Plumbing Traps History

Plumbing Traps History

Timeline of "S" and "P" traps, drum & bell traps & others used on plumbing drains

- POST a QUESTION or COMMENT about plumbing traps or plumbing interceptors

Plumbing drain traps, their types, history, features, and prohibitions.

We describe what S-traps and P-traps are and their variations over time. The pros and cons of each type of plumbing trap are explained and illustrated along with extensive historical citations and excerpts from the inventors' original patent applications. Additional types of early plumbing drain traps are also discussed.

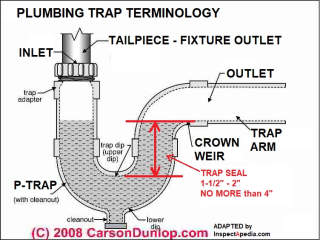

The page top sketch of the detailed parts of a plumbing trap was provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education, & report writing company.

Described as well are the components, designs, and use of each type of plumbing trap and the common problems that occur with each: odors, leaks, noises, etc. This article distinguishes between P-traps and older S-traps as well as drum traps and bell traps, and explains trap siphonage and the dangers that can result from dry plumbing traps.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What is a Plumbing Trap?

When our reader, Ray, asked about the history and timeline of plumbing traps, we found a lack of cohesive summary already compiled. That gap led us to research and compile the following history of plumbing traps, including S-traps, P-traps, drum traps, and bell traps.

When our reader, Ray, asked about the history and timeline of plumbing traps, we found a lack of cohesive summary already compiled. That gap led us to research and compile the following history of plumbing traps, including S-traps, P-traps, drum traps, and bell traps.

There are, in fact, very old devices and the adoption of various plumbing traps varied significantly by country.

We might have to go back to Roman times, but for most locations we will see that various plumbing traps are not as old as when people used to simply empty their chamber pots out the window into the street.

[Click to enlarge any image]

A plumbing trap is a U-shaped bent building plumbing drain component whose job is to maintain a water seal to keep sewer gases from rising back up into the building from the building's sewer drain piping system.

The blue area showing where water rests in the plumbing trap has a maximum allowable height of 4".

But water must remain in this space to act as a seal.

Watch out: Improperly installed, damaged, leaky, or missing plumbing drain traps can release smelly and even dangerous sewer gas odors in the building.

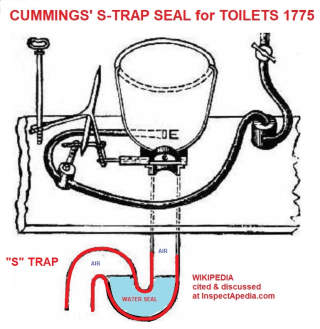

History of the S-Trap and then the P-Trap: 1775

Andy Boyd, at the University of Houston, writes that [according to Boyd's illustration] the P-trap was invented, by a Scottish watchmaker, Alexander Cumming in 1775; or if he wasn't the first to think of a P-trap, he was the earliest to patent the idea.

Andy Boyd, at the University of Houston, writes that [according to Boyd's illustration] the P-trap was invented, by a Scottish watchmaker, Alexander Cumming in 1775; or if he wasn't the first to think of a P-trap, he was the earliest to patent the idea.

Cummings wanted protection against losing small watch parts down the drain when such parts were being cleaned. See Boyd, Andy, TRAPS AND VENTS at https://www.uh.edu/engines/epi3110.htm

Actually it was an "S" trap (not a "P" trap) that was designed by Cumming. The S-shaped drain line formed an early plumbing trap that, by preventing sewer gas from entering the building through the fixture drain, reduced drain odors and also could trap small objects falling down a drain (including hair and sludge).

The S-trap would have been used on sinks, tubs, showers, etc. but NOT on toilets - so in our OPINION, some writing on this topic by some of the sources can be a bit confused and inaccurate.

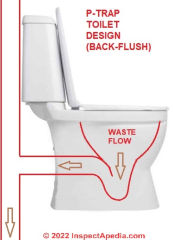

Toilets, to avoid an odor problem, used a water trap in the toilet itself - a sort of large "S" or "P" shape, depending on the toilet's design. If you look through our history of old toilets you'll see some side views that plainly show the toilet base was cast to provide an "S" shaped trap while others, including some wall-mount toilets use a "P" shaped trap.

Below we illustrate the design difference between P-trap and S-trap toilets.

Both the P-trap and S-trap toilet designs ultimately connect to a building drain that should include a vertical vent stack as well - included below in our P-trap toilet illustration.

