Air Conditioning Refrigerant Line FAQs

Air Conditioning Refrigerant Line FAQs

Q&A on Refrigerant piping fittings, connectors, routing, distances, vertical rise, tubing types, re-use

- POST a QUESTION or COMMENT about HVAC system refrigerant piping or tubing routing, connections, materials, charging

Refrigeration equipment piping questions & answers for installing air conditioners & heat pumps:

How-to and diagnostic questions & answers about the installation of HVAC refrigerant system piping or tubing.

These questions add details about selecting, mounting, and connecting refrigeration tubing or piping used in air conditioner & heat pump systems.

This air conditioning repair article series discusses the refrigeration piping requirements, insulation, mechanical fastening, and allowable distances as well as errors in air conditioning refrigerant piping installations that risk future refrigerant leaks or malfunction in the cooling equipment.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Air Conditioner Refrigerant Line Questions & Answers

These questions & answers about refrigerant gas piping installation, repair, troubleshooting were posted originally

at REFRIGERANT PIPING INSTALLATION - be sure to review that article.

Article Contents

- SIZES: METRIC vs U.S. - not interchangeable

- INSTALLATION DURING CONSTRUCTION - before or after the drywall is up?

- LEAK CAUSES - in refrigerant piping

- PIPING / TUBING COPPER TYPES

- PIPING SIZE or DIAMETER - of refrigerant line tubing

- ROUTING CHOICES - buried, outdoors, up or down, under floors, under roofs, support, protection

- ROUTING & DISTANCES - allowable routing and allowable distances, effects of long runs, effects of too-short refrigerant lines

- FITTINGS & CONNECTORS - flare fittings not recommended

- PIPING RE-USE - ok to use old refrigerant piping? Contaminant worries?

...

Refrigerant Line Size & Length Requirement Q&A

Question: Do I need a larger diameter refrigerant line?

I have received quotes from different companies to replace my 20 year old 4 ton central a/c system. The existing system has 3/4 inch copper tubing for the refrigerant.

I am looking at replacing the unit to a 4 ton Infinity or Performance series Carrier or a XR or XLi series Trane system.

One company said that it would be necessary to run a new 7/8" line.

Another company said the existing line would be fine as the newer refrigerant flows easier.

The estimated length of the run between the air handler (inside the house) and the compressor (outside of house)is about 50'. What is the correct answer. (June 24, 2012) david

Reply:

David, I don't know why the piping needs replacement unless it's damaged or leaky.

The diameter of refrigerant piping size depends on the tonnage or capacity of the equipment it serves and the piping run length.

For an existing system, unless the technician is finding that they can't get adequate refrigerant flow, changing to larger pipe just means a larger refrigerant charge, right?

For a replacement A/C or heat pump if you're keeping the tonnage the same, it still might be that the manufacturer of the replacement unit wants you to install a larger diameter line - so check the installation manual for your new unit.

Please ask the first company why a new line is needed.

The "flow easier" argument sounds nonsensical to me but probably that's because the fellow speaking with you was not an English major.

Perhaps what was meant was that to achieve adequate refrigerant flow rate in a high capacity system larger diameter piping is required.

A too-small diameter refrigerant tubing line, especially at longer runs, reduces the efficiency of and increases the operating cost of your air conditioner or heat pump system.

See details in our refrigerant piping article

at REFRIGERANT PIPING SIZE REQUIREMENTS - refrigerant pressure drop & temperature loss vs size

OK to use a smaller-diameter metric refrigerant line on new Mini Split Installation?

I am installing a 27000 btu multi zone Pioneer mini split system with 3 9000 btu heads. My question is, it is recommended to use 1/4 and 3/8 line sets. When I ordered my system , I ordered one of my line sets too short.

To save time , I ordered a longer one on Amazon. When I received it, it was a metric sized 3 and 6. I didn't notice it until I cut it to length and went to flare it. The nuts are the correct size.

I contacted Pioneers technical department and asked if it would be ok to use them. They said that the size difference was so small that it would be fine. However, they didn't know of anyone having done it in the past. Do you think its ok to use them? Thanks. On 2024-12-24 by Buddy -

Reply by InspectApedia Publisher (mod) - Maybe but with some cost & risk of a later re-do: It's a bigger volume reduction than you'd think!

@Buddy,

Bottom line: use the factory or OEM recommended refrigerant tubing size; check the IO manual and increase that diameter for long tubing runs.Normally I would trust the advice of the Pioneer HVAC technical department's engineer in this matter. And honestly I'm embarrassed (and I might be mistaken) to disagree with whomever you consulted by telephone.

OPINION: Considering the cost of having to evacuate the system and replace tubing with the recommended size IF you discover you don't like the operating efficiency or capacity of the new system if installed with the metric sized tubing, it'd be less costly to get the OEM-recommended tubing now and use it from the start.And depending on the run length you may need a still larger refrigerant tubing size so check the IO manual on that point before ordering your replacement tubing.

See REFRIGERANT PIPING LENGTH vs DIAMETER

Watch out: I also note that you mention "flaring the refrigerant tubing" - we never use flare fittings on refrigeration lines as they're not likely to withstand the pressures involved on the high side.

See REFRIGERANT TUBING FLARE CONNECTIONS

Details:

While it's not intuitive , the effect of changing tubing diameter can have more effect on total volume than we'd guess. And I think a reduction of tubing "volume" translates into a reduction in tubing flow rate or flow restriction, varying of course by pressure and by other restrictions such as elbows, fittings, bends, and the TEV itself.

We give examples of the effect of change in diameter on the volume of a cylinder in our article:

VOLUME of WATER IN a CYLINDER - CALCULATION - which works for the volume of any substance, liquid or gas (not considering pressure) inside of a cylinder.

Going to a larger tubing in HVAC systems: In my experience installing and servicing HVAC systems (since the 1980's) I've found that the only effect of going to a larger diameter refrigerant line set is that you might need to increase the refrigerant charge quantity slightly. Even that isn't critical if/when the equipment includes a receiver.

Going to a smaller diameter line set in HVAC systems: may be fine provided the line length's are not so great that the compressor motor is starved for refrigerant or the pressure drop on the suction side isn't too severe.Let's do the math to figure out the impact of going to a smaller diameter refrigerant tubing has on tubing volume.

(Really? Volume isn't the whole story since ultimately we're concerned with flow rate to and from the compressor, but calculating flow rate is beyond my expertise.)

A 6mm diameter tube is 0.2362" - as opposed to 0.375 or 3/8" in the IO manual for your mini split system. That's a 38% reduction in diameter. (The volume reduction will be greater still).To calculate the actual reduction in volume (as opposed to diameter) we use this formula:

V = pi x r2 x h

where r is the radius of the circle (half the diameter) and h is the height or "length" of the tubing. We'll calculate using 12" of length to get volume of tubing per foot of run.

The volume of 6mm tubing, converted to inches for comparison, is 0.52581 cubic inches per foot of tubing length.

The volume of 3/8" tubing's interior is 1.32536 cubic inches per foot.

0.52581 / 1.32536 = 0.396

The smaller diameter 6mm tubing thus provides just 40% as much volume: we're reducing the tubing volume by a bit over 60%!

A 3mm diameter tube is 0.1181 " - as opposed to 0.25" or 1/4" in the IO manual for your mini split system. That's a 54% reduction in diameter!The volume of 3mm tubing, converted to inches for comparison, is 0.13145 cubic inches per foot of tubing length.

