Copper Shingle Roof

Copper Shingle Roof

Types, Inspection Points, Product Sources

- POST a QUESTION or COMMENT about copper shingle roofing

Guide to copper shingle roofs: choices, installation, inspection, troubleshooting & metal roof repair procedures.

This article series describes types of metal roofing products and metals: metal roof choices, installation, inspection, metal roof defects, roofing repairs, and metal roof product sources.

Page top photo, a soldered copper shingle roof, courtesy of home inspector Dovber Kahn cited below.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Soldered Flat Shingle and Flat Copper Metal Roofs

Flat metal shingles with interlocking edges were produced in both steel and copper, then soldered when in place to form a very durable roof covering - a system that has been in use for hundreds of years.

Flat metal shingles with interlocking edges were produced in both steel and copper, then soldered when in place to form a very durable roof covering - a system that has been in use for hundreds of years.

Usually we find these installed on flat or low-slope roofs such as at dormer insets on homes constructed in the U.S. before 1900, often in the mid to later 1800s.

But copper roofing in both sheet and copper shingle form are still produced and installed both in restoration projects and in new construction as we will cite below.

Why don't we see more copper roofs? After all it's beautiful and durable.

The answer, provided by the USDA Forest Service and other sources is its cost.

Copper roofing is expensive, as much as $1000. per square. (A roofing square covers 100 sq.ft.).

Watch out: large expanses of metal roofing with soldered connections may flex and break open the soldered joints due to thermal movement.

As you'll read in our citations below, historically thermal expansion or movement in soldered or large panel metal roofing was one of the most-common concerns and a source of common roof system failure.

Inspection Points for Low-Slope Soldered Copper Roofs

Photo above courtesy of home inspector Dovber Kahn. [Click to enlarge any image]

I [DF] have walked on such roofs (quite a few were in Newburgh NY) but would stay off if the roof looked questionable or if I could see damage in the first place, so as not to risk causing further damage.

Soldered Flat Copper Roof Inspection Points

The roof above may be in excellent condition and not leaking at all. But I have marked a few areas where a closer look would be in order to be sure there is no damage, corrosion, or an edge flashing problem.

First identify the copper shingle roof type. Copper panel and copper shingle roofs have been and continue to be manufactured in several forms including standing seam copper roofs (discussed separately at COPPER ROOFING), as well as soldered copper shingles (shown here) and as crimped or seamed interlocking copper shingles that are installed by nailing and without soldering (shown below courtesy of Zappone manufacturing).

Inspect a soldered flat copper "shingle" roof for the following warning signs:

- Broken copper shingle solder seams -

this can happen on some roofs due to thermal expansion/contraction, particularly on large-area soldered metal roofs if the installation did not provide for thermal movement.

Historically this was the number-one problem with soldered shingle or panel metal roofing. - Evidence of leaks

seen from below - Corrosion damage

at abutments to other metals or to building walls, chimneys, plumbing flashings, etc. - Accumulated debris

(keep cleaned off to reduce corrosion) - Evidence of prior, improper repairs

that shorten the roof's life (more on this below); also any prior repair will give information about the roof's leak history and can provide points deserving further inspection. - Mechanical damage

(rare) but possible, such as a cut or tear from a falling tool or falling tree limb. - Through-corrosion of the copper -

i.e. leaks and worn out copper sections or shingles (rare, but occurs if improperly patched or if the copper is in contact with other metals like an iron railing) - Leaks at any penetrations

(railings, plumbing vents) - Damaged, missing,

leaky edge flashing

Watch out: DO NOT "patch" a roof like this with asphalt or tar or roofing mastic.

Those "repairs" will work just in the short term. In the longer term they will, in my experience, cause a speed-up in corrosion and failure of both the copper and the leaded seams.

Watch out: DO NOT let an asphalt shingle roofer work on this roof.

A roofer who is not familiar with the material may recommend its replacement when only minor repairs are needed, or might take an roll roofing or other approach that will destroy a durable and lovely material, replacing a 100-200 year life material with a 2-7 year life material.

Copper-Shingle Roofs: Sources, Patent History & Contributors

Photo: a new copper shingle roof, crimp connected, not soldered, from Zappone Manufacturing, a Spokane Washington copper roofing manufacturer cited in detail just below.

Photo: a new copper shingle roof, crimp connected, not soldered, from Zappone Manufacturing, a Spokane Washington copper roofing manufacturer cited in detail just below.

