Air Admittance Valve / Studor Vent® Codes, Standards, Manuals

Air Admittance Valve / Studor Vent® Codes, Standards, Manuals

AAV Installation Guides

- POST a QUESTION or COMMENT about plumbing air admittance valves, studor vents, AAVs, installation manuals, applicable plumbing codes, standards.

Plumbing codes, installation standards and installation manuals for air admittance valves or Studor Vents are provided on this page.

This article series explains what an air admittance valve (AAV) or Studor Vent® is and how are they used and gives details about choosing the proper AAV size, loctation, and installation, along with help in troubleshooting AAV or plumbing drain noises, odors, malfunctions.

Page top photo: a Studor Maxi-Vent Vent® air admittance valve cited & discussed here.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Air Admittance Valve & Studor Vent Plumbing Codes, Standards, Installation Manuals

Article Contents

- STUDOR VALVE INSTALLATION SPECIFICATIONS - vertical & horizontal distances, etc.

- STANDARDS & CODES for AIR ADMITTANCE VALVES AAVs

- IPC CHAPTER 9 EXCERPTS on AIR ADMITTANCE VALVES

- AAV INSTALLATION INSTRUCTIONS & MANUALS

AAV Studor Valve Installation Specifications

Photo: another model of air admittance valve or Studor vent from IPS Corporation, cited below in our list of AAV manufacturers, sources, and manuals.

The three most-common questions we're asked about Studor Vents or AAVs are

- Can we install the air admittance valve horizontally?

Answer: No.

Watch out: Do not install a Studor vent horizontally. The vent must be upright, or within 15 degrees of vertical to work properly. - How far away from the fixtrure can we install an AAV?

