BX Greenfield Armored Cable Wiring

BX Greenfield Armored Cable Wiring

AC, BX & MC Electrical Cable / Wiring methods, stripping, bushings, grounding, tools

- POST a QUESTION or COMMENT about flexible metal cable BX wiring methods, history, inspection

How to identify & wire or use BX, flexible armored cable electrical wire.

This article discusses the history of BX electrical cable, its uses, wiring methods, and inspection.

In this article series, we list common old building electrical wiring system safety concerns and we illustrate types of old electrical wires and devices. This article series answers basic questions about assessing and repairing the electrical service, capacity, wiring type, condition, and safety in older homes.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Armored Cable Electrical Wiring "BX" & "Greenfield" - Metallic Sheathed Electrical Wire

The photo above illustrates two generations of metallic-sheathed armored cable or "BX" electrical wire. The vertical armored cable is an earlier generation of BX while the two flexible metal cables coming off the left side of the electrical box are its modern counterpart.

As the terms are generally used, synonyms for "BX" electrical wire include BX cable, armored cable, armor clad cable, and flexible metal conduit cable wire.

The larger diameter wider-wrapped armored cable is probably Greenfield flexible steel armored cable, a wiring type patented in 1898.

The flexible metal exterior of BX flexible armored cable provides considerable protection of the electrical conductors inside, guarding them from mechanical damage.

Article Contents

- BX WIRE HISTORY

- BX CABLE & WIRE STRIPPING METHODS - how to cut & strip BX cable using a hacksaw

- BX CABLE CUTTING TOOL USE - using a special BX Armored Cable cutting tool

- BX CABLE BUSHING REQUIREMENT - Fiber Bushing or Red Hat Plastic Bushing Details

- BX CABLE CONNECTORS - & bushings at electrical panels & boxes

- BX CABLE BENDING RADIUS LIMITATIONS - when routing wiring

- BX vs MC CABLE GROUNDING CONDUCTOR - differences between AC vs MC cable

- BX & MC CABLE WIRING CODE

- BX GREENFIELD CABLE HISTORY, PATENTS, RESEARCH

Origin & History of "BX" Wiring / Cable

Where does "BX" come from? Dini (2006) explains that this cable was produced by Greenfield, one of its inventors, in two experimental forms AX and BX (X = experimental). The second version "B" was the more successful version that was produced.

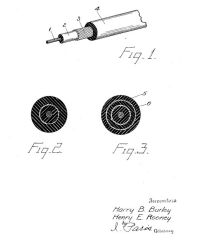

The illustration above is excerpted from Greenfield's 1898 patent for Armored Electric Cable.

The term "BX" stuck on later versions of flexible metal armored cable: the smaller-diameter modern "BX" wire is in the left of the photo and connects to the left side of the electrical box.

BX wire appeared in the U.S. National Electrical Code in 1903, was popular and in wide use as early as the 1920s (earlier in some locations), very widely used in the 1950s, and remains in use today in new work where flexible armored cable is required, often by local codes.

Just above and also below: flexible aluminum BX or armored cable, stamped with AL, found in a 1955 Montreal home, courtesy of InspectApedia reader PE.

This aluminum sheathed BX cable contains a hot (black) and neutral (white) fabric and rubber insulated conductor, a fire-and moisture-resistant paper wrapping, and a thin flat aluminum strip.

Modern BX or flexible metal conduit (FMC) electrical wire provides conductors that will be plastic-insulated rather than the older rubber.

[Click to enlarge any image]

Watch out: Notice that the wire in the photo above does not include an approved grounding conductor.

Below at BX CABLE GROUNDING CONDUCTOR we discuss proper grounding when using BX cable.

Defects often found in the flexible conduit are discussed separately

Greenfield's original armored cable design used multiple strands of copper conductors, typically twisted, and surrounded by a pitch-like insulating material like that we illustrate in Edison's original underground electrical cables shown

at STEAM BOILERS GENERATORS CONTROLS, PRATT.

Greenfield Cable Patented Flexible Conduit

Here are the original image and a text excerpt from Edwin T. Greenfield's 1898 patent:

My invention is directed particularly to improvements in electric cables designed for ocean service, and has for its objects,

first, to devise an armored cable of such nature that the insulation of the cable will be thoroughly protected from the attacks of borers or other insects or animals which usually attack cables of this nature when sunk in the body of the ocean

second, to devise an armored cable of such a nature that its exterior armor will fully protect it (the cable) from unnatural wear when it is suspended over ledges of rock in the body of the ocean;

third, to provide a cable of the nature indicated in which the armor is of steel, phosphor-bronze, or any preferred metal having the desired strength and qualities for adapting it for use in the ocean and in making such armor of a flexible nature, so that the completed cable may be wound upon a drum in the usual way when it is desired to lay it in the bed of the ocean, and,

fourth, to provide a lead or equivalent covered cable with a flexible protecting armor which will protect the lead covering from the action of metal slivers when drawn into a conduit.

