Drain Back Valves & Snifter Valves

Drain Back Valves & Snifter Valves

AVCs,Water Tank Air Volume Controls, & Snifter Valves as Well Pipe Freeze Protection Devices

- POST a QUESTION or COMMENT about sifter valves, Dill valves, and how the snifter valve works together with US Gauge & Similar Type 310WJ, Type 300SL, or Type 6 Rectangular Air Volume Controls

Drain Back Valves, Bleed-Back Systems & Snifter Valves for Well or Lake Pipe Freeze Protection & Air Volume Control:

This article series describes snifter valves and drain-back valve , what they are, how they regulate air in a well water system, how they work with an air volume control,& how these components protect well piping against freezing. We describe how & where the snifter valve, drainback valve and air volume control are installed & what they look like.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Snifter Valves, Drain-back Valves, & Air Inflators Offer Protection From Well Pipe Freezing & Air Volume Control

Snifter valves & drain-back valves along with AVCs are a three-part air volume control system designed to allow water to drain out of well piping and back into the well while also maintaining water pressure in the building and the air charge in a well water pressure tank.

These devices are used on some submersible pump systems or lake water supply systems where a bladderless water tank is installed and where well piping is exposed to freezing.

This article discusses how snifter or bleed-back valves are maintained, replaced, or in some cases how and when they can or should be eliminated.

Article Series Contents

- SNIFTER & DRAIN BACK VALVES

- DRAIN BACK / BLEED BACK VALVE / SNIFTER VALVE PURPOSES

- DRAIN BACK & SNIFTER VALVE SYSTEM COMPONENTS

- DRAIN BACK & SNIFTER VALVE OPERATION

- DRAIN BACK / SNIFTER VALVE TROUBLESHOOTING

- DRAIN BACK & SNIFTER VALVE INSTALLATION / REPLACEMENT

- DRAIN BACK / SNIFTER VALVE CONVERSION to BLADDER-TYPE WATER TANK

- DRAIN BACK / BLEED VALVE / SNIFTER VALVE SUPPLIERS

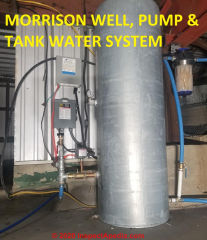

- MORRISON WELL SYSTEM FUNCTION & REPAIR

[Click to enlarge any image]

Why are Drain Back Valves & Snifter Valve Air Type Volume Control Systems Used?

There are three reasons why a snifter valve & drain-back valve may be used along with a submersible well pump, bladderless-type water tank, and check valve.

- Water line freeze protection:

the main one is to allow water to drain out of well piping and back into the well to prevent freezing of well piping that is not buried below the frost line.

Drain back valve systems may be used to freeze-protect water supply piping from drilled wells (well bores) or from other water sources such as freshwater lakes in freezing climates. - Air supply to the pressure tank:

a second feature of drain-back / snifter valve systems is the injection of air into the water pressure tank, a process that involves further air management by an air volume control valve that will vent excess air from the tank. - Water odor & taste improvements:

A third feature claimed by some installers is a reduction in both iron and smelly sulphur odors, though the level of this benefit is questionable.

Snifter Valves, Air Inflator Stems, & Drain-Back Vents Inject Air Into the Well or Lake Water Piping System

Synonyms for this well pipe freeze protection system include: snifter valve system, drain-back valve system, bleed-back system, well pipe freeze protection system, bladderless water tank air injection system as well as Brady valves or Dill valves.

In our well pipe freeze protection system photo (above left) the green arrow points to the air release valve opening on the water tank's air volume control (AVC) and the red arrow points to the snifter valve air inlet fitting mounted on a check valve. Below: my finger points to the snifter valve at its mount on the check valve.

We give a closer look at these components shortly.

Snifter valves (photo above right, shown mounted on the 1/8" tapping on a check valve) provide an air inlet, typically located on a check valve on the water line near the bladderless water pressure tank. The air inlet snifter valve works in concert with a water drain-back valve (a bleeder orifice) that you cannot see - located on well piping inside the well where a submersible pump is used.

At the end of a well pump on-cycle (when the well pump stops) this snifter air valve mounted on a check valve on the well line ahead of water pressure tank opens to allow air into the well piping.

This incoming air allows water to drain out of the well piping at the drain-back valve: a bleeder fitting mounted on a tee on the well piping, inside the well.

A photo of the drain back bleeder mounting tee on the well piping is shown at below left. We've pulled the piping out of the well for this photo. A close up of the drain back bleeder valve itself is shown at below right.