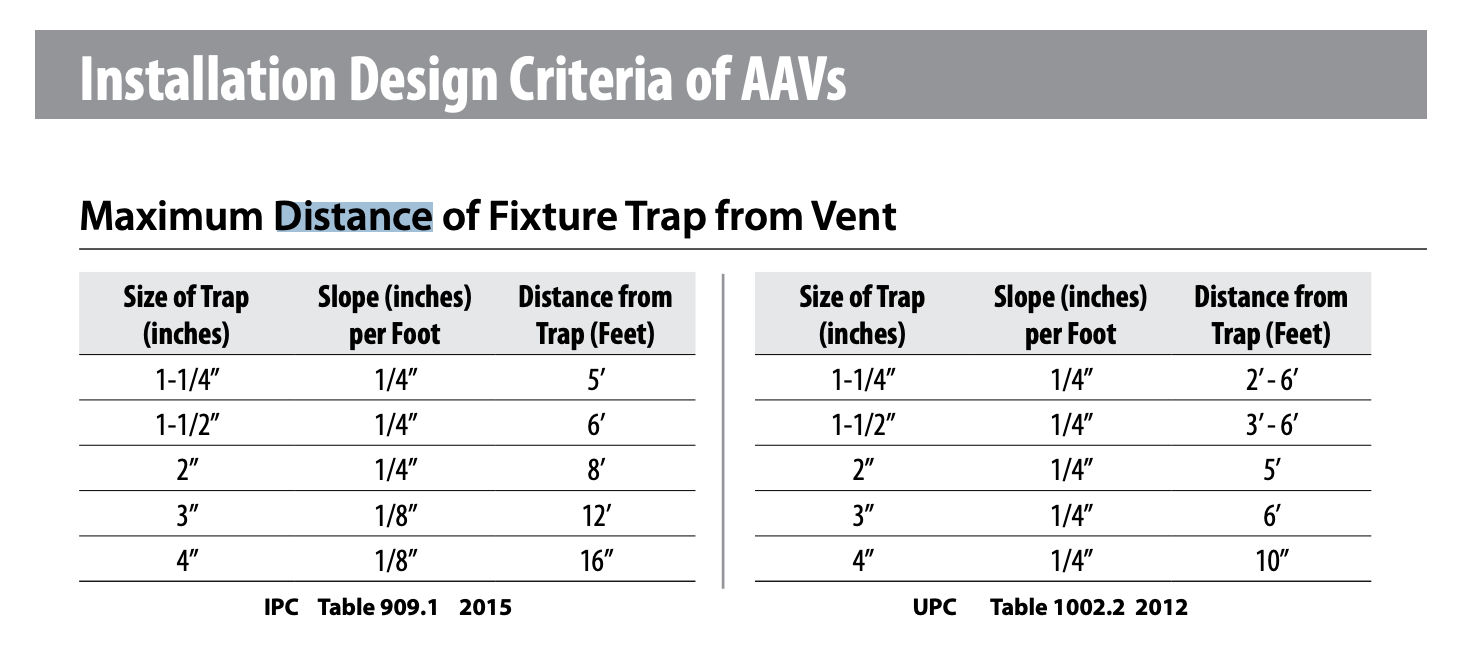

Answer: it depends, but roughly from 2' 6" to 16 ft. as shown in the table below.

The maximum horizontal distance that a Studor Vent can be located from the fixture trap, depending on trap size in diameter.

Note that there are two difference horizontal distance tables depending on which model plumbing code - IPC or UPC - you are going to follow. If you're uncertain, follow the UPC code Table 1002.2 2012 as that's the more-stringent so is least likely to give AAV performance trouble later.

- What's the minimum height at which we can install an AAV over the horizontal drain or fixrture? Answer: 4"

The minimum vertical distance for AAVs: Studor AAVs must be located a minimum of four inches (4”) above the horizontal branch drain or fixture drain being vented. - Source: Studor products manual cited in detail below.

AAV Installation Rules

The AAV complete list of installation specs immediately below are quoted from Studor's Air Admittance Valve Installation Criteria and cover nearly all common AAV/Studor-Vent/Redi-Vent questions:

- STUDOR AAVs must be located a minimum of four (4”) inches above the horizontal branch drain or fixture drain being vented.

- STUDOR AAVs shall be accessible should replacement be required. For in-wall installation, use STUDOR recess box/grill combination.

- STUDOR AAVs location must allow for adequate air to enter the valve. When located in a wall space or attic space lacking ventilation openings, opening shall be provided. Locating the valve in a sink or vanity cabinet is acceptable.

- STUDOR AAVs must be installed in the vertical, upright position. A maximum deviation (in either direction) for plum of 15 degrees is allowed.

- The vent shall connect to the drain vertically to maintain an unobstructed opening in the piping to the STUDOR AAVs.

- A minimum of one vent pipe shall extended to the open atmosphere for each building drainage system for relief of positive pressure, the size of this vent is not specified because this single vent does not determine the total amount of aggregate cross-sectional area of the vent system.

The total amount of the crosssectional area of vents combined on the system has to equal the aggregate cross-sectional area of the building drain. When properly installed an air admittance valve in the system is equivalent to an open vent pipe having the same cross sectional area as any other vent.

Such open air vent is recommended, not required, to be located as close as possible to the connection between the building drain and building sewer. - The Maxi-Vent® must be installed six (6”) inches above the highest flood level rim of the fixtures being vented in stack applications.

- STUDOR AAVs installed in attic area must be located a minimum of six (6”) inches above the ceiling insulation.

- The use of Tec-Vent® in return air plenums shall be allowed only in engineered drainage systems designed by a design professional and approved by the local authority.

- The maximum height of drainage stack being vented by a MAXI-VENT must not exceed six (6) branch intervals unless it is used in conjunction with a stack that is connected to a P.A.P.A. and AAVs on the branches.

- When a horizontal branch connects to a stack more than four (4) branch intervals from the top of the stack a relief vent shall be provided.

The relief vent must be located between the connection of the branch to the stack and the first fixture connecting to the branch.

The relief vent may also serve as a vent for the fixture.

The relief vent must connect to the vent stack, stack vent or extend outdoors to the open air unless it is used in conjunction with a stack that is connected to a P.A.P.A. device and AAVs on the branches. - Only Teflon® tape can be used on the valves’ threads.

Watch out: Use of primer, solvent cement or pipe dope will void the STUDOR warranty. - The Redi-Vent®, Mini-Vent®, Maxi-Vent®, Tec-Vent® and Chem-Vent® must be installed at finish, after the system rough-in and pressure test.

