FPE Replacement Panels

FPE Replacement Panels

Cutler Hammer's Options Replace Federal Pacific Electric FPE Stab-Lok® Electric Panels

- POST a QUESTION or COMMENT about FPE replacement breakers or panels

FPE Replacement Guide:

this document describes how to replace Federal Pacific Stab-Lok® Electric Panels in buildings. We describe two methods for correcting this safety hazard in buildings.

Option 1 - replacement of the panel bus assembly or "load center" while leaving the original electrical panel enclosure or "box" and its attached wires intact, by using the Eaton Corp., Cutler Hammer Products "Adjustable Retrofit Kit" and

Option 2 - conventional removal and replacement of the entire electrical panel.

Replacement FPE Stab-Lok® circuit breakers are unlikely to reduce the failure risk of this equipment. We recommend that residential FPE Stab-Lok® electrical panels be replaced entirely or the entire panel bus assembly be replaced, regardless of FPE model number or FPE year of manufacture. We do not sell circuit breakers nor any other products.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Alternative Methods for Replacement of Federal Pacific Stab-Lok® (FPE) Electric Panels

Where the original panel enclosure is in good condition, Option 1 should cost less and be a faster job than Option 2 because less labor and less disruption is involved. We do not recommend mere replacement of FPE Stab-Lok® circuit breakers themselves, as

discussed

Where the original panel enclosure is in good condition, Option 1 should cost less and be a faster job than Option 2 because less labor and less disruption is involved. We do not recommend mere replacement of FPE Stab-Lok® circuit breakers themselves, as

discussed

This is information for building inspectors, home buyers, home owners, and electricians regarding steps to reduce the hazards associated with Federal Pacific Electric Stab-Lok® circuit breakers and service panels. Safety warning: as with any electrical installation or repair, these steps must be performed by a licensed and qualified electrician and must comply with appropriate building codes and regulations.

Good workmanship and an accurate assessment of the condition of the electrical panel enclosure which is to be re-used are important for FPE Electric Panel.

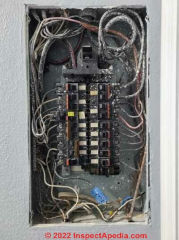

Illustration: a 200A FPE Stab-Lok electrical panel needing replacement, courtesy of an InspectApedia reader.

[Click to enlarge any image]

Watch out: Safety Notice: working with electrical equipment can involve fire, and fatal shock hazards. Electrical repairs must be performed by a qualified, licensed professional electrician. Good workmanship, following manufacturer's instructions, and local and other appropriate code compliance are also essential for a safe and successful outcome.

The first section of this document OPTION #1 RETROFIT KIT describes how to replace Federal Pacific Stab-Lok® Electric Panels in buildings using a retrofit kit provided by Eaton Corp., Cutler Hammer Products (E-CH): Option 1 - replacement of the panel bus assembly or "load center" while leaving the original electrical panel enclosure or "box" and its attached wires intact, by using the Eaton Corp., Cutler Hammer Products "Adjustable Retrofit Kit" and

In a second document section OPTION #2 REPLACEMENT we discuss Option 2 - conventional removal and replacement of the entire electrical panel.

In a third document section OPTION #1 vs OPTION #2 we express an opinion which compares these two methods.

Where the original panel enclosure is in good condition, Option 1 should cost less and be a faster job than Option 2 because less labor and less disruption is involved.

Watch out: We do not recommend mere replacement of FPE Stab-Lok® circuit breakers themselves, as discussed at the REPLACEMENT BREAKERS study cited above and again at the Recommended Articles list at the end of this page.

This is information for building inspectors, home buyers, home owners, and electricians regarding steps to reduce the hazards associated with Federal Pacific Electric Stab-Lok® circuit breakers and service panels.