A check valve located near the bottom of the water tank on the incoming well piping (on which the snifter valve is mounted in our photo) keeps water in the pressure tank from draining back down into the well when the well pump has stopped.

Because the snifter valve system will usually push more air into the water tank than is needed, an air release valve mounted on the water pressure tank is also installed to purge excess air from the water tank as necessary. So if you hear air hissing from the air purge valve, that's normal.

Watch out: The snifter valve stem looks like any other air inlet valve but it uses a weak internal spring to allow the valve to open on its own, admitting air into the piping. DO NOT tighten the valve stem cap found on the snifter valve and don't replace a vented valve stem cap with a solid plastic one - if you do so your well pipes may freeze to death.

That's because if no air can enter the snifter valve, no air can enter the well piping and the well pipe freeze protection system won't work. If you find water leaking out of the snifter valve it needs repair or replacement.

Air introduced by a snifter valve / bleed-back system may reduce unwanted tastes, iron or odors of sulphur in the water supply

Rasmussen points out that in Northern Minnesota and on water systems in other very cold climates, the system's ability to drain water back into the well, leaving just air in the higher sections of well piping can help protect a well system from freezing.

According to our well driller friends, on water systems whose well provides water high in smelly hydrogen sulfide (that rotten egg smell) or perhaps high in iron, the high absorption of air into the well water provided by this design might help oxidize and thus reduce those contaminants in the water supply.

By contrast, a bladder type water pressure tank keeps the water supply physically separate from the pressure tank's air charge - air is never absorbed into the building water supply and other treatment methods would be needed to remove sulphur, hydrogen sulfide, or high iron levels.

Really? We have read this claim in several articles about drain-back or bleed-back systems but have not [yet] found research supporting the claim that added air induction into the well water system was alone able to remove significant levels of iron (FE) nor hydrogen sulfide (H2S). Contact us if you've found such data.

We are not confident that air injection ALONE will cure a serious sulphur odor in the water supply.

More likely we'll need to install a treatment system such as a potassium permanganate "green sand as the plumbers call it" system or a chlorine injection system, combined with filtration, or some equivalent.

Drain-Back Systems Work with Submersible Pump Systems

But the use of a drain-back system to prevent well piping systems is long established as a method that works on well water supply systems that use a submersible pump and a bladderless type water pressure tank.

Why only with submersible well pumps? If we drain the water out of well piping in a jet pump system the pump is going to lose prime and may be unable to re-prime itself, thus losing water supply and risking pump burn-up.

Why with bladderless type water pressure tanks: those tanks can be fitted with an AVC or air volume control that will release the excess air allowed into the system by the drain-back valve and snifter valve.

Drain Back Valve, Dill Valve, & Snifter Valve Components, Definitions & Functions

This discussion has moved to a separate article

at DRAIN BACK & SNIFTER VALVE SYSTEM COMPONENTS

How the Drain Back System Actually Works on Well or Lake Water Piping to Protect from Freezing & to the Keep Air Charge in the Pressure Tank

The bleed-back or drain-back system on a water piping system works automatically to drain water out of piping between the water pressure tank or check valve and the bleed back or drain back valve opening found on the well or lake water piping in the well casing or at a level below the frost line. By allowing air to enter the piping system it is protected from freezing.

Details are at DRAIN BACK & SNIFTER VALVE OPERATION

Troubleshooting Frozen Well Pipes on Drain-Back Valve, Dill Valve, & Snifter Valve Systems

Now found at DRAIN BACK / SNIFTER VALVE TROUBLESHOOTING

Drain Back Valve & Snifter Valve Installation, Repair or Replacement

Moved to DRAIN BACK & SNIFTER VALVE INSTALLATION / REPLACEMENT

Converting a Bladderless Water Tank to a Tank with an Internal Bladder? Remove all the Snifter Valve Components!

[Click to enlarge any image]

In our snifter valve photo (above Rasmussen Well Drilling, Inc., Two Harbors MN & DJ Friedman) ) my finger points to the stem of the snifter valve: an air inlet valve mounted on a bronze check valve.

Stains on the floor show that there has been leakage at this particular valve.

In that photo we have a clue that the snifter valve had not worked for years and was also leaky. You can see the copper stains on the floor below the valve (my finger points to the snifter valve stem). How did the owners get away with this? Their well piping was buried at more that eight feet below ground: below the frost line in their areas of Northern Minnesota.

So the owners didn't have a problem with freezing well piping. But they did report a long-standing problem with a water-logged water pressure tank whose well pump short-cycling shenanigans had been dealt-with by manually adding air to the pressure tank at frequent intervals.

