Freezing water pipe or plumbing drain pipe burst & leak patterns

Freezing water pipe or plumbing drain pipe burst & leak patterns

Freeze damage in plastic & metal supply & pipes

- POST a QUESTION or COMMENT about the different patterns in which ice or frost and freezing will cause building water supply or drain pipes to burst

How & where do pipes burst when they freeze? This article describes the different ways in which plumbing pipes freeze & burst & about the pipe burst variations by different piping materials. We illustrate several burst pipe patterns for copper water supply piping and include photographs of the different failure modes for plastic pipes & for galvanized iron water pipes.

In a second section we illustrate breakage patterns when plastic, galvanized iron, or cast iron drain piping freezes. Our page top photo illustrates that hot water heating pipes in a building can freeze and burst or separate when heat fails or is turned too low.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Patterns in Which Water or Drain Pipes Burst or Leak due to Freeze-Ups & Ice Pressure

Freeze or Frost Damaged Copper Piping Break Patterns

Our photo (left) provides a close up showing one of several patterns in which a copper water pipe will swell and burst due to freezing.

In this common copper pipe freeze and burst pattern pressure from expanding ice in the copper line is localized to a specific point, sometimes further obstructed by a pipe elbow or valve.

Pressure from expanding ice forms a round bulge in the copper that bursts in the pattern shown in our photos.

Learning to recognize the typical locations and patterns in which building pipes from any system (water supply, drains, hot water heating system) burst can help diagnose previous troubles as well as prevent future freeze-ups, burst piping, and costly mold or water damage cleanup projects.

Our pipe-freeze damage photo at left illustrates a different way in which water supply piping can burst or leak due to freezing. In this case the force of expanding ice in the water pipe did not cause the copper pipe to swell nor crack.

Rather the ice pressure along the length of the pipe or between the solder joint and a nearby obstruction formed by an elbow or valve caused horizontal movement that separated the sweat fitting, opening the pipe ends.

Watch out: the copper pipe bulges, splits, separations and damage describe here can occur on hot water heating system piping too (see our page top photograph) if the heat is left off in a building.

You can avoid frozen heating pipes in a shut-down building by draining the heating system when it is shut down , or by providing a proper antifreeze mixture in the boiler and heat piping.

Details are at

WINTERIZE - HEAT OFF PROCEDURE

and at

At AIR BLEEDER VALVES we describe opening air bleeders to remove trapped air in heating piping; but that procedure can also assist in deliberate drain-downs of heating system piping as well.

The pipe frost damage shown in this photo illustrates another pipe damage pattern: splitting. The pressure of ice expanding in a length of piping can cause the pipe to expand and split along the length of the pipe.

Depending on how pipe was manufactured as well as on the location and distribution of expanding ice in the length of pipe, some pipes may tend to split when freezing while others will bulge and burst and still others may leak by separation at solder joints or connections.

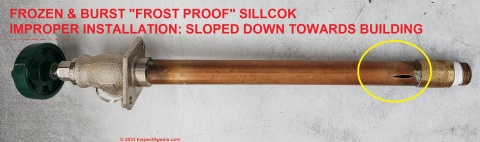

Discussed in more deetail at FAUCET, SILLCOCK ANTI SIPHON / FROSTPROOF LEAK REPAIR, our friends at Davies Hardware, 806 Main St. in Poughkeepsie, NY showed us this frozen, burst "frost proof" sillcock" - the sillcock was installed sloping the wrong way: down towards the inside of the building. It should have sloped down towards the building exterior.

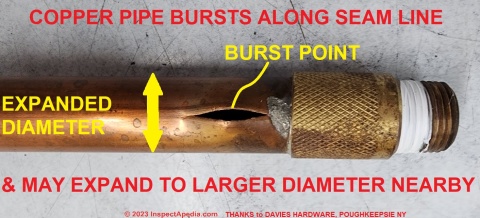

Below our detailed photo of a burst copper pipe component of the sillcock shown above suggests that the pipe burst along what appears to be a manufacturing seam or stress line.