Watch Out: as with any electrical installation or repair, these steps must be performed by a licensed and qualified electrician and must comply with appropriate building codes and regulations. Good workmanship and an accurate assessment of the condition of the electrical panel enclosure which is to be re-used are important for FPE Electric Panel

OPTION #1 Retrofit Kit- Federal Pacific Electric Panel Replacement Using the Eaton Corp., Cutler Hammer Products Adjustable Retrofit Kit

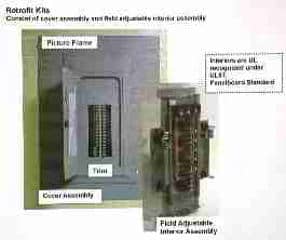

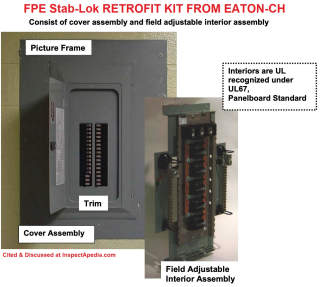

Adjustable Retrofit Kits produced by Eaton Corp., Cutler Hammer Products (E-CH) are a patented design new electric panel interior designed to replace aging electrical panels in residential and light commercial applications. The unique features are that the existing box and wiring can be re-used for convenience, if still in good working condition. Also, a custom trim to fit the existing box is available.

Adjustable Retrofit Kits produced by Eaton Corp., Cutler Hammer Products (E-CH) are a patented design new electric panel interior designed to replace aging electrical panels in residential and light commercial applications. The unique features are that the existing box and wiring can be re-used for convenience, if still in good working condition. Also, a custom trim to fit the existing box is available.

Using the retrofit kit involves disconnecting the electrical circuits from the existing load center "bus assembly"circuit breakers.

The old bus assembly and other internal parts (neutral bus, ground bus, etc) in the existing panel are removed. The panel box or "enclosure" itself is left in place, and the electric circuit wires which entered that box are left undisturbed.

After inspection by the installer to confirm the soundness of the panel box, any openings in the box body are closed, a new load center (panel bus and circuit breaker set, ground and neutral bus bars) is mounted in the existing electric panel box, and the existing circuits are connected to the new circuit breakers.

The "field adjustable electric panel interior assembly" consists of an adjustable riser, the required interior bus assembly, and the appropriate neutral assembly and ground bar assembly. Additional kit components permit a new panel face to correctly fit the new bus assembly which has now been mounted in the old panel box.

On completion, all of the electrical parts inside the original electric panel have been replaced.

Only the steel panel enclosure or "box" has been retained.

The new parts and installation are made using UR and UL approved components. Wiring to comply with the electrical code, workmanship, and final code approval are the responsibility of the installing electrician, assured by an inspection by the local electrical inspector.

Not all Electrical Panels can be Upgraded using the Retrofit Kit

Field reports and comments from the manufacturer have pointed out that not every elecrical panel is a candidate for upgrading using the retrofit kit discussed here. If the original electrical panel enclosure is itself too small to meet the size and space requirements of current electrical codes the entire panel will need to be replaced.

The following text provides an example of a case where, unfortunately, the old electrical panel was just too small to upgrade:

From email between a reader and the product manufacturer

While researching the service panel in a home I purchased this summer, I came across your retrofit kit for FPE service panels at https://InspectAPedia.com/fpe/FPE_Panel_Replacements.php

I have a Stab-Lock C1410-14-125NI panel, 125amp, 120/240, 1 phase 3 wire. It currently has one 30a (dryer), one 40a (range) and one 50a (all other

circuits) controlling 6 15a and 4 20a. I would like to upgrade to 150amp with a few more breaker spaces, if possible.

The FPE Stab-Lok® electrical box measures 4 inches deep, 10 inches wide, 22-3/4 inches high inside measurements. The load center w/breakeres is approximately 6-1/2inches wide by 15 inches high.

The range wire is aluminum. I'm not sure if the incoming service wires are aluminum as well. The home was built in 1960. The existing panel is in excellent condition, no rust, all holes intact or in use. The existing wiring is in excellent shape.

One local electrician told me that your product [the Cutler Hammer Replacement Panel Bus Assembly] violates code.

Here is a clear and concise reply from the manufacturer:

Our retrofit kits are designed to be installed into enclosures where there is sufficient space to wire according to the National Electric Code. As the local electrician pointed out, the enclosure that you have is not large enough to allow for our kits to work. Being from 1960, the existing electrical panel was constructed prior to two NEC revisions that expanded the necessary wire bending space requirements. In addition, to increase the ampacity of the panel would require slightly more space. Unfortunately, for the application described, a new service will need to be installed.

