Guide to Point-of-use & Plumbing Fixture Anti Scald Valves

Guide to Point-of-use & Plumbing Fixture Anti Scald Valves

- POST a QUESTION or COMMENT about anti scald devices and mixing valves on hot water systems

Point-of-Use or plumbing-fixture built-in anti-scald protection for hot water systems:

This article describes the safe regulation of hot water temperatures right at the plumbing fixture, either by a separate hot water temperature controller or by a hot water temperature control or anti-scald feature built right into the plumbing fixture valve used at sinks, tubs, and showers.

These point of use or POU anti-scald devices provide important hot water burn protection but may need adjustment if the hot water they provide is not hot enough or if it is too hot.

In these hot water anti-scalding burn articles we explain how to buy, install, adjust and inspect anti-scald equipment to prevent hot water burns. We explain what a mixing valve, tempering valve, or anti-scald valve is, where and why these valves are installed on hot water systems, and how they work.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Point of Use & Plumbing Fixture Anti-Scald Valves

Guide to Bath Fixture Anti-Scald Valves, Automatic, Thermostatic Mixing Valves, or Tempering Valves to Avoid Hot Water Burns

[Click to enlarge any image]

Article Series Contents

Anti-scald valves that actually sense the water temperature are available built right into bathroom sink or shower fixtures, as you can see in our photo at left.

These devices permit delivery of very hot water to a building area but protect occupants from scalding by mixing in cold water right at the sink, tub, or shower.

As you can see on the control shown in our photo of a shower control in a shower-bath in Molde, Norway, fixture anti-scald valves may include a button and adjustment that lets the user demand hotter water than the control provides automatically.

On this bath shower fixture the left-hand control turns water on or off, and the right-hand control permits adjustment of the water temperature. Turning the temperature control "down" or counter-clockwise increases water temperature but the control "snaps" into a locked position at a safe hot water temperature of about 100 °F. The user can obtain hotter water by depressing a red button and turning the control further.

The point-of-use anti scald protection afforded by this type of pressure-balancing anti-scald valve is discussed further

at WATER PRESSURE BALANCING VALVES

How to Use Point of Supply Water Pressure-Balancing Valves to Control Temperature & Avoid Scalding

Use of Point of Supply or Point of Use Thermostatic Mixing Valves to Avoid Scalding Burns

Use of Point of Supply or Point of Use Thermostatic Mixing Valves to Avoid Scalding Burns

Some models of thermostatic mixing valves are more expensive than pressure-balancing valves and not widely used in the United States. They can be installed either inline near the water heater or as part of the shower control.

The inline type of valve, also called a tempering valve, adds cold water to the hot water as it leaves the water heater to maintain a constant temperature, set by the installer.

These are commonly used with solar water heaters but can also be tied to a conventional water heater.

A check valve is required on the cold water side to prevent backflow, and a hot-water expansion tank is recommended to prevent excessive pressure on the hot water side.

[Click any image or table to see an enlarged version with additional detail, commentary & source citation.]

The other type of thermostatic valve is built into some high-end showers (Figure 6-54). These allow the user to set the temperature on a dial when showering.

The unit will compensate for changes in either pressure or temperature to maintain a constant delivery temperature and flow rate. If the cold water fails or the tempered water is still too hot for any reason, the unit will shut off the flow.

As with the pressure-balancing valve, the installer sets a temperature limit stop to prevent the user from turning the shower control to scalding temperatures. We illustrate this approach as it is installed in a modern bathroom in Molde, Norway

at BUILT-IN FIXTURE ANTI-SCALD VALVES.

Retrofits to Avoid Scalding Burns at Plumbing Fixtures

In retrofits, point-of-use devices can be installed by a plumber or homeowner to limit water temperatures to 120°F. These include antiscald showerheads, as well as point-of-use devices that fit into individual plumbing fixtures, such as showerheads and bath and sink faucets.

For example, MemrySafe and ScaldShield (Antiscald Inc.) are inexpensive retrofit devices that reduce the water flow to less than 1/4 gallon per minute when the water temperature at the faucet or showerhead exceeds 120°F.

These devices do not regulate temperature or pressure, but do offer protection against serious burns.

This is the most commonly used point-of-supply approach. These automatically adjust the water pressure to maintain the mix of hot and cold water to within 2°F to 3°F of where the user set the shower control.

If cold water is diverted to a flushing toilet or other appliance and the pressure drops, the valve automatically reduces the hot water flow proportionately to maintain the temperature.

If the cold water pressure plummets or stops altogether, the flow is reduced to a trickle.

To guard against someone accidentally turning the shower valve to scalding temperatures, these valves typically use a temperature limit stop that prevents the user from turning the shower control past a set point—typically set at or below 120°F.

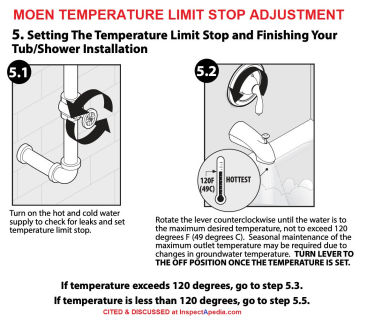

Temperature Limit Stop Adjustment for Moen Tub/Shower Controls

Above and below we excerpt the five steps required for an installer or for the homeowner (twice a year) to adjust the temperature stop limits on a typical Moen one-handle tub/shower control.

