Orangeburg Pipe

Orangeburg Pipe

Identification, properties, history, uses

- POST a QUESTION or COMMENT about orangeburg pipe sewer & drain piping

Orangeburg pipe history, ingredients, and uses.

Orangeburg pipe is black, not orange, and is fragile after spending decades buried underground. We also address the question of the presence of asbestos in Orangeburg pipe manufactured during some years.

This article series defines and describes different types of building supply and drain piping with an alphabetical list of piping materials and properties.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Orangeburg Pipes at buildings: definition, properties

Orangeburg pipes, named not for their color but for the town (Orangeburg NY) where the Fibre Conduit Company, the major manufacturer of this type of pipe material.

Orangeburg pipes, named not for their color but for the town (Orangeburg NY) where the Fibre Conduit Company, the major manufacturer of this type of pipe material.

Despite it's name, "Orangeburg pipe" is not orange in color and it never was.

Orangeburg pipes are black, made of somewhat fragile compressed layers of asphalt impregnated wood pulp, and from 1946-1970 included asbestos and later wollastonite for additional strength.

In North America by the mid 1970's plastic pipe (ABS and PVC) supplanted the use of Orangeburg in new installations, but even today, decades later, Orangeburg pipe may be found at some older properties like the one I (DF) photographed in 2011, shown in our photo.

Photo: an Orangeburg pipe used as a water line, passing above a modern black ABS drain line, courtesy of InspectApedia reader Fabio.

Where found today (2025) any Orangeburg pipe is likely to be in deteriorated condition and not reliable or not working at all.

Article Contents

- ASBESTOS in ORANGEBURG PIPE

- ORANGEBURG PIPE DIMENSIONS

- LIFE EXPECTANCY of ORANGEBURG PIPE

- ORIGIN & HISTORY of ORANGEBURG PIPE

- PATENTS for ORANGEBURG PIPE give historical details and ingredients

...

History of Orangeburg Pipe

Orangeburg piping was first used in Boston in 1865 [earlier than the founding of Fibre Conduit Co].

Orangeburg piping was first used in Boston in 1865 [earlier than the founding of Fibre Conduit Co].

Black coal-tar impregnated fiber piping was widely used in North American from 1950 to 1970.

The name Orangeburg pipe comes from the main producer of this product, the Fibre Conduit Co., in Orangeburg, New York.

The Fibre Conduit Company was founded by Stephen Bradley (owner of electric lighting and power companies) in Orangeburg NY in 1893.

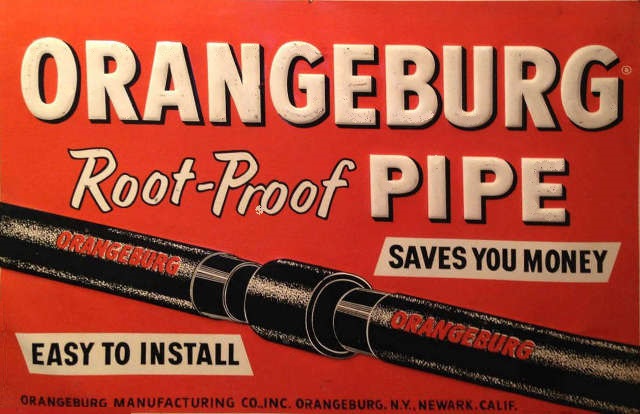

By the time the sign advertising "Orangeburg root-proof pipe" shown here was in use, the company also had facilities in Newark California.

In its earliest production the steam waste exhaust from early steam-generated electrical power plants was used in the manufacture of Orangeburg pipe to heat and dry it.

Later orangeburg pipe was also used as five-foot sections of electrical wire conduit, probably a successor to the much heavier and more costly tar-filled pipes that carried Edison's earliest Solid Iron Tubing or Steel Pipe & Pitch Insulated Electrical Cables.

An advantage of asphalt-based conduit piping was its resistance to corrosion and acids.

The 1939 Worlds' Fair advertisement described wide use of Orangeburg pipe by that year.

Orangeburg pipe was sold for underground ductwork use with a concrete encasement as well as an Orangeburg "Nocrete" version was used for electrical service entrances and similar applications.

By the late 1930's to early 1940's this wood-fibre-based conduit or piping was marketed under the brand Alkacid.

This Orangeburg advertisement, celebrating its installation in Boston was published in the July 15 1933edition of Electrical World.

This Orangeburg advertisement, celebrating its installation in Boston was published in the July 15 1933edition of Electrical World.

Later Alkacid and other brands of fibre-based asphalt impregnated pipe were replced by asbestos-cement pipe or transite pipe.

In the U.S. it's use fell close to zero by 1972 when it was replaced by alternative piping materials.

In North America Orangeburg pipe was used in both municipal water supply piping systems and in both public sewer systems and in private septic systems as well as other site drainage systems from the 1860s to as late as the late 1970s.

Orangeburg piping was used in both un-perforated form as septic distribution piping and more widely in perforated form as effluent distribution piping in septic drainfields and as buried downspout drain lines. Some installations were surrounded by concrete.

Orangeburg pipe was also used without concrete as a no-crete Orangeburg pipe installation for electrical conduit and its early use included steam system piping. In its widest use Orangeburg pipe was sold and installed in five-foot sections.

