Repair Cracks & Splits in Wood Beams or Posts

Repair Cracks & Splits in Wood Beams or Posts

How to Fix Splits in Wood Beams, Posts, Logs, Vigas

- POST a QUESTION or COMMENT about splits or cracks in wood beams or in log home log walls

How to repair cracks or splits in wood posts, beams, or logs such as in a log home.

This article series defines, illustrates, and explains the cause and significance of splits or "checking" in wooden posts, wood beams, or in logs and beams used in log home structures.

Photo at page top: a bending, cracking, and failing wood post by the stairwell of a pre-1900 home in New York. This post is seriously damaged, risking structural collapse. This is not mere wooden post checking. Repair in this case makes little sense. The bending, breaking post needs to be replaced.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Repair Cracks or Splits in Wood Beams, Logs, Vigas

As solid wood beams and logs cure, shrinkage produces not only checking (large cracks that are normal and are not necessarily a problem) but also an actual reduction in log or beam diameter. Most of the split wood beams, posts, logs and vigas seen by our readers are in this category and no repair is needed.

Wood cracks or damage requiring repair:

if the split or damage is compromising a structural connection, or if a supporting beam or post is bending, splitting, cracking so as to actually risk failure, that member needs to be repaired or replaced.

Watch out: If a split at a log or beam or post compromises the bolt, lag-screw, or other connecting device holding a structure together, then almost certainly some repair or reinforcement is appropriate to protect the structure from movement or even from dangerous collapse.

See CRACKS CHECKS SPLITS in BEAMS, LOGS & POSTS for help in deciding if the damage to a wood beam or post or viga or log needs repair.

[Click to enlarge any image]

Our reader's photo [above] also discussed at

CRACKS CHECKS or SPLITS IN HORIZONTAL BEAMS

is an example of a serious split in a horiontal beam, an instance where repair was appropriate.

Watch out: as we discuss at ANTIQUE & OLD LOG CABINS and at other articles in that series on log homes, shrinkage cracks on the upper surface of horizontal logs exposed to the weather on a log-home exterior may increase the chances of rot or insect attack. It may be good practice to seal such upwards-facing splits using a suitable log home repair compound or sealant.

Reader Question: I am worried about the huge crack in this log beam? How can I fix it?

I own a home that was built in the 70's and the construction is cedar on the outside and pine walls and maple floors on the inside. The trusses are round logs bolted together.

I own a home that was built in the 70's and the construction is cedar on the outside and pine walls and maple floors on the inside. The trusses are round logs bolted together.

I have lived in my home for 27 years and the cracks in two of the beams are now deeper and longer than when I first moved in.

[Click to enlarge any image]

I read your information about the logs drying over time causes the cracks to develop, but I still felt the need to send you two pictures showing the worst crack in one of my beams. This crack is 1/2" wide by 2 1/2" deep by 7 1/2 feet long.

The log circumference is 24 inches, diameter 8 inches, and the length is 26 feet.

Should I have someone take a look at this crack or is it something I should not worry about? Is their a clamp made that would fit around this beam and help reduce the crack from expanding more?

Reply: probably not; here are some log checking crack or gap evaluation tips:

Normally even severe log checking is not a structural problem; it's cracking along the grain of the log, almost never continuing all the way through the log body, and is a normal result of building with wet or green logs.

Most checking occurs in the first year or two of construction, though if that wasn't noticed until some time later it might give a false suggestion of new cracking.

Given that one of the horizontal logs has large "crack" near a bolt connecting to a log truss member I can see why you'd have been concerned. While I'm not a structural engineer, I'm experienced with this question. In my OPINION:

IF you saw evidence of new (since construction)

- sagging of horizontal beams

- separation or actual breaks at connections between the log beams or posts and other structural members

would I be more-concerned; in that case some reinforcement, banding, or re-connection might be in order.

Damage from checking that happens to occur where a bolted or other log connection is actually jeopardized could be a reason to add an iron band or clamp.

Reader Follow-up: added clamps around split log beams

Reader Follow-up: added clamps around split log beams

I decided to have some large clamps made to put around the cracked logs. I am glad to see it was one of your suggestions. My wife feels better now that the clamps are in place.

