Vulcanized Rubber & Asbestos or Other Fabrics

Vulcanized Rubber & Asbestos or Other Fabrics

History,

uses,

safety, patents

Apparatus for combining asbestos & rubber

- POST a QUESTION or COMMENT about this vulcanized rubber products that contained asbestos or other fabrics

This article describes vulcanized asbestos and vulcanized rubber-asbestos along with other vulcanized rubber products, giving a definition vulcanization or vulcanized products and by example listing common ingredients, vulcanized rubber end products, and their uses.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Vulcanized Rubber & Asbestos Products: ID Tags, Tires, Hoses & Other Products

Vulcanized asbestos products are made from combining asbestos fiber and rubber, or in modern versions (still produced in China, Aug 2022) a combination of asbestos fiber and synthetic rubber, using a combination of heat and compression.

Vulcanized asbestos products are made from combining asbestos fiber and rubber, or in modern versions (still produced in China, Aug 2022) a combination of asbestos fiber and synthetic rubber, using a combination of heat and compression.

[Click to enlarge any image]

Definition: The vulcanizing process, as we define it here from historical references, involves combining crude or raw rubber with sulphur and asbestos, mixing the ingredients by running the mass through heated rollers, inserting the mass into a mould, and heating and pressurizing the mold, often using high pressure steam. (Calvert 1858)

The result is a hardened, flexible rubber material whose history is traced to pre-historic inventors, the Mayans whose hard rubber soccer ball, made of rubber, possibly mixed with the cremated remains of ancestors, combined religious observance with a game that is the precursor to modern football (soccer).

History & Safety of Vulcanized Asbestos Identification Discs

Reader John D. asked about the safety of handling vulcanized asbestos ID tags. These identity discs, first used in by the British in 1907 as an aluminum tag, were widely used in WWI and later, in a variety of forms or materials.

The Vulcanized (rubber & asbestos) ID tags shown above and a Q&A discussing any possible asbestos exposure hazard from such discs were posted originally

The earliest ID-tags were issued by Prussia during the Franco-German war (1870-1871, possibly as late as 1878) in the form of a stamped steel rectangular tag with rolled edges. (U.S. stainless steel dog tags made much later were also of stainless steel with rolled edges).

Similar identification discs were used by Canada (1914), Australia (1907 - 1917 or later), India, New Zealand, and South Africa. In other literature these discs are referred to as "vulcanized fibre discs" without necessarily mentioning asbestos. Bulgaria, Turkey, France, Belgium, Russia, Italy, Japan, Turkey and other nations issued similar tags to their soldiers.

The "vulcanized rubber-asbestos" identity tags shown here are a hardened asbestos product that may have combined a sealant or coating and a colouring agent to form a durable, lightweight identification tag.

These identification discs or "tags" were made of a mix of rubber and asbestos to create a tag, if made of simple asbestos would have been too soft, and if made of asbestos cement would have been too brittle, easily broken.

In their British use there were three such tags, two worn by the individual and a third attached to the gas mask or "respirator" haversack that identified its owner. The first two tags identified the individual and the third helped assure that the gas mask, fitted to the individual, would be in fact quickly identified for use by that person. A bit of history and research on vulcanized asbestos identity discs and other similar products is given below.

Illustration: Vtg National Vulcanized Fibre Catalog~Asbestos~Phenolite Sheets&Tubing for sale on eBay in August 2022.

In the UK, British HSE has been quoted as follows:

Such tags remaining in the hands of collectors are not normally involved in work activities and so are not subject to HSE’s health and safety requirements.

It is foreseeable that the rubber may perish and fragment over time, but HSE has no information as to the likely degree of fibre release or when this may occur.

Given that such tags are rarely handled, and most fibres will remain bonded in, the risk is thought to be low.

We would recommend placing them in sealed transparent containers or sealed polythene bags. We suggest you may wish to discuss with the Imperial War Museum. - source: "WW1 Identity Discs/ Dog tags" at WW2Talk, retrieved 2022/08/18, original source: http://ww2talk.com/index.php?threads/ww1-identity-discs-dog-tags.22417/#post-766190

History of Vulcanized Rubber + Asbestos or Other Fabrics

The earliest U.S. patents using vulcanization to produce molded or other flexible objects from a mix of rubber, sulphur and asbestos (that we have found) are described here.

The earliest U.S. patents using vulcanization to produce molded or other flexible objects from a mix of rubber, sulphur and asbestos (that we have found) are described here.