Synonyms for Orangeburg pipe

- Alkacid conduit

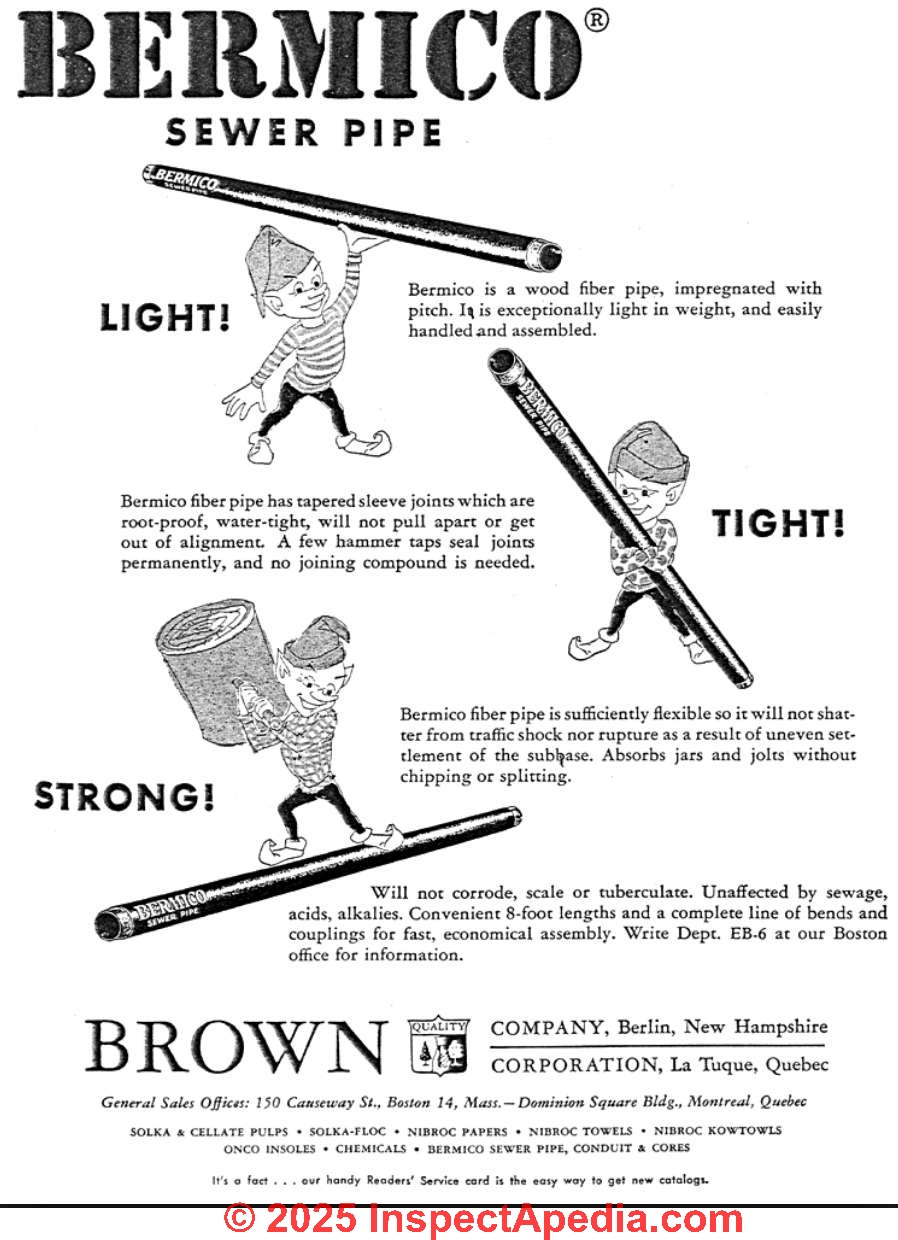

- Bermico

- Black Pipe

- Bituminous Fiber Pipe

- Bituminized fiber pipe

- Fibre Conduit

- No-Corrode Pipe

- Sand Pipe.

As we explain

at AGE of PLUMBING MATERIALS & FIXTURES,

Orangeburg drain & septic field piping, most widely used in drain piping and septic fields, was made of multiple layers of ground wood fibers bound with an adhesive mastic (coal tar), impregnated with coal tar pitch, and typically looking like black"tarred" piping.

Watch out: Orangeburg pipe, where still in use, will often be found delaminating and may have broken or collapsed.

You can see my photo of a section of that earlier electrical cabling

at STEAM BOILERS GENERATORS CONTROLS, PRATT

Manufacturers of Orangeburg Pipe

Orangeburg drain piping and sewer piping was not made just by Fiber Conduit.

- American Manufacturing (East Chicago, IL)

- American Piping Co. (Fulton NY)

- Bermico (Brown Manufacturing Co., 150 Causeway St., Boston 14 MA, Berlin NH, and Dominion Square Bldg., La Tuque, Quebec, Canada) Fibre Conduit Products.

Bermico also produced Solka & Cellate pulps, Solka Floc, Nibroc Papers and towels, Onco Insoles, chemicals, and Bermico Sewer pipe, conduit,, & Cores. - Fibre Conduit Co. (Orangeburg, NY and the largest manufacturer of Orangeburg pipe)

After 1948 the Fibre Conduit company, the originator of Orangeburg pipe, changed its name to Orangeburg Manufacturing. - J.M. Fiber Conduit Co. (Lockport, NY)

- Orangeburg Manufacturing

...

Life Expectancy of an Orangeburg Pipe Drainfield

We estimate by the late 1940's, and continuing through the 1960's perforated Orangeburg pipe was widely used in the U.S. and parts of Canada for area drains and particularly as distribution piping in septic drainfields.

We still come across Orangeburg pipe when excavating old septic drainfields and on occasion when inspecting an older home, say before 1970, you may see the top of a section of Orangeburg pipe peeking up above ground as a connection for a roof gutter downspout.