In the illustration above you'll see that

- After turning on the hot and cold water supply to the plumbing fixture

- You set the mixing control at the tub or shower control to the "desired temperature, not to exceed 120 degF."

Presumably you are

- Using a suitable thermometer to measure the output water temperature,

- You have let hot and cold water run through the fixture long enough that temperature is stabilized,

- You have made sure that the hot water source is at its hottest output temperature.

Watch out: if your water is heated by an electric water heater and you have recently used a lot of hot water, the water heater may not have yet re-heated its contents up to its highest temperature setting. - Aware that if you are setting the ot water temperature limit during very cold weather, the incoming cold water to the building may be much colder than it will be during hot weather - this affects the temperature experienced at the fixture as you're mixing incoming cold water with hot water from your hot water source

Watch out: be sure to read and comply with the complete instructions for the specific brand and model of any plumbing control or temperature control that you are installing. Failing to do so is unsafe - someone could be burned.

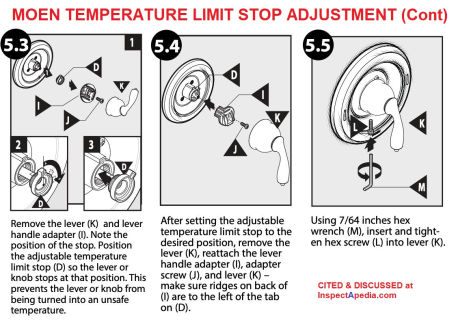

In the illustration above you'll see that you must

- Disassemble the control by removing the lever or handle (K)

- Remove the handle adapter (I) by removing the screw (J)

- Pull out the stop assembly (D) and replace it in the position that causes the control lever to "stop" - Really? OPINION: Having actually performed this task when installing this control, we think that when Moen says "note the position of the stop" they refer to the stub or tab on part (D) in the drawing. But frankly these controls will be in our OPINON opaque to an inexperienced homeowner.

- Follow the additional steps in images 5.3, 5.4, 5.5 (and written by the company in the installation manual given below as a PDF)

See details in these instructions:

- Moen, POSI-TEMP TUB AND SHOWER VALVES INSTALLATION INSTRUCTIONS [PDF] (2002) Moen, retrieved 2022/06/12, original source: https://assets.moen.com/shared/docs/instruction-sheets/mt692c.pdf

- Moen, ONE HANDLE TUB/SHOWER VALVE TRIM INSTALLATION INSTRUCTIONS (2014) Moen, retrieved 2022/06/12, original source: https://assets.moen.com/shared/docs/instruction-sheets/ins2153c.pdf

Note: the word "Scald" does not appear in these instructions, though the phrase "restricted temperature range" is included and the control does provide means to control the temperature range of the tub or shower control by settting a "Temperature Limit Stop" (p. E11. )

The company also warns that you may need to adjust the temperature limit stop seasonally depending on changes in groundwater temperature, i.e. changes in the temperature of water coming into the building..

Really? In our opinion there will not be one homeowner in a million who will ever think about much-less dis-assemble the control and make seasonal changes to the temperature limit stop. In fact we think that few homeowners even own a 7/64" allen wrench - Ed.

So a homeonwer may need to call an experienced plumber twice a year simply to adjust their hot water to a safe temperature limit - or at least call that expert once to teach the how to do the job in the future.

Anti-Scald Valve Point-of-Use Safety Warnings

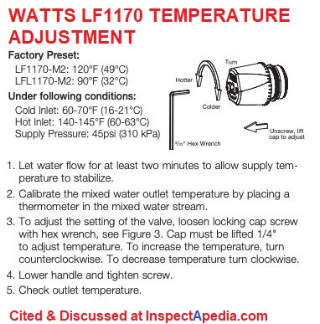

Watch out: the installation instructions for current hot water temperature control valves like the one shown abovestate that this valve is not to be used as an anti-scald device and warn that water pressure changes or water supply temperature changes can result in severe bodily injury (i.e, scalding or chilling) and/or death may result depending on system water pressure changes and/or water temperature changes. This is so (6/2022) at least in the case of Watts and possibly Sparco [Sparco citation needed].

Watch out: read the installation instructions from the manufacturer of the product you are installing, both to make sure it's installed properly and thus will work as expected, and also so that you understand what to expect by way of hot water temperature control the product handles.

At TANKLESS COIL INSTALLATION PROCEDURE where we recommend the use of mixing valves we quote this warning from the Crown Boiler Company:

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Similarly, the Watts Regulator Company's instructions for the installation of the Series LF1170 & LFL 1170 Hot Water Temperature Control Valves includes this warning: [Bold font is our emphasis]

WARNING: FAILURE TO COMPLY WITH PROPER INSTALLATION AND MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO THE VALVE FAILURE.

