at such connectors.

Sources of Moisture, Leaks, Water in Electrical Panels

A significant advantage accrues from having a service panel inspected as part of a more comprehensive property inspection: home inspectors are concerned with the building envelope, with water entry, and with damage to building components from moisture.

These details are now found on a separate page of this study,

at

Electrical Equipment Age vs. Failure Rates in the Studied Population

The age of equipment varied from brand new to more than 50 years old. Most of these were circuit-breaker type panels (835), with the remainder fused equipment (217).

Service panel age did not necessarily match the age of the building. For many older homes historical and other evidence indicated that the service had been upgraded. For homes constructed before 1937, electric panels had often been upgraded two or more times.[Table 1]

| Table 1. Year of Electrical Equipment Installation and Number of Electrical Panels Studied | ||||||

| '90-'87 | '87-'76 | '75-'65 | '64-'59 | '58-'37 | Pre-'37 | Total |

| 60 | 244 | 308 | 145 | 201 | 94 | 1052 |

No relationship was observed between type of equipment (fuse systems versus circuit breaker equipment) and the ability of water or moisture to enter the enclosures.

In this study, older equipment, subject to the same history of water entry, almost always looked less damaged from moisture. On such connectors and devices less extensive corrosion was found than on newer aluminum and steel screws, connectors, bus bars, and other components exposed to the same conditions.

Better data regarding actual failures might be surveyed among electricians performing replacements. Meese and Beausoleil have looked at failures in branch circuits.(3)

A common opinion among some experts was that fused equipment might be more reliable in damp/corrosive conditions than circuit breaker equipment. That view is based on the premise that electromechanical parts are more vulnerable than a fused link. However it's possible that the easier abuse of fuses (overfusing and bypassing) may offset the reliability advantage. (2)(3)(4) However other work by Keyes (1) and Popper (2) indicates that fusible panels may be more dangerous.This study did not test these opinions.

We did not tabulate the occurrence of corrosion, presence of defects, or evidence of failures, as a function of equipment age. However a subjective opinion is that older equipment, subject to the same history of water entry, almost always looks less damaged from moisture. We suspect that a factor is the use in older equipment of heavy copper and plated components. On such connectors and devices we see less extensive corrosion than on newer aluminum and steel screws, connectors, bus bars, and other components exposed to the same conditions.

Home inspectors rarely observe electrical equipment immediately after a catastrophe.

It is common, however, for these specialists to find equipment in various states of deterioration of which the most severe might be just before a hard failure which would lead the homeowner to take corrective measures.

Occasionally the inspector will encounter new equipment in a property for sale and will observe the old devices abandoned (as trash) in the building. In these uncommon instances there may be opportunity to observe first hand the evidence of failure which led to equipment replacement. Better data regarding actual failures might be surveyed among electricians performing replacements. Meese and Beausoleil have looked at such failures in branch circuits.(5)

These views are confounded by the observation that in the geographic area studied service panel equipment is often 1960's vintage or newer.

Older equipment has been replaced for several reasons: desire of owners to improve service ampacity, necessity to replace damaged or failed equipment, and requirements of lending institutions and recommendations from local power utility companies which cause services of less than 100 Amps to be replaced when houses are sold.

CORROSION-RELATED FAILURES - Evidence of Corrosion-Related Malfunction in Electrical Panels

Inspection practices exclude functional testing of electric panels

Normal home inspection practice does not include performance of many tests on electrical equipment. It is common for inspectors to operate switches and controls which are provided for the homeowner (circuit breakers) or for use by service personnel (disconnects at HVAC equipment).

The Standards of Practice of the American Society of Home Inspectors require that every GFCI device be tested, that light switches and receptacles be sampled for proper operation and correct polarity and grounding. Inspectors may also verify that 240 volts is provided by the service. By contrast, testing for proper operation of a circuit breaker under load conditions requires special equipment, training, and procedures which are beyond the scope of a normal home inspection.(6)

Many inspectors are reluctant to operate circuit breakers, particularly main fuses or breakers, in occupied buildings.

Often they will not do so without owner permission, because of risks of losses associated with unexpected power outage (e.g. computer was turned on upstairs, kidney dialysis machine was in operation).

We have field reports of loss of building heat, with concomitant risks of freeze damage, when power was turned off as part of an inspection, only to discover that a faulty circuit breaker or main fuse could not be restored to power. Inspectors approach this topic with caution.(7)

As an incidental study, we tabulated frequency of certain very common "defects" observed in service panels, of which one, burned connectors, could possibly relate to the presence of corrosion. There were 23 such cases out of the 1052 panels observed, a 2% occurrence. In at least two of these 23 cases, the inspector noted evidence of an actual fire in the panel. (The number of panel defects will exceed the number of panels examined, since multiple defects may have been reported for individual installations.)

