Oil Burner Nozzle Guide

Oil Burner Nozzle Guide

Nozzle types, patterns, selection

- POST a QUESTION or COMMENT about oil burner nozzle function, adjustment, & repair

Oil Burner Nozzle selection & installation:

Oil Burner Nozzle Types, Oil burner nozzle size & pattern selection, & properties. Relationship of oil burner nozzle size, oil pressure, & oil burner BTUH output .

Here we explain how to select & install an oil burner nozzle, we describe different oil burner nozzle firing rates & spray patterns; we discuss the setting of the gap and position of oil burner ignition electrodes.

We also discuss how to diagnose oil burner electrodes or nozzle problems, how to inspect, clean, and adjust oil burner nozzles, electrodes, and air turbulators used on heating oil burners found on residential & light commercial oil burners.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Oil Burner Nozzle Types, Flow Rates in GPH, Spray Patterns, Selection Guide

Oil burner nozzles have the job of spraying heating oil into the combustion chamber in a spray pattern of the right size and shape to properly fit the equipment and to assure a fine spray that in turn assures as complete combustion of the heating oil as possible.

Oil burner nozzles have the job of spraying heating oil into the combustion chamber in a spray pattern of the right size and shape to properly fit the equipment and to assure a fine spray that in turn assures as complete combustion of the heating oil as possible.

Like Mike's oil burner nozzle shown in the photograph, oil burner nozzles get grubby during use, especially if the fuel is contaminated or if the oil burner and its electrodes are not properly adjusted.

But actually oil burner nozzles are a beautiful and precision-made and sophisticated device - take a look at the new oil burner nozzle at the top of this page and at the side view of a new oil burner nozzle shown below.

[Click to enlarge any image]

Article Series Contents

- OIL BURNER NOZZLE GUIDE - page top

- OIL BURNER NOZZLE REPLACEMENT: MATCH THE OLD ONE

- OIL BURNER NOZZLE FIRING RATE GPH

- OIL BURNER NOZZLE SPRAY ANGLE

- OIL BURNER NOZZLE SPRAY PATTERN

- OIL BURNER NOZZLE DROPLET SIZE RANGE - separate article

- OIL BURNER NOZZLE SELECTION TABLE

- OIL BURNER NOZZLE COLOR CODES

- OTHER OIL BURNER NOZZLE FEATURES

- OIL BURNER NOZZLE SUBSTITUTIONS - separate article

- OIL BURNER NOZZLE GUIDE BOOKS

Install a New Oil Burner Nozzle that Matches the Old One

In our example photo, the red plastic cap on the oil burner nozzle container shows that I"m holding a 0.85 gph 80° angle A-Pattern nozzle.

In our example photo, the red plastic cap on the oil burner nozzle container shows that I"m holding a 0.85 gph 80° angle A-Pattern nozzle.

[Click to enlarge any image]

Cut to the chase? OK, so if you don't know a reason to change, install the same oil burner nozzle type that was already on the burner.

That means the replacement oil burner nozzle will have the same metering rate (GPH), spray angle, and spray pattern. Those parameters are stamped into the oil burner nozzle tip as well as given on the nozzle container or box.

Watch out: replacing the oil burner nozzle with a new one that matches the specifications of the old one is usually safe and correct. But not always.

An oil burner service technician might have substituted a close but not exact match for the manufacturer-recommended original nozzle type if, for example, she didn't have the right nozzle at hand.

A technician may also substitute a different nozzle spray pattern or type to solve a specific oil burner operating problem like rumbling noise (substituting an AR nozzle).

See also OIL BURNER RUMBLING NOISE

Three Basic Oil Burner Nozzle Parameters: Metering Rate, Spray Angle, Spray Pattern

Below we will discuss three fundamental oil burner nozzle parameters:

1. Oil burner nozzle Metering Rate or Firing Rate in GPH

The metering rate is expressed in gph and is the capacity of the oil burner nozzle to deliver heating oil or the capacity of the oil burner to deliver BTUs.

The metering rate is expressed in gph and is the capacity of the oil burner nozzle to deliver heating oil or the capacity of the oil burner to deliver BTUs.

This is the nozzle firing rate - the number of gallons per hour of No. 2 heating oil that the nozzle will pass, assuming that the oil burner fuel unit is set to 100 psi.

Our oil burner nozzle photo shows you what an oil burner nozzle looks like.

The .85 stamped into the brass nozzle head tells us that this is a 0.85 gph oil burner nozzle.

This is a Delavan brand oil burner nozzle, but all oil burner nozzle brands will include a stamp indicating the three nozzle parameters.

Change the firing rate when operating at a higher oil pressure

Watch out: At higher psi settings such as are often used today, the actual oil consumption rate for a given nozzle, say 0.85 gph, will actually be higher (and can be read from a graph or table of oil pressures and flow rates.)

Back in the old days we used to drop the nozzle one size, say from 0.90 to 0.85 gph and then set up the fuel unit pressure from 100 psi to say 110 or so in order to get better atomization (smaller oil droplets), hotter flame, cleaner burning, and a bit more efficiency out of the oil burner.

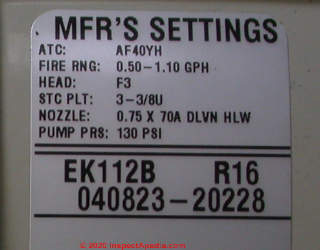

Now many modern oil burners actually are intended to be fired at a higher pressure, possibly at 130 or even 140 psi - as you can see on this data tag affixed to a Beckett oil burner we inspected.

For these oil burners, the nozzle sizes specified by the manufacturer presume that the fuel unit is set to the manufacturer's recommended pressure.

Watch out: when reading the oil burner manufacturer's specifications for the proper oil burner nozzle size in gph, be sure to also read the manufacturer's recommended fuel unit oil pressure setting.

If your oil burner pressure is not adjusted to the manufacturer's specification then your oil burner nozzle size could be incorrect or the system may not operate properly.

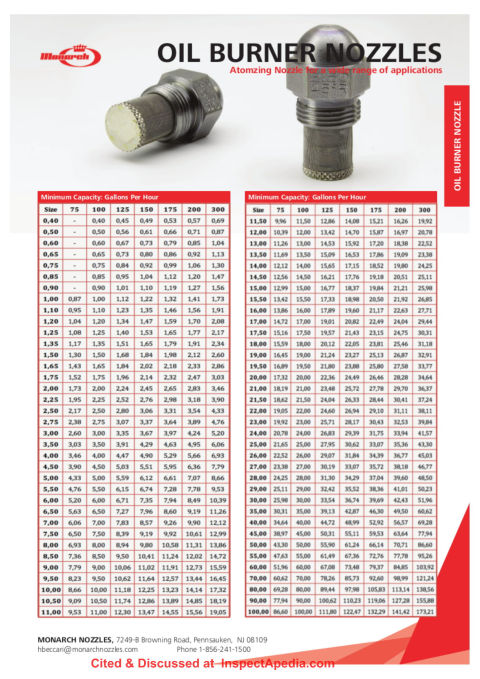

The table below, excerpted from Delavan's A Total Look at Oil Burners (cited below) illustrates the change in actual oil burner nozzle firing rate in GPH as the nozzle pressure is increased at the fuel unit.

Oil Nozzle GPH Rate vs Oil Pressure Setting |

||||||

| 100 psi | 120 psi | 145 psi | 160 psi | 175 psi | 200 psi | 300 psi |

| 100 GPH | 1.10 GPH | 1.20 GPH | 1.26 GPH | 1.32 GPH | 1.41 GPH | 1.73 GPH |

Notes to the table above

- Original source: - these are approximate GPH flow rates; actual flow rate may vary.