In our Orangeburg pipe downspout drain photo above we are pointing out (the pen) that perforated pipe was used as a buried drain right next to the building - inviting basement water entry even if the drain is not yet clogged.

Watch out: if you see a buried downspout drain using a material not commonly installed for 40 years, that the drain itself is likely be blocked or to have collapsed by now.

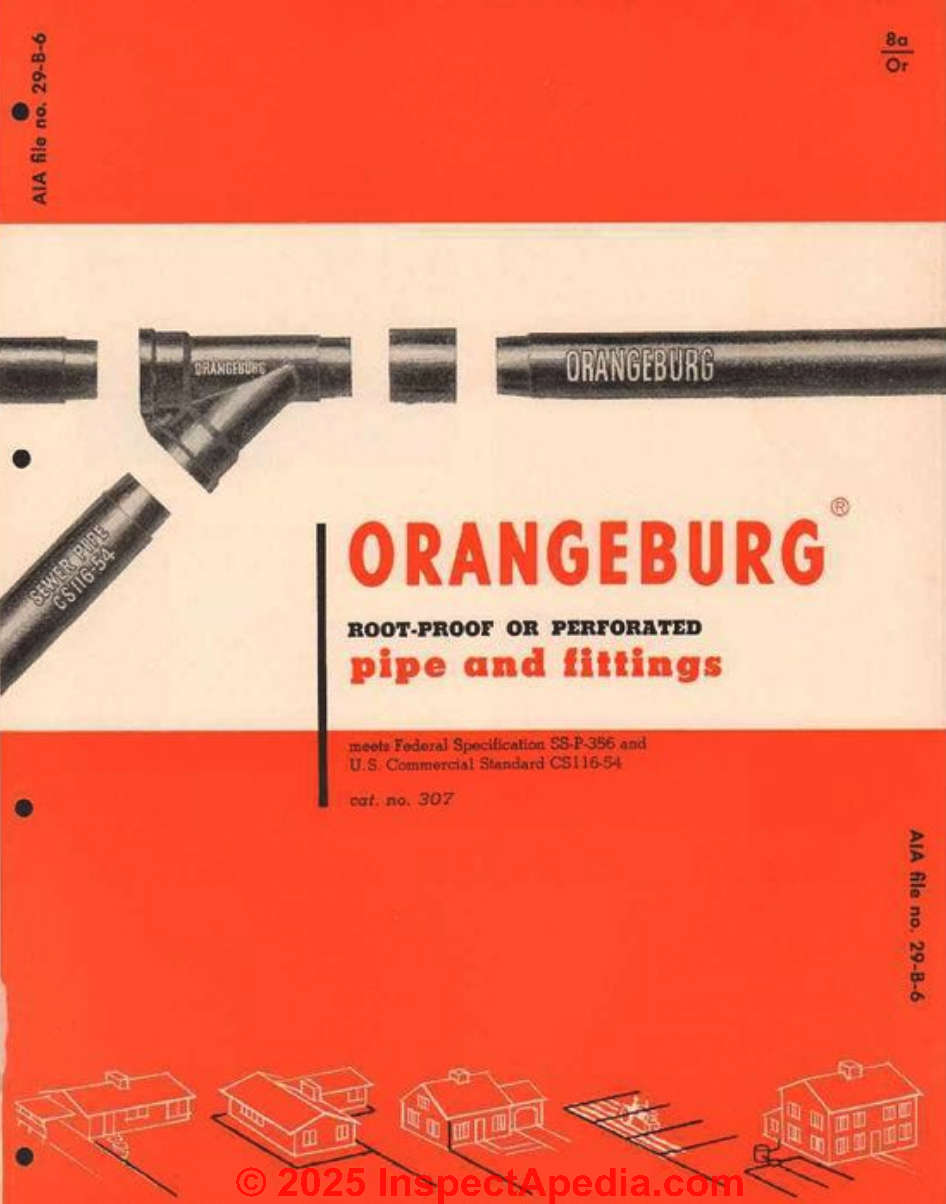

Below is an excerpt from a 1955 advertisement describing Orangeburg as "root proof" pipe. Our experience and other sources cited here found otherwise.

Watch out: What about a septic drainfield built using Orangeburg pipe?

Despite the advertisement above, Orangeburg pipe was less rigid than terra-cotta piping (though also less fragile), making it vulnerable to both crushing-collapse and tree-root invasion.

In fact some of our research sources cited root invasion as the most common mode of orangeburg pipe failure, though with age, collapse is also common.

If you encounter a septic absorption bed or drainfield that used Orangeburg pipe you should not count on the continued usability of that septic system. Such a drainfield is by now likely to be in questionable, if not failed condition.

...

Orangeburg Pipe Dimensions: diameters & wall thickness

Above: a table of dimensions of Orangeburg pipe and couplings from the 1944 Commercial Standard CS116-44 cited in detail below.

Orangeburg pipe was manufactured in a variety of diameters and thicknesses for various applications including electrical conduit and sewer or drainfield effluent distribution pipes.

Orangeburg common diameters ranged from 3" to 8" I.D.

Orangeburg pipe used as perforated septic drainfield piping had a nominal ID of 4.00 inches and an O.D. that varied by manufacturer; the pipe wall was about 3/16" to 1/4" thick.

Orangeburg with a 4.0" ID and that's 3/16" thick would have an OD of about 4.375"

Orangeburg pipe lengths varied; most sources assert that Orangeburg was most-widely used in 5-foot lengths; the table above cites 5 ft and 8 ft. lengths; other sources assert that it was also sold in 10 ft. lengths.

...