- Air Admittance Valves may be used on grease traps as long as they are not subject to positive pressure.

- original source cited just below

- Studor, Inc., STUDOR PRODUCTS MANUAL [PDF] (10th ed) (see p. 8) Studor IPS Corporation, retrieved 2019/08/14 original source: https://ipscorp.com/pdf/studor/Studor_Technical_Manual.pdf

Air Admittance Valve Codes & Standards

- ANSI/ASSE 1050 Performance Requirements for stack type air admittance valves for sanitary drainage systems

- ANSI/ASSE 1051 Performance Requirements for individual and branch type air admittance valves for sanitary drainage systems

- International Plumbing Code, IPC Section 917

- International Residential Code, IRC Section P3114

- International Code Council, 500 New Jersey Avenue, NW, 6th Floor, Washington, DC 20001 Tel: 1-888-ICC-SAFE (422-7233); Fax: (202) 783-2348 International: (202) 370-1800, Email: webmaster@iccsafe.org, Website: www.iccsafe.org

- International Residential Code (IRC), for One and Two Family Dwellings, 2012 (First Printing)

Home Page: publicecodes.citation.com/icod/irc/index.htm

Citation Page:

publicecodes.citation.com/icod/irc/2012/icod_irc_2012_31_sec003.htm - International Mechanical Code (IMC), International Code Council [888] 422-7233, Op. Cit.

- International Plumbing Code (IPC) (see NPC below), Op. Cit.

- National Standard Plumbing Code, (NPC), 2009

obtained From: National Assoc. of Plumbing-Heating-Cooling Contractors in New Jersey at [800] 652-7422 or NAPHCC [800] 533-7694, [Cited by New Jersey State Department of Community Affairs]

state.nj.us/dca/divisions/codes/codreg/pdf_misc_codes/2006_nspc.pdf - New Jersey State Department of Community Affairs, Website: state.nj.us/dca/divisions/codes/codreg/

- NSF 14 for plastic piping system components & related materials

- Oatey Corporation, "Oatey Sure-Vent® Air Admittance Valves Technical Specifications", Oatey® Corporation, - retrieved 2016/05/08, original source: http://www.oatey.com/doc/aavtrifoldlcs420c101812lr.pdf

Excerpt:

The purpose of an air admittance valve is to provide a method of allowing air to enter the plumbing system without the use of a vent extended to open air and to prevent sewer gases from escaping inside a building. - Studor Inc., DESIGN CRITERIA AND INSTALLATION INSTRUCTIONS FOR STUDOR AIR ADMITTANCE VALVES (AAVS) [PDF], Studor, Inc., - retrieved 2016/05/02, original source: https://assets.nationalbuildersupply.com/ul_pdfs/studor-aav-design-and-installation.pdf This document describes the Studor Mini-Vent, Redi-Vent, Tec-Vent and Ultra-Vent (pipe sizes 1 1/2" to 2") and the Studor Maxi-Vent (pipe sizes 3" to 4")

- Uniform Plumbing Code, UPC Section 909.0 - plumbing code discussion of the use of air admittance valves in residential buildings; UPC Section 301.2 (Alternate Materials and Methods)

...

Excerpts from IPC Chapter 9, Vents, on Air Admittance Valve Codes

The photo of an inline plumbing vent or air admittance valve shown here, contributed by reader Megan, was posted originally

The photo of an inline plumbing vent or air admittance valve shown here, contributed by reader Megan, was posted originally

at PLUMBING VENT CODES, DEFINITIONS, TYPES.

This vent, installed in a basement or crawl space, was not properly-located according to Megan's plumbing inspector.

Section 917 Air Admittance Valves

917.1 [Air Admittance Valve] General.

Vent systems utilizing air admittance valves

shall comply with this section.

Stack-type air admittance valves shall conform to ASSE 1050. Individual and branch-type air admittance valves shall conform to ASSE 1051.

917.2 [Air Admittance Valve] Installation.