The discovery that combining rubber with sulphur and applying heat (vulcanizing rubber) is attributed to Goodyear who, it's said, in 1839 accidentally dropped a mixture of rubber and sulfur into a hot frying pan.

Although he never uses the word "vulcanizing" in his text, Nathaniel Hayward described "improvements in preparing caoutchouc (India rubber) with sulphur for the manufacture of various articles" in one of the earliest U.S. patents in 1839, assigning U.S. patent 1,090 to Charles Goodyear of Boston Massachusetts.

In the U.S. in the 1830s Goodyear was working to produce an improved automobile tire. Vulcan the god of fire, is the origin of the Latin word volcanus or volcano in English and hence was Goodyear's name for the process he discovered. By 1844 Goodyear had patented his process of vulcanizing rubber. (Goodyear 1853)

Cheever, in describing his patent for a rubber hose machine, described vulcanization:

To accomplish this, I take the rubber, when con pounded with sulfur in any of the ordinary compounds used in Vulcanized rubber goods, and when it is in the state ready to be submitted to the Vulcanizing heat, that is, a substance like stiff dough or paste, mix it with the fibers of cotton and flax, by grinding the materials between heated rollers in the mode usually practiced by rubber manufacturers, until the fiber is thoroughly incorporated with the rubber.

The proportion I prefer is three pounds of rubber compound to one pound of flax or cotton, although these proportions may be varied according to the quality of the fabric.

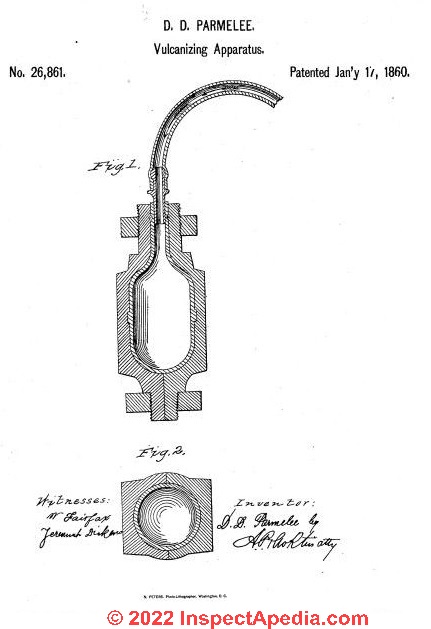

More practical applications of the process of vulcanization were described by Dubois D. Parmelee (1860) in the production of hollow objects of vulcanized rubber, continuing Goodyear's work on automobile tires from three decades earlier.

Another early U.S. patent for vulcanized "rubber" was by Newbrough, J.B. & E. Fagan (1867) in which the authors combined stearing or margarine with melted sulphur. The mixture was heated, melted, solidified, then re-heated for pouring into a mold of "any required form" to make "imitation rubber".

An early and important US Patent describing the vulcanizing process to produce a true vulcanized rubber was by Mosher Sutherland, in which the inventor combined India rubber or caouchoue with asbestos and a quantity of sulphur sufficient to effect a proper vulcanization of the mass. (Sutherland 1869)

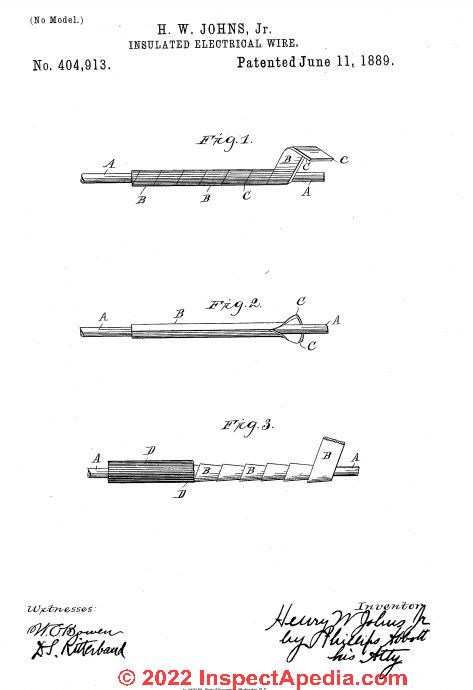

These vulcanised rubber products produced a product with very useful flexibility, durability, and water or oil resistance, for example in Johns 1889 patent for insulated electrical wire described below. Johns found that this electrical wire insulation was heat resistant and practically "fireproof", an important property for electrical wiring if building fires were to be avoided.

By combining asbestos fibers with rubber and sulphur, a flexible but yet strong product was achieved. (De Karavodine 1906). And of course a major and early use of vulcanized rubber with other materials was in the manufacture of tires (Roussillon 1912).