Key Features of the E-CH Adjustable Retrofit Kit for FPE Stab-Lok® Panels

Key in making this retrofit approach possible in the replacement of FPE or other problematic electrical panels is E-CH's development of:

- Load Centers: a series of replacement load centers of varying capacity in amperage and number of circuit breakers, and varying also in overall dimensions

- The Adjustable Retrofit Kit: which offers a set of parts which permit the new load center, mounted in the old electric panel enclosure, to be framed-in or enclosed properly regardless of the dimensions of the enclosure itself. The electrician simply measures the existing enclosure and orders the appropriate load center and adapter kit parts. The Adjustable Retrofit Kit parts may include:

- A "picture frame" which adapts the existing enclosure to allow a new "trim/cover" assembly to be mounted as seen in the figure on page 2 of the E-CH product PDF file available here (450KB to download). The "picture frame" is .073 powder coat painted galvanized steel which not only adapts the trim to the existing enclosure, it extends past the enclosure edge several inches to provide a professional looking finish when the old plaster or drywall is damaged.

- An adjustable "riser" combined with the adjustment feature in the deadfront solves the depth issues and helps greatly when the old enclosure was not installed plumb/square.

- The "trim/cover assembly" is the standard replacement loadcenter/panelboard trims that offered by CH as replacement items and as such carry the standard UL cabinet front label.

One of the biggest hurdles the manufacturer faced was the panel enclosure depth issue. To solve this, CH offers the adjustable depth feature. This allows the "riser" to be adjusted to accommodate enclosures from 4" to 6" in depth. When this is combined with the "picture frame" and "trim" the final product is a very safe, solid, and professional looking final assembly.

To date (June 2014) CH engineers have not had any reports of any brand or model specific enclosure that these have not worked in. Due to the adjustability of the CH kit, it is unlikely there would be an electric panel model that these kits wouldn't fit.

Very shallow panel enclosures:

Eaton Corp., Cutler Hammer Products have just finished the design & patent work on phase 2 of this program. This will consist of an adjustable "extension collar" which will attach to the enclosure and extend it out from the wall for those installations that are very shallow.

This will extend them out and then the standard "Retrofit Kit" can be used. This will accommodate enclosures clear down to 3" or less in depth.

Cost of Replacing an FPE Panel using the E-CH Adjustable Retrofit Kit

Cutler Hammer was unable to inform me of "typical" retrofit installation costs using their product. Electrical panel replacement costs are hard to cite as there really isn't a typical application for this product - it is used in a wider variety of circumstances than just replacement of FPE Stab-Lok® electrical panels. These vary from the smallest single phase, main lug, 125amp units to the largest three phase, main breaker, 42-circuit. 225-AMP kits. (Probably the manufacturer did not want to appear to set the retail prices charged by the electricians who buy their product.)

In addition, custom size adapter collars can add to the costs as well. Materials costs typically run from $225 to $500 per kit plus installation cost. From the feedback CH has received from the field, when you figure in labor, the installed kit is less than half the cost of Option #2 - complete removal and replacement of the electrical panel.

That is exactly in line with my own (DJF's) guess based on the labor and building disruption savings. If there is much cosmetic work with the Remove-and-Replace process, the savings are even greater.

Quotes from electrical contractors on FPE electrical panel replacement using the retrofit kit or using a complete new replacement electrical panel can be expected to vary by area of the country, hardware needed, replacement panel size in ampacity and number of circuits, accessibility to perform the work, and other factors that affect labor or materials.

That said, we've heard FPE panel replacement costs using the Cutler Hammer retrofit panel ranging from about $900. all the way up to $4000. If you are surprised by the quotation you receive from your electrician, ask for a bid from a competitor and compare labor, materials, and other costs.

"REPLACEMENT COST Typical cost of the traditional FPE Electrical Panel Replacement" discusses the costs of FPE panel replacement using a completely new electrical panel assembly.

E-CH Adjustable Retrofit Kit Installation Tips to replace a Federal Pacific Electrical Panel

See the E-CH PDF file given again at the end of this page. That document gives details of how this replacement program works. Obtain and follow the installation instructions that come with the equipment.

See the E-CH PDF file given again at the end of this page. That document gives details of how this replacement program works. Obtain and follow the installation instructions that come with the equipment.

Here are some additional comments:

Distinctive about this approach is that it is not necessary to cut the existing building wall for wire access, and not necessary to disconnect the existing circuits from the original metal panel enclosure "box". Avoiding these steps significantly reduces the labor and installation time.

The Adjustable Retrofit Kit installation procedure is roughly this:

- Select the proper sized load-center that will fit in the existing panel enclosure - measure the existing panel interior dimensions, including depth carefully.