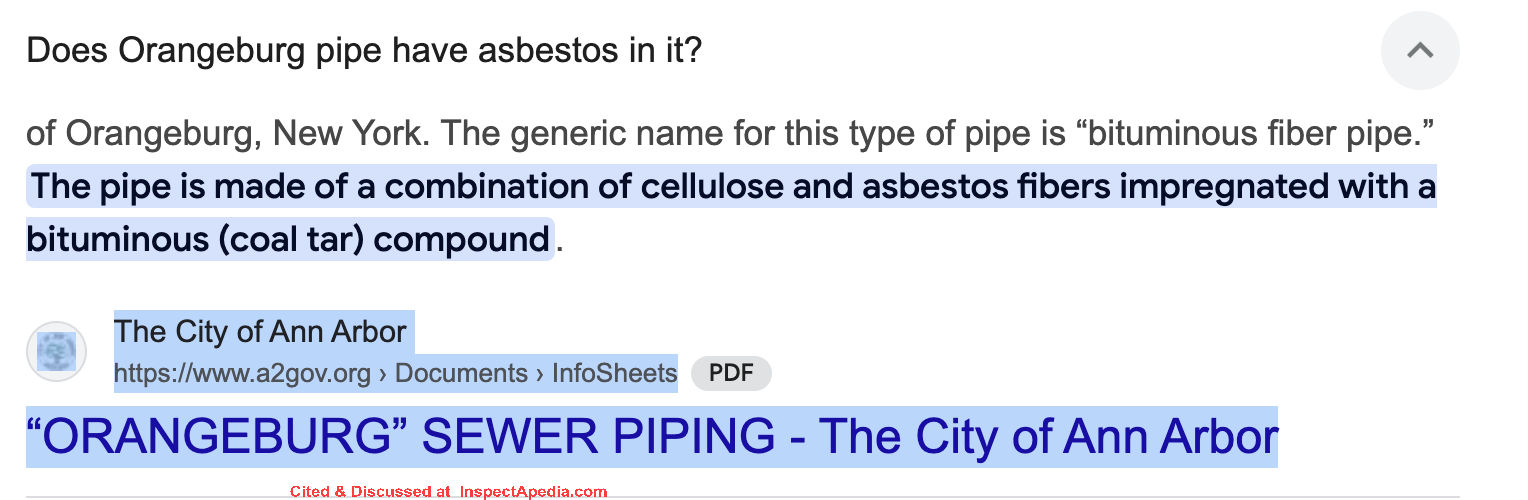

Asbestos in Orangeburg Pipe?

Bottom line: Orangeburg pipe was made principally of asphalt and cellulose (wood fiber or wood pulp) based material or in some texts, less-accurately, "tar paper" reinforced using oakum or hemp (Kirkland 1868).

Bottom line: Orangeburg pipe was made principally of asphalt and cellulose (wood fiber or wood pulp) based material or in some texts, less-accurately, "tar paper" reinforced using oakum or hemp (Kirkland 1868).

At least some Orangeburg pipe manufactured between 1946 and 1970 was made using wood pulp combined with asbestos. (TenTen Env. 2016)

After 1970 the asbestos in Orangeburg pipe was replaced with wollastonite (MgO2 fibrous material). (TenTen Env. 2016)

Asbestos hazard? In any case, in our OPINION, because Orangeburg is not a friable material and it's usually buried, it presents no meaningful asbestos hazard unless it is excavated and demolished using dust-creating methods like sawing or grinding. - Opinion, DF.

Research on "asbestos use in Orangeburg pipe"

While few sources are clear on this point and some research confuses cement asbestos pipe with Orangeburg, it's possible that some production of Orangeburg pipe included asbestos which would have been added as a filler or as a strengthening fiber.

- See also PATENTS for ORANGEBURG PIPE whose texts give historical details and ingredients in early and later formulations of Orangeburg conduit and pipe.

- Arizona, Coconino County, Orangeburg Pipe [PDF] - retrieved 2025/02/05, local copy saved as Orangeburg-Pipe-AZ-Coconino.pdf (No mention of asbestos)

- O'Meara, L. and Turley, J., 1973. Plumbing and Piping: Construction, Supervision, and Inspection. Course of Study.

Excerpt:

Bituminized-Fiber Pipe: Bituminized-fiber pipe is known by many names, the most common of which are Orangeburg and "paper pipe."

The pipe is a compound of bituminized impregnated fibers pressed into a hard, smooth bare material.

This pipe is used primarily for residential work, outside the building foundation, for the building sewer line.

It is a very inexpensive material that lays rapidly. A heavy duty perforated pipe is made for foundation, road way, and other subsoil drainage. (Op. Cit. p. 23) - Michigan, City of Ann Arbor, ORANGEBURG SEWER PIPING [PDF] 2025/02/06 Note: we are providing a local copy of this article, received in response to our email request to the Ann Arbor MI government to provide us with the original document. The City of Ann Arbor copy of this file is temporarily unavailable at city's website.

Excerpt:

The generic name for this type of pipe is “bituminous fiber pipe.” The pipe is made of a combination of cellulose and asbestos fibers impregnated with a bituminous (coal tar) compound.

Bituminous fiber pipe was manufactured with either a homogenous wall or a multiple-ply laminated wall. The ends of the pipe were tapered and fitted together using a butt joint.

The screen shot below states that Orangeburg included asbestos. Clicking on thie image below will also link to our PDF copy of the original document.