A P-trap design does a better job of maintaining its water trap than an S-trap toilet but most modern toilets, even ones flushing "down" through an S-trap will include a toilet bowl and drain design to protect against loss of the toilet's water trap seal.

However when an S-trap is used at other plumbing fixtures such as a sink, shower, or tub, loss of the trap seal by siphonage is a common problem when the fixture is draining.

Toilet types and their history, along with more examples of toilets using an S-trap or a P-trap, are found

at TOILET TYPES, CONTROLS, PARTS

Details explaining the design and problems with S-traps are

at PLUMBING S-TRAP CODES & HAZARDS

Alexander Cumming FRSE (sometimes referred to as Alexander Cummings; 1733 – 8 March 1814) was a Scottish watchmaker and instrument inventor, who was the first to patent a design of the flush toilet in 1775, which had been pioneered by Sir John Harington, but without solving the problem of foul smells.

As well as improving the flush mechanism, Cummings included an S-trap (or bend) to retain water permanently within the waste pipe, thus preventing sewer gases from entering buildings.[2][3] Most modern flush toilets still include a similar trap. - Alexander Cumming at Wikipedia https://en.wikipedia.org/wiki/Alexander_Cumming, source of the photo above of Cumming, the inventor of the S-trap.

The functional differences between an "S" trap (early design credited to Cummings, 1775) and the later "P" trap design (research continuing on dates & inventors) is important as home inspectors and plumbers have learned.

Plumbing traps in an "S" shape are particularly prone to having the water resting in the bottom of the trap siphoned out by the suction created as water exits down the plumbing drain. The result is a smelly leaky plumbing trap that doesn't always "trap" sewer odors below.

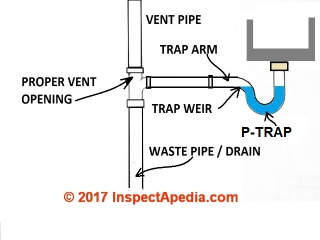

Conversely, because a "P" shaped trap includes a horizontal line out of the top of the trap that then connects to a drain line that runs down (to drain) and up through the roof (in a proper installation) to provide a vent or air intake, water running down the drain won't siphon out water from the plumbing trap.

Continuing from the Wikipedia article we cited, here is a description of Cummings' improvement to toilets that provided a plumbing "trap":

In 1775 he made major advances on the design of the flushing toilet. His improved valve closet incorporated a sliding valve to keep water in the pan and an S-bend trap in the waste pipe, preventing foul smells from re-entering the house and generally giving a "cleaner" solution.[12] He also linked the water inlet valve to the flush mechanism to allow the pan to be emptied and refilled by pulling a single handle.

- Op. Cit.

First Plumbing Drain Traps: 1775-Cumming & 1880-Crapper

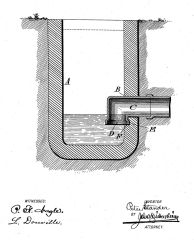

Shown here, again courtesy of Wikipedia (we contribute annually, and we hope you will too) is a sketch of Cumming's toilet water trap, plainly showing that it was an "S" shape.

Shown here, again courtesy of Wikipedia (we contribute annually, and we hope you will too) is a sketch of Cumming's toilet water trap, plainly showing that it was an "S" shape.

See details explaining why "S" traps are a problem (water is siphoned out of the trap)

at PLUMBING S-TRAP CODES & HAZARDS

For comparison, shown at the top of this page, courtesy of our associates, Carson Dunlop Associates, a Toronto home inspection and education firm, we show how a "P" trap has that straight horizontal output leg before it connects to the plumbing drain system.

- 1775: Plumbing S-Trap - Alexander Cumming, credited with invention of the "S" trap used first on toilets, Alexander Cummings; (b 1733 – d 8 March 1814)

The Cumming S-trap is illustrated above; our heavy red lines point out the "S" shaped double bend in this plumbing trap.

- 1880: Plumbing P-Trap - Thomas Crapper, credited for inventing the "U" bend better described as a "modern P-trap" that avoided the trap siphon problem, (baptised 28 September 1836; died 27 January 1910)

Wikipedia excerpt:

Thomas Crapper (baptised 28 September 1836; died 27 January 1910) was an English businessman and plumber. He founded Thomas Crapper & Co in London, a sanitary equipment company. Crapper held nine patents, three of them for water closet improvements such as the floating ballcock.

He improved the S-bend plumbing trap in 1880 by inventing the U-bend. The firm's lavatorial equipment was manufactured at premises in nearby Marlborough Road (now Draycott Avenue). The company owned the world's first bath, toilet and sink showroom in King's Road.