Mod reply: clamps on checked or split logs & beams are generally not needed and might cause trouble

OPINION: Clamping as you did may make your wife feel better - the health benefits of peace of mind would be worth the cost.

However some Viga Log experts warn that these generally-unnecessary viga log clamps can actually add unanticipated stresses in the log beams as indoor moisture levels wax and wane. That may not be great for the logs themselves.

I reiterate that experts do not consider log checking a structural concern.

When I have inspected, on-site, such checking cracks as those in your photos, I've probed crack depth, measured for sagging (easy, using a string and level), and I've taken care to check the connections between structural members.

Even though those cracks in the horizontal log look scary, I suspect that none of them goes more than 50% through the log - usually they stop before the log heart.

It's a basic concept of wood structural members (though not, perhaps obvious to a normal person), that the center of a wood beam is at close to zero stress. It's the upper and lower portions in compression and tension (if the load is down) that are doing the work.

That's why, I suspect, a structural engineer who is expert in log beams would tell us that even though the splits or checks in these logs run diagonally rather than straight along the log center, these checking cracks are rarely a structural concern.

More details about using clamps and epoxy or repairing split or checked beams and repairs to vigas or other logs are

given

at WOOD BEAM LOG VIGA CRACK REPAIR METHODS

Viga Repairs vs. Normal Log or Wood Beam Checking

The clamps shown in this reader's photos above may not have been necessary and are not usually recommended. But where installed they're typically custom-fabricated to fit the specific (and varying) diameters of the logs involved.

Viga in Spanish is translated generally as beam in English. However in adobe construction vigas refer more-specifically to horizontal logs used as beams for floor or roof support, often protruding past the adobe wall construction into the exterior.

Vigas were widel used in adobe structures in the Southwestern United States and of course in Mexico and throughout Central and South America.

Checks or splits in vigas or log-beams are not normally repaired except when the log has actually deteriorated such as from insect damage or rot or weather exposure.

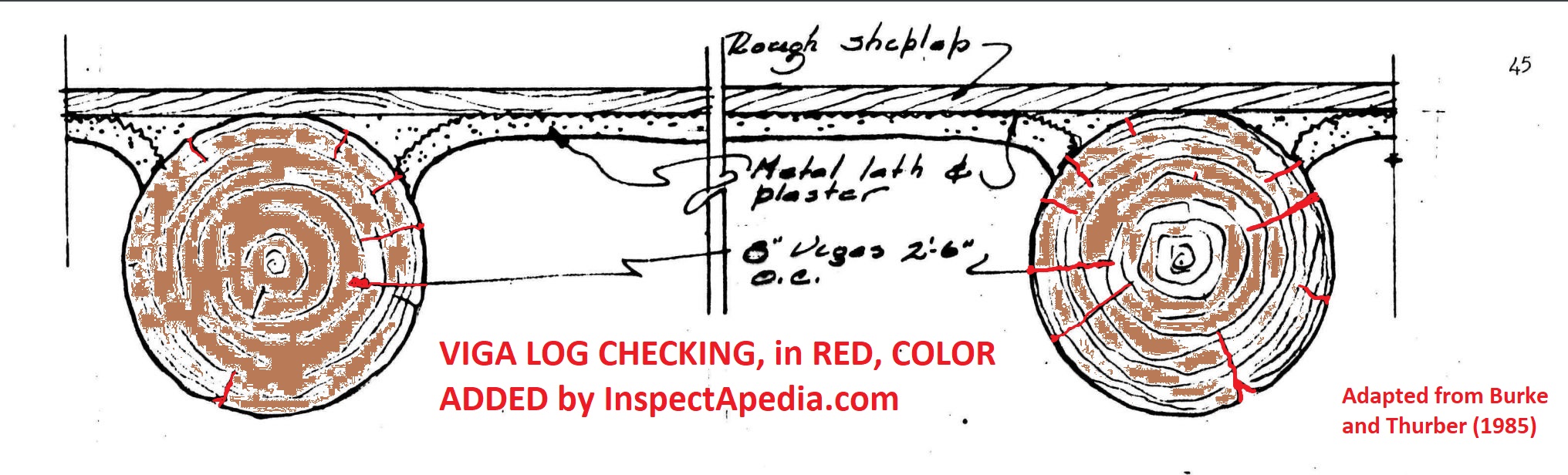

The illustrations above and below, adapted from Burke and Thurber (1985), illustrates the usual pattern or location of viga or wood beam or log checking when viewed from the log end, demonstrating that such checks do not typically pass through the entire log. [Click to enlarge any image]