- Whittaker, Miller Fulton. "A modern agricultural building for State Agricultural and Mechanical College, Orangeburg, SC." (1928) [PDF] Thesis

Note: this is an example of misleading search results that can lead to mis-statement. The word "asbestos" appears in this document, but having to do with asbestos felt and roofing products, not orangeburg pipe. - Wickline, Alfred. Corrective Action Decision Document/Closure Report for Corrective Action Unit 190: Contaminated Waste Sites, Nevada Test Site, Nevada, Revision 0. No. DOE/NV-1263. Stoller-Navarro Joint Venture, 2008. [PDF]

Excerpts:

A sample was collected of the Orangeburg pipe and results showed high concentrations of benzo(a)pyrene.

...

The presumed asbestos-containing material (PACM) samples collected from insulation covering the water tanks and cooling tower piping at CAS 11-02-02 and from the Orangeburg pipe at CAS 11-59-01.

Note that the report used the term PACM - rather than actual or detected asbestos. - Wikipedia, "Orangeburg Pipe" - retrieved 2025/01/11 - Note: we're not sure this article is accurate, original source https://en.wikipedia.org/wiki/Orangeburg_pipe

Excerpt:

Orangeburg pipe (also known as "fiber conduit", "bituminous fiber pipe" or "Bermico" or "sand pipe") is bituminized fiber pipe used in the United States.

It is made from layers of ground wood pulp fibers and asbestos fibres compressed with and bound by a water resistant adhesive then impregnated with liquefied coal tar pitch.[1][2]

This Wikipedia article cites:

"Risks and Problems: Orangeburg Pipe [Updated]". www.expresssewer.com. Archived from the original on 1 May 2022. Retrieved 15 May 2022 and by InspectApedia 05 February 2025.- Petty, S.E. and Knepper, B.E., 2021. Plumbing/Piping/Tubing Failures. In Forensic Engineering (pp. 693-715). CRC Press.

Excerpt:

… the mid-1970s “Orangeburg” pipe refers to the brand name of a sewer pipe made by the …

“bituminous fiber pipe” and is manufactured from a combination of cellulose and asbestos fibers … - Schladweiler, Jon C. (2004). Coal Tar Impregnated Wood Fibre Pipe sewerhistory.org, - 2025/02/05 local copy archived as Wood-Fibre-Pipe-Schlad.pdf

Note: No mention of asbestos content in Orangeburg nor Alkacid pipe.

Excerpt:

During the petroleum “trial” days (1937 – 1944), the fibre conduit pipe tested was called “Alkacid” by the Fibre Conduit Co. of Orangeburg, NY. The oil industry soon stopped using the fibre “Alkacid” pipe, and started using cement-asbestos pipe … as then manufactured by the Johns-Manville and Keasby & Mattison Companies. - TenTen Environmental, Orangeburg Commerce Center Remedial Investigation Summary [PDF] (2016) TenTen Environmental, 121 West 27th Street, Suite 702, New York, NY 10001 and Orangeburg Commerce Center, 5 Greenbush Road Orangeburg, New York 10962 Section 74.15, Block 1, Lot 2 (portion) BCP #C344078, retrieved 2025/02/05, local copy on file as Orangeburg-Remediation-NY.pdf

- U.S. DoC, BITUMINIZED-FIBRE DRAIN AND SEWER PIPE [PDF] Commercial Standard CS116-44 [PDF] (1944) U.S. Department of Commerce, National Bureau of Standards. Local copy filed as Bituminized-Fibre-Drain-CS116.pdf

Excerpt:

USES

3. The requirements of this standard are intended to provide pipe suitable for conducting liquids and for drainage where tight joints are necessary,

and where resistance to corrosion, erosion, and disintegration is indicated, such as the following:

a. House connections to sewers and septic tanks.

b. Farm drainage and low-head irrigation conductor pipe.

c. Downspouts, leaders, and storm drains.

d. Salt water disposal in oil well country.

e. Industrial waste drainage, and other uses outside of buildings, as indicated by pipe characteristics

- Petty, S.E. and Knepper, B.E., 2021. Plumbing/Piping/Tubing Failures. In Forensic Engineering (pp. 693-715). CRC Press.

...

Orangeburg Pipe Patent History

- BIKLEN, Donald W. Bituminized fiber pipe. U.S. Patent No 2,839,088, 17 Jun. 1958.

- BRADLEY JR, Stephen R. Machine for making pulp pipes. U.S. Patent No 799,028, [PDF] 9 12 Sept. 1905.

- BRADLEY, Stephen R. Process of manufacturing pulp pipe. U.S. Patent No 966,729, [PDF] 9 Ago. 1910. Assignee: Fibre Conduit Co., Orangeburg New York. [The company later changed its name to the Orangeburg Pipe Co. - Ed.]

- BULLOCK, P.; MILFORD, M. H.; CLINE, M. G. Degradation of Argillic Horizons in Udalf Soils of New York State 1. Soil Science Society of America Journal, 1974, vol. 38, no 4, p. 621-628.

Excerpt: Lengths of Orangeburg pipe were prepared which were 10 cm in diameter, and perforated at 5-cm intervals with four holes 1.5 cm in diameter and arranged 80 to 100° apart around the pipe. - Ellis, Benhamin F., Construction of tubes and cylinders, US Patent No 6l2,897. Patented Oct. 25, 1898. B. F. ELLIS.

Illustration: from the Ellis patent cited just above. [Click to enlarge any image]

- Fairbanks, Henry, Machine for making pulp pipes and pulp-covered rolls, US Patent 583398, [PDF] June 8, 1897, filed August 14 1893, SN 483,080.

Excerpt:

Be it known that, I, HENRY FAIRBANKS, of St. Johnsbury, in the county of Caledonia, and State of Vermont, have invented certain new and useful Improvements in Machines for Making Pulp Pipe and Pulp - Covered Rolls, of which the following, taken in con-p nection with the accompanying drawings, is a specification.