Crapper was noted for the quality of his products and received several royal warrants. - Retrieved 2021/12/16 original source: https://en.wikipedia.org/wiki/Thomas_Crapper

A "P" trap is illustrated below.You can see that the horizontal trap arm that leads to a combination plumbing drain (down) and vent (up) pipe prevents suction from draining water from siphoning the water out of the trap itself (shown in blue in our sketch).

History of Drum Traps in the U.S.: 1884 & Prior

Drum Traps are essentially a "P" trap whose water container is a small cylinder or "drum" sporting a cap intending to make the trap more accessible for cleaning. Plumbing codes often require that plumbing traps be accessible for cleaning.

Drum Traps are essentially a "P" trap whose water container is a small cylinder or "drum" sporting a cap intending to make the trap more accessible for cleaning. Plumbing codes often require that plumbing traps be accessible for cleaning.

The capped drum trap attempted to make this step easier as one could leave the trap in place, simply opening its cover to clean out the trapped debris.

Otherwise a more conventional plumbing trap must be removed by disassembling the plumbing drain (if it can't be cleared by a plumbing snake or chemicals).

Critics of the drum trap, correctly in our OPINION, point out that because of its flat bottom and vertical sides, a drum trap, unlike the smooth bends of an more-common "P" trap or even an older "S" trap are NOT self scouring - the drain doesn't tend to wash itself clear when in use.

So drum traps in typical household use can be a constant annoyance.

There are special use drum traps explicitly required, such as grease traps where required, on commercial kitchen or restaurant food preparation area drains.

You'll see drum traps in photos of traps in several other articles at InspectApedia.com and above we show a black ABS Plastic Drum Trap manufactured by NIBCO and sold at building suppliers.

Shown below is a drum trap that we inspected in a Poughkeepsie, New York home.

This home, dating we think from the 1940s, used a drum trap and galvanized drain piping at this second floor bath tub. A small access cover was provided in the bathroom floor to give access to the trap for cleaning.

Now let's look at a drum trap installed in 2010.

Shown above is a much more modern plastic drum trap installed below a lavatory sink in Central Mexico. Drum traps, with the exception given later in this article, are prohibited in most plumbing jurisdictions.

Plumbing Drum Trap History Research & Patents

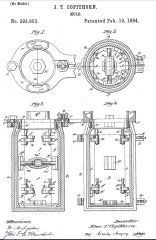

Drum Traps in the U.S. date from before 1884, as we can determine by tracing plumbing drum trap patent history.

Shown below are the earliest US Patents we've found on Drum Traps for plumbing waste systems, but even Copithorn's 1893 Drum Trap Patent makes clear that drum traps had been in use well before that time (manufactured of lead).

The earliest Drum Trap Patent we've found was shown above, from an 1884 patent disclosure. This patent is hard to find as it was not scanned clearly by the US PTO. We've done minor editing corrections to the text.

John Copithorn was an inventor in Boston, Massachusetts, whose patented method for manufacturing plumbing drum traps bears the unfortunate patent name "Mold".

- Copithorn, Joh n T., MOLD, [Method for manufacturing PLUMBING DRUM TRAPS] [PDF] US Patent No. 293.958. Patented Feb; 19, 1884. [Shown above]

Excerpt:

My invention, relating to the manufacture of drum-traps for plumbing purposes, is embodied in an apparatus for producing them.

Drum-traps consisting of a cylindrical chamber composed, mainly, of lead, provided with a threaded neck of brass or metal harder than lead, to be closed by a threaded cap or nut, have usually been made by hand from a piece of lead pipe or tubing forming the sides of the cylindrical chamber, a piece of sheet lead united by solder with the said tubing at one end, to form the bottom of the trap or chamber, and the threaded neck united with the other end of the cylinder by a wiped solder-joint, the traps thus made being very expensive, as a considerable amount of skilled labor is required for their production.

The solder-joints at the bottom and top of the trap are, moreover, liable to be eaten away by acids and gases to which the trap is exposed, and which do not have an equally detrimental effect upon the lead body.

The present invention has for its object to produce a drum-trap the body of which is composed wholly of a single homogeneous casting of lead or of other suitable material, having united with it in the process of casting the previously threaded neck of brass or harder material which is to receive the threaded cap of the trap.

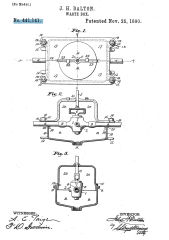

- Dalton, J.H. WASTE BOX [PDF] U.S. Patent No. 441,114 [PDF] Patent Granted 1890-11-25 - describes what was later called a plumbing Drum Trap. [Shown above]

The application, described by Dalton using the term "Waste Box", appears to us to be an anticipation of what was later called a Drum Trap on drains. Even here, as Dalton is describing an improvement to Waste Boxes, we can infer that this plumbing device dates from earlier than his 1890 patent.

