Causes of Rust & Corrosion in Electrical Panels

Causes of Rust & Corrosion in Electrical Panels

- POST a QUESTION or COMMENT about the causes & frequency of occurrence of dangerous leaks or moisture in electrical panels.

This page continues our report on the causes and effects of rust and corrosion in electrical panels, sources of water leaks into electrical panels

A Study and Report on Frequency and Causes of Rust & Corrosion inside of residential electrical panels begins

at CORROSION in ELECTRICAL PANELS. This report by Daniel Friedman was presented to the electrical engineering community at the IEEE Holm Conference on Electrical Contacts.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water or Moisture Sources Causing Rust and Corrosion in Electrical Panels

This page continues with details supporting

CORROSION in ELECTRICAL PANELS - Holm Conference Study.

Here we detail the specific sources of condensation, moisture, water in electrical panels and the panel contents or components, as observed and reported in that report.

Sources of Moisture, Leaks, Water in Electrical Panels

A significant advantage accrues from having a service panel inspected as part of a more comprehensive property inspection: home inspectors are concerned with the building envelope, with water entry, and with damage to building components from moisture.

In normally damp climates moisture is a major factor in building damage; identifying moisture sources and controlling moisture is important both in diagnosing failures and in protecting buildings from future failures. For each panel reported as a "problem" the inspector logged the apparent source of water entry.

(For each of the 126 services for which defects were reported, the apparent sources of water entry was recorded.) [Table 3 below]

Table 3. Apparent Entry Source(s) of Moisture - #Cases - Percent of Total |

||

| Service Entrance Cable Defects | 310 | 66% |

| Condensation | 83 | 17% |

| Surface/Roof Runoff Leakage | 79 | 17% |

Notes to Table 3

1. For a given panel in some instance more than one possible source was recorded

2. High interior moisture levels from any condition could cause condensation.

Naturally a major source of high interior moisture levels is the third item listed,

surface and roof runoff leakage into the building.

3. Percent of total possible sources observed (472)

The most common sources of water and moisture entry were: through service entrance conductor cables which were old and damaged, or which were improperly sealed at meter boxes or building sidewalls; from condensation from high interior moisture levels; and from other building leaks or surface water which passed down building walls where panel enclosures were mounted.

Service Entrance Cable (SEC) Leaks into Electric Panels

By far the most common source of water entry in service panels, 310 out of 472 possible sources observed, is associated with the passage of an above-ground service entry cable from outside, through the building wall, into panels which are located in basements or at a location lower than the point of penetration of the cable through the building wall.

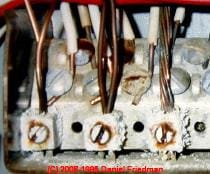

There was often strong visual evidence that water had entered service enclosure, including: water stains and drip marks on components directly below the center of the entry cable when it enters the service equipment; water stains, sometimes rust marks, down the exposed face of circuit breakers; water droplets present on connectors and other components at the time of inspection.

...

...

Water, often in large volumes from wind-driven rain, followed the entrance cable into the building on these paths:

- Frayed electrical service entry cable

and bad seal at meter box top when the SEC is located above and enters the electric meter box top, when mounted outside (exposed to weather). [See [Fig-6 above left ].]

Water entered the meter enclosure and traveled down the interior of the plastic-covered electrical service entrance cable into the building, often entering the service entry cable where that cable exited at the meter base.

Notice the frayed SEC which also admits water into the cable itself as wind-blown rain strikes it.

- Inadequately sealed electrical service entry cable connector:

While frayed fabric-type SEC covering lets wind-blown rain enter the cable, meter box, and electrical panel, plastic-covered SEC wires form a virtual "water pipe into the electric pane" conducting water from the electric meter box into the electrical panel, as shown in our photo just above.

This occurs when there is a leak into the electric meter box (frayed SEC cable or bad seal at top of the box where the cable enters), and where the electrical panel is mounted in the building at a level lower than that of the meter box. - Inadequately sealed opening where the cable passed through the

building wall.

A "drip loop" is not generally used at this location.

Water followed the outside surface of the cable into the building panel. Capillary action may be a factor [Photo below]. - Deteriorated, (worn, frayed fabric-covered) service entrance cables.