My improvement relates to machines by which rolls are covered with wood or paper pulp by winding successive layers of the soft film upon them, which covering may be dried upon the roll or loosened and slid off to be used as tubing.

In order that the pulp-layer may be laid evenly upon the forming-roll A, it is necessary that this roll be held against the pulp-bearing surface with a uniform yielding pressure and follow its motion without jar.

Evidently it is a disadvantage if a heavy frame carrying the forming-roll must be moved with this roll to secure constant contact. T

o correct this, my improved machine has the re volving frame arranged simply to guide the motion of each forming-roll while receiving its layers of pulp, and provides a separate de vice for pressing it against the moving sur face Supplying pulp. - GANNON, Charles R. Pitch-impregnated fiber pipe. U.S. Patent No 3,927,696, 23 Dic. 1975.

- JENKINS, Charles F. Common causes of material degradation in buried piping. Westinghouse Savannah River Co., Aiken, SC (United States), 1997.

Excerpt:

... backfill plays a larger role in mechanical capability of the pipe system than it does for most other materials. Orangeburg pipe 1 frequently fails by root intrusion at joints

- Kirkland, William, IMPROVED DRAN AND WATER PIPES, US Patent No. 76,778, [PDF] April 14, 1868

Excerpt:

Be it known that I, WILLIAMP. KERKLAND, of the city and county of San Francisco, State of California, have invented an Improved Drain and Water pipe

and I do hereby declare that the materials used, and the manner of mixing and preparing the same to manu facture the said pipe, with the best apparatus lknown to me for the purpose, are described in the following specification.

The nature of my invention is to provide an improved drain and Water pipe combining strength with durability and cheapness.

To accomplish this object, I employ a series of strands or cords loosely twisted, and place them in a tank or caldron of boiling asplialtum or pitchy substance, and [confine?] their ends to a cylinder or roller suspended over the tank.

These cords or strands are so attached to the cylinder or form that in turn ing they will cross each other diagonally.

Between each coil of rope I place a layer of oakum or hemp, and when a desired number of coils or layers has been wound upon the l'Oller it is withdrawn, and the pipe is coated With the contents of the tank above described.

To more fully illustrate and describe my invention, I employ a tank or caldron, in which is placed a pitchy substance, (I prefer asphal tum after the oil has been extracted, butcom mon pitch from trees or resin might answer,) which should be well mixed by boiling, and kept heated.

In this I place a series of strands, loosely twisted, or cords in two sets, so arranged as to be easily withdrawn from the tank, which may be accomplished, after they are attached to the cylinder, by confining their ends to a strip of paper or cloth.

After the form has been turned completely around once commence to place a layer of oakum or hemp at right angles to the Strands, turning the cylinder until a pipe of suitable thickness and strength obtained, when the form is removed, and the pipe so formed is dipped in the pitch or asphaltum in the tank, above described, which coats it completely inside and out, this forming a pipe of asphaltum or pitch and fibrous material without iron or other form. - Schladweiler, Jon C., P.E., R.L.S.; Historian, AZ Water, "Coal Tar Impregnated Wood Fibre Pipe (Commonly referred to as “Orangeburg,” “Bermico,” etc. pipe)", retrieved 2018/05/25, original source: http://www.sewerhistory.org/articles/compon/orangeburg/orangeburg.htm

- Schladweiler, Jon C., Tracking down the roots of our sanitary sewers. Proceedings of the Water Environment Federation, 2001, vol. 2001, no 2, p. 1-27

Excerpt:

[Orangeburg pipe] came in sizes from 3” to 8” internal diameter. The couplings were pure compression; no gaskets. The pipe manufacturer changed its name to Orangeburg Pipe ... - STANLEY, William E.; ELLIS, Robert D. Paper Pulp Wastes Treatment: Orangeburg Manufacturing Co. Sewage and Industrial Wastes, [Image file of journal article page] 1954, p. 991-1001.

Excerpts:

Orangeburg sewer pipe and Orange burg electrical conduit have been man ufactured at the present factory loca tion since 1893. The product is a hard coal-tar pitch compound reinforced with a preformed wood fiber structgure, about 75 percent hard coal-tar pitch and 25 percent wood fiber. The raw materials include coal-tar pitch, selected clean waste paper, and mineral fiber. - WOLF, Harold W. Resistance of bituminous fiber pipe to penetration by rats. Public Health Reports, 1962, vol. 77, no 9, p. 806.

Excerpt:

(1) Orangeburg root-proof or perforated pipe and fittings. Catalogue No. 307. Orangeburg Man ufacturing Co., Inc.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Illustration above: an Orangeburg "Root-Proof" pipe advertisement ca 1955.

Did Orangeburg electrical duct and Nocrete duct contain asbestos? Is it Friable?

We encounter and replace old Orangeburg electrical duct and Nocrete duct fairly often.

Does anyone have any information about whether this could contain asbestos, and if so, is it friable. Thanks in advance. On 2024-05-01 by Tom Reynolds

Reply by InspectApedia Publisher (mod) - Asbestos, yes, Friable, no.

@Tom Reynolds,

Orangeburg pipe, as you can read in more detail in the patent citations that we excerpt in this article, was in essence wood or paper pulp impregnated with an asphaltic waterproofing material.However asbestos was added to some Orangeburg pipe from the late 1940's to 1970, as you'll find in the article above on this page.

As "Friable" is defined as easily reduced to a dust or powder (that could thus easily become airborne) by the mere pressure of a thumb and forefinger, no, Orangeburg pipe is not friable.