Be it known that 1, JOHN H. DALTON, a citizen of the United States, residing at Philadelphia, in the county of Philadelphia and State of Pennsylvania, have invented certain new and useful Improvements in Waste- Boxes; and I do hereby declare the following to be a sufficiently full, clear, and exact description thereof, as to enable others skilled in the art to make and use the said invention.

This invention relates to the drips of wastecocks used in the distribution of water-supply in houses, and has for its object the cheap and easy enclosure of stop and waste cocks and the collection of such leakage and drips and their discharge through a suitable conducting-pipe to places where they are unobjectionable.

The following early drum trap patents give us more history of that device, adding to what is cited above:

- Lund, John T. "Water-seal trap." U.S. Patent 839,165, issued December 25, 1906.

- Wensley Jr, Richard. "Drum-trap." U.S. Patent 839,240, issued December 25, 1906.

See this patent at https://inspectapedia.com/plumbing/Wensley-Drum-Trap-Patent-US839240.pdf

- Ayres, Paul. "Drum-trap." U.S. Patent 880,436, issued February 25, 1908.

- Reid, William A. "Drum-trap." U.S. Patent 882,209, issued March 17, 1908.

See this patent at https://inspectapedia.com/plumbing/Reid-Drump-Trap-US882209.pdf

- Ray, William J. "Sink-trap." U.S. Patent 965,836, issued July 26, 1910.

- Beckway, George. "Plumbing system and fittings therefor." U.S. Patent 985,969, issued March 7, 1911.

See this patent at https://inspectapedia.com/plumbing/Beckway-Trap-Patent-US985969.pdf

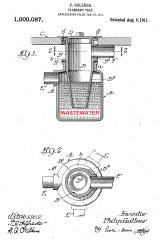

- Gollner, Philip. PLUMBER'S TRAP [PDF] U.S. Patent 1,000,087, issued August 8, 1911.

See this early plumbing drain trap patent, illustrated below, and you'll observe that it is plainly a drum trap.

- Crosby, Thomas E. "Trap." U.S. Patent 1,123,495, issued January 5, 1915.

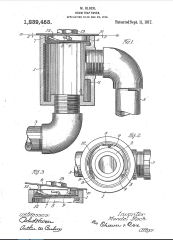

- Block, Mandel. "DRUM TRAP COVER [PDF] U.S. Patent 1,239,453, issued September 11, 1917 and filed in 1916 [Shown below]

See this patent at https://inspectapedia.com/plumbing/Block-Drum-Trap-Cover-Patent-US1239453.pdf

Excerpt:

My invention relates to traps used in plumbing and is particularly concerned with the cover of traps commonly known as drum traps.

In order to readily impart an understanding of the invention I will describe it as applied to a trap connected to the waste of a bath tub and will assume the ordinary installation in which the top of the drum is substantially flush with the floor line of the bath room, It will be readily understood by those familiar with the plumbing art that it is desirable that the trap cover lie as closely upon the floor as possible to there by avoid unnecessary obstruction above the surface of the floor.

- Stone, David I., and David S. Brown. "Drum-trap construction." U.S. Patent 1,731,990, issued October 15, 1929.

- Smith, Daniel R. "Drum trap." U.S. Patent 2,520,859, issued August 29, 1950.

- Book:

Starbuck, Robert Macy. Modern Plumbing Illustrated: A Comprehensive and Thoroughly Practical Work on the Modern and Most Approved Methods of Plumbing Construction. Norman W. Henley Publishing Company, 1915.

History of Bell Traps in the U.S.: 1872 or Prior

Plumbing traps were also called waste traps and "stench traps" for obvious reasons. In the U.S., we see a number of such patents from well before 1870; in response to a search for "plumbing bell traps" we find:

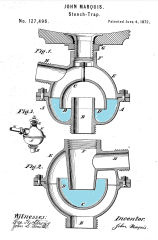

- M arquis, STENCH TRAP [PDF] U.S. Patent No. 127,496, Issued June 4, 1872 [shown below]

Excerpt:

Excerpt:

Be it known that I, JOHN MARQUIS, of San Francisco, in the county of San Francisco and State of California, have invented a new and useful Improvement in Stench-Traps; and I do hereby declare that the following is a full and exact description of the same, reference being had to the accompanying drawing and to the letters of reference marked thereon.