Also see a brother wiring material sold without conductors in this article:

1960 CIRCLE WIRE & CABLE Advertisement [PDF] in Electrical Engineering Magazine, Issue No. 9, Sept.-1960 p. 26A - excerpt shown just above, describes Circlesheath® Type RR armored cable for use underground (buried).

This advertisement describes the company's products as "Rubber covered wire & cable, varnished cambric cable, plastic insulated cable, neoprene sheathed cable, and cirtub EMT."

More Circle Wire & Cable products are described

at CIRCLE WIRE and CABLE Corporation

Below: an early advertisement for Cres-Flex armored cable or "flexible metallic-sheathed" wire:

Crescent Insulated Wire & Cable Co. also made fabric-insulated electrical wire described further

How to Remove the Metal Sheathing from Armored Cable ("BX") Electrical Wires or from Flexible Conduit using a Hacksaw

Armored cable or metallic-sheathed electrical cable has been in use since 1896 (in the U.K.) and in its most basic form contains two electrical conductors (black-hot and white-neutral) each individually insulated and both usually wrapped with a spiral of paper which is in turn enclosed in a flexible metallic sheathing such as shown in our abandoned wire photograph below.

Watch out: often we find that the rubber-insulated conductors in older electrical wire such as this BX, possibly a G.E. product, are so deteriorated that the insulation is crumbly and unreliable. If you can not strip back the wire to conductors whose insulation is intact then the wire should be replaced.

Watch out: When cutting BX, the saw cut should be diagonally across one rib of the armor, and you need to take care to cut just the metal armor and not the wire insulation.

In the U.S., the National Electrical Code Article 320 Armored Cable: Type AC covers the installation and use of BX electrical wire.

See ELECTRICAL WIRE STRIPPING TIPS where we discuss proper wire stripping details and how to work with BX or armored cable.

Hacksaw method for stripping armored cable (AC), BX cable, metallic cable (MC) or flexible metal conduit:

- Make certain that the electrical power has been turned off

and that you've used a test tool such as a VOM or neon tester to confirm that the wires you're working on are not electrically live. Failure to take this step risks a fatal electrical shock. - Determine the length

of metal cable covering to be removed. - Cut diagonally across one of the metal ribs

at the desired distance from the end of the wire. Cut carefully and stop as soon as you have cut through the metal to avoid cutting into the wire insulation. If you use a hacksaw, a fine-toothed blade will work best. - Snap the armored cable

and then grasp the cable on each side of the cut and bend the cable back and forth until the armor snaps. - Slide the armor off the cable.

- Unwrap the paper from the inner conductors and cut it away.

- Check the inner conductors for damaged insulation

Check both at the point where you cut the armored jacket and also along the length of the conductors since in pulling off the armored jacket you could have damaged the individual conductors anywhere along their length.

If the conductor insulation has been damaged ,you should cut off the damaged wires and begin again.

Sketch courtesy of Carson Dunlap Associates . - Add the wire protection fiber or plastic bushing,

(a common version is the "Red Hat" shown above) that is simply slid over the electrical conductors and pushed into the open end of the BX armored sheath.

The Red Hat protects the insulation on the individual electrical conductors from being nicked or cut by the sharp edges of the cut flexible conduit.

Use Special Tool for Cutting Armored Cable (AC) or Metal-clad (MC) Cables

When cutting armored cable (AC) or metal-clad (MC) cables, you can either CAREFULLY use a hacksaw or tin snips or you can use a tool designed specifically for the job. The cable is laid inside the tool, which has a round cutting blade on a crank.

This comment and reply were posted originally

at ELECTRICAL WIRE STRIPPING TIPS

The BX cutting tool is squeezed with one hand to clamp the blade against the armor sheath and the crank is turned a few times with the other hand to cut a clean slot in the metal sheath without damaging the wires.

The cable with the split armor is then taken out of the tool, the sheath is twisted and it pops apart cleanly.

[Click to enlarge any image]

Our photo above of an AC cutting tool provided courtesy of NH Firebear and is discussed in more detail below.

Make certain that the electrical power has been turned off

and that you've used a test tool such as a VOM or neon tester to confirm that the wires you're working on are not electrically live. Failure to take this step risks a fatal electrical shock.

- Bend the BX armored cable

sharply until the armor buckles. - Twist the armored cable

in the direction that will unwind the armor spiral. This causes a section of the armor to spring out at the point of the bend. - Slip the cutting tool through the armor

where it has buckled. Trim away sharp edges. Slide off the end of the armor. - Use the shaping grip

in the jaws to reform the buckled cable-end after stripping the paper from the inner conductors and trimming it off. - Trim away or bend the sharp edges

of the armor at the point of the cut. Make sure no edges are in position to cut into the insulation in the inner conductors. This is important.