Davies also warns that when repairing frozen burst copper pipe or tubing, you may have to cut out and replace more than you thought: the same forces that split the pipe inside the building at its low-end (that held water that then froze), also expand or "stretch" the diameter of the copper tubing nearby.

Don't Just Turn the Water Back On

Watch out: when turning water back on in a building that was left with heat off, regardless of whether or not pipes were drained, be alert for a surprise spray of water from a burst water supply or heating pipe that you did not see at initial inspection as part of your de-winterizing procedure.

See details at DE-WINTERIZE a BUILDING.

Never just turn heat and water back on and leave the building. Make a complete visual inspection for obvious leaks, listen for leaks in wall, ceiling, or floor cavities, and even if no leaks are found, inspect the building again in 24-hours or less to check for small leaks that are slow to show-up.

Leaving a building wet for more than 24-48 hours risks not only costly water damage but a still more costly mold remediation clean-up job.

Galvanized iron water supply pipe can also burst from freezing, and may split at seams depending on how the pipe was manufactured.

Galvanized iron water supply (or drains) are more likely to burst by splitting or fracturing if pipe sections are corroded from an external cause such as corrosive water or by contact with materials or surfaces that increase the pipe corrosion rate.

Our photo below illustrates a galvanized iron pipe failure (and replacement) at a spa in Lourdes, Mexico. Not all burst pipe damage is from freezing.

Drain Pipe Freeze & Burst Patterns Organized by Drain Pipe Material

Cast iron drain piping freeze damage

Cast iron drain pipes damaged by freezing often fracture as our PVC example or pipes may split at cast-joints. The cast iron drain in our photo above was located beneath a basement floor - and failed by cracking as shown in the image.

Watch out: the crack in a cast iron pipe that causes the drain to leak may be on a side of the drain that you cannot see, such as its under-side along the floor, or a pipe side against a building wall. That's why above we warned of the importance of a careful inspection when a building is being de-winterized.

The cast iron drain (now removed at this location) split along a seam when it froze; often cast iron piping will break into fragments if the piping is filled with water and is frozen solid.

Plastic ABS & PVC drain pipe freeze or frost damage

The photo above shows remains of a PVC drain line that froze and burst in an un-heated crawl space.

This burst pattern is most typical of above-ground and some below-ground PVC drain pipe freeze burst damage - the material fractures.

ABS plastic piping also fails by cracking, discussed as a product failure independent of freezing, at PLASTIC PIPING

Watch out: burst drain piping that spills sewage in a building is going to require not just mopping up but disinfecting or sanitizing of the affected areas. Even dust from areas where there was a previously inadequately cleaned sewage spill can carry pathogens into the building air and into other building areas from that of the original sewer backup or burst pipe spill.

The most common cause of drain line freeze-bursting is the combination of

- A blocked plumbing drain line - the line sits full of wastewater

- The drain line is exposed to freezing - because drain lines are not normally expected to be filled with water, drains are not always protected from freezing at all locations in the piping runs.

- Slow running water, leaks or drippy faucets: A third cause of frozen and burst drain piping is important but less obvious: a dripping faucet or a toilet that runs can send a slow trickle of water down a drain line leading to freezing or even a burst drain pipe in an un-heated crawl space, basement, or outdoors where a building drain may be above the frost line.

Frozen drain piping prevention, burst building drains: how to prevent freezing drain piping, watching for leaks and slow drips into drain systems are discussed at Drain Pipe Protection.

Reader Question: hot water thermal shock cracks ABS drain in very cold climate?

I live above 5 garages in a town home community. The homes were built around 1978. Between my shared garage side-wall there is a drain pipe that goes from my kitchen and connects to a common drain line about 18” into the ground. The problem has happened twice now and it currently needs repair.

It cracks when I run hot water from my kitchen sink when it is cold out. I had it repaired 2 years ago and last winter it was very cold in Minnesota and I forgot to open my cupboard door to allow warmer air to try and prevent this problem.