The object of my invention is to provide a stench-trap for wash-basins that can be conveniently attached to the plug or strainer by means of the screws or couplings, and also to the overflow-pipe. To accomplish this I employ that form of trap commonly known as the “bell-trap,” and cover the same with a spherical cap or covering, in which are the places of connection for the strainer, and also for the overflow-pipe.

Referring to the accompanying drawing, Figure 1 is a vertical section of my trap as employed for wash-basins. Fig. 2 is another form of trap on which my spherical cap or covering can be used.

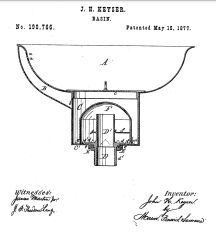

- Keyser, J.E., URINALS or WATER CLOSET BASINS [PDF] U.S. Patent No. 190,767 Issued May 15,1877

Excerpt:

Be it known that I, JOHN H. KEYSER, of the city, county, and State of New York, have invented a new and useful Improvement in urinals or water-closet basins, which improvement is fully set forth in the following specification, reference being had to the accompanying drawing, in which my improved urinal or water-closet basin is represented by a vertical central section.

The nature of my invention consists, first, in the combination of a urinal or water-closet basin with a bell-trap, whereby the bottom of the basin is kept covered with water; second, the combination of a urinal or water closet basin, a bell-trap, and an overflow-pipe; third, the combination of a urinal-basin, a bell-trap, and a water-pipe connection, which forms part of the trap.

The object of my invention is to avoid having a dry bottom in a urinal-basin, and to let the water cover that part of the inner surface of the basin which, by its slight inclination, would retard the flow of the urine and favor the formation of sediment.

Anot her object is to provide a urinal-trap which is of easy access, and which may be conveniently cleaned or repaired without disturbing the waste-pipe. >

See this patent at https://inspectapedia.com/plumbing/Keyser-Patent-US190767.pdf

- EASSIE, W. "THE DANGERS OF BAD PLUMBING: IMPERFECT JOINTING IMPROPER DELIVERIES OF WASTES" Van Nostrand's Engineering Magazine (1879-1886) 22, no. 135 (Mar 1, 1880): 220.

Excerpt:

DURING the Exhibition which was held in Leamington in 1877, I contributed some remarkable specimens of mal-construction in plumbing, and also some curious examples of leaden pipes into which holes had been gnawed by rats while seeking ingress to a house. I also showed several pieces of sheet lead...

This article, from the 1880s, describes troubles with plumbing bell traps.

[Details needed - see next citation] - Easie, William & Rogers Field, HOUSE DRAINAGE [PDF] The American Architect and Building News (1876-1908); Boston Vol. 8, Iss. 238, (Jul 17, 1880): 31.

- Jutrash, Frank. "Trap." U.S. Patent 920,748, issued May 4, 1909.

- O'brien, Hugh M. "Bell trap." U.S. Patent 1,411,125, issued March 28, 1922.

Other Early Plumbing Traps: 1877 & later

- Bruce Barker. PLUMBING VENTS & TRAPS - Barker/ASHI [PDF] (2018) offered online by the author at https://dreamhomeconsultants [.] com/wp-content/uploads/2020/07/The-Word-68_names (2021/12/16)

- Ernest Hart. 1882. The Sanitary Record: A Monthly Journal of Public Health and the Progress of Sanitary Science. London: Smith, Elder and Company. Vol 3, new series: p. 53.

- Keyser, J.H., BASIN [Wash Basin Combined with Trap] [PDF] U.S. Patent No. 190,766 Issued May 15, 1877

Note: this interesting sink trap design uses a bell trap built right into the bottom of a sink basin.

Excerpt:

The nature of my invention consists, first, in a wash-basin constructed with an extension below its bottom proper, for the purpose of forming a bell-trap chamber, said basin and chamber being in communication with one another by means of a removable section of the bottom of the basin, which section, when removed, admits of access to the chamber, and the removal of the bell-cover up through the basin, and thus the trap-chamber can be cleaned out without the necessity of disconnecting any other parts.

It consists, second, in the combination, with the basin, of a bell-trap chamber by means of an overflow-pipe, which discharges first into the bell-trap chamber, as will be presently described. It consists, third, in a coupling - collar formed on the waste-pipe of the bell-trap, in combination with the bell-cover, trap-chamber, and the basin, all as will be hereinafter described.

- Brandeis, Ludwig, BACK-WATER TRAP [PDF] U.S. Patent No. 197,511 Issued Nov. 27, 1877

Note: this invention uses a check valve or flapper in a horizontal valve to avoid sewer backups; it’s not an actual trap.