A TOTAL LOOK at OIL BURNER NOZZLES [PDF] (2000) courtesy of Delavan Fuel Metering Products [Website] a reference guide for oil burner service technicians, Delavan Spray Technologies, Fuel Metering Products Division, PO Box 969, Bamberg SC 29003, Tel: 800-982-6943 or 803-245-4347, ( Delavan is a division of BF Goodrich); web search 12/30/2010, original source: http://www.delavaninc.com/pdf/total_look.pdf - Changes in oil viscosity that occur at lower or higher temperatures also decrease or increase the actual GPH flow rate of an oil burner nozzle. In cold climates heating oil stored outdoors will be more-greatly affected by ambient temperatures.

- See this OIL BURNER NOZZLE GPH vs PRESSURE CHART - [image file, also shown below], Monarch Nozzles Inc., 7249-B Browning Rd., Pennsauken NJ 08109 USA, Tel: 1-856-241-1500, Email: hbeccan@monarcnozzles.com

[Click to enlarge any image]

Is it OK to Change the Oil Burner Nozzle Size? Check the oil burner sticker!

It's ok to change the nozzle firing rate on oil fired heating equipment, but only within a limited range.

Take a look at your oil burner for a sticker provided by the manufacturer that gives the acceptable firing rate or gph range of nozzles for that burner and boiler or furnace or water heater.

Above we show where these data tags are found on a modern Beckett oil burner, and below we give you a close-look at the manufacturer's settings data.

Notice that FIRE RNG: 0.50 - 1.10 GPH - that's telling you that this oil burner can be operated with nozzles in the size range of 0.50 gph up to 1.10 gph.

Watch out: Going to a smaller or lower firing rate uses less oil and might be more efficient, but ultimately if you set the firing rate too low for your building the oil burner won't be able to put heat into the boiler or furnace fast enough, so on very cold days your oil burner may run continuously.

Old timers taught that you wanted the nozzle size chosen to fit the building's heating needs such that on the very coldest day of the year, a day rarely encountered, the oil burner might run half or more of the time, but for most of the year it runs considerably less.

How to Calculate the Oil Burner Nozzle Flow Rate in GPH

If your oil burner manual and stickers indicating the burner's preferred oil burner nozzle firing rate are lost, you can calculate the right oil burner nozzle size or firing rate in gallons per hour or GPH as follows:

[Adapted from Delavan: A Total Look at Oil Burners, cited in this article.]

Oil Burner Nozzle Size Calculated from Heater Input BTUs

Nozzle GPH = BTU INPUT / 140,000

where 140,000 is a benchmark number of BTUs per gallon of No. 2 home heating oil.

Oil Burner Nozzle Size Calculated from Heater Output BTUs & Efficiency

Nozzle GPH = BTU OUTPUT / (Heater % Efficiency) x 140,000

Oil Burner Nozzle Size Calculated from Hydronic Radiation

Oil Burner Nozzle GPH = Total Sq.Ft. Hot Water x 165 / (Heater % Efficiency) x 140,000

Oil Burner Nozzle Size Calculated from Steam Radiation

Oil Burner Nozzle GPH = Total Sq.Ft. Steam x 240 / (Heater % Efficiency) x 140,000

Watch out: these oil burner nozzle firing rate GPS size calculations are only a starting point because, as Delavan and other experts point out, the heater's output requirements are also very much impacted by the building's heating energy requirements that in turn are affected by air leakiness, insulation R-values, solar gain, physical dimensions and shape of occupied spaces, and local climate or coldest heating day requirements.

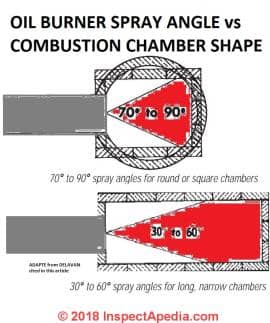

2. Oil burner nozzle spray angle

For example the nozzle may be stamped 80°. That defines an 80° spray angle (80 degrees).

Our illustrations explaining the relationship between oil burner spray angle and flame length are adapted from Delavan's Total Look at Oil Burner Nozzles cited below.

You can see that the spray angle of the oil burner nozzle is chosen to fit the general shape and length of the combustion chamber.

Generally in a larger deeper combustion chamber, that is one that is "longer" with respect to the direction of spray of oil, we use a more narrow (and longer) spray pattern in the 30° to 60° range.

In a shorter or smaller combustion chamber, to keep from impinging heating oil in the combustion chamber rear wall (too much impinging means incomplete combustion) we use a more wide-angle spray pattern, perhaps in the 70° to 90° angle range.

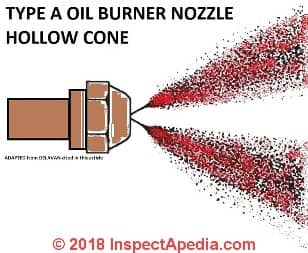

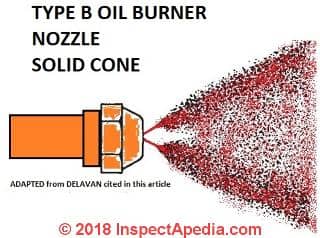

3. Oil burner nozzle spray pattern type, hollow, solid, other - Type A vs Type B nozzles

Each spray pattern is designated by a letter stamped into the nozzle on one of its facets. So the nozzle whose data we showed above, a Delavan 80°A means the nozzle sprays at an 80 degree angle with spray pattern "A" which we know is hollow.

There are at least nineteen different spray patterns possible. The basics are hollow vs. solid spray patterns (hollow means the core of the spray contains fewer droplets), and various combinations of these parameters.

Above: a typical Type A oil burner nozzle, hollow-core spray pattern. [Click to enlarge any image]

Below: a typical type B oil burner nozzle solid core spray pattern. Solid core spray pattern type B nozzles are more-often used in larger oil burners. Delavan notes that a type B spray pattern oil burner nozzle's actual spray becomes more hollow in the core at higher firing rates at or above 8 gph.

Another common oil burner nozzle pattern is the Type W nozzle that is "in between" a hollow-cone and a solid-cone spray pattern. Type W nozzles are sometimes substituted for an A or B spray pattern nozzle.

Oil Burner Nozzle Spray Droplet Size Range

This discussion has moved

to OIL BURNER NOZZLE DROPLET SIZE RANGE - separate article

Table of Oil Burner Nozzle Patterns & Properties

Oil Burner Nozzle Selection, Patterns & Properties |

|

Oil Burner Nozzle Spray Characteristics |

Nozzle Spray Pattern Code |

| Hollow | A, C, H, NS |

| Solid | B, P, R, S |

| High Velocity | HV |

| Semi Hollow | CM, SH |

| Semi Solid | PLP, SS |

| Special Design | Q |

| Special Design | W |

| Special Design - anti rumble | AR |

| Hollow or Solid | H or S |

| Extra Solid | ES |

| Extra Hollow | EH |

Notes to the table above

The duplication in codes accommodates not only a range of oil burner nozzle manufacturers or OEM specifications, but also some special features.

For example, the Special Design AR nozzle is designed to minimize oil burner flame noise or rumble. One of our favorite nozzles was the Monarch™ AR series for just this reason.

Also see OIL BURNER NOZZLE SUBSTITUTIONS for general oil burner nozzle substitution chart, adapted from Delavan and other sources.

Oil fired heater BTU output estimating tip: If there is no data tag on the furnace or you can't find the oil burner output BTUH you can guess it as follows:

Multiply the oil burner nozzle size (firing rate in gallons per hour) x 138,200 (Btus per gallon of No. 2 heating oil) x an efficiency estimate (use .75 for older furnaces and .80 for newer furnaces if you don't have a recent efficiency measurement).