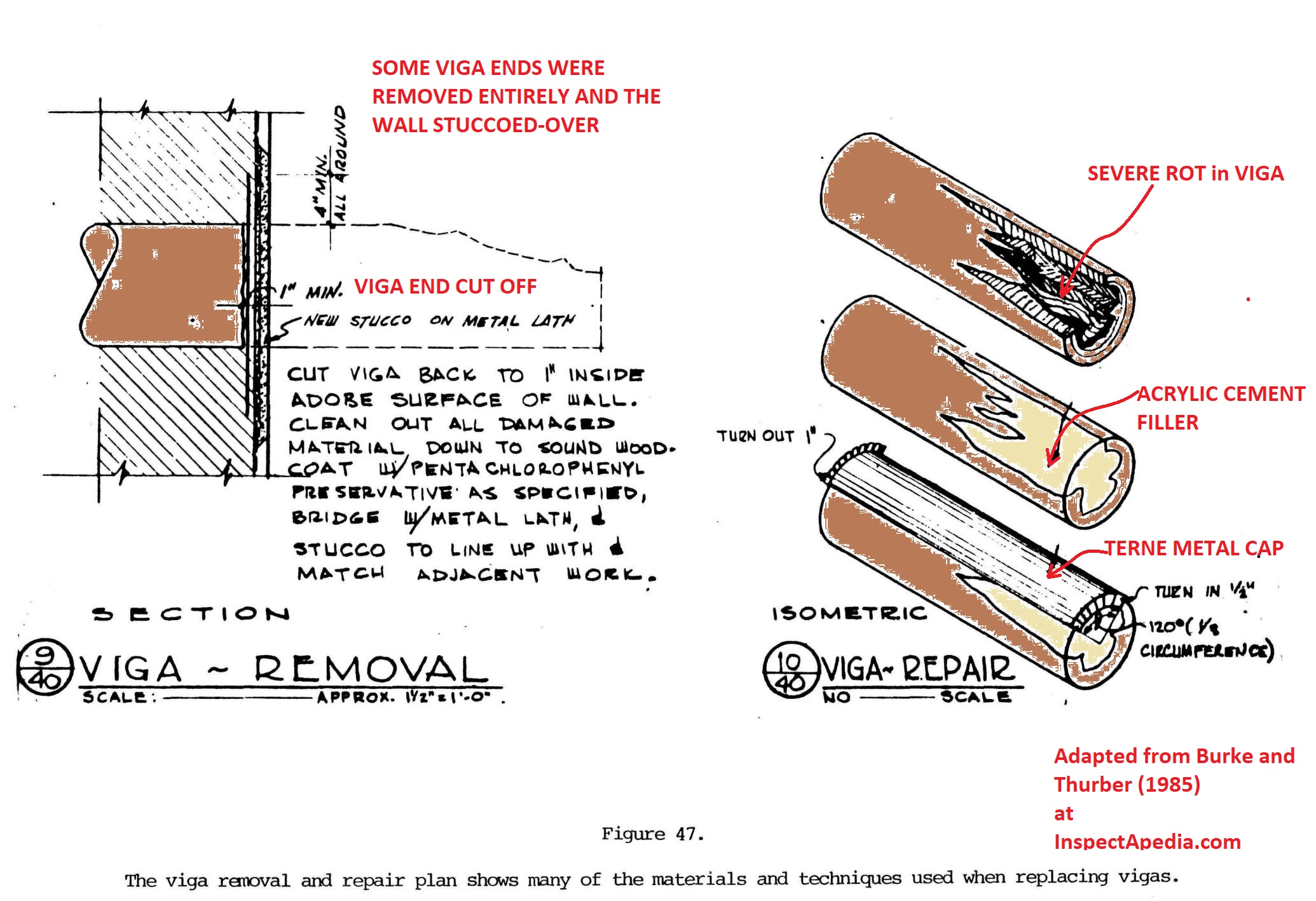

Those authors, on p. 98 of their report describing the historic NPS Southwest Region Headquarters Building, probably the largest adobe structure in the U.S., included a description of repair approaches for more-seriously damaged vigas that have suffered rot or insect damage - illustrated just below.