Can a leak in an Orangeburg sewer or septic pipe be sealed?

Is it possible to seal a leak from an orangeburg soil downpipe or must it be removed, thanks.

The leak is from a joint. - On 2023-07-11 Albert Krawinkel

Reply by InspectApedia Publisher (mod) - Yes but with this warning

@Albert Krawinkel,

Thanks for the helpful question.In my OPINION, while you might make a temporary repair of old orangeburg pipe - probably part of a septic drainfield or downspout drain or foundation drain system - by now the whole orangeburg pipe system is so old that it's likely to be well past its useful life and ready for complete replacement.

The risk is throwing good money after bad in a series of repairs until you toss in the towel and dig up the whole pipe system.

So yes, I'd go for a short term "fix" by excavating and patching the old pipe using Fernco type rubber fittings, but I suspect when you look more-closely you're going to see that the system needs more-extensive replacement.

Watch out: our review of local plumbing ordinances from several U.S. cities and similar authorities occasionally came across the statement in describing septic or sewer pipe installation regulations:

"Where Orangeburg pipe is encountered it shall be removed and replaced with contemporary pipe materials."Still I'd expect most local plumbing inspectors to be okay with your making a temporary repair such as by using a rubber coupling.

What kind of fitting can I use to repair an old Orangeburg pipe water line?

I hope you can help me, passing a new drain pipe I found and a black Orangeburg water line pipe that goes from the meter to the main water valve.

The internal diameter should be 1 inch but the OD (Outside Diameter) is something like 1.39 r 1.40.

I need to make some room and resolve a poor slope of a drain pipe that is just below, I thought something like (kind of bridge) 45 up straight and then 45 down.

I can't find anything that fits that OD Do you know what kind of fitting I have to use? Can I glue it with a 1-inch white PVC On 2022-11-06

by Fabio

Reply by InspectApedia (Editor) (mod) - Rubber couplings

@Fabio,

I doubt that you can glue successfully or reliably if the pipe material is correctly identified as what you are calling Orangeburg.

But in the lower part of your photo you can see that there are two stainless steel clamps with a rubber coupling fitting.

So clearly you can buy an over the counter rubber coupling (See Fernco couplings for examples) that would allow you to make another connections.

Measure the inside diameter as well as the outside diameter.

Then you you have two fitting type options when you ask your plumbing supplier to provide you with a reducing Tee.

What does Orangeburg pipe sound like when hit with a wrenchg

If I rap on an Orangeburg pipe with a metal wrench will it make a metallic sound or more of a wood thud sound On 2022-06-25 by pbfateley@frontier.com

Reply by InspectApedia-911 (mod) - Thud

@pbfateley,

Thank you for a challenging question.

I don't think they are is a single correct answer to the sound that Orangeburg pipe with make when rapped on with a wrench.

Consider that if the pipe is in the ground and surrounded mostly by soil or is filled with debris when you wrap on it will probably make a thunk sound.

On the other hand if you held a hard fired clay section of pipe in the air in one hand or by one edge and tapped on it with a wrench, it may well ring, just as a clay or ceramic pot will make different sounds depending on its contents, firing, and position.

What is the O.D. of 5" Orangeburg Conduit?

I am dealing with concrete encased ductbanks. They have 5" Orangeburg conduits raceways. I am needing to remove the Orangeburg if possible and line it. What is the O.D of 5" Orangeburg conduits? On 2021-04-16 by Richard Geisler -

Reply by danjoefriedman (mod)

@Richard Geisler,

from the page above we have

Orangeburg common diameters ranged from 3" to 8" I.D. Those are "nominal" interior diameters - the actual products varied slightly.

Orangeburg pipe used as perforated septic drainfield piping for residential use had an O.D. that varied by manufacturer; the pipe wall was typically about 3/16" to 1/4" thick. so add those to your 5" ID dimension.

What are the Dimnensions of Orangeburg pipe and what are the options for repairing it in place

2019/07/19 MR. PHIL said:

1. What are the inside and outside diameters of 4" ORANGEBURG PIPE (sewage application) ?

2. What is the pipe wall dimensions of 4" orangeburg pipe?

3. Is there a BRAND NAME company that makes a re-liner insertable into an orangeburg pipe for prevention of collapse???

4. If not (3.) then is there an existing size/type of PVC or metal pipe that would work similar to a reliner insert?

Reply:

Orangeburg common diameters ranged from 3" to 8" I.D. Those are "nominal" interior diameters - the actual products varied slightsly.

Orangeburg pipe used as perforated septic drainfield piping for residential use had a nominal I.D. of 4.00 inches and an O.D. that varied by manufacturer; the pipe wall wastypically about 3/16" to 1/4" thick.

Orangeburg with a 4.0" ID and that's 3/16" thick would have an OD of about 4.375"

I've made emergency repairs and connections using flexible rubber Fernco couplings.

See complete details at ORANGEBURG PIPE DIMENSIONS

Was Orangeburg pipe used as a water supply line?

Was there ever any Orangeburg pipe manufactured as water SUPPLY line? 2020-09-03 by JDStavely

Reply by (mod) - yes in some municipal water mains

JD

Thanks for the helpful Orangeburg pipe question: Yes, Orangeburg was used in some municipal water supply lines as early as the 1860s and remained in widespread use in North America up to the 1970s. We've seen photos of street excavation with Orangeburg pipe fragments.

For water supply piping Orangeburg was replaced most-often with white (or green) PVC (polyvinyl chloride plastic) water supply pipes while Orangeburg pipe used in drain systems and septic systems was usually replaced with black ABS (acrylonitrile butadiene styrene) pipe.

