Wood Building Foundations: Inspection, Diagnosis, Repair

Wood Building Foundations: Inspection, Diagnosis, Repair

- POST a QUESTION or COMMENT about preserved wood foundations, inspection, diagnosis, repair

How to inspect a wood foundation:

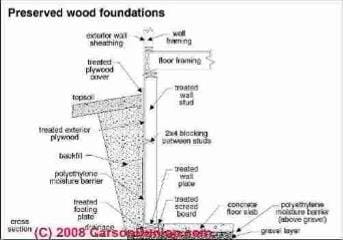

Preserved wood building foundations: this article explains wood building foundations, their inspection, installation, diagnosis, repair, and durability. Page top sketch of a basic wood foundation design is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Identify, Diagnose, & Evaluate Wood Foundation Defects

Some building jurisdictions permit the use of preserved or "treated" wood products for below-grade building foundations. These materials offer advantages of construction speed and low cost. As in the installation of Concrete Pre-cast Foundation walls, treated wood foundations may be installed on a gravel pad rather than requiring a solid masonry footing.

Suggestions for Inspecting a preserved wood foundation

- Check for evidence of foundation leakage at butt-joints where gaskets or sealant may have been omitted.

- Check for evidence of buckling or other damage;

- Outside check for the presence of a moisture barrier against the foundation exterior.

Our opinion is that "30-year guaranteed treated wood foundation products" used below grade mean that no permanent building foundation has been provided. This sketch of the components of a preserved wood foundation is courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Buildings using a wood foundation are in our OPINION a temporary structure. In areas of wet soils and insect damage risk damage may occur sooner than the warranty period.

CONTACT us by email to suggest photos or content regarding wood building foundations.

Note: use of plumb lines, levels, laser levels, & simple measurements of amount by which a wall is out of level or plumb, or of crack widths and patterns are beyond ASHI or other home inspection standards scope but are common simple tools and procedures used by masons, carpenters, builders, as well as foundation experts and engineers.

Below are some articles that offer additional foundation damage analysis methods that pertain to wood foundations as well as other foundation types:

- FOUNDATION BULGE or LEAN MEASUREMENTS explains a simple method for determining how much bulge or lean is present in a foundation or wall,

- FOUNDATION MOVEMENT ACTIVE vs. STATIC helps determine if the foundation movement is ongoing,

- FOUNDATION DAMAGE SEVERITY discusses how we decide the severity of foundation damage and the urgency of further action.

- FOUNDATION FAILURES by TYPE & MATERIAL describes the types of foundation damage, cracks, leaks, or other defects associated with each type of foundation material (concrete, brick, stone, concrete block, etc.).

Watch out: a novice inspector may have trouble distinguishing between a completely-wood foundation and a pre-cast concrete foundation wall such as the structure shown above. If the sills and studs in this wall are concrete then it's almost certainly a pre-cast concrete foundation even though you may see plywood or OSB on the inside surface of the foundation cavity wall.

Sources Of & Research On Pre-Fab Wood Foundations & Prefab Construction

- Brege S, Johansson HE, Pihlqvist B. Wood Manufacture: The Innovation System that Beats the System. VINNOVA; 2005.

- Brock L, Brown J. The Prefabricated House in the Twenty-First Century: What Can We Learn from Japan? A Case Study of the KST-Hokkaido House. InWorld Conference on Timber Engineering 2000.

- Dickens HB. Trends in Canadian house production. [PDF] NRC Publications Archive, National Research Council Canada, (1968), NRC Publications Record / Notice d'Archives des publications de CNRC, source: Contact us / Contactez nous: nparc.cisti@nrc-cnrc.gc.ca. - retrieved 2015/12/09

- Dunkley D. Prefab shear walls. Journal of Light Construction. Dec. 1999 Dec.

- Filiatrault A, Stieda CK. Seismic weaknesses of some residential wood framed buildings: confirmations from the 1994 Northridge earthquake. Canadian Journal of Civil Engineering. 1995 Apr 1;22(2):403-14.

- Goverse T, Hekkert MP, Groenewegen P, Worrell E, Smits RE. Wood innovation in the residential construction sector; opportunities and constraints. Resources, Conservation and Recycling. 2001 Dec 31;34(1):53-74.