At HEATING OIL USAGE RATE and

A TOTAL LOOK at OIL BURNER NOZZLES [PDF] provided courtesy of Delavan explains the effects of increasing fuel unit output pressure on the actual oil burner nozzle flow rate in GPH of oil.

Oil Burner Manufacturer Recommended Oil Burner Nozzles

Below: Delavan's summary table describes the both recommended and substitute oil burner nozzle types or patterns for various oil burner manufacturers including Aero, R.W. Beckett, Carlin, Riello, Intertherm, Wayne, and Weil-McLain.

[Click to enlarge any image]

Also see OIL BURNER NOZZLE SUBSTITUTIONS for more oil burner nozzle cross-reference charts.

Color Codes for Oil Burner Nozzle Caps or Vials

On 2018-06-21 by Craig

I would like to know what does the color caps on oil burner nozzles identify ?

On 2018-06-21 by (mod) - oil burner nozzle box or cap color coding

You might see for example red caps associated with a particular nozzle spray pattern. And blue caps with another pattern. I give some examples of oil burner nozzle color coding below.

If the manufacturer is using color coding for the caps on or vials for the oil burner nozzle containers it may vary among manufacturers, but as you'll see in my table below, there are indeed some conventions such as

- Blue = B - Solid cone spray pattern

- Green = W = All Purpose

- Red = A = Hollow cone spray pattern

- see the table below.

You'll notice that while there are conventions, the letter codes do not map perfectly among manufacturers and some produce nozzle types not sold by others. For example a gray Hago oil burner nozzle vial signifies an air-atomizing siphon nozzle intended for burning waste oil while a gray Delavan oil burner nozzle vial would signify either an AR-D solid anti-rumble nozzle or an R-D center-weighted solid cone nozzle.

Watch out: Take a look at the letters marked on the oil burner nozzle vial cap and then look at the letters and numbers stamped into the nozzle itself to be sure your nozzle is what the vial cap and color say it is. .

...

Oil Burner Nozzle Type Color Coding: Caps, Vials |

||

| Oil Burner Nozzle Brand | Nozzle Cap Color | Nozzle Pattern |

| Delavan Oil Burner Nozzle Color Codes | Black | A - Del-O-Flo™ Low-Flow hollow |

| Blue | B - Solid | |

| Blue - light | SS - Semi-solid | |

| Green | W - all purpose | |

| Gray - Dark | R-D - solid, center concentrated | |

| Gray - Light | AR-D - solid | |

| Orange | MH - Mobile Home low capacity | |

| Red | A - hollow cone | |

| Yellow | B - Del-O-Flo™ Low-Flow solid | |

Danfoss Oil Burner Nozzle Color Codes Hago Oil Burner Nozzle Color Codes |

Black | B - Solid |

| Blue | LC - Large Capacity | |

| Blue | S-S - Semi-Solid | |

| Green | ES - Extra Solid | |

| Green | P - Solid | |

| Grey | Siphon Nozzle | |

| Orange | W - Universal | |

| Red | H - Hollow Cone | |

| Red | EH - Extra Hollow | |

| White | DFN - Dual Filtration | |

...

Notes to the table above:

Danfoss Oil Burner Nozzle Pattern Descriptions

See details of these nozzle types and features at Hago Oil Burner Nozzles below.

- AB - Semi-Solid - 45° to 80°, from 0.40 to 2.00 GPH

- AS - Solid - as above

- AH - Hollow - as above

- B -Solid Cone

- H - Hollow Cone

- S - ? see B

- EH - use with kerosene - 60° & 80°, 0.4 to 1.10 US GPH

- ES - use with kerosene - as above

- OD-B Semi-Solid

- OD-H - Hollow

- OD-S - Solid

- Siphon -

Delavan Nozzle Pattern Descriptions

- Black / Yellow: Del-O-FloTM nozzles are low-capacity

nozzles designed to minimize the plugging problems associated with very low flow rates.

The special interior design of the Del-O-FloTM flushes contaminants through, limiting build-up. These nozzles will satisfactorily interchange with other hollow and solid cone nozzles. The Del-O-Flo is available in 0.40 GPH up to 0.85 GPH. - Blue: B SOLID-CONE

Type B-nozzles produce a spray that distributes droplets fairly uniformly throughout the complete pattern.

The spray pattern becomes progressively more hollow at higher flow rates, particularly above

8.00 GPH. Provides smooth ignition and efficient combustion, particularly in larger burners. - Blue, Light / Powder Blue: SS Semi-Solid nozzle

(.50-2.00) 600, 700, and 800 spray angles; interchanges with other SS nozzles. - Gray, dark: Type R-D

Nozzles have a high concentration of droplets in the center of the spray cone.

They are particularly recommended for burners with a highly concentrated solid air pattern. The average droplet size is slightly coarser than on the Standard Solid Cone Type B. - Gray, light: Type AR-D

Nozzles are of a “solid cone” type similar to Type B but with a slightly lower concentration of the droplets in the center of the cone. They are high performance in burners of low up to medium capacity (up to flows of 2.00 GPH). - Green: Type W

“ALL PURPOSE” -nozzles are neither truly hollow nor solid.

These nozzles frequently can be used in place of either solid or hollow cone nozzles between 0.40 and 8.00 GPH, regardless of the burner’s air pattern. The lower flow rates tend to be more solid. - Orange: MH Type .579 MH Mobile Home Nozzles are low-capacity nozzles designed for mobile home use.

This design will minimize the usual plugging problems associated with low flow rates. - Red: HOLLOW-CONE

Type A-nozzles are mainly used on burners with a hollow cone air pattern and for through puts up to 2.00 GPH.

The droplet distribution is concentrated on the outside of the cone and results in good ignition and low-noise combustion.

Hago Oil Burner Nozzle Descriptions

Note: Hago products are now managed and sold under the Danfoss brand. At our citations below, see Danfoss Oil Burner Nozzle Summary Chart; Also see Danfoss above.

- Black: B – SOLID CONE

BLACK CAPS Designed to give optimum combustion efficiency on high static pressure flame retention burners which specify a “B” pattern. As compared to the “ES” pattern, somewhat more fuel is concentrated towards the center of the spray. - Blue: LC – LARGE CAPACITY

BLUE CAPS These nozzles are uniquely designed for outstanding combustion in large commercial burners. They have large internal passageways to accommodate high flow rates. They produce a semi-solid “universal” pattern. - Blue: S-S – SEMI SOLID CONE

BLUE CAPS Most suitable for general applications where exact air pattern or spray pattern requirements can’t be established. Droplet distribution is relatively even across spray cone in smaller flow rates, but becomes more hollow as flow rates increase.

Also listed as SS - Gray: SIPHON NOZZLE

GREY CAPS Air atomizing nozzle for the combustion of waste oil and other variable waste oil products.

Excerpt from Danfoss: The “Siphon, Air Atomizing” nozzle produces an extremely fine solid spray pattern and is typically used for the combustion of waste oil and other recycled oil products. These nozzles have a multiple fuel grade application ranging from kerosene up to pre-heated #6 oil. - Green: ES – SOLID CONE

GREEN CAPS Our original solid cone series for low flow rates. Available for applications specifying a solid “ES” pattern. - Green: P – SOLID CONE

GREEN CAPS The “P” type is an extension of our “B” and “ES” series for firing rates of 2.00 GPH and above. It produces a solid cone pattern in the low rates and becomes more hollow as the flow rate increases. Specially designed with a pocketed disc to reduce combustion noises and pulsation. - Orange: W – UNIVERSAL NOZZLE

ORANGE CAPS

For installations where the use of a defined hollow or solid nozzle does not provide the combustion result desired.