Because the well piping between the well bore and the building was buried sufficiently to eschew the worry about freezing well lines, the owners decided to tackle the recurrent short-cycling problem of their well pump not by replacing the snifter valve (which was the real culprit) but by replacing the steel bladderless water pressure tank with a new internal bladder water pressure tank.

To complete that installation the well-plumber would keep a check valve at the pressure tank outlet but remove the snifter valve and he'd also have to remove the drain-back or bleed-back valve located in the well piping.

Watch out: if on a submersible well pump system that uses a snifter valve for air volume control you later convert a bladderless water pressure tank to a tank using an internal bladder, you should remember to remove both the snifter valve located on the check valve near the water pressure tank and the bleeder orifice or drain-back valve located on the well piping.

If you fail to remove these components you will suffer from constant air discharge at the building faucets and other plumbing fixtures as the air injected into the piping system will be pushed into the water-containing bladder in the new pressure tank: a location from which there is no escape as there is no air volume control and no mechanism to remove this air on an internal-bladder pressure tank set-up.

See AIR DISCHARGE at FAUCETS, FIXTURES

Drain Back Valve & Snifter Valve Suppliers

- "Drain Back Standard Pressure Tank Fittings Kits", Dean Bennett Supply Co., 1770 East 69th Ave., Denver, CO 80229, USA, Tel: 1-800-621-4291, Email: pumpsdbs@aol.com Website: www.deanbennet.com, retrieved 25 Feb 2015, original source: http://www.deanbennett.com/drain-back-tank-fittings.htm

Excerpt from product description:

The drain back tank fittings kit is designed for use with galvanized standard type pressure tanks. These tanks are used where the well water line will freeze if not drained.

The drain back fitting kit allows the water to drain back into the well from the home to prevent the water line from freezing.

The 2 hole check valve at the standard pressure tank, has a snifter valve, similar to a valve stem on you car tire.

The drain back valve in the tee placed in the drop pipe in the well below frost level, allows the water to drain back to the well.

The snifter valve allows air into the line to allow the water to drain back to the well. Your water line is always empty, when it has drained back.

Each time you turn the pump on, the line is full of air, and the air volume control, installed into the tank bung half way up the tank side, allows the excess air to escape from the tank prior to pressurizing. - FloMatic® Valves, 15 Pruyn's Island, Glens Falls NY 12801, Tel: 518-761-9797, Website: www.flomatic.com, retrieved 25 Feb 2015, original source: http://www.flomatic.com/assets/pdf_files/oem/16016.pdf Excerpt from the product description:

The Model 70 Automatic Drain Valve automatically opens to atmosphere when water system pressure drops below 10 (psi).

The spring-loaded drain valve operates hydraulically and is designed to close thru the water flow velocity in the pipe. The drain valve will provide automatic drainage of pipe water lines in a water system when the line pressure drops below 10 psi. No adjustments are necessary. *Lower then 10 psi drain is available (5psi).

The Model 70 Automatic Drain Valve may be installed in any position, vertical or horizontal.

The Model 70 Auto Drain Valve is recommended to be installed in a 1” NPT pipe tee fitting (See Fig “A” for typical installation). The pipe tee shall be located in a 1” or 1 ¼” water well drop pipe between the submersible pump and ground level.

The pipe tee’s location shall be a maximum vertical distance of 18 feet from the closest drain faucet in the water system.

No check valve can be installed in this pipe section that would prevent water system drain-back. - "Drain-Back System: water leaves the line", Cottage Life, Nov/Dec 2000, 43-44, retrieved 25 Feb 2015, original source: http://www.cottagewatersupply.com/CottageLifeExcerpt.pdf

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-07-13 by InspectApedia-911 (mod) - drain back system with an internal bladder tank in northern Minnesota

@Frank,

Thank you for the additional photos and discussion.

When we replace a drain back system with an internal bladder tank at a building in northern Minnesota, an area also subject to very cold freezing conditions, the line between well and building was buried below the frost line so we weren't worried about Frozen well pipe. We made the change in part because we needed a new pressure tank anyway.

In the case that you describe, while the conventional bladder type water tank and elimination of drain back valves and sniffer valves seems to simplify the system, you could face a risk that in a time of power outage your well line could freeze and take considerable time possibly having to wait until spring, to thaw.

So your discussion is a reminder of the value of a drain back system in very cold climate as a method to avoid frozen water supply piping between well and building. It's a nice solution that, as it doesn't require a heat tape and electrical source for the heat tape, doesn't require that electrical power stay on past the time that the pump last ran.