The volume of 1/4" tubing's interior is 0.58905 cubic inches per foot.

0.13145 / 0.59805 = 0.22

The smaller 3mm diameter tubing thus provides just 22% as much volume as the larger: we're reducing the volume by 78%!

So How Much Will Smaller-Diameter Refrigerant Tubing Going be a Problem?

How will we know if the metric line sets that you ordered are too small in diameter - that is, how will we know if the smaller diameter tubing is creating an operating problem in the installation?

Answer: look at the low side suction pressure when the system is operating.

If the tubing diameter is too small the effect would be seen as excessive pressure drop across the system between the high side and the low side.The effect of that, in turn, would be a reduced cooling (or heating if it's a heat pump operating in heat mode) capacity.

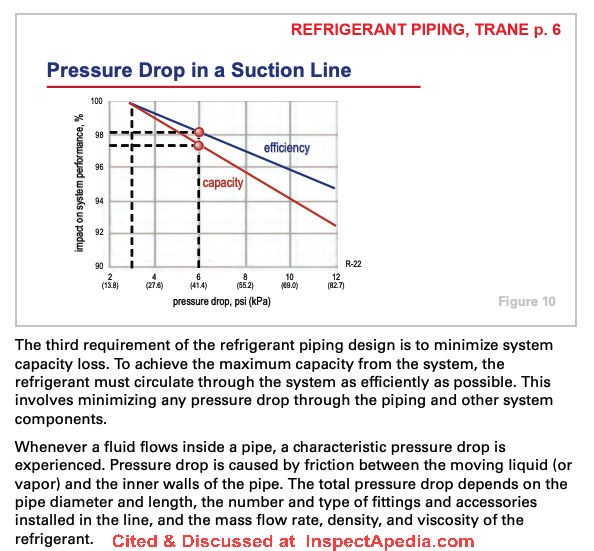

Trane has an excellent publication on this:Trane Belguim's REFRIGERANT PIPING chapter of the company's Air Conditioning Clinic [PDF] - local copy saved in our offline library as Refrigerant-Piping-Trane.pdf

From that publication on p. 6 we excerpt the chart shown above in my reply.Notice that when there is pressure drop more than specified, the result is first seen as a reduction in operating efficiency - not necessarily a disaster but your case might be more of a reduction and a greater efficiency impact than your Pioneer phone contact thought.

I wonder if the Pioneer engineer would reconsider their answer given our calculations above.

Keep me posted.

Daniel Friedman

...

Refrigerant Piping / Tubing Copper Type Q&A

Question: can I use standard 3/4" diameter copper piping instead of flexible 3/4" copper tubing for the refrigerant suction line?

I am running the piping for my central air unit. I will have a qualified HVAC technician make the connections.

I have no problem bending the smaller 3/8 tubing. However, I am having a difficult time installing the ¾ line without crimping the pipe.

My question is can I use standard ¾ inch cooper piping instead of the ¾ in tubing? I’m good at plumbing.

I could then neatly run the pipe to within a foot of the condenser and coil and have the technician complete the install. Thanks for your help and the great website. Steve

Reply: Yes but ... best to use ACR copper for refrigerant piping

Certainly I've seen [DJF] commercial HVAC installations where larger diameter soldered-joint copper piping was used for refrigeration liquid or gas movement - there is no conceptual problem with that approach but

- more solder joints rather than flexible tubing bends increases the risk of a leaky joint, so choice of high quality copper (type M?) and joint soldering or brazing workmanship and proper soldering materials will be important

- as with any new air conditioner or heat pump installation, the amount of refrigerant charge may need to be adjusted to accommodate the volume within the refrigerant piping system.

Bending copper tubing - tips for

Incidentally, among my plumbing tools I keep a set of tightly coiled springs of appropriate inner-diameter to slip over flexible copper tubing that needs to be bent without crimping or kinking.

These springs, sold at HVAC suppliers, slip over the tubing in the area where you want to make the bend, and the steel of the spring holds the copper tubing keeping it round so that you can make a bend without any crimps.

Also you may have noticed that even smaller diameter flexible copper tubing can become increasingly difficult to bend and re-bend in the same area of tubing.

That's because as you bend the tubing the heat of the bending process alone is sufficient to anneal the copper, making it harder. So we try to get the bends nice and neat and right the first time.

Difference between Type L and type R copper tubing on A/C system tubing?

Need to buy flexible 3/4" copper tubing for AC install. What's the difference between L and R tubing? On 2019-07-15 by Howard -

Reply by (mod) - best to use ACR tubing for refrigeration systems not K, L, M copper tubing

Thickness, hardness, intended use.

I hsve not seen "type R" copper piping per se, but type "ACR" is specifically intended for use in refrigeration, air conditioning, heat pump systems.

See also

K, L, and M COPPER DIFFERENCES and Other Types of Copper Pipes

Question: I can't use copper refrigerant piping in my facility

I am installing a 'mini-split' style 3 ton a/c unit. I absolutely can not use copper lines in my facility. It has been done previously using hoses and connectors. What is the max PSI on a typical split 3 ton units refrigerant lines? (Apr 10, 2012) Joe

Reply:

Joe: take a look at the specifications for operating pressure of the equipment you are installing. Typically you could be looking at a safe pressure rating of 200-400 psi. And the rating for hoses protected with metal braiding.

Warning about Chinese refrigerant tubing made with Fe-Al contaminated copper

Our house was built 2000-2001 when cheap Chinese cu tubing made with Fe-Al contaminated Cu tubing was first imported, especially in FL.

Our CA house had a single such water line leak which was fixed with a 4-in line insert.

Now one of two AC units has a seasonal leak, the one with a longer run of Cu tubing. Leak sealant was tried unsuccessful.

The run to and from the evaporator (replaced a few years ago) is long, 50-75 feet in attic under insulation.

Should we try to find lead (how?) or replace it all, including vertical runs? On 2018-07-04 by Robert W Porter

...

Refrigerant Tubing Leak Cause Q&A

Refrigerant leak, corroded A coil, blames insulation?

I've emailed you some time ago regarding a very unique and rare occurrence in my home.

This consists of a water vapor of some sorts which has completely overtaken my entire home.

It carries with it an unknown substance, although my state health department has confirmed there to be cellulose insulation part of it.

After this insulation was installed which is plugging up the soffits for air flow, Mt entire house changed dynamics.

Carpeting became full of a sediment which is what is in this water vapor. Upon my AC unit being replaced recently, I have some concerns as I'm seeing a lot of the same material which is in my carpeting, furniture, bedding, ect. I have what looks like soil filtration lines, yet these lines are jam packed with this sediment.

Building scientists cannot figure this out. These lines where the majority of this settles, although it is absolutely everywhere, even underneath furniture which sits on the floor, has an oily feel to it. Our AC unit had to be replaced due to a refrigerant leak as you will see just how corroded this A coil is that was removed. Possible similarities here? On 2022-08-08

by Michelle Castile -

Reply by InspectApedia-911 (mod)

@Michelle Castile,

Try using the Add Image button to post your image file.

About the water vapor + cellulose insulation + soil filtration lines + sediment - and staining throughout your home, I can't offer an explanation of how that might be connected to a refrigerant leak though inadequate dehumidification could be a factor.

You need an on-site expert to review your observations and to make their own thorough diagnostic inspection.

Do keep us posted as what you find may help others.

Question: Refrigerant leak due to wire rubbing the tubing - who pays for the repair?

