Guide to Synthetic Boards for Deck Construction

Guide to Synthetic Boards for Deck Construction

- POST a QUESTION or COMMENT about using Trex, Boardwalk, ChoiceDek, WeatherBest, TimberTech and other synthetic deck boards for deck & porch construction

This article explains the selection and use of alternative deck and porch floor products such as Trex®, TimberTech®, wood-plastic composites, and plastic or vinyl decking products.

This article series discuss best porch & deck construction practices, including:

- choice of framing materials

- decking or flooring choices & installation

- how to select and use deck and porch structural and flooring fasteners

- actual deck & porch framing construction details & connections

- deck joist & beam span tables

- how to build leak-proof rooftop decks

- construction of covered & screened porches

- deck & porch railing construction & materials

- choices of finishes and stains for decks & porches

- past & current deck lumber preservative treatments with related health & environmental concerns

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Synthetic Decking for Deck & Porch Floors

Manufacturers have introduced a wide range of synthetic

decking products, most of which promise woodlike appearance

and low or no maintenance.

Manufacturers have introduced a wide range of synthetic

decking products, most of which promise woodlike appearance

and low or no maintenance.

Most fall into a few categories discussed below, but each has unique characteristics and installation requirements. In all cases, review the product specifications and, if possible, look at an installation before purchasing.

Our photo shows multiple broken synethtic deck boards on a Tivoli New York home that I inspected. I think that this failure occurred due to a combination of defective material and improper framing - wood support below the boards was rotted. (DF)

The owners had to remove this deck completely in order to provide a suitable replacement.

Wood-Plastic Composites for Decks & Porches

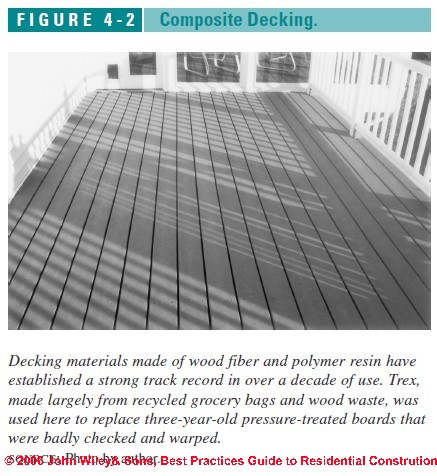

Decking materials made from wood fiber with polymer resin have been in use for over a decade and have generally established a strong track record. T

his article series includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

Also see our BOOK REVIEW of that book.

Many composite deck materials, like Trex®, use a high percentage of recycled materials.

Most wood-plastic composite deck boards have a solid profile and are sold in sizes that match and install like standard wood decking.

Watch out: not exactly like standard wood decking in the opinion of our editor (DF). Our photo, taken at the entry steps to a lumberyard in Minnesota in 2018, shows how easily a composite-deck board will snap right off if it is not properly supported.

If you use composite boards for stair treads (something I (DF) would be careful about), running the end of a synthetic or composite deck board wild over the end of a stair stringer risks a stair-fall injury when someone steps right on the wild-end, snapping it off.

The oldest solid composite decking on the market is Trex®,

but competitors now include Boardwalk® (Certainteed),

ChoiceDek® (Weyerhaeuser), and products from several

smaller manufacturers (see Figure 4-2 at page top).

The oldest solid composite decking on the market is Trex®,

but competitors now include Boardwalk® (Certainteed),

ChoiceDek® (Weyerhaeuser), and products from several

smaller manufacturers (see Figure 4-2 at page top).

Other synthetic decking products are extruded into a hollow 2x6 profile, such as WeatherBest® (Louisiana Pacific) and TimberTech® (TimberTech Ltd.).

These are generally lighter and stiffer than the solid materials, allowing spans up to 24 inches.

These typically fit together in a tongue-and-groove fashion, have built-in drainage systems, and use proprietary fasteners.

End caps and other accessories are used to trim out these products, and some include a modular railing system (Figure 4-3).

In general, composite decking materials are dimensionally stable, impervious to the elements, and can be worked more or less like wood. The solid products are installed like wood decking. Special screws designed for composite decking leave a clean hole without dimpling around the screw head.

Most solid products cannot exceed 16-inch on-center framing, and they feel a little bouncy underfoot due to the material’s greater flexibility (low modulus of elasticity) compared to wood. Some have an embossed wood-grain finish that may wear away over time.

With composite decking, no surface treatment is needed. Once the surface weathers, it bears a strong resemblance to weathered wood, but without the customary warping and checking.

Although these deck surfaces are largely

impervious to the elements and contain no food source for

mold or mildew, manufacturers do point out that a dirty

deck can support mold and mildew growth and recommend

periodic cleaning with a deck cleaner to prevent this.