Abstract

We study the opportunities to increase the use of wood in the Dutch residential construction sector and assess the effects on material related CO2 emission. Four house types are modeled with increasing quantities of wood used in constructions. CO2 emission reductions of almost 50% are technically possible. We assess the innovation characteristics of these wood applications to create insights in the complexity of the necessary change process. Then we relate the innovation characteristics of the wood options to the context in which implementation of the technologies take place. The options vary strongly in the required technical and network changes and so do the opportunities to implement them. Based on this we expect that a 12% CO2 emission reduction related to material use for residential buildings is possible in the short term by an increased share of wood use. We also study the possibilities for increased wood recycling practices. A large technical potential exists. To achieve this potential a significant policy effort is needed since significant changes in both technical and network dimensions are necessary. To stimulate innovation in the use of wood in residential construction, important focus points of policy making should be the culture in the Dutch construction sector, the way new building projects are commissioned, research areas within the building sector, and stabilization of building networks. - Lehmann S. Low carbon construction systems using prefabricated engineered solid wood panels for urban infill to significantly reduce greenhouse gas emissions. Sustainable Cities and Society. 2013 Feb 28;6:57-67.

Abstract

Low-carbon prefabricated modular construction systems, using prefabricated engineered solid wood panel construction systems, such as load-bearing cross-laminated timber panels, and ‘design for disassembly’ principles will offer significant opportunities for greenhouse gas emission reduction and waste avoidance, among other benefits. However, introducing such innovative and sustainable construction systems to the Australian construction industries and housing markets has its challenges.

This paper explores the opportunities offered by an innovative low carbon construction system using cross-laminated timber (CLT, also known as cross-lam) panels to improve the design and delivery of urban infill housing of the Australian construction market. CLT construction has been developed around 1996 in Europe, mainly in Austria and Germany: thick layers of timber boards are glued crosswise in different directions to increase loadbearing capacity. This article describes a multi-disciplinary research project into engineered timber panels which aims to transform the Australian construction and development industry, involving a range of key partners. This project aims to introduce CLT panels as a way to build with a lightweight prefabricated low-carbon construction system that is advantageous for urban infill and residential buildings in the range of 4–10 stories height. The challenges, research questions and advantages of this new engineered timber system are explained, and a research methodology for further research is presented. - Loferski J, Kochkin V, Platt RT. Development of ready-to-assemble wood structures. InProceedings of the 6th World Conference on Timber Engineering. Whistler, BC, Canada 2000.

- Luo, Yupeng, David R. Riley, and Michael J. Horman. "Lean principles for pre-fabrication in green design-build (GDB) projects." (2005): 539.

- Mahapatra K, Gustavsson L. Cost-effectiveness of using wood frames in the production of multi-storey buildings in Sweden.

- Moody R, Ritter M. Structural wood products. InProceedings of the First Materials Engineering Congress Pt 1990 (Vol. 1, pp. 41-52).

- Noguchi M. The effect of the quality-oriented production approach on the delivery of prefabricated homes in Japan. Journal of Housing and the Built Environment. 2003 Dec 1;18(4):353-64.

- Orr RA. Canadian Practice in Wood Frame Construction. National Research Council Canada, Division of Building Research; 1966 Apr.

- Rasmussen TV. Prefabricated Elements Used as Strip Foundation of Single-Family Housing. In Buildings X Conference, Thermal Performance of the Exterior Envelopes of Whole Buildings X 2007.

- Rasmussen TV. Prefabricated EPS Elements used as Strip Foundation of a SinglefamilyHouse with a Double Brick Wall. Nordic Journal of Building Physics: Acta Physica Aedificiorum. 2008.

Abstract:

A new prefabricated lightweight element was designed for a strip foundation that was demonstrated on site as the base of a single-family house with a double brick wall. The element was placed on a stable surface underneath the top soil layer, just 0.25 m underneath the finished ground surface. The prefabricated element was designed to fulfil the requirements of low energy consumption required by the new Danish Building Regulations. The base of the house was cast in one working operation and completed within two working days. The element, made of expanded polystyrene, was designed to be handled on site by one man. A non-freezing ground was established by using outer insulation located at the outer plinth. Temperatures were measured at measurement points located at the outer plinth and onwards from these points underneath the building. In addition the soil temperature, the temperature within the concrete floor slab and indoor and outdoor temperatures and relative humidity were measured. - Shyamasundar SK, Vengala J. Promotion of bamboo housing system and recent development.