- Red: EH – EXTRA HOLLOW CONE

RED CAPS This type “EH” is an extension of our hollow cone series. Available from 4.00 GPH through 30.00 GPH. It is specified in many commercial applications. - Red: H – HOLLOW CONE

RED CAPS - This series distributes the atomized oil particles evenly toward the outside of the spray cone. These nozzles are particularly well suited for low firing rates and burners with hollow air pattern. Normally used in wider spray angles.

Danfoss excerpt:

The “H” nozzle distributes atomised oil droplets evenly throughout a narrow band inside the outer edge of the s pray cone pattern. Typical applications are oil burners that produce a hollow air pattern and lower firing rate applications. - H-DFN

- White: DFN – DUAL FILTRATION

WHITE CAPS Available in hollow (DFN-H) and solid cone (DFN-B) patterns, the DFN nozzles give enhanced protection against clogging in the very low rates.

Steinen Oil Burner Nozzle Designations

- A - Hollow

- AR - Special Design [Anti Rumble]

- B - Solid

- C - Hollow

- CM - Semi-Hollow

- EH - Extra Hollow

- H - Hollow

- H or S - Hollow or Solid

- HV - High Velocity - Narrow Spray

- P - Solid

- PLP - Semi-Solid

- R - Solid

- NS - Hollow

- S - Solid

- SH - Semi-Hollow

- SS - Semi-Solid

- Q - Special Design

- W - Special Design

Other Oil Burner Nozzle Features

At the right side of the nozzle assembly you can see the sintered bronze filter that protects the oil burner nozzle orifice from clogging.

But of course if oil reaching this point is dirty (say you never installed that oil filter or it's leaking debris), this final filter will clog.

Our oil burner nozzle photograph above shows the outlet end of the nozzle and you can see that there is a stainless steel insert with a small opening that forms the spray pattern for this device.

Before manufacturers started using these beautiful steel inserts the entire oil burner nozzle was made of brass - and the spray opening would wear during the heating season, leading to a bad spray pattern. This is not the case any longer and the nozzle below will have no wear problems provided it is replaced during annual maintenance.

In an emergency, oil burner techs suggest cleaning this filter or even removing it and trying to de-clog the nozzle orifice. We don't recommend those steps.

In an emergency, oil burner techs suggest cleaning this filter or even removing it and trying to de-clog the nozzle orifice. We don't recommend those steps.

First off a new oil burner nozzle is not expensive.

Second using a wire in the nozzle orifice will likely damage it and ruin the spray pattern.

When the service company buys oil burner nozzles (in huge quantities in their case) each oil burner nozzle comes in a (usually color-coded) plastic container such as the one we show at left, indicating the gph rating and the nozzle angle and spray pattern.

The number of oil burner nozzle sizes and spray patterns is quite large because the nozzle properties have to accommodate not only models of oil burners themselves but more critically, different sizes and shapes of combustion chambers in boilers, furnaces, and water heaters, and different combustion chamber designs (wet base, dry base, for example).

So how do we choose the right oil burner nozzle? We need to know the equipment specifications for the oil burner nozzle recommended by the manufacturer.

You can find that in the installation and service manual for the oil fired device, you can ask the manufacturer, or you can use a nozzle guide such as the W.M. Steinen Mfg. Co. Nozzle guide - a book that lists literally thousands of oil burner nozzles for every application.

We show an example page from Steinen below.

You will see that for each brand of oil burner, or boiler, furnace, or water heater, and for each model within that brand, there is a listing of the required oil burner nozzle. These oil burner nozzle specifications will show the GPH capacity, spray angle, and spray pattern.

Oil Burner Nozzle Substitutions

This discussion has moved to OIL BURNER NOZZLE SUBSTITUTIONS

Oil Burner Nozzle Guide Books

- Audel, OIL HEAT TEXTBOOK, Audel's OIL BURNER GUIDE, INSTALLATION, SEVICING, REPAIRING re-published here free, on-line, as a series of web pages is the original Audels Oil Burner Guide Installation, Servicing, Repairing, Frank D. Graham, 1940's edition (obsolete).

Updated versions of this guide are available in various editions, 1947, 1950, 1955, 1958, 1959, 1962, 1965, 1967, and at prices from around $3.00 to nearly $70.00 - useful for simple, clear, but not current, explanation of how heating equipment works.

The original retail price was $1.00. Used copies are available

Note that below both Danfoss and Hago oil burner nozzles are essentially the same company; check documentation and nozzle guides under both brand names and substitution charts.

- Beckett, SELECTING the PROPER [OIL BURNER] NOZZLE [PDF] Beckett Corp., - retrieved 2022/05/24, original source: https://www.beckettcorp.com/support/tech-bulletins/selecting-the-proper-nozzle/

- Beckett, THE EFFECT of HIGH OIL VISCOSITY on OIL BURNER PERFORMANCE [PDF] (1985) Beckett Corp., - retrieved 2022/05/24, original source: https://www.beckettcorp.com/support/tech-bulletins/the-effect-of-high-oil-viscosity-on-oil-burner-performance/

- Danfoss, DANFOSS BURNER COMPONENTS SERVICE MANUAL [PDF] Danfoss , Website: burner.danfoss.com, - retrieved 2021/06/20 original source: https://assets.danfoss.com/documents/49906/AX135386471721en-GB0301.pdf

- Danfoss OIL BURNER NOZZLE TYPES SUMMARY CHART [PDF] (2008) Danfoss, retrieved 2021/06/20 original source: Sid Harvey, at https://www.sidharvey.com/documents/danfoss.pdf

- Danfoss, DANFOSS OIL BURNER NOZZLES TYPES AS, AH, AB DATA SHEET [PDF] (2019) Danfoss, Danfoss Toronto, ON / Baltimore, MD Toll Free: 888-DANFOSS (326-3677) Option #3 for Heating, U.S. Website: heating.danfoss.us Website Canada: heating.cs.na@danfoss.com, Nozzles: 0.4 to 2.00 GPH

- Danfoss, DANFOSS OIL BURNER NOZZLES TYPES AB, AH, AS, OD DATA SHEET [PDF] (2019) Danfoss, Op. Cit. , 0.4 to 3.00 US GPH, CSA certified to 2.0 US GPH

- Danfoss, DANFOSS OIL BURNER NOZZLES TYPES B, H, S-S DATA SHEET [PDF] (2019) Toronto, ON/Baltimore, MD Toll Free: 888-DANFOSS (326-3677) Option #3 for Heating heating.danfoss.us heating.cs.na@danfoss.com

- Danfoss, DANFOSS OIL BURNER NOZZLES TYPES EH & ES DATA SHEET [PDF] (2019) Op. Cit.

- Danfoss, EXCHANGE BURNER COMPONENTS with DANFOSS [PDF] (2017) Danfoss, retrieved 2021/06/20, original source: https://assets.danfoss.com/documents/49837/AX031086456770en-US0101.pdf

Tip this document includes QR Scan Codes that provide instructional videos on oil nozzles, pumps, filters, and other oil burner maintenance and repair tasks.

The document includes discussion of oil burner parts conversions such as Danfoss RS to RSA pumps, Danfoss RSL/MSL/MS/BFP pumps to BFP pumps, Suntec to BFP, Eckerle pumps to BFP, and Delta pumps to BFP.