- Check the inner conductors for damaged insulation.

Check both at the point where you cut the armored jacket and also along the length of the conductors since in pulling off the armored jacket you could have damaged the individual conductors anywhere along their length.

If the conductor insulation has been damaged you should cut off the damaged wires and begin again.

Sketch courtesy of Carson Dunlap Associates . - Add the protective bushing or "Red Hat" by pushing it into the open end of the BX Cable

As we described above in the hacksaw method, After Stripping the BX jacket from electrical wire, Protect the conductor wires (hot & neutral) from future damage from the sharp edges of the cut armored cable jacket.

To eliminate the possibility of sharp edges of the armor cutting into the conductor insulation, a fiber bushing, sometimes made of plastic such as the Red Hat shown here, should be inserted under the armor, at the point where the conductors emerge.

Install Protective Bushing or "Red Hat" into End of BX Cable: AC vs MC Differences

Note that when type AC (trade name "BX") is used, there must also an insulated bushing (known as a "red-head" or "Red Hat") inserted to protect the internal conductors from damage and shorting on the cut end of the armor. Connectors for Type AC have a slot through which to inspect for the red-head.

This anti-short bushing is required by U.S. NEC Article 320.40 whenever AC type "BX" cable is being installed.

(See details at NEC Article 320.40 Boxes and Fittings at BX & MC CABLE WIRING CODE )

But MC type electrical cables do not require an anti-short bushing like that shown above.

Where MC (Metal Clad) cable is installed, listed fittings may or may not include an insulated throat or bushing but MC fittings are required to provide a rounded, smooth end-stop through which the conductors pass so that they won't be damaged in passage.

For MC wiring, those bushings are optional and may be provided by the MC cable manufacturer.

Most types of red-heads now have a "tail" that can be left sticking out of the hole for easier inspection. Ref NEC® Article 320.40. The bonding conductor may be bent back, over the sheath, either before or after the red-head is inserted.

Watch out: the BX flexible metal sheathing cut in this case extends through more than one rib and is not good practice.

Unlike AC (Armored Cable), Type MC (Metal Clad) installations do not generally require a red-head and have no inspection hole, although some local codes may still require them.

Type MC connectors are designed to prevent the conductors from contacting the armor. Not all electrical inspectors can recognize the difference without taking things apart.

These photos used a Type MC cable having 12-2 with ground. A type AC would have a bonded ground. The red-head and AC connector were used for demonstration only. Do not use the wrong type of connectors for your particular type of conduit as they may damage the metal sheath.

For instance, a set-screw connector could crush an aluminum AC sheath and damage the conductors inside.

It is worth noting that Type AC and Type MC, while similar in appearance and construction, have different code restrictions on where they may be used. - NH Firebear by private email 2016/07/27

Reader & Editor Comments

Excellent and helpful details, published above. Thank you NH Firebear.

Indeed, as I've reported elsewhere, my brother-in-law, a theater electrician in New York City, re-wired his apartment into an electrical disaster when he used BX armored cable throughout (as required in NYC), with no protective "red-head" plastic protective inserts in the cable ends. That mistake combined with zealously over-tightening the set screw in every BX cable clamp at every electrical box.

Where the BX cable cut into the hot wire, the circuit breaker shorted immediately and sparks flew when power was restored. Those mistakes were quick to find. But additional shorts between the neutral conductor and the (grounded) BX cable exterior shell meant that Matt's GFCI breaker kept tripping until all of those snafus were also found and fixed.

"Fixing" the short circuits in this case was a pain as the nick into the wire insulation was right at the cut end of the BX metal jacket. A proper repair would have involved stripping back past that nick into the insulation and preparing new stripped wire-ends - a proposition that proved difficult where not enough slack or extra length remained in the original wires.

NH Firebear's moisture-resistant or more generically "waterproof" flexible conduit shown in the photo above is most often seen at outdoor compressor/condenser units of air conditioners or heat pumps but may also be proper indoors in damp locations such as shown above.

Electrical Box / Panel Connectors For AC & BX Cables

The electrical connection between the cable exterior and the electrical box body is through the bushing set screw that is tightened against the BX cable exterior - an inconsistent and unreliable electrical connector whose credible function is to mechanically secure the cable to the box as a strain relief.

Here we show two of several types of connectors for use with armored cable/flexible metal conduit, using a set screw (above) and using a two-screw clamp connection (below).

Watch out: our now ex-brother-in-law Matt, a theater electrician, wired his NYC apartment using the NYC-required BX electrical cable. But being a strong fellow he over-tightened every single set screw connector at every electrical box.