Water entered the cable from wind-driven rain and followed a natural capillary path into the service panel. - Missing or inadequate drip loop at the service entry mast head

can send water down the interior of the SEC cable or conduit, onwards into the electric meter base and in some arrangements onwards into the electrical panel itself.

Figure 7, water follows electrical service entry cable exterior into the building and into the electrical panel through an un-caulked opening in the building exterior wall.

Water Entry Pathway- into Electric Panels from the SEC

Water, often in large volumes from wind-driven rain, follows the entrance cable into the building on three failure paths:

- Failure to adequately seal the opening

where the cable passes through the building wall. [A "drip loop" is never seen at this location, probably for aesthetic reasons.] Water follows the outside surface of the cable into the building panel. Capillary action may be a factor. - Failure to adequately seal the connector at the top

of the electric meter, mounted outside. Water enters the meter enclosure and travels onward down the entrance cable into the building, often moving inside the service entry cable where that cable exits at the bottom of the meter base. - Failure to replace worn, frayed fabric-covered older service entrance

cables.

Water enters the cable from wind-driven rain and follows a natural capillary path into the service panel. - Improper or missing SEC drip loop

at the masthead, cited just above. - Rising water through buried or underground SEC conduit

(uncommon) that was not properly sealed and that collects water from an up-hill water source.

- Water stains and drip marks atop panel components, usually the main breaker, directly below the center of the entry cable when it enters the panel from the top.

- Water stains and drip marks on panel components and on panel base directly below the entry cable when it enters the panel from one side.

- Water stains, sometimes rust marks, down the exposed face of circuit breakers

- Visible droplets present on connectors and other components at the time of inspection.

Other Building Leaks that May Affect Electric Panels

A surprising number of occurrences of water entry appear to be due to other building leaks, 79 of 472. These sources include roof leaks (water passing from leaks into soffits through building walls and down basement wall - rare), and basement water entry associated with improper handling of roof runoff (leaky gutters) or surface drainage.

Water concentrated around a building from roof runoff or surface drainage often results in moisture seeping through the foundation wall.

It's an interesting coincidence that service panels are often mounted in the corner of a basement, just where water may be concentrated outside from a faulty downspout.

On a typical modern home with a single downspout at front and rear roof edges, chances are one in four that a service panel and a downspout will find themselves sharing a damp corner.

In such cases we've occasionally observed water entering the rear of the service panel at points of contact with the basement wall, even when the panel is actually affixed to plywood or nailer boards which themselves are fastened directly to the foundation.

However the principal path from roof/surface runoff to panel is probably interior condensation due to high moisture levels caused by general basement water entry, discussed next.

The most common mechanism by which moisture entered these panels was from roof/surface runoff, causing basement water entry and high indoor moisture levels which in turn lead to condensation.

This finding is discussed below. In a few other cases there were indications of water entering the rear of the service enclosure at points of contact with the basement wall, even when the enclosure was actually affixed to plywood or nailer boards which themselves were fastened directly to the foundation.

Indoor Condensation Effect on Electric Panels

When water, corrosion, or signs of a history of wetness in service equipment were found and when there were no obvious contact-paths for droplets to travel in to the panel from outside, condensation inside the panel was recorded as the apparent source. In 83 of 472 cases there were wet-basement conditions but the service panel was mounted well away from points of outside water entry through walls or cables.

When moisture is observed primarily at specific panel locations, such as below the entrance cable or on the panel base, and when most other panel components are not corroded, we suspect specific points of outside entry such as described earlier.

But in many inspections we observe water, corrosion, or signs of a history of wetness in panels where there are no obvious contact-paths for droplets to travel in to the panel from outside.

In these cases, when corrosion is fairly uniform over panel enclosure sides and top, and over other panel components, we suspect that moisture is occurring as condensation inside the panel. Often the inspector will find such indications.

This was so in 83 of 472 cases, when there were generally wet-basement conditions but when the service panel was fortunate to find itself mounted well away from points of outside water entry through walls or entry cables.