I am told that a wire rubbed against the copper pipe on the out door unit.

They said the vibrating caused the wire casing to wear off and cause the bare wire to puncture the copper pipe.

Now the home warranty company is not covering it claiming that it is not "normal wear and tear". Is this correct? or are they just trying to get out of paying? (May 5, 2014) vm

Reply:

VM

My opinion is of course the insurer wants to avoid paying on a claim. You need help from an attorney familiar with home warranty policies to review the terms of your policy.

A wire rubbing that causes a refrigerant leak sounds like an installation error or, less likely, a product defect.

Keep us posted.

Refrigerant leak from cracked flare fittings on the refrigerant piping?

A friend of mine is having some problems with a room sized split air conditioner in his home. The unit is about three years old.

A few months ago the unit stopped cooling and an air conditioning technician confirmed that the gas had leaked out.

To inspect the lines some drywall had to be removed form a lowered ceiling, and upon inspection a cracked flare nut was found. The technician said that this is a not uncommon occurrence.

Have you ever come across cracked flare fittings in small air conditioners? It seems to me that it's just a case of poor quality fittings. What do you think?

Anyway, the damaged fitting was replaced and the unit again functioned properly.

now my friend is having more trouble with the same unit, and the technician says that now there is leaking in the copper tubing itself.

This is also a new on one me. The tubing was professionally installed and there are few bends. Unfortunately the tubing is in the wall, and partly behind a tiled bathroom wall, so revealing all of it to find the point of failure will be serious undertaking.

My friend is thinking of rerouting for convenience though the result will not be as aesthetic and the rerouted tubing will inconveniently routed on the roof of his home, where the compressor is located.

Do you have any experience with leaks in copper tubing except at bends or points of "trauma?" Is the kind of cheap Chinese Fe-Al contaminated Cu tubing mentioned in Robert W Porter's post prone to leaking?

Thanks for any insights. On 2018-08-26 7

by YossiD

Answer by (mod) - We never use flare fittings in refrigeration piping

Yossi

We do not ever use flare fittings on refrigerant piping as they're not likely to withstand the pressures involved on the high side.

I think you probabaly mean swaged connections: one end of the copper tubing is enlarged to permit joining two sections of copper piping.

The swage joint is then soldered or brazed. Some swaging tools are shown in my photo.

Swage joints are discussed

Question: Find the leak in buried refrigerant lines ?

We just bought a new home and discovered that the home inspector and the county inspector both missed the fact that the refrigerant lines outside the house going to the compressor are buried underground.

There is a concern now that we have a freon leak in that 30 foot section of pipe that is outside and under a foot of dirt. If the lines were insulated prior to being buried, is the concern of a leak valid? (June 6, 2012) Soo

Reply:

Soo,

The diagnosis of a refrigerant leak will center around the operation of your system and refrigerant charge measurement, not the refrigerant pipe routing. However depending on your climate and the insulating materials used, your piping insulation may not be effective.

Burying refrigerant lines was probably done to avoid damage that might occur to lines routed over ground for the distance you describe, though we don't understand why there was a need for 30 feet of separation distance.

Happily the shallow depth means it's trivial to excavate and replace leaky piping, perhaps using a protected conduit for the replacement to make service in the future easier.

Question: why are the refrigerant lines vibrating noisily - it sounds like a freight train!

What would cause the refrigerant lines to vibrate so loudly it sounded like a freight train? What is considered normal vibration of the gas line? Because now causes copper line to vibrate very loudly. The new unit was installed last year, but problem just started. Thank you for any advice you can offer. (July 5, 2011) Maura

Reply:

Maura:

Refrigerant lines don't normally cause vibration noises, since they are expected to be covered with foam insulation and thus wouldn't transmit vibration to the building; but if the equipment to which the lines are attached is itself vibrating it is certainly possible that the copper tubing carrying refrigerant could pick up that motion and where the tubing is in contact with the building it could transmit vibration noises.Don't "solve" the problem by just isolating the piping from the building with foam - that's treating the symptom but not an underlying problem.

I'd start by looking for the source of vibration - it's more likely to be a compressor that is not mounted properly, has some loose component, or if originating indoors, a loose fan motor mount or blower assembly. Let us know what you find as it may help other readers.

Reader follow-up:

Thank you Dan I will try to explain exactly what happened. Had a power outage about 2 weeks ago, when the power came back on an extremely loud noise was coming from basement. It was the lines coming from ac unit. Noise was very loud! Turned circuit breaker off than back on it stopped. Unit was also working. Called ac guys said it was a power surge, I don't know.

Then a few days later the lines started to make a similar noise but not as loud turning power off did not stop it. Realized copper pipe was vibrating up against insulated pipe.

Called ac guys again because noise would not stop all they did was tape the copper wiring to stop the vibrating not really addressing why it is happening in first place.

I asked if it might be a problem with compressor. Asked them check they put a hardstarter on which I know I don't need because that is not the problem.

Then again last night air cycled on, the very very loud noise started again only lasted 10 seconds and stopped.

AC guys just left still telling me possible brown outs from electric co. I don't think so. Have you ever heard of anything like this? Should I have them replace compressor it is still under warranty. Thank you very much any advice would be helpful.

Reply:

We need to know if the vibration originates with the outside compressor/condenser or the indoor air handler unit. If it's outside in origin, and because replacing a compressor is costly, you'd sure want that done (if needed) under warranty.

A power surge can damage a control board - in fact more likely than damaging the compressor itself. I'd ask for some more careful testing of the equipment that is buzzing.

Reader Follow-up:

Thank you Dan, it is definitely coming from the compressor/ condenser unit and much more than a buzzing noise.

If you email your phone# I will call you and play back the recordings of the noise they are extremely loud!

I am not sure if what ac guys are telling is accurate. Again thank you for your expertise, I greatly appreciate.

Reply:

Having just arrived on an assignment out of the U.S., a phone playback is probably not practical, but certainly from what you have described, an accurate diagnosis of just what part(s) is (are) failing is in order; call the service co and ask them to send a senior technician.

You might point out that the first tech, who taped the lines, appears not to have the experience to recognize that there is a problem.

You can also ask your electric company if they have been reducing voltage or if there have been brownouts in your area - explaining that you are diagnosing an electrical question, and making clear you aren't coming to them with a claim.

Question: freon leaking from plastic refrigerant lines?

I have an older HVAC system, and my repairman tells me the freon is leaking from "plastic" refrigerant lines used at installation(that were only manufactured for a few years).

He indicated I'd need to replace the entire system because these lines leak. Is it possible to replace these lines and keep the existing system? (July 30, 2016) KJWaddell

Reply:

(mod) said:

Yes, though if your system uses R22 that is no longer used in AC systems it may make sense to change it(July 31, 2016) Anonymous said:

Thanks for responding! Is there any reason it would be impossible to replace the lines without replacing the entire system?(They say I'd also have to replace the furnace if I replace the outside AC unit...because the old furnace "couldn't handle the new AC output". so I would love to replace the lines and keep my existing system to save cost.

(mod) said:

"Impossible" is a bit encompassing; as I don't know what might be encountered. But in general, refrigerant lines can be replaced without changing the equipment. If your tech wants to replace the entire system I'd like to understand what s/he has seen. Sometimes a very competent tech is indeed working in your interest but is not good at explaining. Press for details.To replace refrigerant lines one has to evacuate the system, remove the old piping, install new piping along with new filter/driers, then re-charge the system and test it for leaks.

