Aluminum Wire: Special Concern - shell and inhibitor ignite/burn readily

Aluminum Wire: Special Concern - shell and inhibitor ignite/burn readily

- POST a QUESTION or COMMENT about aluminum wire repair twist on connector shell and antioxidant inhibitor paste that catch fire

This article discusses special problems with the combustibility of antioxidant and plastic used in the Ideal 65 Twist-on purple "twister" connector if used for splicing aluminum to copper wires.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Description of Aluminum Wiring Twist-on Connector Failures: combustible connector shell & combustible antioxidants

This is Aluminum Wiring Repair Procedure - Page 13 Color photos and descriptive captions from CPSC Meeting 9/28/95. In this document aluminum wire twist-on connector failures and repair procedures are described, including aluminum wire repair methods which work and methods which do not work and are unsafe. Color photos of aluminum wire repair procedures, and photos of failed connectors are included.

This document series describes hazards with existing aluminum wiring repair products, explains the aluminum wiring failure mechanism,

and reviews recommended retrofit procedures including use of readily-available materials.

This information was presented to the US Consumer Product Safety Commission by Dr. J. Aronstein, 9/28/95.

The minutes of that meeting were obtained under the Freedom of Information Act and posted by Daniel Friedman January 1996.

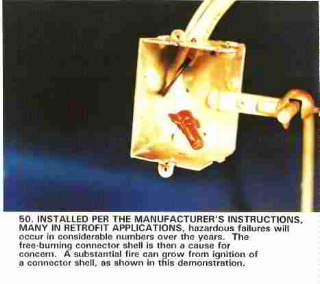

50. Installed per the manufacturer's instructions, many in retrofit installations, hazardous failures will occur in considerable numbers over the years. The free-burning connector shell

is then a cause for concern. A substantial fire can grow from ignition of a connector shell, as shown in this demonstration.

[Click to enlarge any image]

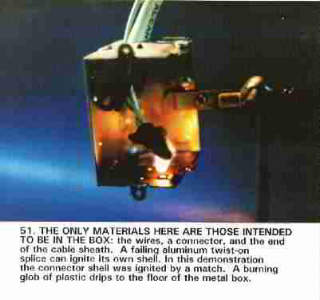

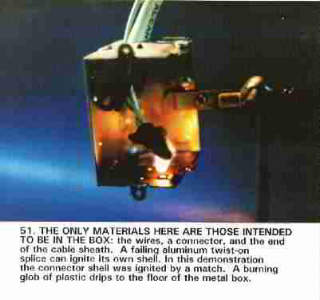

51. The only materials here are those intended to be in the box: the wires, a connector, and the end of the cable sheath. A failing aluminum twist-on splice can ignite its own shell. In this

demonstration the connector shell was ignited by a match. A burning glob of plastic drips to the floor of the metal box,

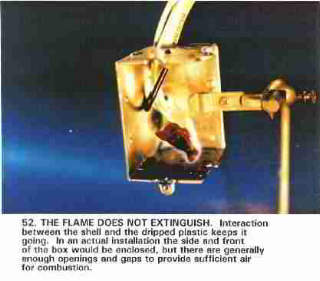

52. The flame does not extinguish. Interaction between the shell and the dripped plastic keeps it going. In an actual installation the side and front of the box would be enclosed, but there are

generally enough openings and gaps to provide sufficient air for combustion.

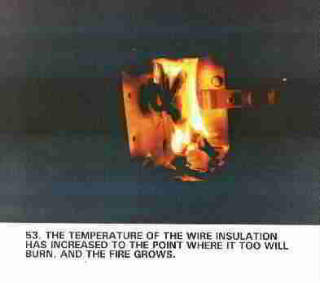

53. The temperature of the wire insulation has increased to the point where it too will burn, and the fire grows.

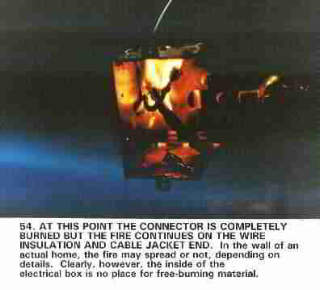

54. At this point the connector is completely burned out but the fire continues on the wire insulation and cable jacket end. In the wall of an actual home, the fire may spread or not, depending on

details. Clearly, however, the inside of the electrical box is no place for free-burning material.

Scroll Down to Rest of This Page

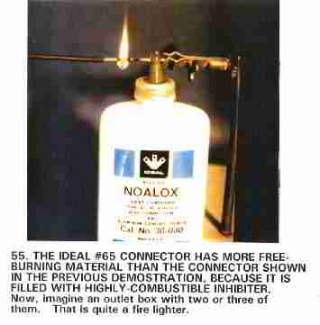

55. The Ideal #65 connector has more free burning material than the connector shown in the previous demonstration, because it is filled with highly-combustible inhibitor. Now, imagine an outlet box with two or three of them. That is quite a fire lighter.

...

Continue reading at ALUMINUM WIRING REPAIRS NOT-RECOMMENDED or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ALUMINUM WIRING HAZARDS & REPAIRS - home

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIR METHODS - CPSC Meeting 9/28/95

- COPPER PIGTAILING for ALUMINUM WIRE

- COPPER PIGTAILING FAILURES in ALUMINUM WIRING

- ALUMINUM WIRING FIELD FAILURES

- ALUMINUM WIRE to WIRE CONTACT

- ALUMINUM WIRING EQUIVALENT CIRCUITS

- ALUMINUM WIRING CONNECTOR CURRENT FLOW

- ALUMINUM WIRING CONNECTOR DETERIORATION

- ALUMINUM WIRING CONNECTOR UL TEST INADEQUATE

- ALUMINUM WIRING SPECIAL CONNECTOR FAILURES

- AMP TYCO COPALUM CONECTORS

- SCOTCHLOK 3M REPAIR CONNECTORS

- ALUMINUM WIRING REPAIR SPECIAL CONCERNS

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

Suggested citation for this web page

ALUMINUM WIRING REPAIR SPECIAL CONCERNS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about aluminum wire repair twist on connector shell and antioxidant inhibitor paste that catch fire.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.