- If necessary, purchase additional panel enclosure parts such as a frame extension (if the panel Enclosure is too shallow) and a new panel cover front and door may be needed.

- Disconnect the existing load center (power has been cut off of course).

If I were doing it I'd Unscrew each circuit so as to have plenty of length to work with, but most will probably just Cut individual circuit wires close to the old breaker. - Remove the old load center from the electrical panel

- Cover with metal any improper openings such as knockouts (to assure that the existing enclosure is properly fire resistant

- Mount the new load center

- Connect the existing circuits to breakers in the new load center

- Mount any panel enclosure box extensions (the "picture frame") and electric panel cover

- Assure the Existing Panel Enclosure is Sound: before ordering the CH Replacement Load Center and Electrical Panel Enclosure Adapter parts, the electrical contractor should take a careful, honest, look at the existing enclosure.

If it is not structurally sound don't use the retrofit kit. Some of those older enclosures are 50+ years old, rusted, bent up etc. In that case pull it out and start over.

These kits are designed and intended to be used in good, safe, sound enclosures. [See More Reading below.] - Cover Openings in the existing panel enclosure (which is to be re-used). Any existing unused holes should be covered.

On the smaller holes, this can usually be accomplished by inserting a pan head sheet metal screw of appropriate size to cover the hole. Any unused open knockouts in an enclosure should always be appropriately plugged whether it's a retrofit, repair, new installation etc. - Measure carefully: before ordering the particular retrofit enclosure parts, including the depth of the existing panel enclosure, so that the correct retrofit can be supplied.

- Existing studs or other protrusions: if in the (to be re-used) panel enclosure there are existing studs in the old enclosure that are in the way these will have to be cut off and removed.

- Flush Mount vs. Surface Mount: These are intended as a "flush mount" application. While they could be used as a "surface mount" the "picture frame" which acts as the adapter collar will extend past the edges of the existing enclosure and may not give a "finished" appearance. This may or may not be of consequence to the owner.

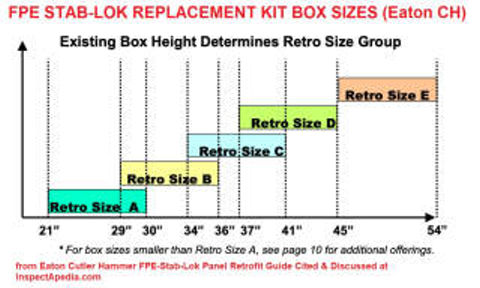

Select the Proper Retrofit Kit Components when Replacing an FPE Stab-Lok® Electrical Panel

By following the CUTLER HAMMER RETROFIT SIZE GRID [PDF] on page 5 of this (450KB) PDF, in combination with the selection charts on the following pages, it can be determined just what exactly can be installed in which size enclosure and meet NEC requirements, wire bend etc.

The charts in the PDF (450KB) detail the most common devices asked for and explain the bus amperage rating, number of circuits, and wire size restrictions for minimum enclosure sizes. However since we can not possibly foresee all of the combinations, we have included our 800# to help explain or offer guidance when needed for those who are not sure or have questions or concerns.

The one thing stress by CH is that these are guidelines to meet the minimum requirements per National Electrical Code. Eaton Corp., Cutler Hammer Products cannot assume responsibility for these units when they are not sized or installed correctly.

All final decisions are the responsibility of the AHJ. To date, with 2 years experience, we have had no issues with any AHJ when these are properly installed.

Sources for Adjustable Retrofit Kit for Federal Pacific Electric FPE Stab-Lok® Panels

Eaton Corp., Cutler Hammer Products Adjustable Retrofit Kits, E-CH Load Centers and load center parts can be purchased through any E-CH distributor.

If your electrician reports that local electrical suppliers are having difficulty finding or specifying kits any of the CH sales force can help. If that effort is not satisfactory contact CH directly at 800-330-6479

or by EMAIL to

FlexCenterLincoln@eaton.com.

Other electrical panels: if you are not taking the retrofit kit route (see OPTION #1 vs OPTION #2) then a wide range of electrical panels are available from electrical suppliers and building supply sources.

Code and Legal Acceptance of the Replacement Load Center and CH Adjustable Retrofit Kit when Replacing an FPE Stab-Lok® Electrical Box

I have corresponded with the lead design engineer for Eaton Corp., Cutler Hammer Products, the company that produces these Replacement load centers. He said that all interiors, neutrals & grounds are their standard UR listed OEM interior components and carry a UR label.