(July 31, 2016) Anonymous said:

Thank you, again. The system is quite old, and they always point that out...but it runs very well with the exception of the freon leak, which has worsened in the past 2 years and is now at the point of failure. Planning to move in the near future, so trying to avoid a $6k investment in a whole new system if I can. I appreciate your insights.(mod) said:

I understand wanting to eschew putting money into the next owner's A/C system.

...

Install drywall before or after testing HVAC refrigerant lines? Q&A

What is the industry standard on whether to drywall before or after testing a new HVAC/refrigerant line installation in a new home construction. On 2024-11-10 by Mari -

Reply by InspectApedia Publisher (mod)

@Mari,

Thank you for a helpful refrigerant line test question.

I am ASSUMING that you really mean refrigerant piping (that refers to the concern about refrigerant gas leakage), and not condensate drain line testing (that's a plumbing lean concern).Photo: by DF, showing location of nail plates to protect refrigerant tubing from damage in a new installation in which tubing is routed through a building wall - shown before drywall is installed.

Bottom line:

The model mechanical codes tell us that refrigerant lines should be tested before the equipment is put into use but that does NOT mean "before drywall is installed" nor "after drywall is installed.

But in new construction (your case) depending on exactly when and what HVAC equipment is being installed and where it is being placed, it may not be possible to complete testing before the drywall is up.

Details:

You'll see from the IMC (International Mechanical Code) citation that I'll give below, that while there is a standard for refrigerant line leak testing it doesn't address when in the construction of a building that test should be performed. In my OPINION that's because the standard can't anticipate those conditions.Refrigerant piping may be installed during new construction, remodeling, retrofit, or the addition of air conditioning or heat pump equipment long after a building's construction has been completed.

So where those lines run and when they're tested has no single "right" answer.

Here's the IMC standard:International Mechanical Code 1110.5 Piping system pressure test and leak test.

The refrigerant piping system shall be tested as a whole or separate tests shall be conducted for the low-pressure side and high-pressure side of the piping system. The refrigerant piping system shall be tested in accordance with both of the following methods:

1.The system shall be pressurized for a period of not less than 60 minutes to not less than the lower of the design pressures or the setting of the pressure relief device(s).

The design pressures for testing shall be the pressure listed on the label nameplate of the condensing unit, compressor, compressor unit, pressure vessel or other system component with a nameplate.

Additional test gas shall not be added to the system after the start of the pressure test.

The system shall not show loss of pressure on the test pressure measuring device during the pressure test.

Where using refrigerant as a test medium in accordance with Section 1110.3, the test pressure shall be not less than the saturation dew point pressure at 77°F (25°C).

2. A vacuum of 500 microns shall be achieved. After achieving a vacuum, the system shall be isolated from the vacuum pump. The system pressure shall not rise above 1,500 microns for a period of not less than 10 minutes.

Source: ICC Codesafe: https://codes.iccsafe.org/s/IMC2021P1/chapter-11-refrigeration/IMC2021P1-Ch11-Sec1110.5

Now all of that said, my OPINION is that during new home construction, we would LIKE the refrigerant piping to be tested before the drywall is installed but in fact that may be impractical or even impossible.

At our home page for this topic (You're posting on its FAQs page) REFRIGERANT PIPING INSTALLATION https://inspectapedia.com/aircond/Refrigerant_Piping.php

you'll see photos of refrigerant piping being installed during new construction. For example I talk about the need to use nail plates to protect the piping from penetration from drywall screws (photo below).

But consider the sequence of new home construction:

Usually, well BEFORE the actual outdoor compressor/condenser is installed and absolutely before any wall-mounted indoor split system air handler is installed, the piping has been routed through the framed wall (our photo).

The installer could do some piping testing then but s/he is going to have to return to the site to complete the installation - the split system indoor unit, for example, isn't installed until AFTER the drywall has been installed. Testing then might also detect the very unfortunate case that the piping was damaged (and leaking) due to installation of a drywall screw.

When I installed refrigerant piping and HVAC equipment I'd never have promised that the piping was leak-free just after it was installed before the drywall was up, but as you'll see in the photo, the I made darn sure that I installed nail plates where needed.In my photo shown above these protect the condensate drain line as well as the high pressure and low pressure refrigerant lines.

Daniel

...

Refrigerant Line Routing Choices Q&A

Questions & answers about running refrigerant lines outdoors, on the ground, above ground, in the attic, in a crawlspace, under a mobile home, or distances of vertical (up or down) routing refrigerant tubing.

Is it Legal to run A/C refrigerant lines outside the building?

Is it legal to run a/c refrigerant line on the outside wall of house On 2022-03-05 by Ed -

Reply by Inspectapedia Com Moderator (mod) - Yes

@Ed,

Yes there's no prohibition against running a refrigerant line on the outside of the building per se.However you will often find that where the refrigerant lines need to run up from the ground to an upper story install the will provide some type of protection or cosmetic surround. Sometimes a downspout drain pipe is used to cover the tubing.

And as you'll read here, there are limits to total distance or to vertical routing of refrigerant tubing.

Post a photo of your installation and we can comment in further.

Can the outdoor pipes and electrical lines be buried from the house to the outdoor unit?

Can the outdoor pipes and electrical lines be buried from the house to the outdoor unit? On 2018-05-08 by traveling mom

Reply by (mod) -

Yes in conduit though there are issues and costs that make buried refrigerant lines not recommended.

See details at REFRIGERANT PIPING UNDERGROUND, BURIED

OK to lay refrigerant tubing directly on the ground ?

hi, running a/c line from a/c unit out back to blower on side of house/ old one leaked / under mobile home can it be laid on ground or do they have to have hangers ? thanks On 2016-10-21 by mike

Reply by (mod) - NO; support the refrigerant line below the mobile home floor

Mike, I'd support the refrigerant line below the mobile home floor or if it is going to be in ground contact I'd use plastic-coated copper refrigerant tubing.

Question: run refrigerant piping above ground or under-ground?

Refrigerant piping between ACCU and AHU (big units) should be underground or above ground installation? (May 23, 2016) Reynan

Reply:

The routing is not specified in a typical HVAC installation manual, but indeed, above-ground risks more damage than buried, while both options require that the tubing be protected from damage or corrosion.

Followup from Reynan: Meaning either above or below ground is acceptable?

Mod said: yep. Adequate protection from damage, insulation, and corrosion are of course required.

OK to route refrigerant lines under a wood floor?

Hi, is it safe to pass refrigerant pipes under a wooden floor? Thanks! On 2021-02-13 by Kate -

Reply by danjoefriedman (mod)

Kate:

I don't see an issue as long as the refrigerant piping or tubing is protected from damageSee

Question: Are exposed copper refrigerant lines ok outdoors?

Is it safe to have all copper refrigerant lines installed on the outside of the house? Thank you, Caren

Reply: Yes but refrigerant piping should be insulated, supported, and where outside, wrapped

A competent onsite inspection by an expert usually finds additional clues that help understand whether or not there are problems with your air conditioning system or its installation details. If you see signs of amateur workmanship on one part of the system it's appropriate to raise a question about other installation details that may not have been noticed, and thus to take a closer look.

That said, it is perfectly normal for copper air conditioner or heat pump piping to continue outside the house in order to connect to and from the compressor/condenser unit.

However air conditioner manufacturers and other expert sources include installation instructions that specify that the refrigerant lines should be insulated, supported, and wrapped with a weatherproof protective tape.