Modern versions of vulcanized asbestos-rubber products are used to form heat and/or oil-resistant pads, gaskets, mats used in engine construction, pipelines, and other applications. These products may also be reinforced with wire mesh.

Vulcanized Rubber Products Patents & Research

- Abel, Frederick Augustus. Handbook of chemistry. Blanchard and Lea, 1854.

- Baumert, M. "VII. On a new oxide of hydrogen and its relation to ozone." The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 6, no. 36 (1853): 51-63

- Calvert, Frederick Crace, and Richard Johnson. "XVIII. On the relative power of metals and alloys to conduct heat.—Part I." Philosophical Transactions of the Royal Society of London 148 (1858): 349-368.

- Cheever, John H., MANUFACTURE of RUBBER HOSE PIPE [PDF] U.S. Patent 22,854 issued February 8, 1859.

- Christenson, George. PACKING-RING AND PROCESS OF MAKING SAME [PDF] U.S. Patent 1,273,738, issued July 23, 1918. Assigned to Johns Manville Corp.

Excerpt: Preferably I make the ring for this reason of asbestos fiber vulcanized under pressure. - Day, AUstin G., IMPROVEMENT IN TREATMENT OF CAOUTCHOUC [PDF] U.S. Patent 21,122 Issued August 10, 1858

Excerpt:

The nature of my invention consists in a new method of heating rubber and sulphur com pounds in order to make an artificial product having definite properties-namely, hardness and elasticity.

It is Well knownto the manufacturers of this article that Charles Goodyear, on the 15th of June, 1844, patented a mode of vulcanizing rubber to preserve it soft and flexible when ex. posed to the summer's sun or winter's cold, or to the action of oils or other solvents.

It is also known that Nelson Goodyear, in 1851, on the 6th day of May, patented a process of making what is usually called “hard rubber compounds;" but which is exactly defined by the patentee calling it in his first claim “a hard and inflexible substance hitherto unknown.' - De Karavodine, Victor. Treatment and utilization of waste vulcanized rubber and ebonite [PDF] U.S. Patent 838,419, issued December 11, 1906. Assigned to Berenard Rough, Paris France.

Excerpt: To the above-mentioned mixture of pow dered material and sulfur mica in Small par ticles or asbestos in fibers could be added and an exceedingly strong article so obtained. - Feigley, Jr David A. PREPARATION OF SHEET MATERIALS CONTAINING FIBERS, CORK PARTICLES, AND A RUBBERLIKE BINDER [PDF] U.S. Patent 2,613,190, issued October 7, 1952. Original Assignee Armstrong Cork. Co.

- Feigley, Jr David A. METHOD OF MAKING FIBROUS SHEET MATERIAL CONTAINING A SYNTHETIC RUBBER BINDER [PDF] U.S. Patent 2,772,970 issued December 4, 1956. Original Assignee Armstrong Cork. Co.

Excerpts: The beater saturation process broadly comprises forming an aqueous slurry of papermaking fibers, which may be either inorganic fibers such as asbestos or organic fibers such as kraft fibers, and adding to the resulting slurry a rubber latex which, in the early days of the practice of this process, was normally a natural rubber latex but which in more recent times has been any one of the synthetic rubber lattices ...

From the above, it can be seen that the process may be used to produce sheet material from organic fibers and mineral fibers, as well as mixtures of such may produce a resilient material composed of cork and fibrous materials. Such materials are particularly useful in the production of gaskets. - Goodyear, Charles, INDIA-RUBBER FABRIC [PDF] U.S. Patent NO. 3,461, issued March 9, 1844

- Goodyear, Charles MANUFACTURE OF INDIA RUBBER GOODS [PDF] U.S. Patent No. 3,462 issued March 9, 1844

- Goodyear, Charles IMPROVEMENT in INDIA-RUBBER FABRICS [PDF] U.S. Patent NO. 3,633 issued June 15, 1844

- Goodyear, Charles. Gum-elastic and its Varieties: With a Detailed Account of its Applications and Uses, and of the Discovery of Vulcanization. Vol. 2. Published for the author, 1853.