My downspout connects to Orangeburg pipe: is there an asbestos hazard?

One of my downspouts was feeding into this pipe. House was built in 1959. I’m guessing it’s some type of Orangeburg pipe? And I’ve read mixed opinions on whether an Orangeburg pipe fo this age could contain asbestos...any insights would be most appreciated. Thanks! On 2020-08-02 by Ellen Rollings

by (mod) -

While the usual description of Orangeburg is paper fiber and asphalt, it's possible that it may contain asbestos; but as your pipe is buried, there is no airborne asbestos hazard.

by Ellen Rollings

Thank you! It’s actually weirdly semi-buried, as you can see in this photo (the black pipe near the new downspout extender I installed)...it seems to be in good condition and is under the deck so it’s a low traffic area. Would you suggest just leaving it alone?

Above: Ellen's photo of the end view of a segment of Orangeburg pipe shows the black asphalt-impregnated layers of wood-based material of which Orangeburg pipe is comprised.

by (mod) -

Yes. Or if you can pick up the pieces intact, without creating a mess, the old pipe can be disposed-of as construction debris.

by Ellen Rollings

Thanks so much! I’d be hesitant to try and remove it as it’s at least half below grade...any value in going over it with some already paint just to seal any potential compromised areas?

What are the dimensions of old clay sewer piping ?

Photo above: clay drainpiping - by InspectApedia. This is NOT Orangeburg pipe. It's fired ceramic clay.

I am repairing root intrusion at the joints of 4" sewer pipe that is older than orangeburg.

It's quite stout thick ceramic pipe.

The pieces of pipe (so far)seem fine.

The roots are just starting to come in at the joints.

I've been digging them up at the joints and cleaning there.

My main question is, do you know how long generally the pieces of pipe are.

If I knew that it will save me quite a lot of unnecessary digging.

Thanks, Jim

650-366-3629 On 2020-05-06 by James Moyles

Reply by (mod) - Orangeburg pipe dimensions: diameters & lengths

I'm sorry but without more information any guesses likely to be wrong. In fact ceramic sewer lines (which are not Orangeburg) were sold in varying lengths.

Orangeburg pipe - discussed on this page - is NOT a ceramic product but is bituminous, made of wood fibre and asphalt. Orangeburg sewer piping had a nominal inside diameter or I.D. of 4.00" and an outside diameter or O.D. of about 4 1/2".

Orangeburg Pipe Inside Diameter:

2" to 18" depending on use

Orangeburg Pipe Outside Diameter:

Orangeburg pipe walls were roughly 3/16" to 1/4" thick, possibly thicker for the larger diameter versions.

It sounds like you're describing an Old Bell and hub system that used what's properly named "Mission Band-Seal Vitrified Clay Pipe" - this is not Orangeburg, though the color of vitrified clay pipe is, indeed, orange or orange-brown.

Ceramic or clay sewer or drain line pipes were usually shorter in length, typically 4 ft. or 6 ft. long with a nominal ID of 4,6,8 or 10 inches.

Details are at ORANGEBURG PIPE DIMENSIONS

My suggestion is to excavate a long one length and then you will know the standard length at least in that area.

Clay drainfield piping (not Orangeburg pipe) or "drain tiles" shown in our photo below is discussed in our article on sewer line replacement,

What kinds of pipe were used in septic drainfields beforer 1963?

What types of piping were used in drain fields prior to 1963 ? 2019-07-21 by David

by (mod) -

Terra cotta, perforated orangeburg, vitreous clay would have been common. Cast iron piping used for building drains would probably change over to these in the septic fields.

What's the right type of copper pipe to use at my urinals?

Inspector is challenging me about the type of copper pipe installed for waste pipe on my urinals. I installed DWV Copper tube and he says type m is minimum. What do you say I cannot find anything in ontario plumbing code 2006. - Karac Rushton - 6/29/2012

Reply: 2007 Ontario Plumbing code permits K & L copper; M above ground; DWV above ground but not buried.

Karac,

I'm not sure why you're asking about copper pipe on a page about Orangeburg pipe but I'll take a stab at answering.

Also see COPPER PIPING in BUILDINGS

the 2007 Ontario Plumbing code is available online at opseu560[dot]org/BuildingCode-2007[dot]pdf and section 7 discusses plumbing.

There are some additional standards that apply:7.2.2.2. Conformance to Standards

(1) Every water closet and urinal shall conform to the requirements in Article 7.6.4.2.

(2) Every vitreous china fixture shall conform to CAN/CSA-B45.1, "Ceramic PlumbingFixtures".

(3) Every enameled cast iron fixture shall conform to CAN/CSA-B45.2, "Enamelled Cast IronPlumbing Fixtures".

(4) Every porcelain enamelled steel fixture shall conform to CAN/CSA-B45.3, "Porcelain-Enamelled Steel Plumbing Fixtures".

Copper pipe shall conform to ASTM B42, "Seamless Copper Pipe, Standard Sizes".

That code includes a table of allowed uses of copper. Table 7.2.7.4. - Permitted Use of Copper Tube and PipeForming Part of Sentence 7.2.7.4.(2)

In the table, if I read it correctly it says that

the drainage system piping can use K & L hard copper, and M-hard above ground but not buried, and DWV above ground but not underground.

So if all your DWV is above ground, by that table you're in compliance. You can show the table to your building inspector, and if you are polite you might get somewhere.

Don't forget that the local code compliance inspector has FINAL AUTHORITY.

...

Continue reading at PIPING in BUILDINGS, CLOGS, LEAKS, TYPES - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Building Piping Articles

Suggested citation for this web page

ORANGEBURG PIPE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE I NDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.