Treated Wood Lumber Life & Warranty

Treated Wood Lumber Life & Warranty

How long will pressure treated wood last and what affects its life?

- POST a QUESTION or COMMENT about choosing & using treated wood or lumber in or at buildings

Preservative treated wood life expectancy, factors & warranty guide.

This article gives the life expectancy of treated wood or preservative-treated lumber, lists typical treated wood warranty periods, and provides a list of factors affect the life of treated wood.

This article series discusses treated lumber processes, properties, and use in construction of decks, porches & other outdoor structures and provides a Guide to Pressure Treated Framing Lumber Methods, Chemicals, Durability, and its Health Concerns.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Life Expectancy & Warranty Period for Treated Wood in Various Applications

What is the life expectancy of treated wood or preservative-treated lumber, what are typical treated wood warranty periods, and what factors affect the life of treated wood?

What is the life expectancy of treated wood or preservative-treated lumber, what are typical treated wood warranty periods, and what factors affect the life of treated wood?

Typical in-use life span of treated lumber used in swing sets, decks and deck posts is 10-20 years.

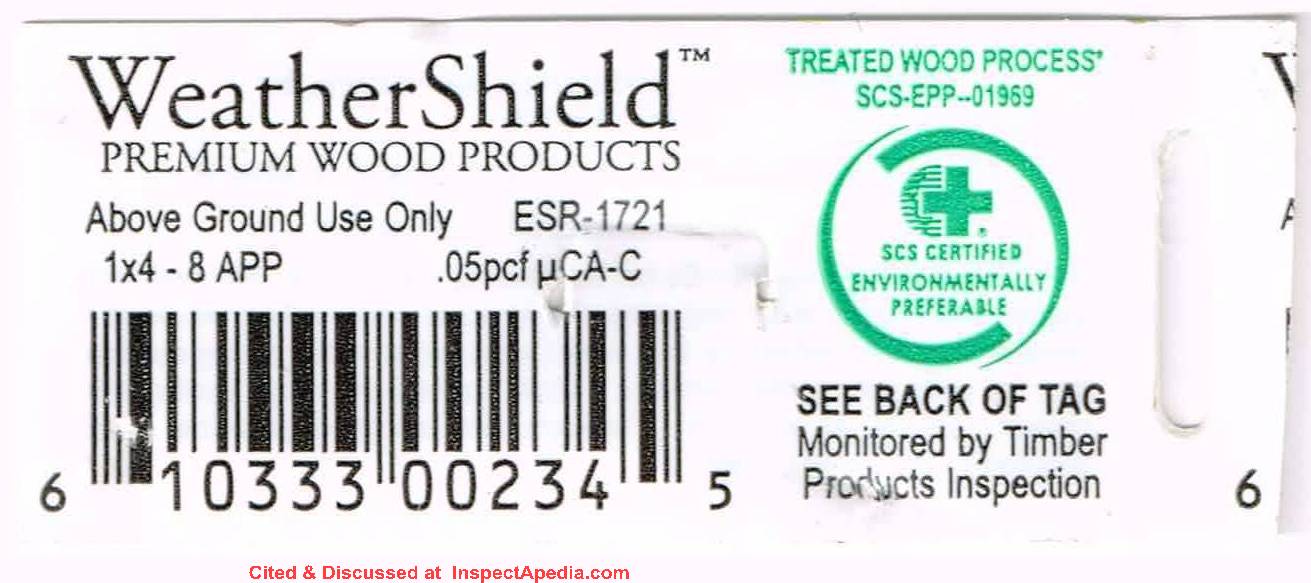

Shown at left, data tag on treated wood deck boards on a ground-level deck in a shaded location in a damp and freezing climate - Two Harbors, in Northern Minnesota.

You can see details of the life of this on-ground deck made of "pressure treated wood"

[Click to enlarge any image]

Keep in mind that actual useful life and "warranty period" for any product may be quite different, and that warranties are usually limited in scope and conditions.

Interestingly there are two different "life expectancy" issues for treated wood:

- The service life of treated wood while it is part of a structure

- The remaining life of chemicals used in wood treatments that may create a disposal issue. Vick (1996) discusses the problem of safe handling of the tremendous volume of demolition materials that include CCA-treated lumber.

The actual service life of preservative-treated wood, like that of many other building materials, is often shorter than its design service life. (Vick 1996).

However a look at the warranty period offered for treated wood products tells us how long the manufacturer expects their product to last, provided you used it and installed it properly. Companies and researchers typically expect properly-treated wood used outdoors, properly-installed, to have a life extension of 25-50 years.

Really? My own field experience shows that actual life of wood outdoors can vary considerably.

18 Factors Determining the Life of Treated Wood Decks, Porches & Other Outdoor Structures

The warranty period for treated lumber varies considerably depending on at least the factors listed alphabetically below. Naturally above-ground use and soil-contact or below ground use of treated wood product means very different exposures and environments.