The valves shall be installed in accordance

with the requirements of this section and the manufacturer’s

installation instructions. Air admittance valves shall be

installed after the DWV testing required by Section 312.2 or

312.3 has been performed.

917.3 [Air Admittance Valve] Where permitted.

Individual, branch and circuit vents

shall be permitted to terminate with a connection to an individual

or branch-type air admittance valve.

Stack vents and vent stacks shall be permitted to terminate to stack-type air admittance valves.

Individual and branch-type air admittance valves shall vent only fixtures that are on the same floor level and connect to a horizontal branch drain.

The horizontal branch drain having individual and branch-type air admittance valves shall conform to Section 917.3.1 or 917.3.2. Stack-type air admittance valves shall conform to Section 917.3.3.

917.3.1 [Air Admittance Valve] Location of branch.

The horizontal branch drain

shall connect to the drainage stack or building drain a maximum

of four branch intervals from the top of the stack.

917.3.2 [Air Admittance Valve] Relief vent.

Where the horizontal branch is located

more than four branch intervals from the top of the stack, the

horizontal branch shall be provided with a relief vent that

shall connect to a vent stack or stack vent, or extend outdoors

to the open air.

The relief vent shall connect to the horizontal branch drain between the stack and the most downstream fixture drain connected to the horizontal branch drain.

The relief vent shall be sized in accordance with Section 916.2 and installed in accordance with Section 905. The relief vent shall be permitted to serve as the vent for other fixtures.

917.3.3 [Air Admittance Valve] vs. Stack.

Stack-type air admittance valves shall not

serve as the vent terminal for vent stacks or stack vents

917.4 [Air Admittance Valve] Location.

Individual and branch-type air admittance

valves shall be located a minimum of 4 inches (102 mm) above

the horizontal branch drain or fixture drain being vented.

Stack-type air admittance valves shall be located not less than 6 inches (152 mm) above the flood level rim of the highest fixture being vented. The air admittance valve shall be located within the maximum developed length permitted for the vent.

The air admittance valve shall be installed a minimum of 6 inches (152 mm) above insulation materials.

917.5 [Air Admittance Valve] Access and ventilation.

Access shall be provided to all

air admittance valves. The valve shall be located within a ventilated

space that allows air to enter the valve.

917.6 [Air Admittance Valve] Size.

The air admittance valve shall be rated in accordance

with the standard for the size of the vent to which the

valve is connected.

917.7 [Air Admittance Valve] Vent required [locations].

Within each plumbing system, a minimumof

one stack vent or vent stack shall extend outdoors to the

open air.

917.8 Prohibited installations.

Air admittance valves shall not be installed in nonneutralized special waste systems as described in Chapter 8.

Valves shall not be located in spaces utilized as supply or return air plenums.

...

AAVs Studor Vents Installation Guides & Sources

- AB DURGO AIR ADMITTANCE VALVES CERTIFICATION [PDF] (2011) British Board of Agrement, Bucknails Lane, Garston, Watford Herts WD25 98A UKe-mail: mail@bba.star.co.uk website: www.bbacerts.co.uk retrieved 2019/08/14 original source: https://www.hunterplastics.co.uk/media/1791/bba-durgo-certificate-06-4325.pdf

- British Plastics Corp., AIR ADMITTANCE VALVES for DOMESTIC PROPERTIES [PDF] (2018) retrieved 2019/08/14 original source: https://www.bpfpipesgroup.com/media/29598/Air-admittance-valves-for-domestic-properties.pdf

Excerpt: Across the UK, Building Regulations and statutory guidance allow for ventilation by either open soil pipes or air admittance valves. The preferred solution, being the simplest and most familiar to install, is the open soil pipe. It

requires minimal maintenance and the visible termination point above the roof means it is less likely to be blocked off during future building work by householders.

Open soil pipes within 3 m of any opening to the building need to terminate at least 900 mm above the opening, for example a window or balcony. Additionally, they require capping with a balloon grating or wire cage to prevent any wildlife from seeking a warm refuge whilst not restricting the flow of air.

Air admittance valves (AAVs) are installed directly on to the soil stack without the need for a hole to be made in the property roof, reducing the amount of pipework required and the costs of making good the roof, and minimising future risk of weather damage and water ingress.