When he turned on electrical power to the circuits none of the breakers would stay "on" because the over-tightened set screws plus the omission of the required plastic bushing insert in the open end of the BX caused the BX exterior edge to cut into either the hot or the neutral wire on every one of his connections.

The BX exterior became electrically live, shorted to the grounding conductor, and blew the breaker.

The flexible aluminum strip is also not usable by itself as a grounding conductor. (It would likely be undersized.)

The flat aluminum tape that you see inside this 1950s BX and the thinner aluminum wire found wrapped around some newer BX cable is an internal "bonding strip" intended to improve the reliability of the external jacket of this cable should it become energized with electrical current.

When the cable is connected to an electrical box, this tape or the smaller aluminum wire is bent back or wrapped around the outside of the cable before it inserted into the BX cable connector that secures the cable to the electrical box.

The electrical code does not explicitly address this question, as we excerpt from Texas' Electrical Code adoption of the NEC:

Article 320.108 Equipment Grounding Conductor

Type AC cable shall provide an adequate path for fault current as required by 250.4(A)(5) or (B)(4) to act as an equipment grounding conductor.

It is also important that you use the proper connectors to secure the metal BX exterior to a metal electrical box so that if the metal exterior does become energized it can also be connected through the circuit ground to earth, thus tripping a circuit breaker or blowing a fuse.

Bending Radius for BX Cable

Watch out: when routing and installing BX cable, don't bend BX over too sharp an angle or you will break the external flexible metal conduit.

Excerpting from the US NEC as adopted by Texas:

Article 320.24 Bending Radius [for BX cable]

Bends in Type AC cable shall be made such that the cable s not damaged.

The radius of the curve of the inner edge of any bend shall not be less than five times the diameter of the Type AC cable.

Grounding Conductor & Other Differences Between AC / BX vs MC Electrical Wire / Cable

Above: BX cable installed at an electrical receptacle box without using the proper strain relief bushing. This is an improper and unsafe electrical wiring job. Note also the additional wires routed through the same electrical box opening - also improper and unsafe.

This photo also illustrates a worst case example of discontinuous grounding of the metal sheathing of the BX cable.

The US NEC specifies that the metal exterior sheath of BX must be electrically continuous - so capable of serving as a ground path. Indeed plenty of sources assert that the external flexible metal sheath on BX armored cable is allowed to serve as the electrical grounding conductor for the circuit whose hot and neutral wires are inside of the cable.

Differences Between AC Cable & MC Cable Include Different Grounding Methods

Both AC and MC wiring provide a protective metal sheath that guards the electrical conductors from mechanical damage.

These electrical wire types can be pulled or "fished" over long distances, can be routed near or even touching metal pipes or ductwork, and the wire can its own weight when run between AC-90® Cables from Atkore, sometimes referred to as BX cable, are a commercial wiring method favored by installers for their flexible interlocked steel armor, which provides mechanical protection.

These versatile 600V cables with THHN conductors have certain construction limitations due to the inception and design of UL Standard 4 over 100 years ago.

The UL Standard allows for 2, 3, or 4 conductors, individually wrapped with moisture-resistant, fire-retardant paper and twisted from 14 AWG to 1 AWG.

Type AC Cable is the foundation of all interlocked armored cable assemblies we have today. - Kaf-Tech cited below.

But there are important differences between AC and MC electrical wires that we describe here.

Watch out: an inexperienced installer or inspector may not see the difference between AC - Armored Cable and MC - Metal-Clad cable. The presence of the insulating sheath in MC cable may not be visible by external inspection unless the open end of the cable and its constituents are visible.

Properties of AC Cable or "Armored Cable" Electrical Wiring

- AC Cable or "Armored Cable" (shown above) uses the flexible external metal sheath or "jacket" of the cable, augmented by a thin flexible metal bonding strip or wire either run inside the cable or around it, to serve as the grounding conductor for the cable.

- Bond strip or wire: In our photo above you can see the flat metal bonding strip that identifies older AC or Armored Cable, in this instance found in a 1955 Montreal home.

Watch out: the bonding strip or wire itself is not considered an equipment grounding conductor. Rather it is the combination of the bonding strip or wire plus the external, interlocking metal armored jacket that forms a low impedance ground path for the circuit where this cable is used. - AC type BX cable requires the use of an anti-short bushing, described separately

at BX CABLE BUSHING REQUIREMENT - Fiber Bushing or Red Hat Plastic Bushing Details - In AC BX cable, there is no separate grounding conductor wire, just the black hot, white neutral, and that flexible aluminum grounding bond strip that helps assure that the flexible external metal jacket can serve as a grounding conductor.

- The bonding wire or strip can be simply cut off at the end of the metal armored jacket, or some installers (including us) like to wrap the extra length of bonding conductor back around the outside of the metal armored jacket before inserting the armored end into its connecting bushing or strain relief.