This Hot Water Master Tempering Valves cannot be used for tempering water temperature at fixtures. Severe bodily injury (i.e., scalding or chilling) and/or death may result depending upon system water pressure changes and/or supply water temperature changes. ASSE standard 1016, 1069 or 1070 listed devices should be used at fixtures to prevent possible injury.

These Hot Water Tempering Valves are designed to be installed at or near the boiler or water heater. They are not designed to compensate for system pressure fluctuations and should not be used where ASSE standard 1016, 1069 or 1070 devices are required. These valves should never be used to provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a construction capable of withstanding the high limit output temperatures of the water heating source. - Watts (2013)

...

Continue reading at POINT of USE ANTI-SCALD WATER TEMPERATURE ADJUST Pfister or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ANTI SCALD VALVES & TEMPERATURE CONTROL / MIXING VALVES - home

- ANTI_SCALD VALVES & HOT WATER QUANTITY

- ANTI-SCALD VALVE INSPECTION

- ANTI SCALD VALVE PROTECTION, Best Practices

- ANTI SCALD VALVE for USE ON STEAM BOILERS

- ANTI SCALD VALVE at TANKLESS COIL

- ANTI-SCALD WATER TEMPERATURE CONTROL TYPES

- MANUAL ANTI-SCALD TEMPERING VALVES

- POINT of USE BUILT-IN FIXTURE ANTI-SCALD VALVES

- POINT of USE ANTI-SCALD WATER TEMPERATURE ADJUST Pfister - how to adjust a point of use anti-scald valve

- SAFETY WARNINGS for ANTI-SCALD VALVES

- HOT WATER ANTI-SCALD REGULATIONS

- TABLE OF SCALDING TEMPERATURES & TIMES

- WATER HEATER TEMPERATURE ADJUSTMENT CONTROLS - home - all types of water heater temperature controls & adjustment devices

Suggested citation for this web page

POINT of USE BUILT-IN FIXTURE ANTI-SCALD VALVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER HEATERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about anti scald devices and mixing valves on hot water systems

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves SPECIFICATIONS [PDF] (2019), Watts Regulator Co. (2013), USA Tel: (978) 688-1811, Fax: (978) 794-1848,

Website: www.watts.com,

Canada: Tel: (905) 332-4090, Fax: (905) 332-7068, Website: www.watts.ca - Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves INSTALLATION INSTRUCTIONS [PDF] Installation, operating, and adjustment instructions for the LF1170 and LFL1170 mixing valves.

- "BDS Series Oil-Fired Hot Water Boilers, Installation Instructions, Models GS-080 -> Crown BDS-236", Crown Boiler Company, BDS 12-99, Crown Boiler Co.

P.O. Box 14818

3633 I Street

Philadelphia, PA 19134

(215) 535-8900,

Website: http://www.crownboiler.com, retrieved 2/26/2014, original source: http://www.crownboiler.com/manuals/content/ All_Models/BDS%20Series%20%28all%20models%29.pdf

The following link provides access to literature or manuals for previous Crown products:

http://www.crownboiler.com/Support/Manuals-And-Literature/Previous-Products - Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- A.O. Smith water heater safety sticker: 182734-000 Rev.00 observed on the gas fired water heater shown at High Efficiency Gas Water Heaters

- Thanks to Bruce Jones, Renewable Energy Solutions Manager, for suggesting clarifications about which way to turn the mixing valve to make water supply hotter or colder. email August 2010.

- Thanks to reader J.S.A. for discussing hot water mixing valves and which way to turn the valve - July 2010

- Thanks to reader Athena for discussing hot water mixing valves and which way to turn the valve to make water hotter or cooler - October 2010.

- Thanks to reader Chris Martino for pointing out inconsistent text about which way to turn the hot water mixing valve or tempering valve. December 2010.

- Thanks to reader Bob for discussing clarifications needed to text about which way to turn the hot water mixing valve. January 2011.

- "Domestic Hot Water Scald Burn Lawsuits, The Who, What, When, Why, Where, How", Dr. D. Bynum Jr., Vernon L. Petri, Esq., John T. Myers, paralegal, Seminar and Technical Paper for the 25-28 Oct 98 Annual ASPE Meeting at the Indianapolis Convention Center, Indianapolis IN, websearch 09/21/2010,original source: http://media.wattswater.com/F-H20LS-Reprint.pdf [Large PDF]

- [5] "Water Saving Tips: For Residential Water Use, Indoors and Out", Alliance for Water Efficiency, 300 W Adams Street, Suite 601 Chicago, Illinois 60606, Tel: 773-360-5100, 866-730-A4WE, Email: jeffrey@a4we.org, web search 12/14/11, original source: plumbingefficiencyresearchcoalition.org/

- [6] "Danger in the Shower: 2008 Forum Looks at Hot Water", John Koeller, Home Energy, Jan/Feb 2009, Home Energy Magazine, 1250 Addison Street Suite 211B, Berkeley, Ca. 94702, Tel: (510) 524-5405 Email: contact@homeenergy.org

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

[Click to enlarge any image]

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.