On 2022-07-13 by Frank

@InspectApedia-911, Hello, Thanks so much for your reply. The fitting on top of the pump looks like the fitting in the house where the snifter valve is screwed into. Maybe the same fitting was used for both but the one on the pump was plugged with a screw plug instead of having a snifter valve. See photo.

Then possibly it corroded and left the hole and then the pump wasn’t able to successfully fill the tank because of spray out from that hole. I plugged the hole and the system seems to be working fine now. When the pump cuts out I hear a hiss from the snifter valve inside so water is draining back down to the well and air is filling in the pipe. I also know the pipe is filling with air when water is draining back because the next time the pump comes on air is pushed into the system to pressurize the system again.

As far as the ball type drain back vale there definitely isn’t one on my black plastic piping. The piping is about 10-12 feet from the ground to the bottom of the well where the submerged pump is. See photo. If I blow on to of the pump fitting air does go out of the pump. Maybe a ball type valve wasn’t needed for my system? Maybe there isn’t any check valve at the pump and water can just drain back from the pump intake?”

Anyway, I’m thinking of replacing my system with a bladder type system and 40 feet of heat line. What is your thoughts/opinion about that? I just got a quote here in Ontario Canada to do that for $2,500 including tank, heat line, and all fittings and labour. Does that sound reasonable? Thanks again, Frank.

On 2022-07-12 by InspectApedia-911 (mod) - drainback system components

@Frank,

Thanks for the helpful question and photo.

A drain-back system has two components:

1. a low-spring-pressure schrader valve above-ground, usually close to the water pressure tank, often on well piping hear the tank (photos above on this page), to allow air to enter the system at the end of a pump-on cycle.

2. a drain-back valve, a one-way ball type check valve (usually) in the well, on piping, above the high water level in the well, to allow water in the well pipe above that point to drain slowly back into the well at the end of a pump-on cycle. This drain-back is what draws air in at the Schrader valve.

Notice that this valve will not normally be close to the submersible pump, it'll be quite a few feet above that point, since the pump will be under-water in the well while the drain-back valve will be above the high-water line in the well.

So I'm unclear what was the purpose of the hole you found on fittings just above the pump. Was it an obvious, deliberate opening, or due to corrosion?

When I click to enlarge your photo and zoom-in, that hole sure looks like a corroded opening, not a deliberate one.

Was the hole smooth-sided or threaded?

And higher on the well piping did you find the drain-back valve itself, out of the water, and similar in appearance to the valve shown at the top of this page?

I don't expect water to drain back through a pump's intake opening; usually the pump will contain one or more check valves. But then none of us knows it all.

On 2022-07-12 by Frank

Hello, I have a drain back system at my cottage. One day I noticed I wasn’t getting water coming in at a normal rate to fill my tank. I could hear the well’s submerged pump running tho. I looked in the well and saw a hole in the fitting on top of the pump. This is where water was spraying out of and therefore the pump couldn’t successfully fill my tank, see image.

I plugged the hole with JB weld and it’s holding ok for now.

While I was in the well I didn’t see any drain back valve on the piping.

My snifter valve seems to be working since I hear a hiss when pump stops.

Could the water in my system just drain back from the pump’s intake and if so is that acceptable?

Thanks,

Frank.

...

...

On 2021-04-02 by (mod) -where & how to buy replacement snifter valve or well drain-back valve parts

Thanks, that's a helpful question about replacement snifter valve "size".

Size of the air inlet snifter valve at the pressure tank

At or near the water pressure tank, the air inlet or snifter valve outlet is a standard size, either a 1/4" MNPT or 1/8" MNPT depending on the size of the tapped or threaded fitting into which the snifter mounts on your well pump system - and sold by your well or plumbing supplier.

Watch out: At the water pressure tank, the air inlet snifter valve fitting looks like a standard Schrader valve or tire valve, and its size and threads are identical, and so it also looks exactly like the air pressure adjustment valve found on many water pressure tanks. But it is NOT. The difference is in the spring used on the actual valve core.

Because the air inlet needs to open at a lower pressure range than a tire valve, the spring is a "weaker" one and is special to and sold with that device, also purchased from your well or plumbing supplier.

Examples of the air inlet snifter valve with a "light spring" are the

Campbell Snifter Air Valve with Light Spring - sold in both 1/8" MNPT and 1/4" MNPT sizes and shown below.