- Spelter H. Comparing in-place costs of wood and masonry foundations. Forest Products Journal. 1983 Jan 1;33(9):45. [PDF] retrieved 2015/12/09, original source: http://www.fpl.fs.fed.us/documnts/pdf1983/spelt83a.pdf

Abstract:

This study analyzes the in-place costs of treated-wood foundations versus masonry foundations. The use of wood foundations in homes and low-rise structures is not high although the growth rate is strong. The potential for increasing lumber and plywood use in homes is significant if the wood-foundation system continues to perform well and the economics remain favorable. Labor and material cost data for the years 1974, 1977, 1980, and 1981 were collected and combined with the labor and material requirements of wood and masonry foundations in 1969. Based on the data, the in-place costs of both foundations were calculated for those periods. For each of the 4 years examined, treatedwood foundation costs were lower than masonry costs, as much as 10 percent lower in the recession-affected year of 1981. Lower labor costs strongly favor wood foundations as do very low lumber and plywood prices experienced in the early eighties. - Toole TM. Technological trajectories of construction innovation. Journal of Architectural Engineering. 2001 Dec;7(4):107-14.

- Trent RL, Whiteside TM, Robertus J. Field Experiment on a Prefabricated Expandable Foam/Wood Structure. CONSTRUCTION ENGINEERING RESEARCH LAB (ARMY) CHAMPAIGN IL; 1976 Oct.

- Vorgefertigter Wl, Beanspruchung Z, Prefabriques P, Lamelle Me. Racking Behaviour Of Light Prefabricated Cross-laminated Massive Timber Wall Diaphragms Subjected To Horizontal Actions. Otto-graf-journal. 2006;17:125.

- Wraber I. Comparative study of Danish prefab houses made of wood. In6th Nordic Conference on Construction Economics and Organisation 2011 Sep 3 (pp. 441-452).

- Zal FH, Cox K. Pre. Fab: Myth, Hype+ Reality. InWood Structures Symposium 2009 Jul 7 (p. 15).

...

Continue reading at STRUCTURAL DAMAGE PROBING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FOUNDATION FAILURES by TYPE & MATERIAL

- FRAMING DAMAGE, INSPECTION, REPAIR - home

- INSECT INFESTATION / DAMAGE - home

- WOOD STRUCTURE ASSESSMENT

Suggested citation for this web page

WOOD FOUNDATION DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about wood building foundations: construction, inspection, diagnosis,.repair.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Superior Walls of America, Ltd, 937 East Earl Road, New Holland, PA 17557, Phone: 1-800-452-9255, Fax: 717-351-9263. Website: http://www.superiorwalls.com/ Technical support:

Ed Helderman our Codes and Standards Manager. Email: ehelderman@superiorwalls.com or 717-351-9744

Robert Hare, Director of Technical Operations, rhare@superiorwalls.com, Tel: 717.351.9735

Thanks to Robert Hare for technical critique & content suggestions for this article - August 2010 - Superior Walls of America Builder Guideline Booklet MAN 42-9000 booklet, [local copy] web-search 09/01/2010 original source (indirect link): http://www.superiorwalls.com/faq.php?&answers=1&details=53

- "Concrete Slab Finishes and the Use of the F-number System", Matthew Stuart, P.E., S.E., F.ASCE, online course at www.pdhonline.org/courses/s130/s130.htm

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Sal Alfano - Editor, Journal of Light Construction*

- Thanks to Alan Carson, Carson Dunlop, Associates, Toronto, for technical critique and some of the foundation inspection photographs cited in these articles

- Terry Carson - ASHI

- Mark Cramer - ASHI

- JD Grewell, ASHI

- Duncan Hannay - ASHI, P.E. *

- Bob Klewitz, M.S.C.E., P.E. - ASHI

- Ken Kruger, P.E., AIA - ASHI

- Aaron Kuertz aaronk@appliedtechnologies.com, with Applied Technologies regarding polyurethane foam sealant as other foundation crack repair product - 05/30/2007