- Cohen, A.J., "Metallic Roofing Plate", U.S. Patent 622,417, issued 04 April 1899, including roof covering by making use of tiles, slates, shingles or other small roofing elements. This invention relates to metallic roofing plates.

Patent excerpt:

The general use of copper, zinc, aluminium, and kindred metals (which are comparatively non-corrodible or unaffected by atmospheric conditions) for roofing purposes is not possible, owing to the expensiveness of the metals, although such plates are used to a limited extent. - Rodgers, A.D., "Snow-Guard for Roofs", U.S. Patent 250,850, issued December 06, 1881, illustrates that flat shingle metal roofs were already in wide use in the U.S.

- Perry, John Henry. "Sheet-metal roof." U.S. Patent 1,240,773, issued September 18, 1917.

Patent excerpt describes a NO-SOLDER metal shingle roof covering:

JOHN H. PERRY, a citizen of the United States, and a resident .of Middletown, in the county of Orange and State of New York, have invented anew and improved Sheet-Metal Roof, of which the following is a full, clear, and .exact description.

The object of the invention is to provide a new and improved sheet metal roof arranged to enable a tinsmith or other person to readily join the metal sheets for. forming the roof sides and the ridge without the use of solder,.and to render the joints rainproof and thereby prevent leakage - Hodgeson, Joshua [spelling estimated], "Improvement in Roofing", U.S. Patent 56,751, Issued July 31, 1866

Excerpt:

This invention relates to a new and improved mode of applying copper to roofs, whereby the expansion and contraction of the sheets of copper by extremes of temperature will not have a tendency to tear open the joints and cause the roof to leak.

The nature of my invention consists in applying sheets of copper to roofs by bending the edges of the sheets over angular blocks that are applied firmly to the sheathing, and securing said edges permanently in dovetail grooves by means of solder or other fusible metal, which will, when properly applied, form inverted wedges in said grooves and effectually prevent the drawing out of the edges of the copper by the contraction of the sheets, as will be hereinafter described. - Park, Sharon C., THE USE of SUBSTITUTE MATERIALS on HISTORIC BUILDING EXTERIORS [PDF], Sharon C. Park, AIA, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9/29/2010 original source: http://www.nps.gov/history/hps/tps/briefs/brief16.htm

- Smith, Thomas L., AIA, "Metal Roofing: 'Fixing' for Thermal Movement [ copy on file as /roof/Metal_Roof_Movement_NRCA.pdf ] - ", Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] p. 72, NRCA http://www.nrca.net/

- USDA, ALTERNATIVE ROOFING MATERIALS: A GUIDE for HISTORIC STRUCTURES [PDF] (2007) U.S. Department of Agriculture, Forest Service, retrieved 2018/11/15, original source: https://www.fs.fed.us/t-d/pubs/pdf/07231812.pdf

- U.S. National Park Service, FROM ASBESTOS to ZINC - TYPES of ROOF SHINGLES & TILES [PDF]

- Walker, William P., Metal Roofing, U.S. Patent No. 230,161 Issued July 20, 1880, describes weather tight joints in sheet metal roofing.

- Zappone Manufacturing, COPPER SHEET INTO COPPER SHINGLES: FRESH APPROACH TO QUALITY ROOFING [PDF] Zappone Manufacturing, 2928 North Pittsburg St., Spokane, WA 99207 USA, Tel: 1-800-285-2677, Website: http://www.zappone.com/

- Zappone Manufacturing, WRIGHT-FOUNDATION DESIGNED HOME FEATURES INNOVATIVE COPPER SHINGLES [PDF] Zappone Manufacturing, Op. Cit.

- Also see additional sources at References or Citations below

- Dov Ber Kahn, a home inspector in Rockland County, NY has contributed photographs of various building features. Mr. Kahn is a licensed home inspector in New York and New Jersey, and can be reached at Website: Kahnbhomeinspectors, Tel: 845-445-8234, Email: kdovber@googlemail.com

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-08-01 by InspectApedia Publisher - McFarlane-Douglas was a Canadian producer of metal roofing, ceilings and similar products

@Norval Campbell,

More about McFarlane-Douglas who produced this copper bearing shingle plate can be read in this company catalog

McFarlane-Douglas

Company, Limited

Architectural Sheet Metal

Building Materials

250,260 Slater Street, OTTAWA Canada

MCFARLANE-DOUGLAS STEEL CEILINGS & SIDE WALLS CATALOG

On 2023-08-01 by InspectApedia Publisher

@Norval Campbell,

The manufacturer, McFarlane-Douglas, was a Canadian in Ottawa, a producer of metal roofing, ceilings and similar products.