- In newer AC cable, the bond wire is 16 AWG but in older AC the bond wire may be in a different form such as the flat metal strip illustrated in our photos on this page.

- Armored Cable or AC Cable is not waterproof and is not suitable for use outdoors nor in wet or damp locations.

- AC Cable is not rated for direct burial.

- AC cable will carry at most 4 conductors, size 14AWG to 1 AWG, plus a grounding conductor for a total of 5 wires.

Properties of MC Cable or "Metal-Clad Cable" Electrical Wiring

The outermost PVC jacket in our example above is not present on all MC cable.

Photo: adapted from NNC, Nassau National Cable Co., Tel: 1-516-482-6313, nassaunationalcable.com. The company describes this product as Type MC Metal Clad Aluminum Interlocked Armor AIA PVC Jacketed Copper Feeder Conductor, available in various gauges.

- MC Cable or "Metal-Clad Cable" is a more recent form of flexible metal conduit or metal-clad electrical cable that can be used more widely than traditional AC cable. MC cable does not use its external sheath or "jacket" as the grounding conductor.

- MC Cable includes a PVC sheath or jacket that makes the MC cable water resistant and suitable for use outdoors. Our photo above illustrates type MC cable that sports an external PVC jacket as well as an internal waterproof sheath. Notice the "bare" stranded grounding conductor inside the cable sheath (green arrow).

- MC Cable does not require an anti-short bushing or "Red Hat" though such optional-use bushings may be provided by the manufacturer.

However the fittings used to connect MC cable to electrical boxes and panels are required to be manufactured with smooth, rounded edges and an end stop so that the cut end of the metal sheath can not damage the insulation on the conductors passing through the end of the cable and into the electrical fixture. - MC cable never includes a bonding wire (described for AC cable above) and instead, will always include a grounding conductor so there will always be at least three wires: hot, neutral, and ground, in MC cable.

- Unlike AC, the number of conductors inside MC cable is not limited [Per Kaf-Tech cited below] and the wire sizes will be 18 AWG or larger.

- MC cable does not include a fire- and moisture-resistant paper wrap but does include a surrounding polypropylene assembly tape or sheath inside the metal conduit.

- MC Cables may be rated for direct burial if the MC cable has the required jacket and waterproof insulation.

- In sum, MC cable is designed to be resistant to corrosion and moisture that allow this cable to be run outdoors or in other challenging environments without having to use an external PVC or metal conduit. Special versions of MC cable that add a vapor-tight sheathing are sold for use in hazardous locations.

BX FMC Electrical Wiring Code

Excerpting portions of the Texas electrical code adoption of the US NEC:

Article 320 Armored Cable: Type AC

320.1 Scope

This article covers the use, installation, and construction specifications for armored cable, Type AC. 3

20.2 Definition [of Armored Cable, Type AC]

The definition in this section shall apply within this article and throughout the Code.

Armored Cable, Type AC.

A fabricated assembly of insulated conductors in a flexible interlocked metallic armor.

See 320.100. 320.6 Listing Requirements Type AC cable and associated fittings shall be listed.

320.10 Uses Permitted [for Armored Cable, Type AC]

Type AC cable shall be permitted as follows:

For feeders and branch circuits in both exposed and concealed installations

In cable trays

In dry locations

Embedded in plaster finish on brick or other masonry, except in damp or wet locations

To be run or fished in the air voids of masonry block or tile walls where such walls are not exposed or subject to excessive moisture or dampness Informational Note: The "Uses Permitted" is not an all-inclusive list.

320.12 Uses Not Permitted [for Armored Cable, Type AC]

Type AC cable shall not be used as follows:

Where subject to physical damage In damp or wet locations In air voids of masonry block or tile walls where such walls are exposed or subject to excessive moisture or dampness

Where exposed to corrosive conditions

Embedded in plaster finish on brick or other masonry in damp or wet locations

320.15 [Routing Armored Cable] Exposed Work

Exposed runs of cable, except as provided in 300.11(B), shall closely follow the surface of the building finish or of running boards.

Exposed runs shall also be permitted to be installed on the underside of joists where supported at each joist and located so as not to be subject to physical damage.

320.17 [Routing Armored Cable] Through or Parallel to Framing Members

Type AC cable shall be protected in accordance with 300.4(A), (C), and (D) where installed through or parallel to framing members.

320.23 [Routing Armored Cable] In Accessible Attics

Type AC cables in accessible attics or roof spaces shall be installed as specified in 320.23(A) and (B).

(A) [BX - Armored] Cables Run Across the Top of Floor Joists

Where run across the top of floor joists, or within 2.1 m (7 ft) of the floor or floor joists across the face of rafters or studding, the cable shall be protected by guard strips that are at least as high as the cable.