Another brand is made by A.Y. McDonald - the company's Pump Snifter Valve also sold in two models:

A.Y. McDonald 6512-372, Model 7891, Snifter Valve, 1/8 Inch

or

A.Y. McDonald 6512-373, Model 7892, Snifter Valve, 1/4 Inch

Size of the Bleeder Valve or Drain-Back Valve in the Well

An example of the in-well snifter valve component - the water outlet or "bleeder valve" or drainback valve, also referred to as a "Bleeder Orifice" is this rubber version sold by plumbingsupply.com

Usually sold as a 3/4" MNPT sized device this is installed in the submersible pump drop pipe, approximately 10 to 12 feet below the well head.

The manufacturer notes that this bleeder:

Provides fast water bleed capacity through its large orifice opening when pump shuts off

Orifice completely closes when the pump is running and prevents loss of pumping volume

Molded virgin rubber construction

And shown below, these brass well bleeder valves, like the rubber bleeder valve shown above, and also sold as 3/4" MNPT threaded devices are also used as the traditional and most-common drain-back valve in the well.

These are an exact replacement for the 30 year old brass drain-back valve shown in the article above on this page.

These brass bleeder valves are available from your local well or plumbing supplier as well as from online plumbing suppliers such as the Denver WinPump Company at denverwinpumpsales.com

On 2021-04-01 by Gene Heard - How do I know what size sniffer valve I need

How do I know what size sniffer valve I need to replace the one I have? Also, will a regular valve stem from a car tire work to replace the one that's gone bad in mine. Just the stem, not the whole valve.

On 2020-11-15 by (mod) - Can a snifter valve let in too much air

Yes, Tom

The snifter valve works in concert with a vent or AVC on the pressure tank designed to let out the excess air; so if that AVC is not working you may end up with excess air in the system that is discharged at a nearby faucet

On 2020-11-15 by Tom Purnell

Can a snifter valve let in too much air and cause air at faucets in my deep well system?

On 2020-10-19 by (mod)

Interesting;

Interesting;

I just spent the day learning about another way that all this air can be vented back to the well in a drain-back system; you might want to take a look at

MORRISON WELL SYSTEM FUNCTION & REPAIR

On 2020-10-19 by James

And the Sulfur and taste has gone away in my water. That could be that I use more water now and the well does not sit unused for weeks and months at at a time

yes the noise is the biggest problem , If I am not going to have too much air in the tank. It seams like over 130 feet of 1" pex holds too much air volume for the small AVC on the tank to handle.

The larger vacuum breaker was my well guys suggestion so that in very cold days the water drains back faster.

I was over thinking it and in the warmer months . just shut off the Vacuum breaker . snifter valve and keep the pipe Full.

On 2020-10-18 - by (mod) -

James

Thanks, that's an interesting well problem to figure-out.

Usually an air-release valve on the AVC on the pressure tank is there specifically to release the excessive air that may be sent back to the pressure tank from the snifter valve system at each pump-on cycle.

If that valve is present and working on your AVC then there ought not be a problem of too much air in the tank.

So what's left is the annoying noise of air entering the tank bottom?

Have I misunderstood something?

On 2020-10-18 by James

I have a Deep well 500 feet and a Drain Back setup , but the amount of AIR interring my 82 gallon galvanizes tank is over 3gallons by volume, the well is 130 feet down hill from my basement . I get a very loud Burp when the air his the bottom of the tank.

I need a way an Automatic Air Vent to let off this large volume before it enters the tank. I have not found one in hrs of internet searching and letters written to suppliers and Manufacturers. Can you help?

I put in a larger Vacuum breaker to help the water drain back to . the Snifter Valve was too small and the water risked freezing in the pipe as its only possible to cover the pipe 18" over some of the Granite on it way back to the Well

On 2020-06-06 - by (mod) -

Adding that from your earlier comment I infer that your water pressure tank is waterlogged or has lost its air charge.

On 2020-06-06 by (mod) - air valve located at the well casing: what for?

Jean:

Jean:

If the rusty pipe we see in the center of your photo, to which the black-capped schrader valve is attached, is connected to a buried water pressure tank it may have been for restoring the air charge to a bladderless water pressure tank buried near your well

- an unusual and in my opinion poor installation as it makes servicing the tank or replacing it expensive and it may reduce the tank life (by burying it).

If this is the case you'd simply use a canister of air or even a simple bicycle pump to add air to your pressure tank by connecting the pump or tank to the Schrader valve shown in your photo (yellow arrow added by us).

If the air valve is connected simply to a pipe teed off of the well piping between the well casing (at left in your photo?) and the house, it could be an air inlet valve like the snifter valves discussed on this page. .

Can you confirm that your water tank is really buried near the well?