It is very difficult to even look at the drain pipe to see where the crack is but I know it leaks because the sheetrock has some black mold from the water leaking out of the crack and it makes quite a loud noise when I run hot water down my sink. I am hoping there is some way to insulate or heat this ABS pipe (maybe use some other type of pipe) so when I have it repaired, it won’t crack again. The most recent quote I got was a couple of months ago for about $1400.00. - Anon. by private email, 2016/01/19

Reply:

I was surprised to read about cracking ABS drain piping just in response to thermal shock. Usually I find the problem of cold weather damage to ABS drains is traced to a slow drain, freezing and ice-pressure bursting or cracking of the drain.

Stressing of the piping from improper routing or support can also cause such cracks.

Where exposed to sunlight, photo-oxidation also leads to ABS pipe failures.

I would certainly be reluctant to spring for a repair before we are confident that we understand the problem and thus agree on how it's to be solved.

I tried a google scholar search for research citing thermal shock causing cracks in ABS drain piping and found no clear citation pointing to damage from thermal shock to cold ABS drains caused by residential hot water drainage. There was some related research that I cite below: (Search argument: thermal shock damage to ABS pipe)

- Kashima, T., A. Yamanaka, T. Takasugi, and Y. Nishihara. "Thermal expansion of ultra high strength fiber and its fiber reinforced plastics." In Advances in Cryogenic Engineering Materials, pp. 329-336. Springer US, 2000.

- Durosinmi, Adelakin. "Mechanical and Structural Properties of PVC When Subjected to Heat." (2015).

- Martin-Nown, Chris. "Freeze isolation of polymer pipeline using cryogenic liquids." PhD diss., University of Southampton, 2008.

Galvanized Iron drain pipe freeze damage

Galvanized iron pipe can also burst from freezing, and ma

...

Continue reading at PIPE FREEZE-UP POINTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

PIPE FREEZE-BURST PATTERNS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FREEZE PROTECTION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- John Platts, "The World's Encyclopedia of Wonders and Curiosities of Nature and Art, Science and Literature: Representing Anatomy, Physiology, Phrenology, Astronomy, Botany, Geology, Natural History, Ichthyology, Mythology, Ornithology, Meteorology, Mineralogy, Chemistry, Zoology, Entomology, Biography, Etc." Union publishing house, 1880 - Encyclopedias and dictionaries - 958 pages (available as a Google e-Book. Quoting:

Astonishingly Expansive Force of Freezing Water. — Although cold, in general, contracts most bodies, and heat expands them, yet there are some instances to the contrary, especially in the extreme cases or states of these qualities of bodies. Thus, though iron, in common with other bodies, expands with heat; yet, when melted, it is always found to expand in cooling again. Thus also, though water expands gradually as it is heated, and contracts as it cools, yet in the act of freezing it suddenly expands again, and that with an enormous force, capable of rending rocks, or bursting the very thick shells of metal, &c. A computation of the force of freezing water, has been made by the Florentine academi cians, from the bursting of a very strong brass globe or shell by freezing water in it ; when, from the known thickness and tenacity of the metal, it was found that the expansive power of a spherule of water only one inch-in diameter, was suffi cient to overcome a resistance of more than twenty-seven thousand pounds, or thirteen tons and a half. - "An Investigation into Freezing and Bursting Water Pipes in Residential Construction Laboratory and field tests conducted to discover the mechanics of freezing and bursting of pipes and why they freeze", 51 pages, 1996, Building Research Council, School of Architecture University of Illinois at Urbana-Champaign, Building Research Council Order Dept 1 East St. Mary's Road Champaign, Illinois 61820, Tel: 800-336-0616, Website: http://brc.arch.uiuc.edu Contact: Jeff Gordon, jrgordon@uiuc.edu

- "New Electric Heat Tapes Help Prevent Fires," US Consumer Product Safety Commission (CPSC) #00936