There you can see that the authors are discussing very badly damaged logs, not simply logs that have experienced normal checking or splitting.

Excerpt:

During the 1967 remodeling, half of the 209 vigas were in immediate need of repair or replacement. Where the exposed upper surfaces or ends of the vigas were in a severe state of decay, the rotted wood was removed and the viga was rebuilt to its original shape with an acrylic cement.

After the cement had set, the viga tops were covered with a metal terne plate and cut back to a maximum projection of 2 feet. Of all the vigas repaired, only two were removed entirely. One of these was on the east side of the building and the other on the west side of the large patio.

After the ends had been removed, the remaining portions of the vigas were cut back to 1 inch inside the adobe surface of the wall. The damaged material was then cleaned down to the sound wood. A wood preservative called pentachlorophenyl was then used to seal the ends.

Finally, the viga holes were bridged with metal lath and stuccoed to match the adjacent work (Figure 47) [shown above].

Clearly both the abandonment of outdoor exposed-ends of vigas and the repair of badly-damaged vigas was not concerned with normal checking splits.

A special Viga log repair involving replacement of the outdoor-exposed viga log ends is described in an NPS article cited below.

Controlling Wood Log / Beam Splits

For small scale splits in wood beams, American Signumat

produces an interesting product that is driven into wood to control splitting, principally by driving a device into the log or beam end. We cite that company at the end of this Q&A.

For larger splits (checking) in structural log beams such as those in our photo the clamps were most-likely custom-made by a local forger, since each log diameter is a bit different. A standard-sized clamp, even in a range of sizes, would not work without some ugly shimming.

Furthermore, in most cases the clamps shown are not actually necessary to protect a structure. In most circumstances log or beam checking is not a structural concern whatsoever, as we explain in the article above.

When a beam is still new and is green (that is has not been kiln dried) some timber framers cut a saw kerf along the line of the most-prominent existing (still fine) checking crack, hoping to create a stress relief point and to reduce overall log or beam checking. I'm researching the actual benefit of this approach.

I've also read some log and beam experts' suggestion that sealing the ends of new beams and cut logs will reduce checking a bit.

The fact is that once a beam or log is enclosed in a modern conditioned space like a home, the reduced interior humidity will virtually always produce further drying of the beam, causing additional checking-splits that can even produce loud audible cracks during the first 1-3 years of the home's new life as a completed structure.

Warnings About Using Clamps or Filler on Beam or Log Checks or Splits

Watch out: some log and beam experts specifically warn against clamping checked beams and log-beams because the clamp can introduce additional tension in the beam that can actually damage it.

Watch out: also: do not fill checks or cracks in log or square cut timbers and beams. As moisture levels vary the beam picks up or gives off moisture, changing in dimension. Filling a checking crack with any filler material such as epoxy or plastic wood filler will result in compression of the wood around the crack when the beam takes up moisture on the next moisture change.

As I have warned separately at WOOD FLOOR DAMAGE REPAIR, when restoring or repairing old wideboard wood floors, filling cracks between the floor boards pretty much guarantees further damage.

The US NPS discusses repairs to antique and historic Viga logs in a technical bulletin that I cite just below.