- Danfoss, FACTS WORTH KNOWING ABOUT OIL [BURNER] NOZZLES [PDF] Danfoss , Website: burner.danfoss.com or heating.danfoss.com Email: heating@danfoss.com - retrieved 2021/06/20 original source: https://assets.danfoss.com/documents/100682/AG045286452015en-010101.pdf

Danfoss has offices world wide

Excerpt:

The oil nozzle plays a vital role in combustion and it is quite impossible to get CLEAN, STABLE and ECONOMIC plant operation if it is not handled correctly. A technician in the oil burner field will, naturally – or to put it more strongly – necessarily, know about the function of the oil nozzle and of its significance in the combustion sequence.

Fortunately, to learn about oil nozzles it is not necessary to read for a science degree. Instead, more convenient means are to hand – a moment or two, somewhere to relax, and this book. - Danfoss, PRACTICAL TIPS for OIL BURNER NOZZLES [PDF] Danfoss, retrieved 2021/06/20 original source: https://assets.danfoss.com/documents/100691/AG045286446960en-010101.pdf

- Danfoss Oil Burner Nozzles - India: Website: http://www.danfossoilnozzles.com/charts.html

- Delavan, A TOTAL LOOK at OIL BURNER NOZZLES [PDF] (2000) Spray technologies, Fuel Metering Products Operation P.O. Box 969, Bamberg, South Carolina 29003 USA, Tel: (803) 245-4347 (800) 982-6943 Web: www.delavaninc.com

courtesy of Delavan Fuel Metering Products [Website http://www.delavaninc.com/] a reference guide for oil burner service technicians, Delavan Spray Technologies, Fuel Metering Products Division, PO Box 969, Bamberg SC 29003, Tel: 800-982-6943 or 803-245-4347, ( Delavan is a division of BF Goodrich); web search 12/30/2010, original source: http://www.delavaninc.com/pdf/total_look.pdf

Note & disclosure: when we (DF) were servicing oil burner equipment, Delavan nozzles gave us such excellent results, especially using hollow cone spray patterns in solving combustion problems, that this brand was our standard stock-item on our truck.

Other brands of oil burner nozzles are of course also of excellent quality. It is the proper matching of nozzle size and type and spray pattern to the equipment that is critical. - EccoSupply, OIL BURNER NOZZLE CATALOG [PDF] (2011) EccoSupply, 1131 Central Avenue

Thunder Bay, ON

P7B 7C9

Canada, Tel: 807-346-4464

Fax: 807-346-4423

Toll Free: 1-877-530-3223 Website: www.eccosupply.ca retrieved 2020/01/10 original source: https://www.eccosupply.ca/pdf/price-lists/14.%20Miscellaneous/Oil%20Burner%20Nozzles.pdf

Ecco Supply has locations or suppliers in most of the Canadian provinces. - Hago: A TECHNICIANS GUIDE to HAGO OIL BURNER NOZZLES [PDF] Danfoss, original publisher, Hago Manufacturing, Inc., retrieved 2021/06/20 original source: https://assets.danfoss.com/documents/49837/AX031086456770en-US0101.pdf

- Olson, E.O., FUEL NOZZLES FOR OIL BURNERS, TECHNICAL ASPECTS OF APPLICATIONS [PDF], E. O. Olson, Chief Engineer (deceased) Delavan Fuel Metering Products Operation, Bamberg, South Carolina, Delavan Fuel Metering Products, a reference guide for oil burner service technicians, Delavan Spray Technologies, Fuel Metering Products Division, PO Box 969, Bamberg SC 29003, Tel: 800-982-6943 or 803-245-4347, ( Delavan is a division of BF Goodrich); web search 12/30/2010, original source: http://www.delavaninc.com/pdf/Fuel_Nozzles_for_Burners.PDF

Editor's note: if you are only going to read one article to understand oil burner nozzles, make it this one. - OHSM, The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- OIL BURNER ELECTRODES - at InspectApedia.com

- Steinen, Nozzle Guide,(1970) [Copy on file] WM. Steinen Manufacturing Co., 29 East Halsey Rd., Parsippany, NJ 07054, Tel: 201-8887-6400

This guide provides specifications including oil burner nozzle for every oil fired equipment manufacturer to 1970. - For other models of oil burners and their adjustments

see OIL BURNER MANUALS .

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2024-01-09 by InspectApedia DF (mod) - what is the increase in BTUH when we increase the oil burner fuel unit pressure?

@SAH,

How interesting, thank you.

Above on this page we provide a

Oil Nozzle GPH Rate vs Oil Pressure Setting

that includes our data sources - from experts.

As an example, that table says that if we increase the fuel unit pressure from 100 psi to 120 psi, a 1 gph nozzle will increase its delivery rate to 1.10 gph.

That's the change in flow rate in gph. One would think that the BTU delivery would change proportionally, though a more sophisticated look at oil burner performance might suggest that that's not exactly the case. That's because for the same oil burner nozzle size, spray angle, spray pattern etc., upping the pressure tends to deliver oil in finer droplets.

Those smaller droplets might be expected to ignite more readily and possibly burn more completely, perhaps delivering a bit more BTUH.

So let's try your formula to sophisticate the answer to the question of what is the increase in BTUH when we increase the oil burner fuel unit pressure?

We don't get 100% of the btus out of no. 2 heating oil we get maybe 80% or more depending on burner tune and operating efficiency.

But let's look at your formula:

At 100 psi and 1 gph output we're getting 140K BTUh nominal output (before adjusting for burner efficiency or inefficiency).

If we change the "actual psi" from 100 to 120 and use your formula:

[Sqrt (120) ] / 10 = 10.95 gph

10.95 x 10 = 109.5 gph

This corresponds exactly to the table that we include above in this article - rounding up to 110 gph.

Now if you want to convert the firing rate in gph to BTUh, yes you can multiply the new gph number x 140 (kbtus per gallon)

but as I warned above, that's theoretical, nowhere near actual.

If you want to know what the oil burner is actually delivering in BTUh or btus per hour you must know the burner's efficiency rate - how many BTUs are being delivered into the building as heat vs how many are going up the chimney as exhaust.

And as I've noted, at higher pressure the burner's efficiency improves. So it's not exactly linear and our calculation is theoretical, not actual.

Thank you for the discussion.

On 2024-01-09 by SAH

The BTU output of an oil burner at X psi is found by multiplying the nominal GPH output (140k btu/gal) by the square root of the actual burner psi, then dividing by 10.

On 2023-12-24 by InspectApedia Publisher - need to know the proper nozzle for your particular mobile home heater

@Greg,

Can you tell me the original, manufacturer's oil burner nozzle specified for your burner and heater?

That is to say no one can give a "safe" answer to your question without knowing what is the proper nozzle for your particular mobile home heater.

Often the recommended nozzle size, pattern, angle are given on a sticker right on the oil burner that came with your furnace.

You can also contact the manufacturer, Nortek, at 8000 Phoenix Parkway, O'Fallon, MO 63368 Tel: 1-800-422-4328

You'll see above on this page that we give some guidelines for substituting among oil burner nozzles; you need to stay pretty close to the original specified nozzle, though the firing rate in gph of the nozzle is of course not a fixed number - depending on the oil pressure to which the fuel unit (oil pump) on the burner has been set.

If you don't have the manual for your furnace you can down load this copy

https://inspectapedia.com/heat/CMF-Furnace-Manual.pdf

On 2023-12-24 by Greg

Is there any advantage or disadvantage to using a delovan .579MH nozzle in an older Miller mobile home furnace (model MF80P ? with a Beckett burner)

On 2023-12-18 by InspectApedia Publisher - What does the AS stand for on my oil furnace nozzle

@Dominick C Barone,

For most brands the letter A on an oil burner nozzle refers to a hollow cone spray pattern

And the letter S refers to a solid cone spray pattern

If you have a nozzle that is stamped both A and S I'm guessing that it was a universal substitute nozzle that claimed it would work equally well for either requirement.