- "Solar Water Heaters Begin your consideration of installing a solar water heater by understanding its five parts. Covers collectors, storage devices, circulation systems, safety systems, and freeze-protection systems", Building Research Council, School of Architecture University of Illinois at Urbana-Champaign, 8 pages, 1988

- "New Electric Heat Tapes Help Prevent Fires," US Consumer Product Safety Commission (CPSC) #00936

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- "Freezeproof Your House," Mike McClintock, Rodale's New Shelter, p. 30, October 1985 (approximate date)

- "How to Winterize Your Pipes," Mike McClintock, Homeowners How-To Magazine, p. 59-62, Nov-Dec 1979.

- "HUD Regulation for Manufactured Homes; Requirement that Heat-Tape not include a GFCI [ copy on file as /plumbing/GFCI_Heat_Tapes_HUD_CPSC_Letter1994.pdf ] - ", Meeting Log, US CPSC, HUD, Dennis McCoskrie, ESEE, 2/14/1994

- "Houses in Hibernation," Steve Bailey, New York Times, 24 October 2008 p. D2.

- Thanks to reader Ryan T. Duffy for discussing the suggestion for GFCI's on heat tape circuits to reduce fire risk, October 2010.

- Thanks to reader David Gould, BC, Canada, for pony pump requirements discussion, 1/27/2010

- [8] Colorado Climate Center, "How deep is the frostline in the winter in various parts of Colorado?", website http://ccc.atmos.colostate.edu/questions.php, retrieved 3/1/13

- [9] Easy Heat heating cables, "Easy Heat AHB-013 Cold Weather Valve and Pipe Heating Cable",

http://www.emersonindustrial.com/, retrieved 3/2/2013,

Product Description: Temperature-controlled cable runs straight along pipe and valves, held in place by application tape and plugs into grounded electrical outlet. Keeps water flowing down to -380. For odd lengths of pipe over 3/4 inches in diameter, we recommend two separate cables on opposite sides of the pipe with up to 3 feet of overrun at center of pipe run. Metal pipe requires 1/2-inch fiberglass insulation around cable. For plastic pipe, its recommended wrapping pipe with aluminum foil before cable installation. The traditional resistance cable produces a fixed amount of heat based on the electrical line feed. It comes with a built-in thermostat that switches the flow of electricity on and off based on temperature. Cable installs fast and easy. Each package contains grounded plug, built in thermostat and instructions. Cable has weather resistant PVC outer jacket and inner insulation. Keeps water flowing down to 40 F. - [10] Easy Heat, "Easy Heat® Freeze Free® Preset Thermostat (EH-38)" , EGS Electrical Group, 9377 W. Higgins Rd.

Rosemont, IL 60018, USA or EGS Electrical Group, 99 Union Street

Elmira, ON N3B 3L7, Canada. Tel: 800.621.1506,

Product specifications: 15 amps, 120 volts 1800 watts Thermostat for use with Freeze Free Self-Regulating pipe heating cable, For dry location only, UL listed, CSA certified - [11] RayChem "Self-Regulating Pipe Heating and Roof/Gutter De-Icing Cable", Rachem Corporation, 300 Constitution Drive, Menlo Park, California 94025-1164, U.S.A., Website: http://raychem.te.com/, retrieved 3/2/2013, Product Description:

Self Regulating Heating Cable, Mounting Location Dry, Cable Length 50 ft., Max. Circuit Length 200 ft., Voltage 120, 6 Watts per Foot @ 40F, 0.050 Amps per Foot @ 40FFeatures Self Regulating, Automatically Adjust Heat Output, For Use With Lighter Plastic or Metal Pipes Up to 8 In. Dia., Standards UL Listed and CSA Certified, Includes Cable Only; Characteristics : Tough Metal Braided Self Regulating Heating Cables, Can be Overlapped and Insulated without Overheating or Burning Out, Automatically Adjust Heat Output at Each Point Along its Length without Using Thermostats, Standards : UL Listed and CSA Certified, Includes : Cable Only - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.