- Goodear, Nelson, IMPROVEMENT IN THE MANUFACTURE OF INDURATED RUBBER FABRICS [PDF] U.S. Patent 4,005 issued April 22, 1845

- Goodyear, Nelson, IMPROVEMENT IN THE MANUFACTURE OF INDIA-RUBBER FABRICS [PDF] U.S. Patent 4,047 issued May 13, 1845

- Goodyear, Charles, Jr. IMPROVEMENT IN MAKING. HOLLOW ARTICLES OF INDIA-RUBBER [PDF] U.S. Patent 2,169 issued February 13, 1866 and U.S. Patent 5,536 issued April 25, 1848, Charles Goodyear Jr., of New York, executor of the estate of Charles Goodyear, Deceased.

- Hayward, Nathaniel, IMPROVEMENT IN THE MODE OF PREPARING CAOUTCHOUC WITH SULPHUR FOR THE MANUFACTURE OF VARIOUS ARTICLES [PDF] U.S. Patent No. 1,090 assigned to Charles Goodyear of Boston, Massachusetts.

Excerpt:

The article termed in commerce vulcanized india-rubber’ consists, usually, of a com position of gum-elastic and sulphur subjected to a high degree of heat, or one sufficient to “cure' it or divest it of adhesive properties, and impart to it powers of resistance to the action of various chemical or other matters not enjoyed by caoutchouc in its primitive or manufactured state. - Hayward, Nathaniel. Some Account of Nathaniel Hayward's Experiments with India Rubber: Which Resulted in Discovering the Invaluable Compound of that Article with Sulphur. Bulletin Job Office, 1865.

- Hipple, Alpheus Hugh. PROCESS OF TREATING MATERIALS TO RENDER THEM WATERPROOF [PDF] U.S. Patent 694,859, issued March 4, 1902.

Excerpt: In rendering asbestos waterproof I incorporate with it a sufficient quantity of oil to render it impermeable to water and then fix this oil by vulcanization, for which purpose I add sulfur to the oil and incorporate it with the oil and asbestos, as hereinafter described. The materialis compressed by suitable means.

I incorporate about sixty parts, by weight, of linseed-oil and twelve parts, by weight, of flowers of sulfur with one hundred parts, by weight, of asbestos and vulcanize the mass thus obtained at a temperature of about 300 Fahrenheit for a period of time-say two hours. - Hipple, Alpheus Hugh. METHOD for TREATING ASBESTOS [PDF] U.S. Patent 828,114, issued August 7, 1906.

Excerpt: My invention relates to an improved proc ess for treating asbestos so as to vulcanize the same. .

- Identity Discs / "Dog Tags" 1914 - 1918, retrieved 2022/08/18, original source: http://web.archive.org/web/20100220214542/http://www.pathsofglory.co.uk/identity_discs.htm

- Johns, H.enry W., INSULATED ELECTRICAL WIRE [PDF] U.S. Patent No. 304,555, issued Juen 11, 1889.

Excerpt:

My invention relates to an improvement in the insulation of wires for electrical conduction; and it consists in applying to the exterior of the wire a practically fire-proof covering of insulating material, composed, essentially, of strips of asbestus fabric,

the meeting edges whereof are united and cemented to each other by interposed cementing material, preferably a vulcanizable substance, and the strips of asbestus material are also preferably composed of a vulcanizable asbestus compound,

so that the entire covering may be vulcanized when completed, thus securing fire - proof and water - proof qualities. - Lofton, Herbert M. "Throttle-valve." U.S. Patent 795,715, issued July 25, 1905.

- Mayall, Thomas J., MACHINE-BELTING [PDF] U.S. Patent No. 27,060 issued February 7, 1860

Excerpts:

Indian rubber or gutta percha machine belting is made usually from strips of the ordinary cotton sail duck, covered with a coat of india rubber, or gutta percha and then folded together.

The outside of the belt is covered with a thicker coat of rubber, or gutta percha, the seam is covered by an other narrow strip of rubber or gutta percha, and the whole is then vulcanized in the ordinary process of vulcanization. - Morita, Keiko, and Mineo Takayama. "Long term tests for creep of laminated rubber bearings." In 12th World Conference on Earthquake Engineering, vol. 6. 1838.

- Murphy, John, IMPROVEMENT in the MANUFACTURE of INDIA RUBBER PACKING, BELTING and HOSE [PDF] U.S. APatent 101.905 issued April 12, 1870

Excerpt: My invention relates to that class of rubber manu factures which are made by uniting duck, canvas, or other fabric with rubber or similar vulcanizable compounds; and

The invention consists in the use of asbestos in such articles as packing, belting, and hose, so as to improve them greatly. - Newbrough, J.B. & E. Fagan, IMPROVED COMPOSITION for IMITATION RUBBER [PDF] U.S. Patent 69,470 issued October 1, 1867.