Also be sure that the opening in the building wall where the refrigerant lines emerge has been properly sealed against leaks and insect pests.

OK for refrigerant lines to run "down" to the condenser unit? Oil trap issues?

Can refrigerant lines be run above a Mitsubishi MLZ-KP18NA and supply feed down into the unit coil when the condenser is located beneath this elevation? Does this cause problems with the suction line trapping refrigerant oil and ultimately causing the compressor to fail? On 2021-09-16 by Debbie B

Reply by inspectapedia.com.moderator (mod)

@Debbie B,

Your question about trapped refrigerant oil in a refrigerant line is spot-on; thank you.

Refrigerant line can run above, up, or down with respect to a condenser and do in most installations,

but with this exception:

The routing of the refrigerant lines, particularly the low pressure or suction line, should never include dips or low areas that do not slope back to the compressor; otherwise it's possible for refrigerant oil to collect in and block a low point in the line.

Details are at REFRIGERANT PIPING INSTALLATION

and other articles in this series.

Is it ok to run air conditioner coolant line down through the clothes chute?

Can air conditioner coolant line be run down a clothes shoot? On 2018/05/25 by Elsene -

Answer by (mod): beware of the limits on vertical rise of refrigerant piping

Can you run A/C refrigerant piping through a laundry chute?

Physically possible, sure. Within very specific total vertical height limits and refrigerant pipe diameters that need to be reviewed with the manufacturer of the air conditioning equipment.

Watch out: Good idea?

Maybe not: dumping clothes down a laundry chute risks damaging lines, causing a leak, or knocking off insulation. If there is room to route the refrigerant lines through the clothes chute I'd expect the installing contractor to make sure the piping is protected from damage, perhaps enclosing it in a suitable conduit.

There are vertical height limits for refrigerant piping. That's because vertical refrigerant piping can run into limits on its ability to move droplets

The minimum velocity required to carry oil droplets up a vertical riser is higher for a larger diameter pipe than it is for a smaller diameter pipe.

This is due to the velocity profile of the refrigerant flowing inside the pipe.

In a smaller diameter pipe, the higher-velocity refrigerant is closer to the inner walls of the pipe than it is in a larger-diameter pipe.

For instance, while the minimum allowable velocity in a 2 1/8 in. (54 mm)-diameter suction riser is approximately 1,000 fpm (5 m/s), the minimum velocity in a 1 1/8 in. (28 mm)-diameter riser is only 700 fpm (3.6 m/s).

While the old minimum-velocity limits were easy to remember, they may lead to the unnecessary use of double suction risers.

The recommended maximum-velocity limit of 4,000 fpm (20 m/s) has not changed. A higher velocity inside the suction line may cause objectionable noise for those nearby. -

Source: TRANE AIR CONDITIONING REFRIGERANT PIPING MANUAL [PDF], Trane Belgium, retrieved 2018/05 25, original source: http://www.tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf

Should my compressor unit be mounted at a higher elevation than the head unit on my mini split air conditioner?

Should my compressor unit be mounted at a higher elation than the head unit on my mini split air conditioner? On 2016-06-16 by Paul

Reply by (mod) - doesn't matter

NO, doesn't matter.

Is it OK to route refrigerant lines UP through the attic?

Hi,

I am installing a split air conditioner onto a block wall and the only way to run the pipes without having to have ducting going half way around my room is to take the pipes up into the ceiling through the attic and then down the other side of the building.

This means the pipes will go up about 2.6m, across the attic about 7m then about 3m down the other side of the building to the compressor.

Will this piping arrangement be ok, will there be any major downsides to this approach. P.S. The drain can be taken outside another way so this is not a concern.

Thanks. On 2017-05-01 by Tyrone

Answer by (mod) re: yes but don't forget to calculate the volume of refrigerant needed when increasing piping lengths

Don't forget to calculate the additional refrigerant that will be needed, and be meticulous about insulating the suction line so that you don't have condensate drips into the ceiling.

See but

Watch out: see the vertical height limits for refrigerant line piping for example as given by Trane in

TRANE AIR CONDITIONING REFRIGERANT PIPING MANUAL [PDF], Trane Belgium,

Note by Tyrone

Yes I will be sure to add the extra refrigerant and insulate the pipes. I was just concerned about the two vertical runs playing havoc with the refrigerant oil or the performance of the system.

Question: using running boards to support refrigerant piping in the attic

We have to install refrigerant lines in the attic. Could we use running boards (e.g. 2x4 lumber) which would run at an angel to the trusses to shorten the distance between coil and condenser? (May 31, 2014) Petra

Reply:

Petra

That sounds quite reasonable. Don't cut or modify trusses.

See details at

Question: what support is required for refrigerant line set routed through an attic?

What are the requirements for line set support in the attic? Type and spacing? (June 7, 2016) Bill Paxton

---

I live in an outside unit of a four-plex.

My air condenser and the next door neighbor's air condenser are outside my unit.

My neighbor had to have a new condenser installed and the company is telling him that the copper piping that runs under my part of the building to his part of the building are leaking.

They want to run piping up my side of the wall outside, through my attic and then down to his air handler in his garage.

I don't think the piping is leaking and don't really want freon pipes through my attic.

Is this a safe alternative or is there another solution? Anxious for your answer. (June 21, 2016) Rosemarie Greaser

Reply:

Rosemarie,

Refrigerant piping run through building attics and walls is not normally considered a danger; most likely it'll run with no joints or fittings, as continuous tubing (thus reducing the risk of a leak).

Refrigerant leaks are really bad for the environment but the gases are pretty inert and at low levels such as leaking out of a residential A/C system, not likely to be a hazard to neighbours.

If it were my place I'd let them install solid piping where needed.

Details are at

Rosemarie Greaser said:

Thank you danjoefriedman for your suggestion.

I'll see if I can request the company do the solid piping. I think I will need to see some evidence that there is indeed a leak first in the underground piping and not just some poor installation techniques. I've read some reviews on this company and they don't seem to be very good.

(mod) said:

That sounds reasonable.

OK to run coolant lines inside of a laundry chute?

Can air conditioner coolant line be run down a clothes shoot? - On 2018-05-25 by Elsene -

Reply by (mod) - NO; also, possible problems with very tall vertical refrigerant piping runs

Can, physically, sure. Within very specific total vertical height limits and refrigerant pipe diameters that need to be reviewed with the manufacturer of the air conditioning equipment.

Good idea? No.Dumping clothes down a laundry chute risks damaging lines, causing a leak, or knocking off insulation. If there is room to route the refrigerant lines through the clothete I'd expect the installing contractor to make sure the piping is protected from damage, perhaps enclosing it in a suitable conduit.

There are vertical height limits for refrigerant piping. That's because vertical refrigerant piping can run into limits on its ability to move droplets

Source: Air Conditioning Clinic - REFRIGERANT PIPING [PDF], Trane, Belgium, retrieved 2018/05/25, original source: http://www.tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf

A copy can also be found at InspectApedia.com at

Excerpt: The minimum velocity required to carry oil droplets up a vertical riser is higher for a larger diameter pipe than it is for a smaller diameter pipe.This is due to the velocity profile of the refrigerant flowing inside the pipe.

In a smaller diameter pipe, the higher-velocity refrigerant is closer to the inner walls of the pipe than it is in a larger-diameter pipe.