- UL-Listed The products are all UL Listed. The individual internal components are UR listed and the trim/cover is UL listed as a cabinet front.

- Code authority accepted: CH have had no code authority refusals

- Field installations: CH has sold these products in large numbers, sometimes in the thousands to public housing authorities.

Local code approval: Readers should review the CH product specifications and listing information with their electrician and with local code enforcement officials. As with any electrical work, independent inspection and approval of the work is recommended and is required in many jurisdictions.

As CH informed me: As we have no control over how /where these are installed, we don't have a "file" we can list these under. Individual OEMs that use many of these on a repeat basis actually get a UL listing on their own device. This is where CH relies on the local inspectors or AHJ to make sure that electricians are installing these products in a safe, and professional manner.

Eaton Corp., Cutler Hammer Products' Adjustable Electric Panel Retrofit Kit Development Background

The E-CH electric panel adjustable retrofit program was begun in response to an overwhelming number of contractors who were buying complete loadcenters (metal enclosure, bus assembly, breakers, neutral and ground bars, etc), removing the interior components, neutrals etc and trying to "cobble" something together with "whatever" cover/trim in order to retrofit a new bus assembly into an existing, already mounted electrical panel.

The manufacturer reports that often they saw electric panel interiors shimmed with an unbelievable assortment of items, covers that were questionably attached and in general a "less than professional" final job.

Early on it was discovered that there is a tremendous assortment of old electrical enclosures in the field. These old enclosures vary greatly in size (width, length & depth) and in how they were originally installed.

In response to those problems E-CH patented the "Adjustable Retrofit Kit".

OPTION #2 Complete Replacement of the Federal Pacific Electric Panel - Option #2 Conventional R & R Method

Traditional Electric Panel Replacement by Complete Removal of Old Equipment

The traditional and conventional method of replacement of an obsolete (or in this case unsafe) electrical panel has been to completely remove the complete original electrical panel by disconnecting all wires from their individual circuit breakers, disconnect every strain relief, pull the wires out of the panel enclosure, and then to remove the entire electrical panel, enclosure and all.

The new electrical panel is then mounted in place and all of the existing wires are routed back into the new panel, strain reliefs secured, and wires routed to breakers in the new panel. (See "Short wire problem" below).

If the panel being replaced has been mounted on a finished wall (such as behind drywall or paneling) additional labor and disruption are necessary to provide access for wiring and panel mounting.

Electrical Panel REPLACEMENT COST Typical cost of the traditional FPE Electrical Panel Replacement

A number of factors affect the actual cost of replacing an electrical panel, including base labor cost variations in different geographic areas, costs of electrical permits, and the specifics of a particular installation: working space, wire lengths, condition of old wiring, and other factors.

In order to more easily add electrical cost updates in one place, our section on typical costs to replace an electrical panel have been moved to a separate web page. Please

see ELECTRICAL PANEL REPLACEMENT COSTS

Links on that page will easily permit you to continue reading this article.

OPTION #1 vs OPTION #2 - Comparing Federal Pacific Electric Panel Replacement by Use of the CH Adjustable Retrofit Kit vs. FPE Complete Panel and Enclosure Replacement

WHEN TO USE OPTION#2 - When replacing an FPE Electric Panel When Should the Entire Panel and Enclosure be Replaced?

Using the Retrofit Kit is not appropriate, and complete electrical panel removal and replacement, including the panel enclosure or "box" is going to be necessary when:

- The existing panel enclosure is not structurally sound, such as if it has become badly rusted.

- The building needs a larger ampacity service, say moving from 100A to 200A at a building, and the building needs more electrical distribution circuits than what are presently installed.

In this case it is likely that even if a new bus assembly that could handle the higher ampacity of a new service it will not handle the needed number of circuit breakers.

The installer may consider a retrofit anyway, using a circuit in the retrofit panel to feed a new subpanel which is located elsewhere in the building and which provides additional circuits.

That approach may suit where the added circuits and ampacity are in support of a building addition such as a new wing or level. - The area where the panel is located is being gutted and re-modeled in concert with installing a new larger panel, service, ampacity, and number of circuits.