For diagnosing a pump that turns on and off too rapidly see the advice

at WATER PUMP SHORT CYCLING

On 2020-06-06 by Jean

Sorry here’s the image of the valve [photo above]

I have pump short cyclying - pressure guage moves between 35 - 60 in 5 seconds. The pressure tank is buried outside the house. House was built in 1971.

How do tell what type of valve it is? See attached impage

How to drain water out of a buried tank? Or add air to it

Thanks!

On 2019-11-27 by (mod) - what type of water tank works with a drain-back freeze-proofing system?

On 2019-11-27 by (mod) - what type of water tank works with a drain-back freeze-proofing system?

Arch.

This illustration of the key parts of a snifter-valve and drain-back system is adapted from Dean Bennett Supply in Denver, Colorado - retrieved 2019/11/26 original source: www.deanbennettsupply.com/drain-back-pressure-tank-systems.html

Of course you should be able to find all of these parts at your local well and plumbing supplier as well.

www.deanbennettsupply.com/drain-back-pressure-tank-systems.html

Case 1: need a drainback system to avoid freezing water pipes:

Yes, Arch, with a drain-back well pump and tank system, the drain-back components (air control at the tank, snifter valve, drainback valve in the well) work together with a bladderless pressure tank.

The components for a drain-back well pump system include:

(1) a well pump pressure control switch and

(2) brass nipple to mount the switch on well piping, at the pressure tank, or on the check valve (4)

(3) the snifter or air inlet valve, a schrader type valve or air valve that permits air to enter the well piping at the end of a pump-on cycle; this valve also often mounts on the tank or right on the check valve (4)

(4) a check valve that prevents water in the pressure tank (and house piping) from all draining back into the well

(8) a drain-back tee that is installed on well piping in the well, above the high water line

(8) a drain-back valve that allows water to drain out of the tee and into the well at the end of a pump-on cycle.

(not shown) a bladderless (no internal bladder) water pressure tank

I would stay with a bladderless pressure tank; otherwise you may find (using an internal-bladder type tank) air discharge at the fixtures every time your system cycles on and off.

Also see this older and less-common drain back system:

MORRISON WELL SYSTEM FUNCTION & REPAIR

Case 2: don't need drainback: (on an well system whose water pipes are all below the frost line)

On an older well that used a drainback system we demonstrated that one can use a pressure tank that uses an internal-bladder;

However when converting that older set-up that previously used a bladderless water pressure tank we had to remove the drain-back valve that's found in the well on the well piping riser.

Above is a photo of the key parts of a snifter-valve and drain-back system, sold by Dean Bennett Supply in Denver, Colorado (but of course you should be able to find all of these parts at your local well and plumbing supplier)

See more details at

DRAIN BACK & SNIFTER VALVE OPERATION

On 2019-11-27 by archbald

Is a bladderless pressure tank (instead of bladder tank) required for using with a "drain-back" set up for water piped from a well I have an existing tank that is failing. It is in a cold climate. It is set up as a "drain back" system, so it has a Schrader valve.

When the tank reaches its max psi, the pump shuts off, and the Schrader valve allows the water to drain back from the tank and back down into the well.

The pressure tank in a shed 20' from the well head. The 20' of horizontal underground pipe to the well head is NOT below frost line (too much underground rock). That's why there is the drain-back apparatus. The tank is old and corroding; needs to be replaced.

QUESTION: I think, for a "drain-back" set up, you HAVE to use a bladderless tank. Is this correct? Any recommendations for a brand/model? Thank you for any info you can provide.

On 2018-11-25 by (mod) -

Gary,

The purpose of a snifter valve is to keep the air charge in a water pressure tank for pressure tanks that do not use an internal bladder.

Therefore you would not normally use a snifter valve on a bladder type tank water system.

However if you need to install a drain back system in order to prevent frozen water pipes to a well it may be possible to install both the drain back valve in the well and the snifter valve on well piping inside the building near the water pressure tank.

What will happen is excess air will be sent by that system into the water portion of the bladder tank. That are in turn will eventually emerge at faucets and fixtures when you run the water.

So it's a rather hybrid system. I think that would work but if I were going to install that I would discuss the plan with the tank manufacturer because they may have a suggestion about venting some of that excess are ahead of the fixtures.

On 2018-11-22 by gary osterman

can you install a drain back valve and sniffer valve with a bladder tank?

On 2017-10-30 by DAG

I have an HP-9 pressure tank which was installed about 10 months ago in a new house with a new well. Well water stunk of hydrogen sulfide gas and this system was recommended.

It worked for 8 months and then starting experiencing bursts & lulls when faucets were turned on. Well man said the "Micronizer" needed adjustment.