For instance, while the minimum allowable velocity in a 2 1/8 in. (54 mm)-diameter suction riser is approximately 1,000 fpm (5 m/s), the minimum velocity in a 1 1/8 in. (28 mm)-diameter riser is only 700 fpm (3.6 m/s).

While the old minimum-velocity limits were easy to remember, they may lead to the unnecessary use of double suction risers.

The recommended maximum-velocity limit of 4,000 fpm (20 m/s) has not changed. A higher velocity inside the suction line may cause objectionable noise for those nearby.

Allowable Distance for HVAC Components & Refrigerant Line Runs FAQs

Questions and answers about refrigerant line runs that are too long or too short.

Is there a code on routing of refrigerant lines?

My question is about the route of the freon line from the outdoor AC unit to the indoor air handler:

My question is about the route of the freon line from the outdoor AC unit to the indoor air handler:

This goes up the side of my house and under the roof line.

The last time I had a new roof, the roofers punched a hole in the freon line.

Is there a code on whether the line should be installed low enough to prevent this from happening? On 2018-08-28 by Des de Souza

by (mod) - Yes, given here, and also, Refrigerant piping should be protected from physical or mechanical damage

Refrigerant piping should be protected from physical or mechanical damage by either routing or shielding.

For example where a line runs through a wooden stud you'd use nail plates to keep someone from driving a nail through the line.

See this York, REFRIGERANT PIPING APPLICATION DATA SHEET [PDF] (2016) General Piping Recommendations and Refrigerant Line Length for Split-System Air Conditioners and Heat Pumps, Johnson Controls, York International Corporation 5005 York Drive Norman, OK 73069, retrieved 2021/04/11

York's refrigerant piping guide document includes refrigerant line sizing tables and charts for long runs, vertical runs, etc.

See more-extensive details and refrigerant routing code source citations at our home page for

REFRIGERANT PIPING INSTALLATION [web page]

Is it proper (or necessary) to have a loop in the refrigerant line?

Just had a Lennox split system installed. The refrigerant line and the condensation line were installed on the outside of the air handler cabinet in a loop. The air handler is in a closet in my home. It looks very strange.

Is this an acceptable installation?

Thank you. On 2017-01-26 by Donna

by (mod) re: refrigerant piping loop: probably ok

Donna,

A loop in refrigerant tubing, or at least a generous bend of extra length, particularly outside at the compressor/condenser unit may be proper and good practice to give flexibility against vibration damage.But an excessive loop might be a bit odd - multiple coils, for example - at least unnecessary and possibly subject to more vibration or movement than we want. Post a photo if you can.

See

REFRIGERANT PIPING INSTALLATION

and

Carlyle MINIMIZING REFRIGERANT LINE VIBRATION [PDF] (2021)

What is the Typical Allowable distance between condenser and A/ C unit?

What is allowable distance between condenser and A/ C unit? On 2016-01-20 by Rick

Reply by (mod)

If you mean maximum piping distance between the outdoor compressor/condenser and the indoor evaporator coil/air handler, it will vary by manufacturer; typically even 30 or 40 feet can be accommodated by increasing the refrigerant charge.

Bottom line: typically HVAC manufacturers recommend keeping refrigerant lines as short as possible (but including enough line to avoid vibration damage).

For example see this

Trane A:Ae: Refrigerant Tube Size and Component Selection for IntelliCore™ Split Systems (20 to 120 Tons) R-454B Refrigerant Microchannel Condensers [PDF] - retrieved 2025/04/16.,

local copy filed asTrane APPLICATION GUIDE: REFRIGERANT TUBE SIZE [PDF] (2024) - retrieved 2025/04/16Excerpt:

[NOTE: this specification is for the specific Trane equipment noted above. Specs for other HVAC equipment can be expected to have different manufacturer-recommended distances and allowable elevation or height routings for refrigerant lines.]

Minimize Distance Between ComponentsFor a split air-conditioning system to perform as reliably and inexpensively as possible, the refrigerant charge must be kept to a minimum. To help accomplish this design goal:

Site the outdoor unit (cooling-only condensing unit or heat pump) as close to the indoor unit as possible.

Route each interconnecting refrigerant line by the shortest and most direct path so that line lengths and riser heights are no longer than absolutely necessary.

Use only horizontal and vertical piping configurations.

Determine whether the total length of each refrigerant line requires Trane review.

Be sure to account for the difference in elevations of the indoor and outdoor units when calculating the total line length.

Interconnecting lines of 150 lineal ft (45.7 m) or less that comply with the figures in the following section do not require Trane review.

Reference the following section for the maximum liquid and suction riser elevation.

What is the maximum distance from the house that an A/C or Heat Pump Condenser Unit Go?

How far from the house can an ac condenser go? The hvac people said its ok to have it 38 feet away from where the line goes in and they can run additional lines?

Right now the old unit location does not have enough clearance.

What is the maximum allowed length of the pipe between the compressor unit and the fan? On 2016-04-13 8 by Marion

Reply by (mod) How far from the house can an ac condenser go?

Marion, Your HVAC people are right. They'll need to adjust the refrigerant charge when adding extra length of piping and for much longer distances it may be necessary to use a larger diameter refrigerant line as well.

Question: will the AC unit still work with extra length of refrigerant line?

If the tech left more coolant line than needed but still charged the unit for the amount of line he had will the unit still work as it is supposed to. (July 28, 2012) Steve

Reply:

Steve I'm not sure "more coolant line than needed" is quite the case - good practice leaves some slack in the refrigerant tubing at the condenser unit, even an extra coil, so that vibration and slight movement don't rip open a brazed refrigerant piping joint.

The refrigerant charge used by the HVAC tech normally includes an allowance for the total length (and diameter) of piping in the system. If the charge is too low you'll probably discover it as frosting at the cooling coil. - Daniel

Question: what is the effect of too-short refrigerant piping?

I just installed Sharp brand split system air conditioner (photo above).

The product leaflet says that the minimum refrigerant pipe length is 3m,

but my final pipe seem only less then 50cm between the outdoor and indoor unit.

Do this short pipe length cause any trouble to the indoor unit or outdoor condenser?

Hope to get reply to release my worry On 2018-06-24 by Walter Sui

What is the effect of short refrigerant line pipes between indoor & outdoor split AC unit? (Apr 24, 2012) MHND

Answer by (mod) -Yes: too-short refrigerant pipes may be missing the vibration dampening loop - causing leaks

Yes the short pipe is likely to risk refrigerant leaks because it doesn't allow the extra length and loop or bend which would accommodate vibration and movement.

I've also seen compressor/condenser units that settled or tipped slightly after installation, especially at new construction when the unit is set on a support pad that was placed on soft backfill.

A slight settlement or tipping shouldn't impact the condenser unit operation, but if the piping was too short then I expect settlement or tipping of the unit to cause a leak.

Can we move the A/C compressor further away to solve a noise problem?

BTW - the compressors fine...its location and hard floors multiply the effect (hums, fan noise, etc) of normal compressor operation.

We have an ice machine in the middle of the home that the compressor/fan is very loud. Its a great Hoshizaki residential under counter machine that gravity drains to the basement utility room below and never has issues.

With that said the fan/compressor noise forces us to turn it off for periods. Alternatively, is it a feasible idea to extend the compressor lines below the floor into the utility room? Moving the compressor to a room where the noise is isolated?

I may want to use a flexible line so the machine can still be pulled out when needing to be serviced. Never needed to in 7 years but planning for the worst if possible.