Where this space is not accessible by permanently installed stairs or ladders, protection shall only be required within 1.8 m (6 ft) of the nearest edge of the scuttle hole or attic entrance.

(B) [BX - Armored] Cable Installed Parallel to Framing Members

Where the cable is installed parallel to the sides of rafters, studs, or ceiling or floor joists, neither guard strips nor running boards shall be required, and the installation shall also comply with 300.4(D).

320.24 Bending Radius [Limits for BX - Armored Cable]

Bends in Type AC cable shall be made such that the cable is not damaged. The radius of the curve of the inner edge of any bend shall not be less than five times the diameter of the Type AC cable.

320.30 Securing and Supporting [BX - Armored Cable]

(A) General [Support AC on 4 1/2 ft. intervals]

Type AC cable shall be supported and secured by staples; cable ties listed and identified for securement and support; straps, hangers, or similar fittings; or other approved means designed and installed so as not to damage the cable.

Unless otherwise permitted, Type AC cable shall be secured within 300 mm (12 in.) of every outlet box, junction box, cabinet, or fitting and at intervals not exceeding 1.4 m (4 1/2 ft).

(C) Supporting Unless otherwise permitted, [for BX - Armored Cable]

Type AC cable shall be supported at intervals not exceeding 1.4 m (41/2 ft).

Horizontal runs of Type AC cable installed in wooden or metal framing members or similar supporting means shall be considered supported and secured where such support does not exceed 1.4 m (41/2 ft) intervals.

(D) Unsupported [BX - Armored] Cables

Type AC cable shall be permitted to be unsupported and unsecured where the cable complies with any of the following:

Is fished between access points through concealed spaces in finished buildings or structures and supporting is impracticable Is not more than 600 mm (2 ft) in length at terminals where flexibility is necessary

Is not more than 1.8 m (6 ft) in length from the last point of cable support to the point of connection to a luminaire(s) or other electrical equipment and the cable and point of connection are within an accessible ceiling

For the purposes of this section, Type AC cable fittings shall be permitted as a means of cable support.

320.40 Boxes and Fittings [for BX - Armored Cable Wiring]

At all points where the armor of AC cable terminates, a fitting shall be provided to protect wires from abrasion, unless the design of the outlet boxes or fittings is such as to afford equivalent protection, and, in addition, an insulating bushing or its equivalent protection shall be provided between the conductors and the armor.

The connector or clamp by which the Type AC cable is fastened to boxes or cabinets shall be of such design that the insulating bushing or its equivalent will be visible for inspection.

Where change is made from Type AC cable to other cable or raceway wiring methods, a box, fitting, or conduit body shall be installed at junction points as required in 300.15.

320.80 Ampacity [for BX - Armored Cable Wiring]

The ampacity shall be determined in accordance with 310.14.

(A) Thermal Insulation [for BX - Armored Cable Wiring]

Armored cable installed in thermal insulation shall have conductors rated at 90°C (194°F). The ampacity of cable installed in these applications shall not exceed that of a 60°C (140°F) rated conductor.

The 90°C (194°F) rating shall be permitted to be used for ampacity adjustment and correction calculations; however, the ampacity shall not exceed that of a 60°C (140°F) rated conductor.

Where more than two Type AC cables containing two or more current-carrying conductors in each cable are installed in contact with thermal insulation, caulk, or sealing foam without maintaining spacing between cables, the ampacity of each conductor shall be adjusted in accordance with Table 310.15(C)(1).

(B) Cable Tray [for BX - Armored Cable Wiring]

The ampacity of Type AC cable installed in cable tray shall be determined in accordance with 392.80(A).

320.100 Construction

Type AC cable shall have an armor of flexible metal tape and shall have an internal bonding strip of copper or aluminum in intimate contact with the armor for its entire length.

320.104 Conductors

Insulated conductors shall be of a type listed in Table 310.4(A) or those identified for use in this cable.

In addition, the conductors shall have an overall moisture-resistant and fire-retardant fibrous covering.

For Type ACT, a moisture-resistant fibrous covering shall be required only on the individual conductors.

320.108 Equipment Grounding Conductor [for BX - Armored Cable Wiring]

Type AC cable shall provide an adequate path for fault current as required by 250.4(A)(5) or (B)(4) to act as an equipment grounding conductor.

320.120 Marking [Requirements for BX - Armored Cable Wiring]

The cable shall be marked in accordance with 310.8, except that Type AC shall have ready identification of the manufacturer by distinctive external markings on the cable armor throughout its entire length.

History & Installation References for BX / Greenfield Electrical Cables

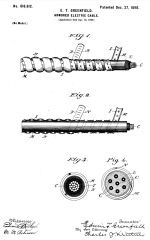

- Burley, Harry B., and Henry E. Rooney. INSULATED ELECTRIC WIRE [PDF] U.S. Patent 1,458,803, issued June 12, 1923. Application US534469A filed in 1922.