ANECDOTAL EVIDENCE - of Electrical Panel Malfunction from Corrosion

We did not tabulate severity of corrosion. Every case reported however was severe enough to merit having been reported to the building owner or buyer as a potential safety concern. As anecdotal evidence, we report having found:

- during rainy weather, water visibly dripping into the panel through the entry cable

- droplets clinging to interior panel breaker terminals and bus bars

- standing water completely filling the panel base when a steel lip is installed thereon

- moisture in small droplets, apparently condensation, soaking all panel components

- circuit breaker terminals so completely rusted and corroded as to make removal of the terminal screw impossible

- evidence of corrosion at aluminum entrance cables, regardless of use of anti-corrosive flux, sufficient to cause overheating of the cable and partial melting of its insulation

- in an unheated basement subject to freezing, a Bakelite fuse pullout which had been damaged by moisture, cracked, and disintegrated when the inspector attempted to pull the main fuses, leaving one fuse in place, one fuse half-removed<196>an exciting moment for the inspector

- steel screws connecting main breakers to aluminum bus-bars failed at the point of connection resulting in loss of power in half the electric panel

- sheet metal screws, very commonly used to replace lost machine-thread panel cover screws, have been found to pierce electric wires in the panel, in two cases resulting in a fire in the service panel.

- In 1991 the author participated in investigation of a fire (Pok NY Arnold Road) which was attributed to SEC cable fraying, leaks, corrosion, and a burn up at the electric panel in the building.

Electrical Panel Corrosion Conclusions and Recommendations Regarding Electric Panel Leaks and Corrosion

Moisture from exterior leaks and interior condensation must be accepted as a very common hostile environment for service equipment in homes throughout a good part of the United States. Based on a large sample of electric service panels found in homes ranging from new to more than 100 years old in Southern New York, at least one of every ten units examined showed evidence of corrosion and moisture.

One might expect worse conditions in more humid regions.

The most common sources of water and moisture entry appear to be: through service entrance conductor cables which are old and damaged, or which are improperly sealed at meter boxes or building sidewalls; from condensation from high interior moisture levels; and from other building leaks or surface water which pass down building walls where panel enclosures are mounted

Electric service components are not adequately protected from corrosion. In this study, corrosion was found at main entry cable connections, wire connectors on circuit breakers, wire connectors on neutral and grounding bus bars, and on the panel enclosure itself. Steel and aluminum components more often showed significant corrosion than do heavy solid copper components.

As a result of moisture and corrosion in service equipment, hazardous conditions may be expected. At some service cable connectors there was visual evidence to strongly suggest that corrosion had led to overheating and damage to the conductors.

The observation of corroded circuit breaker and other panel connectors, and the presence of highly visible water marks and even water itself on circuit breakers raises serious questions: what is the corrosion resistance of internal parts? What conditions might be found on critical parts inside those devices?

Improvements in the design of electric service panel enclosures might include drainage and ventilation for service equipment enclosures and moisture-entry-resistant panel enclosure or panel backs and fastening methods. Similar improvements, possibly by minor design changes in the stamping of steel back and base plates of electric meter enclosures might be considered.

Leaks at and through contemporary service entry cables might be reduced by: reliable weather tight connectors at the top of exposed electric meters; use sealant to encapsulate the stripped cable end (inside the meter enclosure) whenever a service cable passes out the bottom of a meter enclosure to service equipment located below the meter; use improved sealant at the building wall opening made for passage of the cable to the building interior, or use of a weather tight bib designed for a variety of uneven and often flexible wall surfaces.

Steps to increase the corrosion resistance of entrance and breaker wire connections, bus bar connectors, screw terminals, might compensate for very common field conditions which continue to place this equipment at high risk of damage from moisture.

St-Onge, addressing copper services, has made other suggestions for corrective measures, (11) and other studies have made more broad suggestions for design and installation improvements.(9) Improved materials are available and have been discussed in the literature by Breedis and Hauser.(10)

Effective corrosion resistance should be added to the present standards for qualification of electrical service equipment.

Perhaps it's not startling to note that we omit from these suggestions a greater emphasis on field training for installers.

When electrical work is performed by a trained qualified electrician, it's generally obvious immediately when a device cover is removed. Unfortunately we are not the first observe a broad range of skill and training in electrical work, particularly in rural areas where building code enforcement may be lax and "improvements" are made by property owners and untrained mechanics. (9)

Combined with demanding field conditions which we've described in this article, improvements in component design may be a more successful step to reduce water entry, moisture, corrosion, and failures in electric service panel connectors and components.