While not a part of this study, we have observed this pattern of rust and corrosion on panel components even in very dry climates (Tucson and Phoenix) where electrical equipment was installed against masonry walls in service closets accessed from outside the building.

From these observations we suspect that the combination of high interior moisture levels in many basements, combined with temperature changes, results in movement of moisture to the interior of service panels on a regular basis during humid weather.

Also see BACKDRAFTING & SEWER/SEPTIC ODORS for an explanation of how negative air pressure in buildings can cause unexpected air and moisture movement, condensation, and moisture-related problems such as rust, corrosion, or odors, or mold.

OTHER LEAKS - and Related Damage in Corroded Electrical Panels

Burned connectors:Among other common panel "defects," any burned connectors observed in service panels were recorded and tabulated. There were 23 such cases out of the 1052 panels observed, a 2% occurrence. In at least two of these 23 cases, the evidence of an actual fire in the panel was found.

Other Observations:The following incidents, observed one or more times during the 1052 inspections are reported:

- during rainy weather, water visibly dripping into the panel through the entry cable See [Fig-5] ; white streaks down both black hot leads were deposited by water running inside the service entry cable.]

- droplets clinging to interior panel breaker terminals and bus bars

- standing water completely filling the panel base when a steel lip is installed thereon

- moisture in small droplets, apparently condensation, soaking all panel components

- circuit breaker terminals so completely rusted and corroded as

to make removal of the terminal screw impossible

[See previous Figures [Fig-1] , [Fig-2] , [Fig-4]] - evidence of corrosion at aluminum entrance cables, regardless of use of anti-corrosive flux, sufficient to cause overheating of the cable and partial melting of its insulation

- in an unheated basement subject to freezing, a Bakelite fuse pullout which had been damaged by moisture, cracked, and disintegrated when the inspector attempted to pull the main fuses, leaving one fuse in place, one fuse half-removed<196>an exciting moment for the inspector

- burnout at connection between breaker, steel connecting screw, and aluminum bus-bar, resulting in loss of power in half the electric panel

- unintended "connections" between sheet metal screws, very commonly used to replace lost machine-thread panel cover screws, and electric wires in the panel, in two cases resulting in a fire in the service panel.

See more details about sources of moisture and corrosion in this separate article

CORROSION & MOISTURE SOURCES in PANELS

...

Continue reading at ELECTRICAL PANEL AGES VS FAILURE RATES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BACKWIRED RECEPTACLE FAILURE REPORT - corrosion of wiring and electrical connectors may be a factor in device failure, loss of power, flickering lights

- CORROSION in ELECTRICAL PANELS - Holm Conference Study

- CORROSION & MOISTURE SOURCES in PANELS - separate report, Hankey/Friedman

- ELECTRICAL PANEL MOISTURE / WATER SOURCES - Holm Conference Study Details

- ELECTRICAL PANEL RUST & CORROSION RESEARCH / BIBLIOGRAPHY - Holm Conference Study Research

- ELECTRICAL SERVICE DROP - mistakes can send water into the electrical panel

- FLOOD DAMAGE ASSESSMENT, SAFETY & CLEANUP

- GALVANIC SCALE & METAL CORROSION

- LIGHTNING DAMAGE to ELECTRICAL SYSTEM

- MOISTURE CONTROL in BUILDINGS

Suggested citation for this web page

ELECTRICAL PANEL MOISTURE / WATER SOURCES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the causes & frequency of occurrence of dangerous leaks or moisture in electrical panels. .

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- "Electrical System Inspection Basics," Richard C. Wolcott, ASHI 8th Annual Education Conference, Boston 1985.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "How to plan and install electric wiring for homes, farms, garages, shops," Montgomery Ward Co., 83-850.

- "Simplified Electrical Wiring," Sears, Roebuck and Co., 15705 (F5428) Rev. 4-77 1977 [Lots of sketches of older-type service panels.]

- "Home Wiring Inspection," Roswell W. Ard, Rodale's New Shelter, July/August, 1985 p. 35-40.

- "Evaluating Wiring in Older Minnesota Homes," Agricultural Extension Service, University of Minnesota, St. Paul, Minnesota 55108.

- Directory of Home Inspectors accessible via internet

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.