When he got here he said the tank was water logged. He has now made multiple trips out to adjust micronizer, replaced micronizer twice, changed out "O" ring, drained and filled back with air each time. This rights the system for about 4 days and then all the water logged symptoms return.

The manufacturer said it is the AVC but as your article points out and the well man says "the AVC only function is to release excess air".

The well man says that the way I use water is why this is happening. I ask him why it worked for the first 8 months - seems more like something is defective. He said the pressure is not dropping enough to put air into the tank.

I really need some help/advice with this issue as I am getting nowhere with the manufacturer or the well man and in the mean time I am sure this has put a huge strain on my well pump motor for the last two months.

On 2017-09-27 by Doug

Maybe you can help,i have a deep well with a bladderless tank.Where the snifter valve should be next to the check valve there is a plastic stem attached.There don't seem to be a scrader valve inside that I can detect,but every time the pump runs a vacuum is present at the top of the plastic tube.I have looked on the web for this plastic tube/valve and can't find it anywhere.

On 2017-01-19 by JR

I replaced a bladder less tank for a bladder tank. But did not know I needed to remove the bleeder valve in the well piping. I removed the snifter valve and air volume control in fact I re-piped all above ground piping. Everything was ok for a month or so but now I am getting air in the faucets as you mentioned above in the WATCH OUT.

I do not want to go through trouble and or have the money to pay a big bill on having a well person come pull the pump out and remove the bleeder valve. I read that if I remove the check valve that I installed before it goes into the tank, then there will be water constantly in the the well down pipe thus preventing the bleeder valve to open.

This will be a temporary fix until it it time to replace the pump then I will remove the bleeder valve. thanks in advance!

On 2016-09-27 by jamesroberts

My water gets milky at the tank, but air clears out after a couple of cycles. So I turned the pump off and allowed the water to drain.

At about 10lbs, air comes out of the air volume control valve until the pressure equalizes. As the water continues to fall in the tank, air starts to draw back in replacing the water.

I turned the pump back on and checked the fresh water, no air, its clear. A few days later there's air in the water valve at the tank again. Should the air valve between the well and the tank have a cap on it?

On 2015-12-26 by (mod) -

Cliff

Check the piping layout and look for valves - it sounds as if air is not entering the pressure tank. You could have a check valve problem.

On 2015-12-26 by cliff

What does it mean when I have drained all the water from a fiberglass no bladder tank and try to put air back into the system, and it won't pump up because the air is going back into the well?

I have done this before to stop frequent pump starts and the air pressure pumped up to 40 pounds. Thanks

Question: snifter valve air volume control systems can remove iron and sulphur from water?

(Jan 22, 2014) joe said:

Hello I am writing about the snifter valve. If you read your article on why are snifter valve air volume control systems used one it states that the high absorption of air into the system helps oxidize and thus reduce hydrogen sulfide or perhaps iron. But in your last email to me you said it would not. So you have me confused. Thanks for your reply. JOE

Reply:

Thanks so much Joe, I will review these articles and fix that inconsistency.

Honestly, I am sure that I added the statement to which you refer while I was reviewing research about snifter valves, but in replying to your email I simply forgot about it.

You were right, I was mistaken. However we need some clarification:

A snifter valve is only used on deep wells that are operated by a submersible pump AND that feed water into an older-style bladderless expansion tank. The snifter valve, installed in the well piping lets air into the system at each pump on cycle. A companion vent valve installed above ground, close to the pressure tank, or in some cases ON the pressure tank, vents excess air out of the tank to keep the tank's air charge at the proper level.

A water supply system that uses a "captive air" type water pressure tank that incorporates an internal bladder does not need this automatic injection of make-up air, so will not have a snifter valve.

In fact when a plumber converts a water supply system from bladderless-tank to internal-bladder tank, s/he needs to also pull the well piping and remove the old snifter valve if one was installed. That is what was going on in my photo series about snifter valves.

So if your water system uses a bladder type tank you wouldn't have a snifter valve installed.

Finally, and here is where we need to do more research, despite the claims of the snifter valve camp, I am doubtful that air injection ALONE will cure a serious sulphur odor in the water supply. More likely we'll need to install a treatment system such as a potassium permanganate "green sand as the plumbers call it" system or a chlorine injection system, combined with filtration, or some equivalent.

Do keep me posted, and thank you VERY much for helping me out with clarity and pointing out an inconsistency on this topic.

Question: to drain the water line I should open the cap on the snifter valve?

(Oct 13, 2014) Ray said:

I recently had a new well installed, drilled w/ a submergible pump. a internal bladder tank was installed .