See this patent at https://inspectapedia.com/plumbing/Brandeis-Patent-US197511.pdf

- Keith, D.S., WATER CLOSET [PDF] U.S. Patent No. 258,433 Issued May 23, 1882

Excerpt:

Another part of my apparatus consists in a safe embracing a cistern bell-trap overflow and ventilator, in combination with a basin and a connecting-tube for the passage of water from basin to safe, said safe basin and tube being made in one piece, but in separate compartments, so as to effect a saving of water and keep the soil out of the compartments in which is the valve apparatus.

The connecting-tube feeds the cistern with water in such manner as to prevent any soil going with the water from the basin into the cistern and clogging the ball or valve, thus preventing the emitting of noxious odors or gases.

Into this safe is also brought the horn or inlet of the basin, so that the valve can be connected therewith without piping, and requiring no putty joints, but merely a rubber washer, thus keeping all water-connections inside the safe.

See this patent at https://inspectapedia.com/plumbing/Keith-WC-Patent-US258433.pdf

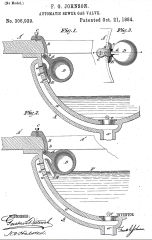

- Johnson Frank G., AUTOMATIC SEWER GAS VALVE [PDF] U.S. Patent No. 306,929 Issued Oct. 21, 1884 [Illustrated below]

Note: Illustrates the complexity of some efforts to prevent passage of smelly, dangerous sewer gases out of the fixture drain and into the building.

See this patent at https://inspectapedia.com/plumbing/Johnson-Sewer-Gas-Valve-Patent-US306929.pdf

- McFarland, S.G., OVERFLOW PIPE for BATH TUBS [PDF] U.S. Patent No. 327,295 Issued Sept. 29, 1885

Excerpt:

Bath-tubs have been made of a wooden case, A, lined with sheet metal, as at B, and having a waste-pipe, C, and into the upper end of this waste-pipe C a tubular overflow, D, has been inserted, the lower end of said tube D tapering and forming a tight joint where it enters into the waste-pipe C.

When the water in the bath rises above the top of the pipe D, it overflows through the same.

Devices similar to this have been used for basin overflows within a vertical trunk at the side of the basin, and said overflow-pipe has been provided with a stem passing up through the slab by which to lift the overflow-pipe, and the same has been sustained by giving to the stem a partial rotation, so as to turn a projection upon the stem above the metal plate at the surface of the slab.

My present improvement is made for preventing towels, sponges, or articles of that character drawing down into the waste-pipe C, and at the same time allowing small substances-such as hairs and lint-to escape freely.

See this patent at https://inspectapedia.com/plumbing/McFarland-Patent-US327295.pdf

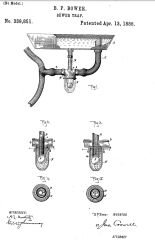

- Bower, Buckland P. SEWER TRAP [PDF] U.S. Patent No. 339,851 Issued April 13, 1886 [Shown below]

Note: notice the lead drain piping and wiped lead joints in this effort at a sewer trap.

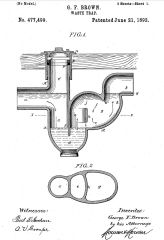

- Brown, George F., [Plumbing] WASTE TRAP [PDF] U.S. Patent No. 477,499 Issued June 21, 1892 [Illustrated below]

Note: this offers an early example of a P-Trap design and incorporates a feature of drum traps: a cleanout access cover.

Excerpt:

To all whom it may concern: Be it known that I, GEORGE F. BROWN, a citizen of the United States, and a resident of Philadelphia, Pennsylvania, have invented certain Improvements in waste-traps, of which the following is a specification.

The object of my invention is to so construct a trap to be placed in the waste-passage from a wash-basin, sink, or bath-tub that it will be proof against siphonage under the ordinary circumstances and which will be scoured by the water passing through it.

- Peter Stander, SEWER TRAP [PDF] U.S. Patent No. 505,302 Issued Sept. 19, 1893

Note: this sewer trap forms an outdoor drum trap for sewer mains. Stander calls it an “inverted bell” trap. Traps like this are still used in many countries including Mexico.

See this patent at https://inspectapedia.com/plumbing/Stander-Sewer-Trap-Patent-US505302.pdf

- C. Knispel, SEWER TRAP [PDF] U.S. Patent No. 541,208 Issued June 18, 1895

See this patent at https://inspectapedia.com/plumbing/Knispel-Sewer-Trap-Patent-US541208.pdf

Note: this is a type of drum trap that includes a provision for venting, intended for use with bath tubs where there is insufficient space between the bottom of the tub and the floor to place a sewer trap.