- The electric panel is not built into a finished wall (for example exposed in a basement or garage), so that all of the panel's exterior is readily accessible, and the panel capacity is not being upgraded. In this case I'd do a cost comparison of all of the retrofit equipment needed vs. the whole new box approach. CH believes that even in this case the retrofit approach might be less costly.

- The electrical panel needs to be relocated for other reasons.

Comparing the Two Electric Panel Options: #1-Adjustable Retrofit Kit or #2-Complete R&R Replacement of Everything

[OPINION offered by the web author]

- Cost: Option #2, Federal Pacific Electric Panel removal and replacement with a new Brand-x electrical panel is likely to cost twice as much as Option #1 with the CH Replacement Load Center and Electrical Panel Enclosure Adapter.

- Time: Option #2 can be expected to require at least twice the labor of Option #1.

- Disruption: When the original Federal Pacific Panel is installed in a finished wall, Option #2 requires partial demolition for working space that should not be necessary for Option #1

- Availability: Option #2 permits choice of any manufacturer's electrical equipment; Option #1 is available only from Eaton Corp., Cutler Hammer Products. This is a widely distributed brand but may not be stocked at the same levels as products by other manufacturers.

Additional delay may be encountered if your electrician's electrical supply house has to order the CH Panel Enclosure Adapter parts. I will report here what readers encounter - feedback is invited. - Suitability: Option #2 is required when the original panel enclosure is damaged or for other reasons I listed earlier. Option #1 is not suitable in those cases.

Where Option #1 is suitable it strikes me as appealing for reasons of cost and trouble.

When performing a conventional electrical panel replacement, in order to have adequate wire length to connect things in the new electrical panel the electrician would have to not only disconnect or clip wires at each breaker, s/he would also have to unscrew every strain relief and pull each individual wire out of the existing panel enclosure - a crowded and tedious operation that has to be done with great care so as not to damage the insulating jacket on the existing wires.

This has to take considerably more time than just replacing the load center in the existing panel enclosure where all of the wires entering the original box can be left in place.

There is no cosmetic damage to the wall where the existing panel is mounted when using Option #1.

By comparison, with an conventional electrical panel replacement if the panel is in a finished area, the electrician has to cut away the finished wall surface to have access to the individual wire strain reliefs entering the panel box in order to disconnect them, and also in order to have working room to get the new wires into the new electrical panel enclosure.

Further, it is unlikely that a new panel enclosure will have the same dimensions or "footprint" as the old, possibly meaning additional adjustments at the finish wall.

Many people have contacted me to ask advice about FPE electric panel replacement options. More than I am able to answer by telephone or even email. Both for individual home owners and especially for larger buildings or building complexes where there are many, sometimes hundreds of FPE Stab-Lok® electric panels installed, the cost of a complete gut-out replacement of the panel is a significant burden.

If this sounds as if I'm writing a commercial, that's not my intention, and I have no connection with the manufacturer of this product nor any financial interest in it nor in any other products discussed at this website.

I am afraid that the cost of complete electrical panel replacement has been a factor in moving some owners to try to just "replace the FPE circuit breakers themselves" with the mistaken notion that somehow this reduces their risk of a fire. Unfortunately it does not appear to do so. I have found no data suggesting that replacement FPE breakers perform any better than their predecessors in the U.S. and probably not in Canada.

Even if a new perfectly reliable circuit breaker were built to fit these panels, underlying problems with the FPE bus design, breaker to bus connections, and bus overheating and failures would remain. This is why I continue to recommend a complete panel replacement for these problem brands.

I also have received reports of reluctance to report the hazards with this equipment, either because of the conflicting interests surrounding pre purchase home inspections or in one instance a correspondent was afraid of losing his/her job by reporting a costly problem at a multi-building complex where many problem panels were installed.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-06-22 by InspectApedia-911 (mod) - Check with Eaton CH about a 200A FPE Panel Replacement Kit

@Electrician not an FPE Expert,

@Electrician not an FPE Expert,

Oh sorry - now I understand.

You're replacing a 200A FPE panel. FPE L120-40 that uses FPE Stab-Lok NA NC or NAGF circuit breakers. That's a 120/240VAC 1-phase 3-wire 200A (Maximum) panel that could support 40 circuit breakers.

FPE is an unsafe electrical panel: breakers, especially the 2-pole units, fail to trip as much as 60% of the time while in the industry the no-trip rate is more like 0.01%

See

to read up on it

So it's indeed smart to replace the FPE Stab-Lok panel.