AAVs are normally located in the roof space and can provide the same ventilation capacity as an open system. They are particularly suitable for installation on stub stacks – a short stack from ground floor appliances which avoids the need for a full house height pipe.

Whilst not permitted by statutory guidance, except in Scotland under controlled conditions, the use of air admittance valves on the outside of the property is commonly used to overcome space restrictions between the stack and a window opening or to ventilate appliances without access to the main soil stack, for example in a property extension. . - DURGO AIR ADMITTANCE VALVES for Drainage Systems [PDF] DURGO AB BOX 3021, SE-169 03 SOLNA, SWEDEN RÅSUNDAVÄGEN 25, SE-169 67 SOLNA, SWEDEN PHONE +46 8 730 5280, FAX +46 8 735 6955 SALES@DURGO.SE WWW.DURGO.SE retrieved 2019/08/14 original source: http://www.durgo.dk/pdf/afloeb.pdf

- FloPlast AIR ADMITTANCE VALVES [PDF] (2007) FloPlast Limited Castle Road Eurolink Business Park Sittingbourne Kent ME10 3FP UK Tel: +44 (0)1795 431731 Fax: +44 (0)1795 431188 Sales Office Direct Line: +44 (0)1795 421422 Email: sales@floplast.co.uk Website: www.floplast.co.uk

- Oatey SURE-VENT ® AIR ADMITTANCE VALVES [PDF] Oatey SCS Supply Chain Services, 4700 W. 160th St. Cleveland, OH 44135 USA Tel: 800.321.9532 Fax: 800.321.9535 Website: www.oatey.com retrieved 2019/08/14 original source: https://www.oatey.com/ASSETS/DOCUMENTS/ITEMS/EN/aavtrifoldlcs420c101812lr.pdf

Excerpts from features of the Oatey AAV: (w/ minor edits for clarity)

Oatey provides four vent models rated at 6, 20, 160 and 500 DFUs for optimized installations

Sweet Spot™ technology opens at - 0.01 psi (-0.25” H2O) and seals at 0 psi and above

Screening on air inlets to guard the seal

INSTALLATION: Individual, branch and circuit vents are permitted to terminate with a connection to a Sure-Vent® AAV.

The Sure-Vent® AAV will only vent fixtures that are on the same floor level and connect to a horizontal branch drain.

The horizontal branch drain shall connect to the drainage stack a maximum of four branch intervals from the top of the stack.

The Sure-Vent® AAV should be located within the maximum developed length permitted for the vent.

The Sure-Vent® AAV must be located a minimum of 4 inches above the horizontal branch drain and 6 inches above any insulation material and within 15 degrees of vertical.

Every structure in which plumbing is installed shall have at least one primary stack vent. The stack vent should run as directly as possible from the building drain through to the open air. - Studor, Inc., STUDOR PRODUCTS MANUAL [PDF] (10th ed) (see p. 8) Studor IPS Corporation, retrieved 2019/08/14 original source: https://ipscorp.com/pdf/studor/Studor_Technical_Manual.pdf

Excerpt: The Studor AAV was initially developed by Sture Ericson who applied for the patent on his first designed valve, the Bjare Valve, in July 1973. The valve was named after a specific region of Sweden where his factory was located. - Studor, Inc., STUDOR MAXI-VENT PRODUCT SPECIFICATIONS SHEET [PDF]

- Studor Inc., DESIGN CRITERIA AND INSTALLATION INSTRUCTIONS FOR STUDOR AIR ADMITTANCE VALVES (AAVS) PDF], Studor, Inc.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-01-27 6 by (mod) - how to use an AAV or Studor Vent on a sump pit

Thanks for the question, E

Thanks for the question, E

At PLUMBING DRAIN FIXTURE UNITS DFUs

we see that a private toilet is rated as 3 DFUs (Drain Fixture Units)

You can plug that into the AAV use tables given above on this page. You'll see that a 2-inch drain should be adequate;

Reasoning:

your toilet drain is 4" in diameter

the vent pipe must be at least 1/2 the diameter of the rain pipe (2")

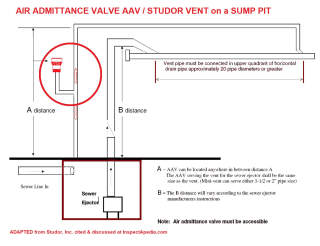

The sketch below, using a sump pit as an example that I bet will be similar to your toilet installation, is from

Studor Inc., DESIGN CRITERIA AND INSTALLATION INSTRUCTIONS FOR STUDOR AIR ADMITTANCE VALVES (AAVS) PDF], Studor, Inc.