Excerpts:

Our present invention relates to electric wires or cables of the class in which rubber or rubber compound' is used for insulating purposes. Our invention relates more specifically to wires or cables covered by a vulcanized rubber compound designed for use in the transmission of high voltages.

The common method of insulating such wires is to increase the thickness of the rubber wall when it is desired to transmit a higher voltage.

It is found, however, that by this method a point is reached beyond which the increase in the thickness of the wall does not give any commensurate advantages in the voltage carrying capacity of the wire or cable.

It is the object of this invention to increase the dielectric strength of the insulation of the rubber covered wire or cable, to increase their voltage carrying capacity and to render such wires or cables capable of withstanding a higher voltage without increasing the thickness of the insulating wall of wire or cable.

We accomplish these objects by embedding within the rubber compound insulation one or more interlayers of cotton, flax, hemp or similar fibrous material of a flexible character.

An interlayer of such material has a conductivity substantially greater than that of rubber. This interlayer, therefore, acts to distribute over the inner surface of the rubber, surrounding said interlayer material, any leakage of the current through an interior portion of the insulation.

- Dini, David A., P.E., SOME HISTORY of RESIDENTIAL WIRING PRACTICES in the U.S. [PDF] (2006) Underwriters Laboratories, Inc.

Abstract:

On December 31, 1879, Thomas Edison exhibited his newly invented electric lighting in a few houses along a residential neighborhood in Menlo Park, New Jersey.

That New Year’s Eve night proved to be not only historical in terms of its significance to American ingenuity and invention, but it also signified the beginnings of residential electrification in the United States.

Although originally available to only the wealthiest of families, by the turn of the century electricity in the home was becoming a reality for more and more people. This paper traces the history of some residential wiring practices from the early days of electricity into the 21st century.

Wire and cable systems, overcurrent protection, raceways and boxes, wire splices and terminations, wiring devices, grounding, polarity and special protection devices are presented from the historical perspective of time, necessity, and technology. The influence of Code1 requirements and common trade practices are also presented. - Greenfield, Edwin T. "Means for giving rigidity to elbows or turns of flexible conduits." U.S. Patent 644,858, issued March 6, 1900.

Above: electrical wire insulation illustration from Burlery's 1923 patent cited below.

- Greenfield, Edwin T. ARMORED ELECTRIC CABLE [PDF] U.S. Patent 616,612, issued December 27, 1898. Filed 1986

Excerpts:

Be it known that I, EDWIN T. GREENFIELD, a citizen of the United States, residing at New York, in the county of New York and State of New York, have made a new and useful Invention in Armored Electric Cables, of which the following is a specification.

My invention is directed particularly to improvements in electric cables designed for ocean service, and has for its objects,

first, to devise an armored cable of such a nature that the insulation of the cable will be thoroughly protected from the attacks of borers or other insects or animals which usually attack cables of this nature when sunk in the body of the ocean

second, to devise an armored cable of such a nature that its exterior armor will fully protect it (the cable) from unnatural wear when it is suspended over ledges of rock in the body of the ocean;

third, to provide a cable of the nature indicated in which the armor is of steel, phosphor-bronze, or any preferred metal having the desired strength and qualities for adapting it for use in the ocean and in making such armor of a flexible nature, so that the completed cable may be wound upon a drum in the usual way when it is desired to lay it in the bed of the ocean, and,

fourth, to provide a lead or equivalent covered cable with a flexible protecting armor which will protect the lead covering from the action of metal slivers when drawn into a conduit. - Greenfield, Edwin T. Machine for making ARMORED ELECTRIC CABLES [PDF] U.S. Patent 630,502, issued August 8, 1899.

- Greenfield, Edwin T. "Coupling for armored hose." U.S. Patent 746,497, issued December 8, 1903.

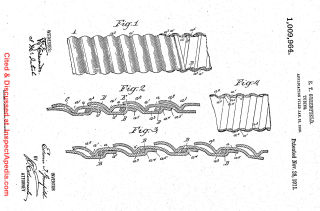

- Greenfield, E.T., FLEXIBLE METALLIC TUBE [PDF] U.S. Patent 817,057 granted Apr 3, 1906

Excerpt:

The tubes referred to, which are known widely in the art of flexible armored conduits, are made by the use of the mechanism and practice of the method disclosed in United States Patents 630,502 and 630,503, granted to me on the 8th day of August, 1899.

In the manufacture of such tubes so long as the same are of reasonably small diameters, say one inch in internal diameter, it is possible to construct the same with flexible convex and concave strips of comparatively thin metal, the practice of the method referred to and the use of the machine constructing a tube which is reasonably flexible and with sufficient interlocking friction to prevent the same from being drawn apart by ordinary stress or bending. - Greenfield, Edwin T., TUBING [PDF] U.S. Patent 1,009,964, issued November 28, 1911.