MORE STUDY TOPICS - Additional Study of Electrical Panel Defects Is Needed

The author is continuing and expanding this study to allow examination of additional variables

- Inspection field note forms have been modified to allow collection of pertinent details including manufacturer and model of service equipment.

- A more aggressive attempt will be made to obtain failed and removed older equipment in order that it may be provided to professionals interested in testing for actual reliability of the devices which were removed as "suspect."

- Effort will be made to extend the scope of collection of field data to other geographic regions: warm-dry regions of the Southwest where use of cooling equipment and a more casual attitude towards protection from weather are common; colder-more dry regions of northern regions.

- Effort will be made to obtain survey results from a wider selection of professional inspectors, within guidelines to provide consistency of "opinion" regarding reportable defects.

Readers who have suggestions for critical observations which should be collected during field work are urged to contact the author, Dan Friedman - contact information is given at the end of this document.

PANEL PHOTO LIST - List of Illustrations of Electrical Panel Corrosion

The original illustrations and photos, available by clicking on the links below, are called-out in the article text by individual [Figure #].

- External electrical panel rust, is a clue indicating that water is likely to have entered or condensed in this electrical panel [Fig. 0] - inspectors should be extra cautious when opening an electric panel where external rust is visible

- External electrical panel rust at the breaker knockouts, is a further clue indicating that water is likely to have entered or condensed in this main electrical panel[Fig. 0a] - watch for in-panel corrosion

- Corroded neutral/grounding bus, water in bottom of the electrical panel [Fig. 1] - this is reportable neutral bus and enclosure base corrosion.

- Severe rust on circuit breaker and electrical connectors in electrical panel [Fig. 2]

- Common corroded ground connectors with evidence of overheating [Fig. 3]

- Severe Rust on steel neutral/ground bus in electrical panel, corroding neutral wires [Fig. 4]

- Water runs inside Electrical Service Entry Cable (SEC) in electrical panel [Fig. 5]

- Frayed SEC, poor seal at top of electric meter box [Fig. 6]

- Opening in house wall at Electrical Service Entry Cable (SEC) lets water run into building by capillary action [Fig. 7]

- Wet basement wall at service panel creates conditions conducive to high interior moisture, condensation, and corrosion in the electrical panel [Fig-8]

- Uniform condensation in the electric panel caused by wet basement conditions, contrasted with actual water leaks into the panel. Condensation will wet most in-panel surfaces uniformly and cause a more-even rust distribution in the panel rather than causing very rusty spots at the panel bottom and along the drip pathway from the point of water entry. The overheating at one of the shared-neutral circuit wires here may be due to another problem in the building. [Fig-9]

- Water drips in panel - new equipment with the old leak remaining - old panel failed, was replaced, but leak source was not corrected, water entering inside the SEC plastic covering. [Fig-10]

- Corroded neutral bus in the electric service panel [Fig-11]

- Rusty electrical service panel, overheating equipment [Fig-12]

- Very rusty old electrical fuse panel, connectors ok - copper - some older equipment tolerated leaks better than more modern electric panels and circuit breakers [Fig-13]

- Sketch of common direct water entry points which admit water into the electrical equipment at a building [Fig-14]

- Overheated electrical branch circuit wires may or may not be due to failure of a corroded circuit breaker to trip on overcurrent [Fig-15]

- Water tracks behind main bus are visible below the bottom of the column of circuit breakers in this badly rusted electrical panel [Fig-16]

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2018-12-01 by (mod) - how to free up a corroded, stuck treminal screw in an electrical panel or circuit breaker

Sorry John, you're right, the article above is about the frequency of occurrence and causes of rust and corrosion in electrical panels, not how to remove corroded, stuck screws or bolts.

Sorry John, you're right, the article above is about the frequency of occurrence and causes of rust and corrosion in electrical panels, not how to remove corroded, stuck screws or bolts.

You might, however, have success by the combination of using a penetrating oil combined with a tool that gets an adequate grip on the screw in the existing breaker,

Watch out:

or smarter still, you should simply replace the corroded breaker as if it is corroded most likely it's also unsafe and unreliable.

On 2018-12-01 by John Watson

Nothing here helps. I am trying to replace a regular breaker with a gfi is a square d panle.

The problem is I have to connect the with wire to the breaker and I am unable to get the screw out of the hole it is that holds that white wire tight. I is so tight I cannot move it. What else can I do> I have soaked it in oil.

On 2016-11-29 - by (mod) -

T Hallock

You should not try to repair a corroded main breaker nor should you try to clean-up corrosion on the bus bars to which breakers or wires connect.