Excerpt: This invention consists in the combination of stearine or margarine with one or more materials described hereafter, whereby a substance or compound possessing many of the properties of vulcanized rubber is produced. - O'Mara, David, IDENTIFYING the DEAD, A Short Study of the Identification Tags of 1914-1918, [PDF] (2020) retrieved 2022/08/18, original source: Western Front Association, https://www.westernfrontassociation.com/world-war-i-articles/identifying-the-dead-a-short-study-of-the-identification-tags-of-1914-1918/

- Parmelee, Dubois D., MANUFACTURE of HOLLOW MOLDED ARTICLES [PDF] U.S Patent 26,861 issued January 17, 1860

Excerpt:

The method or process for making articles of the description named, which I am now about to describe, dispenses with the appli cation of heat either to effect the vulcaniza tion or molding of the article.

It also, by reason of rubber being used, which has not admixed with it sulfur to effect Vulcanization by heat, admits of the employment, in connection with the rubber, of clay, oxids, carbonates, and other earthy substances, and which are calculated to produce finer lines in various molded articles. - Parmelee, Dubois D., IMPROVEMENT IN THE MANUFACTURE OF HARD RUBBER OR VULCANITE [PDF] U.S. Patent No. 48,992, issued July 25, 1865

- Reynolds, Charles H. PACKING [PDF] U.S. Patent 889,807, issued June 2, 1908.

Excerpt: In the manufacture of my improfved packing, I mix fibrous asbestos with sulfur, black sulfid of antimony, litharg and about five percent of pure gum rubber. The rubber is dissolved in gasolene, benzene or other suitable solvent and the solution is then thoroughly incorporated with the above ... - Rook , J.J., MICROBIOLOGICAL DETERIORATION of VULCANIZED RUBBER [PDF] (1955) - retrieved 2022/08/18 original source: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1057125/pdf/applmicro00301-0052.pdf

Excerpt: A brief survey of the principal publications on microbial attack of rubber is given. It is stressed that many data dealing with vulcanized rubber are vague and

should be interpreted with great caution. - Roussillon, Philippe. "Apparatus for vulcanizing tires." U.S. Patent 1,039,323, issued September 24, 1912.

- Simpson, Maxwell. "XXII.—On two new methods for the determination of nitrogen in organic and inorganic compounds." Quarterly Journal of the Chemical Society of London 6, no. 4 (1854): 289-306.

- Sutherland, Mosher A., IMPROVED RUBBER COMPOUND [PDF] U.S. Patent 95,162 issued September 21, 1869.

Excerpt:

This invention consists in a new “rubber compound,” so called, which is composed of India rubber, or caoutchouc, and asbestos, with a quantity of sul phur sufficient to effect a proper vulcanization of the mass.

To produce a compound of sufficient hardness to answer for a great variety of purposes, I find that the following proportions of the above-named ingredients will answer, to wit:

Crude rubber or caoutchouc, say, eight pounds.

Asbestos, say, eight pounds.

Sulphur, say, one pound.

The mixing together of the ingredients may be accomplished in any suitable manner; for instance, in the way usually practised in this art, that is to say, the pulverized or disintegrated asbestos is mixed with the rubber by running both together through heated rollers. The sulphur may be mixedwith this compound in the same way.

After the ingredients have been properly incorporated, I put the compound into moulds of the requisite shape, and effect the vulcanization of the compound in one of the modes at present practised. I prefer to place the moulds in a steam-heater, and vulcanize with steam of say about eighty pounds pressure.

Asbestos, it is well known, is of a fibrous nature, and, when properly disintegrated, it has a tendency to hold, the mass together. It is, moreover, a very poor conductor of heat, and, therefore, my compound is well adapted for use when it is to be subjected to heat. For instance, it provides a good steam-packing.

As before stated, the proportions of the ingredients used may be considerably varied. For instance, I can take asbestos, eight pounds; rubber, four pounds; sulphur, half a pound, and incorporate them, and vul canize, and I obtain a harder compound.

I do not, therefore, limit myself to any particular proportions of the several ingredients, nor to the man ner of mixing them together; nor to the pressure of steam or degree of heat used for vulcanizing the compound. In proportion as the asbestos is used in regard to the rubber, the compound increases or decreases in hardness. - Strickler, Wilson H. "Heat-resisting vulcanized fabric." U.S. Patent 1,048,912, issued December 31, 1912.

...

Continue reading at ASBESTOS in PLASTICS, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

VULCANIZED RUBBER & ASBESTOS PRODUCTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.