- Kaf-Tech, INSTALLATION INSTRUCTIONS for TRADITIONAL TYPE AC & MC CABLES [PDF] Kaf-Tech, retrieved 2023/06/21, original source: turtle.com/ASSETS/DOCUMENTS/ITEMS/EN/Kaf_Tech_18BF_42_500_Manual.pdf and atkore.com/About-Us/Brands/Kaf-Tech

Atkore website excerpt: AC-90® Cables from Atkore, sometimes referred to as BX cable, are a commercial wiring method favored by installers for their flexible interlocked steel armor, which provides mechanical protection.

These versatile 600V cables with THHN conductors have certain construction limitations due to the inception and design of UL Standard 4 over 100 years ago.

The UL Standard allows for 2, 3, or 4 conductors, individually wrapped with moisture-resistant, fire-retardant paper and twisted from 14 AWG to 1 AWG.

Type AC Cable is the foundation of all interlocked armored cable assemblies we have today. - NACMA INSTALLATION STANDARD for TYPE AC & TYPE MC ARMORED CABLES [PDF] (2013), NACMA, National Armored Cable Manufacturers Association, National Armored Cable Manufacturers Association 106 Village Center Drive Freehold, NJ 07728 (732) 866-0704 www.nacmaonline.com includes cable selection guidance, installation procedures, and NEC & UL references. - retrieved 2023/06.21, original source: static1.squarespace.com/static/53fe2cb4e4b02adad6b7fc68/t/54006c3be4b006127c1f79a6/1409313851294/nacmaAcMcStandard.pdf

Excerpt:

This standard covers the installation of Type AC and Type MC cables, which are used for electrical wiring for residential, commercial and industrial occupancies. It also includes information on fittings and other accessories necessary for a quality installation of these cable systems. - NEMA, USE of ANTI-SHORT BUSHINGS for TERMINATING TYPE MC CABLE [PDF] (2016) NEMA Engineering Dept., retrieved 2023/06/21, original source: bptfittings.com/wp-content/uploads/2016/06/NEMA-Bulletin-90-Use-of-Anti-Short-Bushings-for-MC-Cable.pdf

- Phillips, George E. "Manufacture of flexible metallic tubing, armored cable, and like products." U.S. Patent 1,471,057, issued October 16, 1923.

- Sawyer, W.H. ELECTRIC CABLE [PDF] U.S. Patent US473353, April 19, 1892

Excerpt:

My present invention relates to improvements in that class of electric cables which are especially designed for telephone service, but which are also equally adapted for telegraph purposes, the object being to provide an electric cable wherein the wires or conductors of each metallic circuit are kept equidistant from each other to produce an equilibrium of inductive effect and to provide the greatest amount of separation within the smallest possible space, thereby securing a low specific inductive capacity combined with high insulating properties. - USESI, INSTALLATION INSTRUCTIONS for TRADITIONAL TYPE AC & MC CABLES [PDF] USESI, excerpted from the USESI Catalog cited below, pages 59-64

Also see the complete

AFC ARMORED CABLE PRODUCT CATALOG [PDF] AC, HCF & MC Cables, AFC Cable Systems, retrieved 2023/06/21, original source: assets.usesi.com/product-media/catalogs/USESI_513676_catalog.pdf

...

Continue reading at OLD HOUSE ELECTRICAL SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ARMORED CABLE or BX WIRE IDENTIFICATION

- CONDUIT, ELECTRICAL - including BX

- ELECTRICAL GROUND DEFINITION

- ELECTRICAL GROUNDING in OLDER HOMES

- ELECTRICAL WIRE STRIPPING TIPS

- ELECTRICAL WIRE TYPES CODES USES

- OLD ELECTRICAL WIRING HISTORY

- OLD ELECTRICAL WIRING TYPES

Suggested citation for this web page

BX WIRING GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Bazerman, Charles. The languages of Edison's light. Cambridge, MA: MIT press, 1999.

- Dini, David A., P.E., "Some History of Residential Wiring Practices in the U.S.", [PDF] Underwriters Laboratories, Inc., (2006)

- Dini, David A., Thomas Z. Fabian, and J. Thomas Chapin. "An analytical study of some physical properties of wire and cable samples collected from older homes." [PDF] Underwriters Laboratories Inc (2006). David Dini, Northbrook, Ill. Tel: 1.847.664.2982;

Email: David.A.Dini@us.ul.com

These two papers were presented at the FPRF Aged Electrical Systems Symposium of 2006. These papers on this subject can be downloaded for free.

nfpa.org/research/fire-protection-research-foundation/projects-reports-and-proceedings/proceedings/2006-proceedings/aged-electrical-systems-symposium

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.