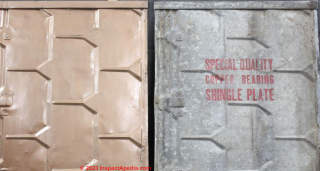

Continuing with images showing how with age the copper plating may first oxidize, and eventually thin:

Here is a third image: you'll see that several online auction vendors frequently list this Special Quality Copper Bearing Shingle Plate and that it appears in various degrees of wear.On 2023-08-01 by InspectApedia Publisher - Special Quality Copper Bearing Shingle Plate made by McFarlane-Douglas manufacturer

@Norval Campbell,

"Hardware merchandising September-December 1922" Vol. XXXIV. No. 38,

THE MACLEAN PUBLISHING COMPANY. LIMITED, PUBLICATION OFFICE: TORONTO. CANADA

includes notes on "Special Quality Copper Bearing Shingle Plate" that we excerpt below, identifying three brand names.

Excerpting:

An extra 40c. per 100 lbs. is charged for Keystone and Premier brands copper-bearing sheets.

An extra is now charged on galvanized sheets,

[Text lost - we're researching this detail] ...

Will Outlast Them All

... are being used where efficiency in roofing is of the greatest concern. They

are absolutely storm and wind proof. Locked together securely on all four

sides, they make the strongest roof on the market, ornamental in design; they are

easily sold and you have only mention the ease with which ; roof can be laid to make

many sales.

Point out that they require no solder, mallets, seamers. toiigs, [sic] etc. Point out that they are made from Special Quality Copper Bearing Shingle Plate, a guarantee of their long life. We will be pleased to give you further details or any advice on sheet metal work — write us.

McFARLANE DOUGLAS CO., LIMITED , Ottawa Canada

You will see that these are copper plated galvanized metal roofing sheets in an embossed shingle pattern. The amount of copper is very small - an electro-plated coating.

On 2023-08-01 by Norval Campbell - who made this 1927 copper barn shingle?

this shingle is off 1927 barn. who might have made it? how much copper might it contain?

...

Continue reading at LIFE EXPECTANCY of METAL ROOFS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

COPPER SHINGLE METAL ROOFING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- American Galvanizers Association, "Zinc Coatings, A comparative analysis of process and performance characteristics", American Galvanizers Association, 6881 S. Holly Circle, Suite 108 Centennial, CO 80112 720-554-0900 | 800-468-7732 aga@galvanizeit.org www.galvanizeit.org

- Architectural elements: the technological revolution: Galvanized iron roof plates and corrugated sheets; cast iron facades, columns, door and window caps, ... (American historical catalog collection), Diana S Waite, available used out of Amazon.

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- [1] Follansbee Roofing, Follansbee WV 26037, Tel: 800-624-6906, website: www.follansbeeroofing.com and http://www.follansbeeroofing.com/products/TerneII.aspx Quoting Follansbee on TerneII properties:

Follansbee Steel is the only manufacturer of a pre-painted or natural Terne roof and is a leading supplier of metal roofs for new and retrofit commercial, institutional, residential and historic preservation projects.Terne II - Classic Terne-Coated Steel ... is a new and improved version of historic Terne metal, ... Terne II has improved capability for resisting corrosion in all environments ... also has excellent formability, solderability, and affinity for paint ... without compromising mechanical characteristics. It can be used in flatlock, standing seam, vertical wall designs and virtually any other application in which original Terne has been used. It is strong and ductile, having high yield and tensile strengths as well as workability. This new material can easily be formed with conventional roofing tools.

With Terne II roofing, it is advisable to paint the material as soon as conditions permit. Oxide formation is slower than with the original Terne and the wait for proper painting conditions provides substantially less risk. The new material is coated with Follansbee's new ZT® alloy, a combination of zinc and tin. This coating is designed not only as a barrier but also to be anodic to the steel substrate and reduce the potential for oxidation before painting.

The traditional oil-based paints long required on original Terne are not recommended for application on Terne II. Follansbee's Rapidri paint with its faster drying time and ease of application is much superior to the old painting system. The Rapidri acrylic paints are aesthetically pleasing while offering enhanced durability and color retention. ...