Just checking if its feasible if I find a good AC or fridge guy to do it. On 2020-06-11 by TuxIvy -

Reply by (mod) -

Tux

Yes it's possible to relocate a refrigeration compressor - commonly done with commercial systems and walk-in coolers. Not below a floor - it needs to be able to cool.

Can I place the AC compressor about 50' away from my house - Noise worry

Can I place the AC compressor about 50' away from my house, nest to my garage? If I put it next to the house it will have to be right next to the deck and I am worried about the noise. On 2016-08-19 by Laurie

by (mod)

Laurie

You will need to

1. adjust the refrigerant charge according to the volume of additional piping

2. provide pipe routing, insulation, and damage protection specified by the unit's manufacturer

Can I add R410A to my R32 refrigerant system to make up for long refrigerant line run?

I have just installed an air con with a long pipe run and as such I need to add some extra refrigerant (50 grams to be exact).

The system uses R32 refrigerant, however I only have R410A refrigerant, would it be ok to add the extra 50g of R410A into the system or will this not be comparable with the R32 refrigerant already in the system?

I know the proper solution is to just buy a tank of R32 but I don't do much work with this refrigerant and it is hard for me to get. On 2017-05-02 by Sam

Reply by mod:

I wouldn't do it. Mixing refrigerants, even if it doesn't rapidly do serious harm to the system, changes the operating properties, pressure, temperature, cooling capacity in ways that can make adjustment and repair difficult.

Perhaps you can find a service tech who'll generously let you have the small amount of R32 you need.

...

Refrigerant Line Connectors & Fittings FAQs

Are refrigerant tubing connections soldered or brazed?

How are the joints of the condenser piping completed. Are the soldered or brazed? On 2021-05-16 by James Ouchi -

Reply by danjoefriedman (mod)

@James Ouchi,

I have used silver solder to join refrigerant lines on residential equipment, but usually these connections are brazed for a stronger, vibration resitant connectdion.

How to fit refrigerant tubing of different sizes

If the connection on new AC is bigger and and the lines coming out house is smaller can you get a converter and join both together? On 2020-07-14 by Jd

Reply by danjoefriedman (mod)

JD

Yes, you can buy a suitable copper tubing reducer, but depending on the difference in piping diameter the technician may simply use a swaging tool to join the copper tubing.

Shown above is an example, a NIBCO copper reducer that converts from 1/2" to 1/4" copper.

What kind of fitting is used on a Carrier Air conditioner that attaches freon line to condensing unit?

Need to know what kind of fitting is used on a Carrier Air conditioner that attaches freon line to condensing unit - VInce

Reply:

Vince the two common piping attachment on refrigeration lines are soldered/brazed copper tubing at which a female connecting end is prepared using a swaging tool, and in some communities, carefully-prepared flare fittings.

Details are in REFRIGERANT PIPING INSTALLATION.

Watch out: Flare fittings on refrigerant lines caused A/C failure

A friend of mine is having some problems with a room sized split air conditioner in his home. The unit is about three years old.

A few months ago the unit stopped cooling and an air conditioning technician confirmed that the gas had leaked out. To inspect the lines some drywall had to be removed form a lowered ceiling, and upon inspection a cracked flare nut was found. The technician said that this is a not uncommon occurrence.

Have you ever come across cracked flare fittings in small air conditioners? It seems to me that it's just a case of poor quality fittings. What do you think?

Anyway, the damaged fitting was replaced and the unit again functioned properly.

now my friend is having more trouble with the same unit, and the technician says that now there is leaking in the copper tubing itself. This is also a new on one me. The tubing was professionally installed and there are few bends. Unfortunately the tubing is in the wall, and partly behind a tiled bathroom wall, so revealing all of it to find the point of failure will be serious undertaking.

My friend is thinking of rerouting for convenience though the result will not be as aesthetic and the rerouted tubing will inconveniently routed on the roof of his home, where the compressor is located.

Do you have any experience with leaks in copper tubing except at bends or points of "trauma?"

Is the kind of cheap Chinese Fe-Al contaminated Cu tubing mentioned in Robert W Porter's post prone to leaking?

Thanks for any insights. On 2018-08-26

by YossiD -

Reply by (mod) - We do not ever use flare fittings on refrigerant piping

Yossi

We do not ever use flare fittings on refrigerant piping as they're not likely to withstand the pressures involved on the high side.

I think you probabaly mean swaged connections: one end of the copper tubing is enlarged to permit joining two sections of copper piping.

The swage joint is then soldered or brazed. Some swaging tools are shown in my photo.

Swage joints are discussed

at REFRIGERANT PIPING INSTALLATION https://inspectapedia.com/aircond/Refrigerant_Piping.php

Why not use quick connect automotive type AC line fittings on home air conditioning refrigerant tubing?

Curious, why do home AC units not use easy-to-replace fittings like automotive AC units?

I can continue to use the AC system in my car if my compressor fails by just replacing the compressor and reusing the flexible lines, vs what seems to requires cutting and re-welding each time a compressor fails in a home.

I feel it's annoying now that the home warranty doesn't want to cover a failed compressor, and am being told it'll have to be cut and new compressor installed and welded to the old lines - On 2021-09-15 by Wil

Reply by inspectapedia.com.moderator (mod)

@Wil,

A couple of guesses:

1. the manufacturers of home A/C units don't design them to be maintained by the homeowner; additional measurements, equipment, and training are needed.

2. the cost of a foul-up of the charge on a home A/C system can destroy a very expensive part like the compressor unit.

3. A home A/C system or commercial building A/C or heat pump system should never lose refrigerant; it should never leak.

If a leak occurs it is a problem that needs to be found and fixed.

Now let's compare that home or business A/C system to an automotive A/C system:

4. Leaks and loss of refrigerant are very common in automotive systems. That's due mainly to differences in design of the compressor unit.

On a home A/C system the compressor motor is in a hermetically sealed "can" - it cannot leak refrigerant out to the atmosphere unless there's a perforation or leak somewhere, usually in a cooling coil, condensing coil, or occasionally in a refrigerant line.The compressor motor is inside that "can" and is driven by electricity. The electrical connectors to the motor are brought out to the exterior of the canister through welded fittings. There are no openings for refrigerant to find.

But in an automotive A/C system the compressor motor is mechanically driven by a pulley that is in turn driven by the vehicle's motor and fan belt(s).

For the automotive compressor to operate, then, the rotating force of the compressor occurs via drive shaft: the pulley driven by the fan belt causes a compressor drive shaft to rotate.

The drive shaft passes into the automotive A/C compressor motor interior through a bearing that permits the shaft to rotate AND that contains a seal that tries to keep refrigerant from leaking out around the drive shaft.

But leaks at that point can occur, especially if the automotive compressor for the A/C system sits idle for months at a time (say during winter). Sitting idle, without its shaft rotating, lubricant around the shaft may dry out and refrigerant may leak out around that shaft.

So adding refrigerant to the automotive system is likely to be a far more-common event than in a home or business building air conditioner.

So the manufacturer provides quick-connect fittings for that purpose.

I've also found that on at least some automotive A/C systems if an untrained owner tries a DIY refrigerant re-charge and if she over-charges the system, the compressor includes an emergency over-charge or over-pressure valve that simply opens with a sort of hissing BANG! that will release a puff of refrigerant into the atmosphere (contaminating it, violating law, and contributing to environmental problems, but saving the compressor from ruin).

This same over-charge event could easily destroy a building A/C compressor - liquid slugging sends liquid refrigerant into the compressor, killing it.