- Bob Peterson, Magnum Piering - 800-771-7437 - FL*

- Arlene Puentes, ASHI, October Home Inspections - (845) 216-7833 - Kingston NY

- Greg Robi, Magnum Piering - 800-822-7437 - National*

- Dave Rathbun, P.E. - Geotech Engineering - 904-622-2424 FL*

- Ed Seaquist, P.E., SIE Assoc. - 301-269-1450 - National

- Dave Wickersheimer, P.E. R.A. - IL, professor, school of structures division, UIUC - University of Illinois at Urbana-Champaign School of Architecture. Professor Wickersheimer specializes in structural failure investigation and repair for wood and masonry construction. * Mr. Wickersheimer's engineering consulting service can be contacted at HDC Wickersheimer Engineering Services. (3/2010)

- *These reviewers have not returned comment 6/95

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Construction Drawings and Details, Rosemary Kilmer

- CRAWL SPACE MOISTURE CONTROL [PDF] U.S. Department of Energy

- Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Design of Wood Structures - ASD, Donald E. Breyer, Kenneth Fridley, Kelly Cobeen, David Pollock, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328

This book is an update of a long-established text dating from at least 1988 (DJF); Quoting:

This book is gives a good grasp of seismic design for wood structures. Many of the examples especially near the end are good practice for the California PE Special Seismic Exam design questions. It gives a good grasp of how seismic forces move through a building and how to calculate those forces at various locations. THE CLASSIC TEXT ON WOOD DESIGN UPDATED TO INCLUDE THE LATEST CODES AND DATA. Reflects the most recent provisions of the 2003 International Building Code and 2001 National Design Specification for Wood Construction. Continuing the sterling standard set by earlier editions, this indispensable reference clearly explains the best wood design techniques for the safe handling of gravity and lateral loads. Carefully revised and updated to include the new 2003 International Building Code, ASCE 7-02 Minimum Design Loads for Buildings and Other Structures, the 2001 National Design Specification for Wood Construction, and the most recent Allowable Stress Design. - Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Defects and Deterioration in Buildings: A Practical Guide to the Science and Technology of Material Failure, Barry Richardson, Spon Press; 2d Ed (2001), ISBN-10: 041925210X, ISBN-13: 978-0419252108. Quoting:

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level. - Guide to Domestic Building Surveys, Jack Bower, Butterworth Architecture, London, 1988, ISBN 0-408-50000 X

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- "A Foundation for Unstable Soils," Harris Hyman, P.E., Journal of Light Construction, May 1995

- "Backfilling Basics," Buck Bartley, Journal of Light Construction, October 1994

- "Inspecting Block Foundations," Donald V. Cohen, P.E., ASHI Reporter, December 1998. This article in turn cites the Fine Homebuilding article noted below.

- "When Block Foundations go Bad," Fine Homebuilding, June/July 1998

- Historic Preservation Technology: A Primer, Robert A. Young, Wiley (March 21, 2008) ISBN-10: 0471788368 ISBN-13: 978-0471788362

- LOG HOMES: MINIMIZING AIR LEAKAGE [PDF] U.S. Department of Energy

- Log Homes: Controlling Moisture in Log Homes, U.S. Department of Energy

- Log Homes: Log Home Design, U.S. Department of Energy

- MOISTURE CONTROL in BUILDINGS [PDF] U.S. Department of Energy

- MOISTURE CONTROL in WALLS [PDF] U.S. Department of Energy

- Quality Standards for the Professional Remodeling Industry, National Association of Home Builders Remodelers Council, NAHB Research Foundation, 1987.

- Quality Standards for the Professional Remodeler, N.U. Ahmed, # Home Builder Pr (February 1991), ISBN-10: 0867183594, ISBN-13: 978-0867183597

- Natural Ventilation for Buildings, U.S. Department of Energy

- Spot Ventilation for houses, U.S. Department of Energy

- Slab on Grade Foundation Moisture and Air Leakage, U.S. Department of Energy

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- BASEMENT MOISTURE CONTROL [PDF] U.S. Department of Energy

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.