- Metal Roofing Alliance, E. 4142 Hwy 302, Belfair, WA 98528, Telephone:(360) 275-6164, Customer Support 410-534-6900, Email: support@metalroofing.com,

Website: www.metalroofing.com. Quoting:

The Metal Roofing Alliance was formed in 1998 by a small group of forward-thinking metal roofing manufacturers with the main goal of educating consumers about the many benefits of metal roofing. Since our inception, we've shown millions of people just how beautiful, durable and money-saving metal roofing can be for them. Over the years, our membership has grown to include paint companies, material suppliers, industry publications and more. Be sure to take advantage of all of the great resources our members offer. - The Metal Initiative, 4700 W. Lake Ave., Glenview, IL 60025, P:847.375.4785 Website: www.themetalinitiative.com/, Email: Louise Ristau lristau@connect2amc.com Quoting:

The Metal Initiative is a coalition of manufacturers, individuals and associations that have come together to provide information on the features and benefits of metal in construction. Carrying its message of metal primarily to the professional building owner community, The Metal Initiative seeks to gather and disseminate useful information for decision-makers. - Metal Roofing, an Illustrated Guide, R.A. Knowlton , [metal shingle roofs],

- "Metal Roofing: 'Fixing' for Thermal Movement", Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] p. 72, NRCA

- NRCA, Smith, Thomas L., AIA, CRC, METAL ROOF SYSTEMS: DESIGN CONSIDERATIONS FOR SNOW AND ICE [PDF] Professional Roofing, [date pending] p. 74, NRCA, http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, STEEL [ROOF] DECK ISSUES for the 1990s [PDF], NRCA, http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, STEEL [ROOF] DECK CORROSION BULLETIN [PDF] Professional Roofing, [date pending] p. 58, NRCA, http://www.nrca.net/

- NRCA, Smith, T. THE MANY ASPECTS of METAL [ROOF] SHINGLES [PDF] Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] NRCA, Web: nrca.net

- Copper Roofing, by CDA

- Copper Roofing, Master specifications for copper roofing and sheet metal work in building construction: Institutional, commercial, industrial, I.E. Anderson, 1961 (hard to find)

- Corrugated Iron, Building on the Frontier, Simon Holloway

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Grapevine Design Guidelines - Web Search 07/12/2010

- NPS, FROM ASBESTOS TO ZINC, ROOFING FOR HISTORIC BUILDINGS, METALS [PDF] chnical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9/29/2010, original source: nps.gov/history/hps/tps/roofingexhibit/metals2.htm

- NPS, FROM ASBESTOS TO ZINC, ROOFING FOR HISTORIC BUILDINGS, METALS-PART II, Coated Ferrous Metals: Iron, Lead, Zinc, Tin, Terne, Galvanized, Enameled Roofs [PDF] Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9/29/2010, original source: nps.gov/history/hps/tps/roofingexhibit/metals.htm

- NPS, FROM ASBESTOS TO ZINC, ROOFING FOR HISTORIC BUILDINGS, METALS- ROOFING TODAY [PDF] Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9/29/2010, original source: nps.gov/history/hps/tps/roofingexhibit/roofingtoday.htm

- Sweetser, Sarah M., ROOFING for HISTORIC BUILDINGS [PDF] (1978) Preservation Brief 4, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source: http://www.nps.gov/history/hps/tps/briefs/brief04.htm

- Park, Sharon C., AIA, THE USE OF SUBSTITUTE MATERIALS ON HISTORIC BUILDING EXTERIORS [PDF] Preservation Brief 16, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source:

http://www.nps.gov/history/hps/tps/briefs/brief16.htm - NRCA, Smith, Thomas L., AIA, CRC, METAL ROOFING: 'FIXING' FOR THERMAL MOVEMENT [PDF] Professional Roofing, [date pending] p. 72, NRCA - Web: http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, METAL ROOF SYSTEMS: DESIGN CONSIDERATIONS FOR SNOW AND ICE [PDF] Professional Roofing, [date pending] p. 74, NRCA, http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, STEEL [ROOF] DECK CORROSION BULLETIN [PDF] Professional Roofing, [date pending] p. 58, NRCA, http://www.nrca.net/

- "Steel [Roof] Deck Corrosion Bulletin, NRCA [ copy on file as /roof/Steel_Roof_Deck_Corrosion_NRCA.pdf ] - ", Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] p. 58, NRCA

- NRCA, Smith, Thomas L., AIA, CRC, THE MANY ASPECTS of METAL [ROOF] SHINGLES [PDF] Professional Roofing, [date pending] NRCA, Web: nrca.net

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.