Take a look on the oil burner itself as well as in the manual for your heater where often the manufacturer will give you the preferred pattern.

On 2023-12-18 by Dominick C Barone

I have a hot air oil furnace. I typically change the filter and the Nozzle every year. The nozzle type and brand is Danfoss 0.85 70degree AS. I cannot find this nozzle. I know the the 0.85 is the gallons, the 70 degree is the spray pattern.

What does the AS stand for. I went to a plumbing supply and they have a Steinen 0.85 70 degree S nozzle. Will this work?

Dom Barone

email: dbarone@nycap.rr.com

On 2023-02-10 by InspectApedia Publisher - oil burner nozzle electrode placement

@Mike k,

Thank you, that's an interesting oil burner nozzle electrode placement question.

I figure that the oil burner design engineers have spent almost a century designing oil burners and electrode replacement, so I trust their judgment.

I suspect that they figure that as oil is delivered under pressure the electrodes' spark could be almost anywhere in a rather symmetrical spray of oil leaving the nozzle tip, but perhaps placing the electrodes above the tip as is usual, makes routing inside the burner tube easier and might reduce fouling from any dribbles that occur at shut-down. (Those shouldn't but they do occur).

On 2023-02-10 by Mike k

Would the Electrobes be placed better if they were below the oil nozzle instead of above ?

On 2023-01-09 by InspectApedia Publisher - what size nozzle should I use on my Carlin 701CR to cut back on heat to my maple evaporator?

@Brian,

On a conventional heating furnace or boiler, the manufacturer has matched the properties of the combustion chamber size and shape, the heat exchanger, the heater's venting capacity and other features when they include a data tag, usually right on the oil burner or on the heater, that gives an acceptable firing range in gph as well as the specific nozzle pattern (angle and spray type).

We don't know who made your maple evaporator - brand and model. If it's not a home-made system you would call the manufacturer to check with their engineers about the acceptable nozzle firing rate.

Normally you can step down the firing rate but I'm not sure that you can drop it by a whole gph or enough to stop caramelizing the maple syrup without a too-small flame.

Our options are to ask the manufacturer's engineers or to do some experimenting with smaller firing rates, say dropping to 3 gph and 2.75 gph and have a trained oil heat service tech monitor the stack temperature, CO2 and smoke level so that we're sure that the system runs clean-enough and safely.

The angle of fire should be matched to the combustion chamber size and shape and isn 't something you'd vary by much at all. For example going to a too-wide or too-long flame can cause flame impingement on the combustion chamber liner that in turn causes incomplete sooting, clogging up of the system or worse, a puffback explosion.

On 2023-01-09 by Brian

Hi, I have a Carlin 701CR that I use on my 3.5’ X 10’ maple evaporator. I now use the following nozzles; low fire - 3.5 gph 45 H

High fire- 3.25 gph 80 B.

My burner is running at 150 psi. The combustion chamber inside demensions are 38” wide X 54” deep and 24” high.

My problem is, the syrup is carmilizing to much before it reaches the correct densityI would like to change my nozzles to cut back on heat, not sure if I should step down GPH or angle of fire or possibly both?

On 2022-12-03 by InspectApedia (Editor) - Any idea what J20 nozzle means?

@Gerry,

OIL BURNER NOZZLE SUBSTITUTIONS

Lists all of the oil burner nozzle codes we've been able to find but j20 is not among them.

I'll do some further research but it would help if you could post photos of the nozzle, one per comment, showing the markings on its various facets.

On 2022-12-01 by Gerry

I have a Delevan .75 .70A nozzle, but unlike others I have, it also has a J20 stamped on it. I can't find anywhere online that says what this means. it did not perform well in my furnace.

Flame sounded "rough' or like there was air in the fuel and the furnace would shut down every few days. Once I noticed, while troubleshooting, the J20 I changed it out with one that didn't have J20 on it and so far the furnace seems to be running fine.

Any idea what J20 means?

On 2022-09-12 by InspectApedia-911 (mod) - over-tightened nozzle can strip threads on the nozzle adapter

@Rod sassic,

Leaks back where, from where? We need to inspect and find the leak point before we know which fittings to replace.

Watch out: an over-tightened nozzle can strip threads on the nozzle adapter or on the nozzle tube, causing oil leaks.

On 2022-09-12 by Rod sassic

Oil leaks back when running as if not getting total burn.

On 2022-08-03 by InspectApedia-911 (mod) - complete table of oil burner nozzle codes

@Brian,

Above on this page, you'll find a complete table of oil burner nozzle codes and a translation of those codes into nozzle spray pattern properties,

https://inspectapedia.com/heat/Oil-Burner-Nozzle-Selection-Guide.php#Pattern

and you'll see that NS is a type of hollow-cone spray pattern.

On 2022-08-03 by Brian

What does NS mean on a oil burner nozzle question

On 2022-05-24 by InspectApedia-911 (mod)

@Á Ramírez A.,

Favor de encontrar su pregunta y nuestra repuesta, in ingles y tambien en espan~ol, arriaba a

OIL BURNER NOZZLE DROPLET SIZE RANGE

Mil gracias por la pregunta - digme si hay mas preguntas.

Daniel

On 2022-05-24 by Á Ramírez A.

Saludos cordiales.

He leído que el tamaño de la partícula pulverizada del aceite combustible N.2. para que exista una buena combustión debe ser entre 10 y 50 micras, me podrían indicar si es correcto, y cual es el tamaño de las partículas pulverizadas a una presión de 100 psig. de las boquillas marca Delavan o de otras marcas. Mi correo ssatiar@hotmail.com. Gracias.

On 2022-02-07 by Inspectapedia Com Moderator - oil burner troubleshooting tuning and adjustment

@dennis meguire,

Our article index has articles that give you detail on all of the steps in oil burner troubleshooting tuning and adjustment. I don't think it would be safe for you to rely on a brief succinct summary since making a mistake could be dangerous.

There's also an entire oil heat textbook online that you will find in the links above and in the article index. Please take a look

On 2022-02-07 by dennis meguire

Can you explain how to set the draft and or air combuston air settings?

On 2021-10-25 by inspectapedia.com.moderator

@LEROY and Ian,

Thank you.

We've worked on this material for a long time to make it accurate and trusted, so we are always grateful when a reader finds it useful.

On 2021-10-24 by LEROY

This artical is no joke! Clean crisp and to the point.

On 2021-02-09 by Ian

One of the most comprehensive, no bullshit and well written articles on ANYTHING i have read.

All the facts, underlying information and tips required.

On 2021-02-26 by danjoefriedman (mod) - What would changing the angle at 10 degree affect?

@Sam Wise,

A 10 degree wider spray angle with the otherwise same oil burner nozzle GPH and flame type (A) means that the flame produced will be a bit shorter (extending less far from the tip of the oil burner nozzle into the combustion chamber) and a bit wider across.

That might be a small-enough change as to be OK.

What a technician would watch for would include watching for too much flame impingement on the combustion chamber sides, resulting in less than complete combustion of the heating oil being sprayed, and, though probably less likely, incomplete combustion of a small volume of droplets that might otherwise hit the hot back of the combustion chamber and thus be assisted in burning by the hot surface of the chamber liner.

In other words, too little impact on the chamber liner or too much on the liner might both result in less-perfect combustion of the sprayed fuel.

You'd probably detect these with a combination of observation (smoky flame, noises), and measurement of smoke and CO2 or O2 and temperatures in the breech.