In sum, an automotive A/C system might survive an untrained refrigerant re-charge effort by a vehicle owner, but a home A/C system is likely to suffer very expensive and permanent damage from liquid slugging.

What are the average number and type of COPPER fittings that go inside a commercial rooftop unit refrigeration piping system?

I wanted to know the average number of COPPER joints inside a commercial rooftop unit (avg size 25 tons of refrigeration)

OR

I was looking to understand the average number and type of COPPER fittings that go inside a commercial rooftop unit... I'm specifically looking at the fittings used for connecting the refrigerant piping inside the AC equipment itself.

I can count between 20 to 30 odd joints in this diagram...The number of fittings would help to arrive at an average number for joints, is my assumption.

Anybody who could throw some light on this...I would really appreciate. Thank you On 2017-07-28 by Jyo Gupta -

Comments by (mod) -

Jyo

Are you asking about all of the copper fittings in the rooftop unit or just the connections between the refrigerant piping to the unit itself? The latter is trivial.The former depends on the manufacturer's design and the A-coil design. There is not a standard one-off design nor number. We'd need to answer the latter question by looking at a specific rooftop unit design.

Meanwhile, sure it's reasonable to count fittings in the *theoretical* drawing you found of a rooftop HVAC unit and to use 20-30 piping joints as common.In part the higher number may be due to the illustrator's presumption that larger-sized copper pipes are more-likely to be in use in a commercial rooftop HVAC unit, so she assumed that the design would not use flexible copper tubing to make some of the bends and thus to avoid some of the elbows.

I'm not sure that a manufacturer would accept that in practice.

Followup by Jyo Gupta

Thanks for the insights, Daniel! That really helps.

I actually wanted to get a basic idea about the minimum number of copper fittings (connections) used to joint refrigerant piping between the cooling coil/evaporator and the compressor/condenser unit in an average-sized commercial rooftop unit.

And if possible to understand the break-up share by type (tee’s, elbows, caps) would be great.

I understand this number is rather trivial given that flexible tubing (to reduce no of fittings) would possibly be preferred by a rooftop unit manufacturer, but any idea nevertheless would be greatly appreciated.

Thanks for your help.

Do I still want a sight glass on a replacement refrigerant line?

Just changed my entire ac system .

Now have a matching 14seer 4ton Rheem system.

I had a sightglass in the old 3/8 freon line.

Do I still use the sightglass since I changed from freon22 to r410a ? ( yes it's an expansion valve coil ) On 2017-07-10

by Johnny P

Answer by (mod) - signs of low refrigerant

sure, Johnny.

The sight glass will show bubbles of gas and loss low refrigerant in the liquid line of the refrigerant piping system for virtually all refrigerant types.

...

Refrigerant Line Re-Use vs Contaminants

Question: OK to re-use refrigerant lines?

I have concealed 1/4 and 1/2 inch copper lines that feed my existing split case heat pump that recently died. Can I reuse these lines for a larger size heat pump system that says is needs 3/8 and 5/8 inch lines? My existing lines are embedded in the wall (Aug 19, 2012) Tom D

Reply: Larger diameter tubing is harmless but may need to adjust charge

Generally if the refrigerant piping is larger in diameter than needed that's not an issue except for having to calculate the refrigerant charge correctly. Lines that are too small may limit the system's operating capacity.

Question: cut and cap unused refrigerant lines?

I am demoing my ac unit. its old and i do not use it anymore. I wanted to know if i could just cut the copper lines and cap them in case i want a new on in the future. (Oct 2, 2012) John

Reply:

I agree that soldering a cap in place on the refrigerant lines makes sense to keep them clean for possible future use. It's a trivial and inexpensive step.

Question: concern for contaminants when re-using existing refrigerant tubing?

After meeting EPA requirements for demolition of a system, it is best to totally remove all system piping and not reuse it due to unknown contaminants which could damage a new system. (Nov 18, 2012) Dave

Reply:

Thanks for the opinion Dave. But of course when a new system is installed, a filter/drier is installed as a matter of course. And previously used, clean copper tubing that was kept sealed ought to be as clean as copper tubing that was sitting somewhere in a warehouse.

I'd agree however that if older copper refrigerant piping was damaged, corroded, or had previously leaked I'd junk all of it rather than use suspect piping on a new installation.

Dan

Safe to unhook old refrigerator tubing?

I have an old small deep freeze no longer any good I went to take the coils off back and the motor or whatever it is is it safe to unhook Arquette the copper tubing On 2020-05-07 by Deb -

Reply by (mod) -

Deb

If in the course of removing a freezer compressor motor or coils you break open the refrigerant piping, if there is refrigerant in the system you'll discharge it into the environment - a step that's illegal in many countries as it's a contaminant.If you keep them intact then you avoid that issue, but you may still need to contact your local environmental authority to ask how to dispose of that equipment.

The greater hazard is leaving doors on old refrigerators and freezers - a child hazard.

Question: solder suction and high pressure refrigerant lines together?

My refrigerant lines go about 10' vertically down the outside wall of my house. They are right next to each other.

If I solder them together would it increase the efficiency of my unit? It's a 3.5 ton R22 heat pump. Thanks. (June 29, 2012) JohnSmith

Reply:

In general I think the answer is yes. How about giving the manufacturer of your unit a call at their tech support number for confirmation that you're not creating any problem.

I wouldn't do it, however. I'd worry about creating oxidized crud inside the piping - which then fouls the refrigerant metering equipment, as well as increasing line rigidity, perhaps increasing damage risk, and certainly making future refrigerant line replacement more costly.

See details at

Can new condenser unit use old refrigerant lines?

I have an old Lennox A/C unit: it finally died. Can a new outside unit be replaced and still use all the existing lines that go into house? On 2018-06-24 by john

Answer by (mod) - Yes if ...

Yes if they are in good condition and are the right size for the new system.

...

Thank you to our readers for their generous comments

Good article for Air Conditioner Refrigerant Line Installation Requirements & Refrigerant Line Defects. On 2019-12-16 by Rohit Patel

Reply by (mod) -

Thank you Rohit; we're very grateful when you find our information accurate, useful, un-biased. We also welcome criticism, content suggestions, questions.

...

...

Continue reading at REFRIGERANT PIPING INSTALLATION - topic home, or select a topic from the More Reading links just below or see the ARTICLE INDEX.

Or see REFRIGERANT LINE SIZE or DIAMETER FAQs - more- questions and answers about refrigerant piping installation

Or see these

Air Conditioning & Heat Pump Refrigerant Piping Articles

- REFRIGERANT GASES & PIPING - home

- REFRIGERANT PIPING INSTALLATION

- REFRIGERANT PIPING DAMAGE & LEAKS

- REFRIGERANT PIPING GURGLING

- REFRIGERANT PIPING INSULATION

- REFRIGERANT LINE MOUNTING

- REFRIGERANT LINE NAIL PROTECTION

- REFRIGERANT PIPING LENGTH vs DIAMETER

- REFRIGERANT TUBING BRAZING & SOLDERING

- REFRIGERANT TUBING FLARE CONNECTIONS

- REFRIGERANT TUBING ECONOMIZER & HEATING TRICKS

- REFRIGERANT PIPING UNDERGROUND, BURIED

- REFRIGERANT PIPING CODES & STANDARDS

- REFRIGERANT PRESSURE DIAGNOSIS

Suggested citation for this web page

REFRIGERANT PIPING INSTALLATION FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.