[Click to enlarge any image]

On 2021-01-26 by E L Boze

I am planning to use an AAV for the toilet in my workshop. I am using a 2" vent pipe and plan to have the AAV about 8' above the floor the toilet is set on. Could this be problematic or should it work?

On 2021-01-02 by (mod)

Suppliers of AAVs such as Oatey, Studor, Dura Easy, Campbell, provide a wide range of air admittance valves. But I have not seen such a valve designed to handle the pressure differences ascribed only to variation in air density due to variations in ambient temperature.

Check with Kinetic and with SolarPoolRepair

On 2021-01-02 by Ron

I need a very low resistance 3” air admittance valve to allow air into a solar convection device when hot air is rising and the stop the Backflow at night when it is cold

On 2020-11-07 by (mod) - can an AAV be used for venting a toilet?

Terry,

Terry,

Yes, possibly. Take a look at the large capacity air admittance valves like the Studor Maxi-Vent shown below and capable of venting at 32 L/sec. at -250 Pa. This AAV is described as a "soil stack vent".

Here is the STUDOR MAXI-VENT PRODUCT SPECIFICATIONS SHEET [PDF]

On 2020-11-06 by terry

can an AAV be used for venting a toilet?

On 2020-06-25 - by (mod) -

Dave

Not in the installation instructions I've seen

On 2020-06-25 by Dave

Can a aav vent be installed horizontally

On 2019-08-14 by (mod) - plumbing drains should never be vented into a heating appliance vent system.

No John, plumbing drains should never be vented into a heating appliance vent system.

Doing so is unsafe.

On 2019-08-14 by TN John

Hello;

In your opinion can a 2 inch grinder pump that is in the slab be vented up and across the mechanical room ceiling and Tee into the 2 inch vent pipe for the gas furnace?

On 2019-07-19 by (mod) -

No, Joe, the air admittance vents described here are for drain pipes. THey have nothing to do with water heating equipment.

On 2019-07-19 by Joe

With the Studor vent 200 auto vent work with a hot water heater?

...

Continue reading at AIR ADMITTANCE VALVES AAVs - home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AIR ADMITTANCE VALVES AAVs - home

- AIR ADMITTANCE VALVE AAV DEFINITION

- AAV COMPARED with PLUMBING VENT - what's the difference?

- AAV CAPACITIES & SIZING GUIDE - choose the right air admittance valve

- AIR ADMITTANCE VALVE AAV REPAIR GUIDE - noises, slow drains, test procedure

- AIR ADMITTANCE VALVES CODES, STANDARDS, MANUALS

- PLUMBING DRAIN FIXTURE UNITS DFUs

- PLUMBING DRAIN NOISES where we explain the basics of proper plumbing vent piping and how errors cause trap siphonage, odors, and noises

- PLUMBING VENT CODES, DEFINITIONS, TYPES - home

- FUNCTION: how plumbing vent piping works

- DEFINITION of a Plumbing Stack Vent

- DIFFERENCE Between Soil Stack & Waste Stack

- DISTANCE: vent piping be located from a plumbing fixture?

- DRAIN & VENT SIZE & DISTANCES to FIXTURES

- ROUTING SPECS for PLUMBING VENTS

- DIRECT VENTED Plumbing Fixtures

- WET VENTED Plumbing Fixture

- AIR ADMITTANCE VALVES AAVs

- VENT DISTANCES to BUILDING FEATURES

- PLUMBING VENT REPAIR

Suggested citation for this web page

AIR ADMITTANCE VALVES CODES, STANDARDS, MANUALS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.