Before changing the oil burner nozzle spray angle width, check the sticker on the oil burner or boiler or furnace where you find the manufacturer's recommended nozzle type and pattern.

On 2021-02-26 by Sam Wise

What would happen if I changed from a 1.5 GPH 70 degree A to a 1.5 GPH 80 degree A. What would changing the angle at 10 degree effect.

On 2020-11-15 by (mod) - ok to downsize the oil burner nozzle?

Claude,

Generally, yes.

in the article above take a look at OIL BURNER NOZZLE FIRING RATE GPH

On 2020-11-11 by Claude

Can a 75 × 70A nozzle be replace with a 65 × 70A nozzle. What are pros/ cons?

On 2020-09-22 by (mod) - oil burner soots up alot

If the burner is sooting abnormally AND has a nozzle that's within the range permitted by the manufacturer for your oil burner, the tech will look for any of quite few other causes of oil burner sooting like air leaks, dirty oil, wrong pressure, poor combustion air, wrong draft settings, bad electrodes.

See SOOT on OIL FIRED HEATING EQUIPMENT

Watch out: you risk a puffback explosion too.

See OIL BURNER SOOT & PUFFBACKS

On 2020-09-22 by Dean

My oil burner soots up alot and it looks like there is un burned oil on the flu and it also clogs up the entire burner body at least once a year i have to take the whole burner apart and vacuum it could my nozzle be to big spraying to much oil thats not igniting?

On 2020-09-11 by (mod) - can I go down to a .40 gph nozzle?

Depending on your oil depending on your oil burner that depending on your oil burner that might be a depending on your oil burner that might be a pretty big depending on your oil burner that might be a pretty big change depending on your oil burner that might be a pretty big change in gallons per hour depending on your oil burner that might be a pretty big change in gallons per hour depending on your oil burner that might be a pretty big change in gallons per hour.

Look at your oil burner for a tag or sticker that gives the allowed range of nozzle sizes and also be sure you're using the proper angle or width of spray

On 2020-09-11 by Jason squirrel

I just changed a riello nozzle from .50/70w to a .80/85 could I use a lower .40 gph

On 2020-08-09 by (mod) - replace a .75 80 A with a .75 80 H

Matt,

See OIL BURNER NOZZLE SPRAY PATTERN

you'll see that as long as you keep the nozzle spray angle the same, going to a hollow cone might work ok on your burner but you'll want to check what the manufacturer permits for your burner and boiler or furnace.

On 2020-08-09 by Matt Collins

Can I replace a .75 80 A with a .75 80 H

On 2020-06-16 by (mod)

Vince, see OIL BURNER NOZZLE SUBSTITUTIONS

On 2020-06-16 by Vince - nozzle substitution 120 60 w

What crosses with 120 60 w

On 2020-01-17 by (mod) - hollow cone vs solid cone operating problems on a Riello RG 1 oil burner

Nick

Nick

Even when changing from solid to hollow cone nozzle while keeping the same spray angle and GPH rating it would make sense to check and adjust the air shutter.

You would not change the electrodes. The electrode gap, height, and forward-space from nozzle face would remain the same. However when changing a nozzle, if the nozzle dimensions moved the face of the nozzle forward or backward from the previous one the electrodes might need fine tuning.

Also, of course, its possible to foul up the nozzle electrode position during nozzle change as often the electrodes have to be loosened and moved to replace the nozzle.

A blocked oil burner nozzle can occur for a range of reasons, of which the most-obvious is debris in the oil supply, perhaps made worse by failing to change the oil filter and fuel unit screen; but an improper adjustment of electrodes or combustion air supply or draft can result in a smoky flame that fouls the nozzle end.

You might see that by inspection: a build-up of oily soot on the nozzle face and on the electrode tips.

On the other hand changing nozzle spray pattern would not explain nozzle clogging at the nozzle's inlet filter -that sintered bronze filter shown in our photo below. That clogging comes from debris in the oil supply combined with failure to change the oil filter or the screen in the fuel unit.

Watch out: for nicking or stripping the threads in the nozzle adapter when fooling with oil burner nozzles. If you've made that mistake no nozzle will work properly as air or oil leaks will foul up the burner at the nozzle.

Watch out: unless you're trained and equipped to tune an oil burner, unfortunately you can't get it right just by eye alone.

It's necessary to measure the smoke level, stack temperature, and CO2 or O2 level as well as draft over the fire and in the breech.

On 2020-01-17 by Nick Livanios - Riello RG 1 oil burner nozzle pattern

Hello ,

I have a Riello RG 1 oil burner . While It works fine with a nozzle with a solid cone when I put a nozzlewith hollow cone as the service manual says, it doesn't start or it does after 4-5 times that is blocked.

Do I have to make some other adjustments like air damper setting or different position of the electrodes?

Thanks a lot

On 2020-01-10 by (mod) - are A- and B- oil burner nozzles interchangeable?

Anon

Thanks for asking about nozzle pattern substitutions.

A look through our data and tables such as in the article above we see that at least for some burner brands and models the manufacturer will say, quite explicitly, that you can use either an A- (hollow cone) or B- (solid cone) nozzle.

By staying with the same spray angle 80 deg and gph 0.85 you should be ok.

There are a couple of reasons a tech might go from A to B or B to A spray patterns.

1. she thinks she's getting better burner flame and thus better burner operation

2. she (or he) didn't have the other version (has A but not B or vice-versa) in the right angle and gph rating on the truck.

I used to think that I preferred hollow as burning more efficiently but that's opinion, not fact.

On 2020-01-10 by Anonymous

I cleaned my buner and replaced the nozzle. The specs label called for 80x85 B, when I removed the old nozzle it was 80x85A.

I seen the difference between the spray pattern. was is appropriate for the service company to change the nozzle type?

On 2019-12-27 by (mod) -

Sorry I don't get the question.

On 2019-12-26 by Anonymous

What does all goes into the AF burger with it if three here

Reader Question: how do I convert oil burner nozzle rates in GPH to litres per hour LPH?

(Nov 2, 2014) tking said:

What is the conversion factor to litres per hour? Are they using British Gallons (4.5l) if they are using British thermal units?

Or US gallon (3.78l)

Reply:

This article is using U.S. oil burner nozzle ratings in U.S. gallons per hour.

1 U.S. Gallons (or for oil burner nozzles gallons per hour or GPH) = 3.79 Litres

1 British Gallon = 4.5 Litres

1 British Gallon = 1.6 U.S. Gallons

So if a US-made or US-specified oil burner nozzle is rated at 1.0 gph (at say 100 psi) then it will burn 3.79 litres per hour or LPH.

Also see HEATING OIL USAGE RATE for more details.

(Dec 3, 2012) John said:

By the way Nice Site.

Question: Every time my oil furnace fires I can smell raw heating oil/diesel smell from my chimney.

Every time my oil furnace fires I can smell raw heating oil/diesel smell from my chimney. It may last up to 5 minutes. No smell in the house. The furnace gets serviced every year,new filter,new nozzle and cleaned. - Joe. 10/10/11

Reply: Improper oil burner operation, unburned oil, or bad draft - watch out for a puffback

Joe,

I agree that you should not smell heating oil when the equipment is running. Because you describe the smell as not continuous, just at start-up, I suspect a dirty system that needs cleaning and service. Or you could have a dirty chimney and bad draft.

Most likely you've got a system that is not running properly and is stinking up things at start-up. Once strong draft is established and the system is up to full operating temperature (typically 5 minutes), the draft improves and combustion may improve enough to keep going. But the system is not running properly.

Watch out: if this condition continues the risk is a puffback that can damage the equipment and blow soot around the building.