First there is a risk of death by electrocution from fooling around in the electrical panel

Next, you cannot disassemble, fix, and reassemble a circuit breaker that has been exposed to water, condensation, corrosion, and such a breaker is unsafe because it no longer can be expected to trip when and how it should, risking again, fire or shock or worse.

And similarly you cannot clean up a corroded bus bar in most electrical panels; you'll remove plating and increase the risk that the equipment fails in the future.

The right repair is to replace corroded parts or the whole panel

On 2016-11-29 by t hallock

I have corrosion buildup just below the main breaker what can I do to clean this up

On 2016-11-28 by Anonymous

So is there a short-term remedy for cleaning this corrosion until I can afford to replace the panel and Breakers

On 2016-04-06 - by (mod) -

Thomas,

Just cleaning up the contacts may not be a reliable repair if a suitable antioxidant was not used or if the connection was not torqued to factory specifications for your meter or disconnect panel.

If one of the two 120VAC wire connections was lost, you'd still have 120V on the other leg but not 240V as at most residential electrical service the 240V is achieved as a connection between the two individual 120V lines.

On 2016-04-06 by Thomas Eaves

Exterior Disconnect for Mobile Home. Digital meter reading showed 240 volt to the breaker and also on contacts after breaker.

However 60 feet of Aluminum wire later, input to House breaker only one leg of 120 volts measured. The second leg was 0 volts with digital meter.

Another indication was with main breaker inside of the house open the meter still showed minute movement or current flow. When Electrician was called he discovered corrosion on the tabs of the exterior disconnect breaker

Once this was cleaned up power was restored to the house. My question if 240 volts were measured at the output of breaker in the disconnect box, why could it not be measured at the input to the house panel? Shelton77x@gmail.com

On 2015-07-30 by linette leong

email linetteleong123@gmail.com need pro bono work father is 100 i am 64. 2 wood doors cover on exterior of building a disconnect switch without a cover and an indoor circuit breaker panel the wood doors have a horizontal air space above these items and circular holes around electrical meters?

with the indoor circuit breaker panel and disconnect letting in fog and rain. need better garage doors and locks cause someone comes in and does arson. father believes me more if you send me infor like internet information or written information with photos and words by engineering professors.

On 2015-07-30 - by (mod) -

Linette what you describe sounds unsafe to me. The risk is that corrosion will prevent a circuit breaker from tripping when it should. In turn that can result in a house fire or in someone being shocked or worse.

There is electrical equipment that is rated for outdoor use - and is weatherproof.

On 2015-07-29 by linette leong

father is 100 i am 64 on outdoor circuit breaker panel doors that have air spaces allowing fog and rain directed by wind to hit indoor circuit breaker panel outdoor circuit breaker panel and disconnect switch with no cover on it. email linetteleong123@gmail.com

father is 90 i am 64 indoor circuit breaker panels are on exterior of building . wood doors that cover circuit breaker panels has horizontal air space on top of doors and round circles in doors that allow fog and rain directed by wind onto circuit breaker panels

father is more convinced if you show visual photographs and written words as evidence for example the internet by professor engineers. gas clothes dryer and gas water heater and gas air force duct heater has not been clean for over a year how to get garage doors and good locks that people cannot go to inside to arson my father and mine living quarters send information to linetteleong123@gmail.com

...

Continue reading at CORROSION & MOISTURE SOURCES in PANELS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BACKWIRED RECEPTACLE FAILURE REPORT - corrosion of wiring and electrical connectors may be a factor in device failure, loss of power, flickering lights

- CORROSION in ELECTRICAL PANELS - Holm Conference Study

- CORROSION & MOISTURE SOURCES in PANELS - separate report, Hankey/Friedman

- ELECTRICAL PANEL MOISTURE / WATER SOURCES - Holm Conference Study Details

- ELECTRICAL PANEL RUST & CORROSION RESEARCH / BIBLIOGRAPHY - Holm Conference Study Research

- ELECTRICAL SERVICE DROP - mistakes can send water into the electrical panel

- FLOOD DAMAGE ASSESSMENT, SAFETY & CLEANUP

- GALVANIC SCALE & METAL CORROSION

- LIGHTNING DAMAGE to ELECTRICAL SYSTEM

- MOISTURE CONTROL in BUILDINGS

Suggested citation for this web page

CORROSION in ELECTRICAL PANELS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the causes & frequency of occurrence of dangerous leaks or moisture in electrical panels. .

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards. See Aluminum Wiring Bibliography and see FPE HAZARD ARTICLES, STUDIES for examples.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.