But no you can't buy from us.

We do not sell anything. No products, no services.

At page bottom Recommended Articles you'll find a link to the FPE REPLACEMENT KIT ordering instructions from Eaton CH

Take a look at that, then you can call the Lincoln Flex Center at 800-330-6479

- Eaton Corp., Cutler Hammer Products Adjustable Retrofit Kits, E-CH Load Centers and load center parts can be purchased through any E-CH distributor.Cutler Hammer Contact Points: Telephone: 800-330-6479

EMAIL: FlexCenterLincoln@eaton.com.

OR

check with their retail vendors like

- US Electric https://store.usesi.com/eaton-rtbr12l100p-mp-retrofit-interior-kit-used-on-br-type-loadcenter-and-circuit-breaker - this is a 100A panel but they may have 200A units too

Though I'm not enchanted: you have to sign-up and open an account just to ask them a damned question!

Continuing: here's why you can't buy an Eaton CH replacement FPE panel or bus from us: we don't sell anything.

InspectAPedia.com provides building and environmental diagnostic and repair information.

In order to absolutely assure our readers that we write and report without bias we do not sell any products nor do we have any business or financial relationships that could create such conflicts of interest.

On 2022-06-22 by Electrician not an FPE Expert needs a replacement for a 200A FPE Panel

@InspectApedia-911,

I see that, I don’t know anything about the stablok panels but he sent me some pics that I attached. Is city electric setup to buy from you? or can he deal direct with you?

On 2022-06-22 by InspectApedia-911 (mod)

@Electrician not an FPE Expert,

Check out the Eaton Cutler Hamemr options at

FPE REPLACEMENT PANEL

https://inspectapedia.com/fpe/FPE_Panel_Replacements.php

but consider that for an old panel vs modern level of electricity usage the client might be better off with a service upgrade to higher amps or at least a physically bigger panel that can permit more circuits

On 2022-06-22 by Electrician not an FPE Expert

Need info about buying a retro kit to replace stablok panel

On 2020-09-02 - by (mod) - Local Cutler Hammer Dealer never heard of FPE Replacement Kits

Jim

It's no surprise that a local distributor would be unfamiliar with a product which is probably sold and rather low volume. This case your best bet is to contact Eaton Cutler-Hammer directly.

On 2020-09-01 by Jim McCaddin

Question: I need to replace the interior of my FPE model L120-40 panel with a CH adjustable retrofit kit, for a variety of reasons. The Cutler Hammer distributed in my area has no idea what I'm talking about.

never heard of them! Could you p!ease guide me to a dealer near me who knows if these kits and can help me. If you could forward some literature on them to me, it would be extremely helpful

Thank you,

Jim McCaddin

27 Emerson Rd.

Durham, NH. 03824

Email: monkus27@yahoo.com

On 2020-05-28 - by (mod) - Typically a used CH 60A pullout fuse panel alone costs about $40

Typically a used CH 60A pullout alone costs about $40. USD and is more costly than a completely new fuse box with a new fuse pullout, plus fuses.

On 2020-05-28 - by (mod) - Typically a used CH 60A pullout alone costs about $40

Ali

I found quite a few sources for replacements for Cutler Hammer 60A fuse pullouts, such as on eBay and at https://www.bonanza.com/ as shown below - and also at electrical suppliers. But those were all used devices.

Typically a used CH 60A pullout alone costs about $40. USD and is the same cost as a completely new fuse box with a new fuse pullout, plus fuses.

On 2020-05-28 by Ali

Cutler hammer 60,a 2 fuse pullout. Please help. Where can I find

On 2020-02-03 - by (mod) -

Check with Eaton Cutler Hammer - contact information is given above. ,

On 2020-02-02 by loven

i have a federal pacific electrical panel catalog number 108-06-2, main 100 amp, max 16 breakers, 120/240 3 wire 3.6 deep 10.5 wide, 13 3/4 breaker height panel total height 22.14 ,, what retro kit would i need to replace my stab locks,

On 2019-10-02 - by (mod) -

Yes Frank, ALL of those circuit breaker panels - as long as its breakers, not fuses - sport the same problematic design and manufacturing hazards.

Federal Electric is one of the older brands and models of those electrical panels. It'd be useful if you'd let us know the country and city and age of the church where this Federal Electric panel is installed; you're also welcome to post a photo of the unit.