A blocked or dirty chimney or lack of combustion air or other causes could be present - ask your heating service company manager to send a technician who will diagnose and fix the problem. It sounds as if the usual annual service procedure has not been sufficient.

That's no surprise. During the heating season the techs are overworked and over committed and sometimes will just clean the system without taking the time to diagnose an actual problem and fix it.

Question: Sometimes my oil burner won't re-ignite

I have an aero burner on my hot water furnace. Starts and runs perfect most of the time. Every once in a while it will not re-light I press the reset button, it might run perfect for a week or two, then one day it will not light Press button again,starts right up and runs perfect, maybe for two days or two weeks again, then all of a sudden it will not light Any suggestions what to look for. - Joe Daye 12/3/11

Reply:

Joe, take a look at the oil burner diagnostic suggestions beginning

at OIL BURNER INSPECTION & REPAIR.

Usually when a system is limping along as yours is described, the operating problem is going to get worse. I'd look for an air leak in the oil piping, a dirty oil burner, a clogging filter, a draft problem.

Question: I kept my oil furnace running for two hours - would that damage the electrodes or transformer?

I kept the oil furnace running continuous for about two hours, then it stopped running by itself. I pushed the reset on the stack control, it ran for a few seconds then kicked off. Did I burn out the electrodes or transformer by running it non stop? - Bob 2/9/12

Reply:

Bob:

No. Running a furnace non-stop for two hours should not itself damage the equipment. On the coldest windiest day of the year in a poorly insulated home an oil burner might run almost continuously for hours. Something else is wrong.

Question: Our oil burner only ignites if the door is open. What might be wrong.

We have replaced the electrodes and nozzle on the furnace. It will only light with the door open and stay going after you close the door - seems like it is not getting enough air. What could be the problem? - Simone

Reply:

If you mean that the door to the boiler room (or furnace room) has to be open for an oil burner to work, that suggests it's air starved - we need about 1 sq. in. of air intake into a small utility room per 1000 BTUH for oil fired heating equipment - so a 90,000 BTUH oil heater would need 90 sq. in. of unfettered air intake opening. If you add louvers and screening the sq. in. requirement is increased.

Take a look at COMBUSTION AIR REQUIREMENTS

and COMBUSTION AIR for TIGHT BUILDINGS

But lack of combustion air usually leads to sooty operation and the oil burner going off on reset, or worse, loss of heat.

The bit about "... stay going after you close the door " is baffling. If we don't have enough combustion air to ignite then we shouldn't have enough combustion air to keep going. I figure you need a service call from an expert heating service tech who will check the condition of the burner, combustion air setting, cleanliness of the flue vent connector and chimney, the draft, and a few other parameters.

Question: oil burner runs continuously, won't stop, doesn't fire-up

(Jan 16, 2013) Burner Runs continuously without said:

hi,my burner wen started up it runs constantly without any change,no attempt off fire or ignition!!would this be electrodes??

Reply:

Watch out: turn off the system immediately. When a fuel unit keeps pumping oil into the combustion chamber without ignition, later ignition can cause a dangerous puffback explosion.

(OIL BURNER SOOT & PUFFBACKS )

It sounds as if your oil burner safety controls are not working or have been bypassed. This is an unsafe heating system that needs repair by a trained service technician.

Question:

5/20/2014 NATHAN said:

Anyone know what can goes wrong with the valve in the oil gun assembly and where can I buy the gun assembly with the valve and the nozzle adapter?

Reply:

Nathan

Armed with the brand and model of oil burner you could certainly buy an entire assembly, even the burner tube, and replace those parts, but before considering that I'd look for normal maintenance replacements instead.

The usual parts that are replaced are the electrodes if the ceramic is cracked or damaged, and of course the nozzle at annual service.

If someone heavy-handed has worked on the system and over-torqued the nozzle into the nozzle adapter there could be damage and leaks at the nozzle adapter or at the connection of the adapter to the oil tube.

The turbulator, if your oil burner gun has one, is cleaned but rarely would need replacement.

Question: where can I buy the oil burner gun assembly

(May 20, 2014) NATHAN said:

Anyone know what can goes wrong with the valve in the oil gun assembly and where can I buy the gun assembly with the valve and the nozzle adapter?

Reply:

Nathan

Armed with the brand and model of oil burner you could certainly buy an entire assembly, even the burner tube, and replace those parts, but before considering that I'd look for normal maintenance replacements instead.

The usual parts that are replaced are the electrodes if the ceramic is cracked or damaged, and of course the nozzle at annual service.

If someone heavy-handed has worked on the system and over-torqued the nozzle into the nozzle adapter there could be damage and leaks at the nozzle adapter or at the connection of the adapter to the oil tube.

The turbulator, if your oil burner gun has one, is cleaned but rarely would need replacement.

Question: soot out of the damper - is that a problem?

(Sept 21, 2014) Anonymous said:

I have an old Brock engineer oil furnace and black soot comes out of the damper on the floor. Is that normal?

Reply:

Richard, it sounds like an oil burner clean out and tuneup are needed along with a chimney and combustion air check.

Watch out: be sure to read OIL BURNER SOOT & PUFFBACKS

Question: use Beckett brand oil burner electrodes in an Aero oil burner?

(Dec 22, 2014) Lloyd said:

I have an Aero burner, can Beckett brand electrodes be used in this burner?

Reply:

Lloyd

I think that you're ok as long as the electrodes, including the metal electrodes themselves and the ceramic insulators and their end connectors that marry the oil burner transformer power supply contacts are in all regards the right dimensions.

Question: hot water heater oil burner keeps turning on and off when it first fires

(Jan 14, 2015) Anonymous said:

my hot water heater oil burner keeps turning on and off when it first fires. It will then stay running after that. A couple times it tripped out

Reply:

Check the diagnosis above at CONTINUE READING titled

There could be simply a loose wire, or the oil burner may simply need service. Don't let it go too long. The risks include loss of heat or a puff back.

Question: I changed the nozzle on my oil burner but it still won't fire up

(Jan 15, 2015) Anonymous said:

i changed nozzle and it still wont start up

Reply:

See the diagnostics at OIL BURNER WONT RUN

...

Continue reading at OIL BURNER NOZZLE SUBSTITUTIONS - troubleshooting a new oil burner nozzle that doesn't seem to work, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- OIL BURNER ELECTRODES - how to set the electrodes on the oil burner once you've got the right nozzle

- OIL BURNER RUMBLING NOISE

- OIL BURNER NOZZLE GUIDE

- OIL BURNER NOZZLE REPLACEMENT: MATCH THE OLD ONE

- OIL BURNER NOZZLE FIRING RATE GPH

- OIL BURNER NOZZLE SPRAY ANGLE

- OIL BURNER NOZZLE SPRAY PATTERN

- OIL BURNER NOZZLE DROPLET SIZE RANGE - separate article

- OIL BURNER NOZZLE SELECTION TABLE

- OTHER OIL BURNER NOZZLE FEATURES

- OIL BURNER NOZZLE SUBSTITUTIONS - separate article

- OIL BURNER NOZZLE GUIDE BOOKS

- OIL BURNER INSPECTION & REPAIR - home

- OIL BURNER WONT RUN help diagnosing and fixing oil burners

Suggested citation for this web page

OIL BURNER NOZZLE GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Beckett Corporation, 38251 Center Ridge Rd., North Ridgeville, OH 44039 440-327-1060 Email: sales@beckettcorp.com supplies residential and commercial oil burners for boilers, furnaces, and water heaters - see www.beckettcorp.com/

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- Principles of Home Inspection: Steam, Electric & Wall/Floor Heating, Carson Dunlop Associates, at Amazon.com>

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.