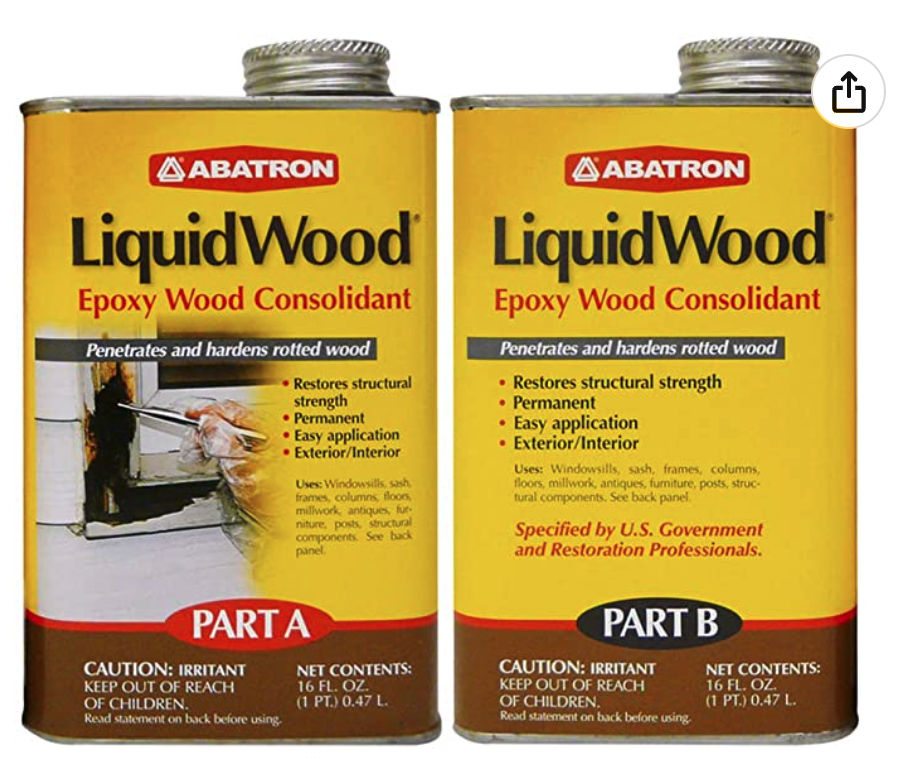

Those authors DO discuss use of a diluted epoxy on viga log beams but only as part of their screw-on Viga Log restoration project not as a general band-aid for what should be considered normal and generally harmless log checking.

Use Epoxy Resins in Beam or Log Checks or in Viga Logs?

Watch out: an exception to the general rule that viga log or other wood beam checking is always harmless might be a checking split or crack in a log or beam that runs right through a bolt connection, causing a loosening or loss of secure connection at that point.

If one or more of your log connections is split through some epoxy treatment (EPON 828 resin is a general purpose structural epoxy resin) may be appropriate as is discussed in the document I cite just below.

Notice (by reading the document) that this repair approach is being used only to repair weather-exposed ends of viga logs that are otherwise enclosed within an adobe structure. This is not a structural beam repair.

Photo: Abatron's wood consolidating expoxy, one of several wood repair products discussed

at GLUES ADHESIVES, EXTERIOR CONSTRUCTION

Photo: viga log ends after attaching them to the structural viga ends via epoxied double-ended screw connectors. These Viga repairs are described in the US NPS article cited just below.

- US NPS, HISTORIC VIGA RESTORATION USING SCREW-ON VIGAS [PDF] DSC TECHNICAL BULLETIN 04- 05, National Park Service, U.S. Department of Interior, Denver Service Center, Design & Construction, 12795 West Alameda Parkway, P.O. Box 25287,

Denver, CO 80225-0287 USA, retrieved 2018/11/16, original source: www.nps.gov/dscw/upload/TechBulletin0405-HistoricVigaRestorationScrewOnVigas_AF_010418.pdf

This US NPS discusses repairs to antique and historic Viga logs by using a screw-connected extension to replace damaged components.

- Burke, Steven M., & Marlys Bush Thurber, HISTORIC STRUCTURE REPORT, SOUTHWEST REGION HEADQUARTERS BUILDING Santa Fe, New Mexcio, [PDF], National Park Service, Southwest Cultural Resources Center Professional Paper No. 6,

U.S. Department of the Interior,

National Park Service,

Santa Fe, New Mexico,

March 1985

Excerpt:

The Southwest Regional Office building, National Park Service in Santa Fe, New Mexico, is thought to be the largest adobe office building in the United States. The 24,000 square foot building, now listed on the National Register of Historic Places, is located on Old Santa Fe Trail off Camino del Monte Sol in the foothills of the Sangre de Cristo Mountains ("Park Service Moves," Santa Fe New Mexican, July 1, 1939), ... - FauxWoodBeams, provides "Classic Faux Beam Straps" made of rubber that can be custom-cut and fastened around beams as a cosmetic-only add-on to wood (or faux-wood) beams and logs.