- Samders, Barney H., SINK TRAP [PDF] U.S. Patent No. 558,569 Issued Apr. 21, 1896

See this patent at https://inspectapedia.com/plumbing/Sanders-Sink-Trap-Patent-US558569.pdf

- Lombard, Victor E., and Clifford E. Cole. "Waste-pipe trap." U.S. Patent 705,769, issued July 29, 1902.

- Wood, William J. "Back-pressure valve for traps." U.S. Patent 783,493, issued February 28, 1905.

- Bonser, James E. "Trap." U.S. Patent 828,595, issued August 14, 1906.

- Cornelius, Louis A. "Trap." U.S. Patent 869,625, issued October 29, 1907.

- Chew, Thomas S. "Trap for bath-tubs." U.S. Patent 886,943, issued May 5, 1908.

Finally - for now -

Early Plumbing Trap's Role in Public Health: 1860 & Later

By the second half of the nineteenth century, certainly by the 1860s in the U.S., experts were writing in depth about the hazards of sewer gases in buildings and described efforts to prevent sewer gases from simply being delivered to the indoors as waste, particularly sewage waste, which had moved from the outhouse to indoor plumbing and toilets.- Allen, C. Bruce. Cottage Building: or, Hints for improving the dwellings of the labouring classes. Virtue & Company, 1867.

- Burn, Robert Scott. Handbook of the Mechanical Arts.. W. Blackwood & Sons, 1860.

- Collins, H. H. On the Ill-Construction and want of sanitary provisions which exist in the dwellings of the upper and middle classes, and suggestions for rectifying the same0: By HH Collins. Being a Paper read at Brighton, before the" Health" Section of the National Association for the Promotion of Social Science, at the Annual Congress, October, 1875. Benjamin W. Richardson, 1875.

- Collins, H. H. "Social science congress at Brighton, 1875," paper", causes of ill construction of dwellings of upper and middle classes." RSA Journal 23 (1874): 968.

- Eassie, William. Sanitary arrangements for dwellings: intended for the use of officers of health, architects, builders, and householders. Smith, Elder & Company, 1874.

- Eassie, William. Healthy Houses: A Handbook to the History, Defects, and Remedies of Drainage Ventilation, Warming, and Kindred Subjects; with Estimates for the Best System in Use,... and Illustrations. D. Appleton, 1876.

- Gerhard, William Paul. Sanitary Engineering of Buildings. Vol. 1. Comstock, 1899.

- Gerhard, Wm Paul, "House Drainage And Sanitary Plumbing: Extension Of Soil And Waste Pipes Fresh Air Inlet Trap On Main Drain Trapping Of Fixtures Venting Of Traps Evaporation Of Water In Traps Absorption Of Gases By The Water In Traps Traps Forced By Back Pressure Branch Wastes From Fixtures Safe-wastes Rain Leasers Cistern Overflow Pipes Refrigerator Wastes", Essential Elements Of A System Of Plumbing, Van Nostrand's Engineering Magazine (1879-1886); New York, Nov 1, 1882

- Jensen, Gerald JG. House Drainage and Sanitary Fitments. Sanitary Publishing Company, 1900.

- Notter, J. Lane. "The Sanitation of Barracks." Royal United Services Institution. Journal 34, no. 153 (1890): 651-674.

- Reynolds, Osborne. Sewer gas, and how to keep it out of houses. 1872.

- Storer, Dr Horatio R. "The Progress Of Sanitary Protection At Newport RI." The Sanitarian (1873-1904) 9, no. 105 (1881): 529.

- Simpson, A. "Some Causes of Preventible Disease." Glasgow medical journal 32, no. 4 (1889): 269.

- Teale, Thomas Pridgin. Dangers to health. Churchill, 1879.

- Whipple, George C., (Chair), USDoC, RECOMMENDED MINIMUM REQUIREMENTS for PLUMBING, Report of Subcommittee on Plumbing of the Building Code Committee, [PDF] (1929) U.S. Department of Commerce, Bureau of Standards, August 30, 1928

Excerpts:

Sec. 6. Trap. — A trap is a fitting or device so constructed as toprevent the passage of air or gas through a pipe without materiallyaffecting the flow of sewage or waste water through it.

Sec. 7. Trap Seal — The trap seal is the vertical distance between the crown weir and the dip of the trap.

Sec. 8. Vent Pipe — A vent pipe is any pipe provided to ventilatea house-drainage system and to prevent trap siphonage and backpressure.