Although these deck surfaces are largely

impervious to the elements and contain no food source for

mold or mildew, manufacturers do point out that a dirty

deck can support mold and mildew growth and recommend

periodic cleaning with a deck cleaner to prevent this.

Also, synthetic decking is vulnerable to oil and grease stains, which can be difficult to remove if not cleaned right away with a degreasing agent.

Vinyl and Other Plastics for Decks & Porches

A variety of manufactured decking systems are aimed at the commercial and do-it-yourself (DIY) markets. Materials include FRP (fiber-reinforced plastic), recycled HDPE (high-density polyethylene), and polyvinyl chloride (PVC).

Most of these products are available in a nominal 6-inch width and have an etched surface to provide traction and a wood-grain appearance. Most products are sold as a complete system with integral fasteners, end caps, and other accessories, making them well suited to the DIY market.

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

See STAIR CODES & STANDARDS for details about stair building codes and specifications.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Flashing was used over the joists - is this OK?

How would you feel if flashing was used over the joists (and headers)? I have seen references to flashing applied to the tops of the joints.

One reference was using felt paper but I would think an self adhesive ice/water membrane material would be better. There are some excellent flexible flashings used in the installation of windows and doors but they may not hold up over time with the movement between the composite decking and wooden joints due to temperature and moisture cycles.

Somewhere on this web site I believe I saw stainless steel flashing in use covering headers/joists. - On 2019-10-08 by Anonymous -

Reply by (mod) - flashing used over the joists (and headers)?

Indeed, Anon, on older decks we sometimes see rotted joist tops and I suspect that's mostly because the deck doesn't drain well (no gaps between deck boards) perhaps aggravated at decks with no air circulation below or built on or close to the ground;

In my OPINION felt paper as a joist top flashing isn't durable; copper or metal flashing works but is perhaps an unnecessary expense. Space the deck boards properly and use flashing where it's critical such as at a deck ledger and at deck-wall abutments.

Details are at DECK FLASHING

There you'll see Mark Morsching's discussion of using peel and stick membrane atop joists and at other locations.

Which type of deck boards are more rot prone?

Question: Which is more prone to rotting of the joists

a) tongue and groove (T&G) decking or

b) decking with open spacing between the deck boards?

It was recommended to me to use composite tongue and groove decking to prevent water from getting through the deck to the area underneath. I have installed composite T&G decking; however, water drips through the decking. Also, the overhanging ends of the composite decking have “curled” upward slightly due to expansion/swelling on the lower surface and/or shrinkage/contraction on the upper surface.

This causes water to pool on the deck which aggravates the problem.

The composite decking is not solid but has three hollow chambers at its core. Perhaps this also makes matters worse as any condensation within would again tend to wet the lower side causing expansion. The deck is about five feet up over the ground.

I would imagine that the interface between the decking and the joists is continually wet since water gets into and through the T&G joints and there is no air flow to assist in drying.

I now wonder if it would have been better to have used decking with a spacing between the boards to permit airflow around and through the boards.

I have seen decks with open spacing between the deck boards of around 5/8”. Beside assisting airflow, a wide spacing would have less of a tendency to “trap” debris (particularly on the joists) and would permit periodic cleaning of the exposed portion of joists. - On 2019-10-07 by Anonymous -

Reply by (mod)

Anon

In my OPINION a deck with gaps that assure drainage ought to be more rot-resistant provided that all other factors (wood species, wood treatments, air circulation below deck, sun vs shade exposure, etc.) remain identical.

However I add that the Two Harbors MN Summerblue state that we built many years ago using treaded 5/4 tongue and groove deck boards has lasted without rot to date.

See details at DECK BOARD GAPS & SPACING

Question: synthetic decking manufacturers to avoid?

(Apr 10, 2014) bill c said:

We are about to replace a front porch and we are considering using composite boards. do you know of any manufacturer that we should avoid because of poor results and durability?

Reply:

Thanks for the important question, Bill C. I have added citations and research information on the durability of composite lumber of several types into the article

...

Continue reading at SYNTHETIC & COMPOSITE DECK SOURCES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see

Recommended Articles

- COMPOSITE LUMBER DURABILITY

- DECK DESIGN & BUILD - home

- DECK FLASHING

- ROT-RESISTANT Deck Lumber & Flooring

Suggested citation for this web page

SYNTHETIC & COMPOSITE DECK BOARDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Prescriptive Residential Wood Deck Construction Guide, based on the 2009 International Residential Code, American Forest & Paper Association, Inc., provided by reader Mark Morsching from Everflashing.

- Mark Morsching, Everflashing, Tel: 800-550-1667, Email: everflashing@gmail.com. The Everflashing product comes in G-185 and Stainless Steel and is intended for use with treated lumber with copper in it. Everflashing produces a variety of specialty flashing products including flashings for use with decks at deck ledgers and deck perimeters.

- Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.