Website: https://www.fauxwoodbeams.com - Leonardi, Angela, A. Meda, and Z. Rinaldi. "Fire‐damaged R/C Members Repair With High‐Performance Fibre‐Reinforced Jacket." Strain 47 (2011): 28-35.

Abstract:

A new repair technique, developed for fire‐damaged R/C structures and based on the application of jackets made of high‐performance fibre‐reinforced concrete, is presented and discussed. The proposed technique may be in principle applied to both beams and columns, as shown in this article.

At first, the residual bearing capacity of the reference members is determined for different values of the fire duration. At this aim, an analytical model based on the direct integration of the hot or residual mechanical properties of the three materials (concrete, steel and fibre‐reinforced concrete), throughout the member cross section, is here adopted.

Then, after discussing the pros and cons of the application of concrete jacketing to the structural cases in question, the performance of the composite structures is analytically investigated, to make comparisons with the performance of the original undamaged structures, as well as with that of damaged structures.

Finally, the fire resistance of the repaired members is evaluated, to show the effectiveness of the proposed technique. - LOG HOMES: MINIMIZING AIR LEAKAGE [PDF] U.S. Department of Energy

- WOOD FLOOR DAMAGE REPAIR

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2024-01-09 by Douglas F - Support posts in our log cabin are splitting: I want to find collars to "prevent further splitting" - in Tennessee

We live in a log cabin, about 8 months now. two of my support post are splitting. looking for post collars to prevent further splitting. live in the Brighton TN area.

thefrosty13@yahoo.com

On 2024-01-09 by InspectApedia Publisher - structural repair not needed unless the crack or split is actually compromising a structural connection

@Douglas F,

Checking cracks like those in our photo that you've posted here rarely need structural repair unless the crack or split is actually compromising a structural connection.

In that case you'd use a combination of through-bolts and custom-made strapping or steel or iron clamps like those in the photo; they're custom fitted because for logs the dimensions are not uniform - the clamp has to fit. Any local metal-working shop can fabricate these with ease.

For vertical posts, the need for such repair is rare. You're welcome to post a photo of your situation to let us take a look.

The photo that you attached is from our article

WOOD BEAM or POST or LOG VIGA CRACK REPAIR METHODS

we'll move this discussion to that page so as to have best response from both moderators and other readers who have experience with checks and cracks in logs and beams.

Please make any follow-up questions or post photos there.

On 2020-10-16 by josalynn - how do I fill holes or small cracks in wood?

Reply by (mod) -

Josalynn

are we discussing smoothing or "filing"

or

filling in holes and gaps "filling" (two L's" ?

If the latter, there are dozens of wood filler products; you'd choose one depending on the location (indoors, outside) and type of wood product (furniture, flooring, structural members, etc) and on the intended finish coating on the wood: natural, painted, varnished, etc.

Below is just one example

...

Continue reading at WOOD BEAM LOG VIGA CRACK REPAIR METHODS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ANTIQUE & OLD LOG CABINS

- CRACKS CHECKS SPLITS in BEAMS, LOGS & POSTS

- DECK COLLAPSE Case Study

- GLUES ADHESIVES, EXTERIOR CONSTRUCTION

- LOG HOME GUIDE

- ROT, TIMBER FRAME - cause and prevention of log checking during log or timber dry out, & a case study of rot in timber frame construction

- ROT, TIMBER ASSESSMENT

- ROT TYPES, BROWN SOFT WHITE

- SHRINKAGE & HEIGHT CHANGES, LOG WALL

- WOOD STRUCTURE ASSESSMENT - home

Suggested citation for this web page

WOOD BEAM LOG VIGA CRACK REPAIR METHODS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about splits or cracks in wood beams or in log home log walls.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Arlene Puentes for the photograph of a checked log in a log home exterior. Arlene Puentes, a licensed home inspector, educator, and building failures researcher in Kingston, NY. Photographs © Arlene Puentes 2006 All Rights Reserved. Text © Daniel Friedman Arlene Puentes 2008 All Rights Reserved.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.