RESEALING OR ANTISIPHON TRAPS

The committee has given attention to the subject of antisiphon, nonsiphon, or resealing traps, as they are called. Practically all traps, except the plain traps already mentioned, may be included in this class.

There are many different kinds, many of them patented and more expensive than plain traps. They are supposed to resist siphonage better than plain traps by reason of having a deep seal, a greater area or volume, tortuous passages for the water, projecting lips, partitions, or, in some cases, moving parts. The best of the resealing traps when clean resist siphonage more than a plain trap of 2 to 4 inch seal, and this may be the case even when slightly fouled.

When more completely fouled, this resistance to siphonage rapidly lessens.

Properly designed resealing traps unvented and clean resist back pressure somewhat more than unvented plain traps of the same depth of seal, but the difference is not sufficient to justify their general use without vents. Their greater complexity causes them to clog more quickly than plain traps, and, if clogged, they are less easily cleaned by the householder and can not be thoroughly cleaned by the usual method of using a force pump or plunger.

Lack of standardization of these traps makes replacement more troublesome and expensive. The supposed advantages of a resealing trap lie in the fact that greater resistance to siphonage makes it possible to omit some of the vent pipes commonly installed and to use longer horizontal unvented waste-pipes and thus secure greater freedom in the location of fixtures. Long unvented horizontal runs, however, are in themselves objectionable.

Sewer gas / methane hazards & the difference between traps and interceptors

Now found at PLUMBING TRAPS & INTERCEPTORS

S-Traps on Plumbing Fixtures & Drains

This discussion is now found at

at PLUMBING S-TRAP CODES & HAZARDS

...

Continue reading at PLUMBING TRAPS, ILLEGAL or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see PLUMBING TRAP, INTERCEPTOR FAQs - questions, answers, comments about plumbing traps

Or see these

Recommended Articles

- PLUMBING MATERIALS & FIXTURE AGE

- PLUMBING TRAPS & INTERCEPTORS - home

- CLOGGED PLUMBING TRAP CAUSE & CURE

- DEFINITIONS: PLUMBING TRAPS & PLUMBING INTERCEPTORS

- DRY PLUMBING TRAP CAUSE & PREVENTION

- GREASE INTERCEPTORS TRAPS

- LOOSE TOILETS LEAK SEWER ODORS

- PLUMBING S-TRAP CODES & HAZARDS

- PLUMBING TRAP HISTORY

- PLUMBING TRAPS, ILLEGAL

- PLUMBING TRAP LEAKS & MISSING INTERCEPTORS

- PLUMBING TRAP MATERIALS & PROPERTIES

- SEWER GASES vs PLUMBING TRAPS & VENTS

Suggested citation for this web page

PLUMBING TRAP HISTORY at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Guidance Document for Sizing and Installation of Grease Traps and Interceptors", Carrolton Texas, January 2012, retrieved 2/16/2014, original source: http://cityofcarrollton.com/Modules/ShowDocument.aspx?documentid=8181

- Kia Gregory, "New York Tries to Clear Its Sewers of FOG (Fat, Oil, and Grease)", The New York Times, p. A18, 15 February 2014

- Thanks to Slade Franklin for the reminder that a leaky wax ring at a toilet can lead to septic odors in bathrooms. 11/2007

- Thanks to J.V. (privacy protected) for the reminder to make a detailed inspection of the plumbing vent system when sewer gas odors are present. 07/2008

- Thanks to Roger Hankey & Cheryll Brown, www.hankeyandbrown.com, ASHI home inspectors in Minnesota, for the deteriorated transite pipe gas flue vent photograph and comments. Mr. Hankey is a past chairman of the ASHI Technical Committee, serves as co-chairman of ASHI legislative committee, and has served in other ASHI professional and leadership roles. 7/2007.

- Thanks to Alan Carson and Bob Dunlop, Carson Dunlop, Associates, Toronto, for permission to use illustrations from their publication, The Illustrated Home which illustrates construction details and building components. Carson Dunlop provides home inspection education, publications, report writing materials, and home inspection services. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

- Steve Smallman, Raleigh, NC, Email: steve@stevesmallman.com, Website: http://stevesmallman.com/ - Quoting: Steve Smallman Property Inspections (SSPI) inspectors have performed or supervised over 25,000 inspections since we introduced home inspections to the Triangle area in 1980. Mr. Smallman is a contributor to InspectApedia.com and has commented on or provided information on plumbing traps, commercial FPE electrical panels and DIY Tests of FPE equipment,, roofing underlayment, and building exteriors.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.