I was concerned about the water in the tank and water line freezing in the winter , so a sniffer valve was installed on the the check valve.

I was told when shutting the system down for the winter, to open and drain the water tank, and to open the green valve cap on the sniffer/check valve to introduce sir to the system , that would allow the water in the line to drain back into the well.

Will this advise work? is their any problem with the sniffer valve installed with an internal bladder water tank? thank You

Reply:

Yes there's a possibility that the advice you were given will work, Ray. But just removing a valve cap won't do it. That cap is supposed to be loose and able to admit air at all times.

You shouldn't have to open the snifter valve (found on a check valve usually mounted at the bottom of the water pressure tank) as it should open to admit air on its own - at the end of a pump-on cycle.

If your snifter valve is not working it probably needs a replacement. If you're replacing just the valve stem core don't buy one at your auto parts store - those schrader valves and valve cores operate at different (higher) pressure ranges and are not designed for this application.

...

Continue reading at DRAIN BACK & SNIFTER VALVE SYSTEM COMPONENTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AIR DISCHARGE at FAUCETS, FIXTURES

- AIR VOLUME CONTROLS, WATER TANK

- SNIFTER & DRAIN BACK VALVES

- DRAIN BACK / BLEED BACK VALVE / SNIFTER VALVE PURPOSES

- DRAIN BACK & SNIFTER VALVE SYSTEM COMPONENTS

- DRAIN BACK & SNIFTER VALVE OPERATION

- DRAIN BACK / SNIFTER VALVE TROUBLESHOOTING

- DRAIN BACK & SNIFTER VALVE INSTALLATION / REPLACEMENT

- DRAIN BACK / SNIFTER VALVE CONVERSION to BLADDER-TYPE WATER TANK

- DRAIN BACK / BLEED VALVE / SNIFTER VALVE SUPPLIERS

- MORRISON WELL SYSTEM FUNCTION & REPAIR

- WATER PUMP SHORT CYCLING - home

- WATER TANK AIR INLET VALVE - separate air valves used to manually adjust water tank air pre-charge pressure

- WATER TANK AIR VOLUME CONTROLS

Suggested citation for this web page

SNIFTER & DRAIN BACK VALVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS & SPRINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] U.S. Gauge Special Application Gauges: Type 300L and 310WJ Air Volume Controls, product description, 2002, Ametek® Inc, U.S. Gauge, 820 Pennsylvania Blvd., Feasterville PA 19053, USA, Tel: 215-355-6900 www.ametekusg.com Customer Service: 863-534-1504, web search 03/23/2011, original source: http://www.jlwinstruments.com/PDF_files/D17_MODEL300-310.PDF Sadly this URL now reroutes to a dead end

- [2] AMTEK, 900 Clymer Avenue 8600 Somerset Drive Sellersville, PA 18960 U.S.A. or Customer Service at AMTEK, Largo, FL 33773 U.S.A.Sales/Technical Support: 215-257-6531, Customer Service: 727-536-7831, Website: www.amtekusg.com, Email US Gauge at usg.sales@ametek.com.

- [3] flosource.com/ provides links to some US Gauge air volume control products installation and adjustment

- Rasmussen Well Drilling, Inc., 1793 Hwy 61, Two Harbors MN. Jeremy Rasmussen provides third generation well drilling and plumbing services on the North Shore of Lake Superior. Photos by DJF. Tel 218-834-3387. Email: rasmussenwell@frontier.com

Quoting: We serve the north Shore – Lake, Cook, St. Louis, Carlton and Pine counties, including Duluth, Grand Marais, Clouqet, Carlton, Finland, Isabella, Silver Bay, Grand Portage, Saginaw, and everywhere in Northeastern Minnesota. - [5] Dill Air Controls Products, 1500 Williamsboro St., PO Box 159, Oxford, NC 27565, Tel: (919) 692‐2300, Website: http://dillaircontrols.com

- Smart Tank, Installation Instructions, Flexcon Industries, 300 Pond St., Randolph MA 02368, www.flexconind.com, Tel: 800-527-0030 - web search 07/24/2010, original source: http://www.flexconind.com/pdf/st_install.pdf [Copy on file as /water/Smart_Tank_Flexcon.pdf ] -

- Typical Shallow Well One Line Jet Pump Installation, Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf, [Copy on file as /water/Jet_Pump_Grove_Elect_Jet_Pumps.pdf ] -

- Typical Deep Well Two Line Jet Pump Installation, Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf, [Copy on file as /water/Jet_Pump_Grove_Elect.pdf ] - Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.