On 2019-10-01 by Frank

We have an old Federal box in our church, it does not say Federal Pacific, it just says Federal electric. Is this different, or should it be replaced for the smae reason as federal Pacific?

On 2017-10-10 - by (mod) - replacement panel sources for just an electrical panel cover

Above we include replacement panel sources such as from Eaton Cutler Hammer, but for just a cover you may have to find a used part. FPE panels should be replaced, not just a missing cover.

Watch out: for OTHER READERS: if your elecrical panel is an FPE Stab-Lok circuit breaker panel, you shouldl not replace the cover, you should replace the whole panel assembly.

On 2017-10-10 by Rowchelle

How to find panel cover for free 400amp service

On 2017-09-13 by Richard

Need to find 4 hinge clips for 100 amp Sylvania box with horizontal bus. Will pay salvage value of 2 old boxes. Look in your bone yard. Keep the boxes and ship me hinge clips.

Question: need a inside cover to a cutler hammer loadcenter br2030b150r

(Oct 12, 2011) tommy said:

need a inside cover to a cutler hammer loadcenter br2030b150r

Reply:

mmy, Contact Cutler Hammer at Eaton Corp who distributes their products:

See PRODUCT SOURCES above in this article or if you cannot find a local CH distributor contact the company as follows:

Telephone: 800-330-6479 EMAIL Cutler Hammer Eaton COrp at FlexCenterLincoln - AT - eaton - DOT - com

Question:

(Jan 2, 2013) Mel said:

After installing a kit, the assembly is not U.L. listed. Correct ... and if not listed, cannot be used in areas regulated by regulatory code inforcement?

Reply:

[pending comment]

Question: replacement for the locking mechanism on a Stab-Lok panel

(Jan 16, 2013) Vanessa said:

Do you or anyone you know sell or replace the locking mechanism of a stab lok panel? It is for one of the units in a condomium of 300+ units. We are searching everywhere regarding this and will buy a few.

The panels are from the 1980s and again how can I find the locking mechanism itself or do I have to replace the whole cover panel?

Question: why not just install replacement FPE circuit breakers?

Anonymous: what about keeping the old FPE Stab-Lok panel and installing replacement circuit breakers.

Reply: that's not a recommended option - see this test data

Just replacing the breakers, even if the replacement breakers performed well (which apparently they do not) would not correct other design and safety defects in these electrical panels.

Please see FPE REPLACEMENT BREAKERS

Information Source Citations & Feedback Request

Information Source Notice: portions of the text of this document are from email exchanged between the web author and the Eaton Corp., Cutler Hammer Products Lead Design Engineer and Eaton Product Manager involved with the products discussed in this document.

The illustration at page top is from the Eaton Electrical PDF which describes their product line. The author has no financial nor any other connection with Eaton Corp., Cutler Hammer Products, nor any other company whose products are discussed at this website. Corrections of errors or omissions, product user feedback, or other critique are invited.

Our editorial policies are at ACCURACY & BIAS PLEDGE

We would welcome some photos and description of field experience from installing electricians and from consumers.

CONTACT Us to report field experience with this equipment.

...

Continue reading at FPE REPLACEMENT PANEL COSTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CAN'T AFFORD A NEW ELECTRIC PANEL?

- Eaton Corp., CUTLER HAMMER PRODUCTS ADJUSTABLE RETROFIT KIT [PDF] ordering Instructions

- FEDERAL PACIFIC FPE HAZARDS - home

- FPE HAZARD SUMMARY - full detail of this FPE topic.

- FPE REPLACEMENT BREAKERS - studies of the failure rate of after-market UBI-brand replacement circuit breakers for FPE Stab-Lok Panels

- FPE REPLACEMENT PANEL COSTS

- RUST & CORROSION in ELECTRICAL PANELS A Study and Report on Frequency and Cause for Electrical and Home Inspectors at Residential Electric Panels

Suggested citation for this web page

FPE REPLACEMENT PANEL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to FPE STAB-LOK BREAKERS & PANELS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Lance Caddell, Master Electrician, Caddell Electric, LLC. for comments and corrections 2/16/08

- Eaton Corp., Cutler Hammer Products Adjustable Retrofit Kits, E-CH Load Centers and load center parts can be purchased through any E-CH distributor.Cutler Hammer Contact Points: Telephone: 800-330-6479 EMAIL: FlexCenterLincoln@eaton.com.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.