- Application

(proper use) of the treated or preservative-treated wood product, such as above-ground vs. below ground use, structural vs. non-structural; - Drainage

details such as post top cuts, facing cupped deck boards arch-up, providing for drainage gaps between floorboards, and use of flashings and air gaps at deck ledgers as well as flashing over built-up beams all increase the life of decks and other outdoor structures made using treated lumber. - Elevation:

beyond above-ground vs. ground-contact, depending on location and climate, wood structures built above ground but close to it are less ventilated, retain more moisture, and are likely to have a shorter life. - Lumber species & quality;

most treated wood used in deck structures is #2 or #3 SYP, often knotty, prone to twisting, and lower quality than other more costly species & wood selections. - Manufacturer or wood treatment processor:

companies use different processes, chemicals, quality control procedures, lumber grades; some warranties extend as long "lifetime" of the customer - Maintenance -

keeping above-ground wood clear of algae, organic debris; use of preservative coatings or stains. Preservative coatings increase the moisture resistance of wood, treated or not, thus improving its rot-resistance as well as its resistance to photo-oxidation. - Shade exposure:

in some climates, a deck located in high shade or always-shaded areas may be prone to rot, algae, wood-rotting fungi - Shipment & storage

conditions of the treated wood before use (possibly) - Sunlight exposure

(for above ground applications): high sun-exposure is a factor in photo-oxidation, checking, warping, color loss, & life of preservative coatings; - Soil moisture

level and moisture level variation - Soil chemistry

and composition, including soil drainage properties - Structural integrity:

inadequate supporting footings, piers, connections, missing or improper fasteners contribute to early structural failures; combining rot, movement, and poor connections invites a deck collapse. - Treatment method & chemistry:

borate vs copper derivatives, &c. have different treatment efficacy, lifetimes, & applications; also important are the extent of pre-drying, use of & level of pressure, moisture content of the wood at time of treatment, concentration of treatment chemical and extent of chemical treatment up-take in or penetration throughout the wood - Weather variations & weather exposure,

temperature, sunlight, wind, rain, snow, ice, algae & mold growth on surfaces - Wood hygroscopicity

of the particular wood species or wood product at the time of treatment; importance varies by treatment method - Wood density,

moisture-level when treated, and similar factors (possibly) - Wood destroying insects,

presence of - Workmanship

of the wood-construction product including cuts, treatment post caps, accuracy of joints between connected members, fasteners, drainage (cited above), use of flashing, wood orientation, & other factors such as placing walking surface or deck boards with the arch of cupped boards facing upwards all affect life of the treated wood as well as the structure. (Haapio 2008)

Also see FIRE RETARDANT PLYWOOD where thermal degradation is discussed

Examples of Treated Lumber Warranty Periods - 2 years to "lifetime"

- Borate-treated "Green" treatments for sill plates &c: SillBor® treated wood, used in qualifying residential and agricultural structures, is

- ... backed by a limited warranty against damage from termites and fungal decay. Contact producer for details or visit www.SillBor.com

- Kopper Performance Chemicals: Below: from koppersperformancechemicals.com Koppers Performance Chemicals (also provides chemicals to other wood treatment companies]

- Terms of Warranty–LifeWood brand treated wood products:

A Lifetime Limited Warranty for LifeWood brand products treated with Micronized Copper Azole Compounds for above ground (treated to minimum 0.06 pcf preservative retention level) used in above ground residential or agricultural applications and ground contact treated lumber, timber, and plywood products (treated to minimum 0.15 pcf preservative retention level) used in residential or agricultural applications.

Pressure treated wood products are deemed to be used in Above Ground Use when used in an above ground application where the treated wood product is not in contact with soil, or placed on/over soil using a synthetic barrier or plastic material, or is continually exposed to heavy vegetation, mulch products, fill dirt, or other conditions that could simulate a ground contact exposure.

Some regional and local building code authorities may have policies requiring pressure treated wood products used in “close proximity” to the ground be treated for “Ground Contact Use”.

- Terms of Warranty–LifeWood brand treated wood products:

- Wolman WOW and WEraWood consumer deck lumber warranty: Subject to the terms and conditions set forth in this Limited Warranty

- (“Warranty”), Arch Treatment Technologies, Inc. (“Arch”) warrants that Wolmanized® Wood will be resistant against damage caused by termites or fungal decay that renders such Wolmanized Wood structurally unfit for its Permitted Use for as long as a Homeowner owns the structure built using Wolmanized Wood.

In this Warranty, the term “Wolmanized® Wood” refers to both Wolmanized® Residential Outdoor® Wood (pressure treated with our Wolman® E copper azole preservative) and Wolmanized EraWood® Lumber (pressure treated with our Wolman® AG preservative).

- (“Warranty”), Arch Treatment Technologies, Inc. (“Arch”) warrants that Wolmanized® Wood will be resistant against damage caused by termites or fungal decay that renders such Wolmanized Wood structurally unfit for its Permitted Use for as long as a Homeowner owns the structure built using Wolmanized Wood.

- Wolmanized® CCA-treated pole or crossarm, and is good for fifty (50) years from the date of first purchase

- Yellawood: yellawood.com: Summarizing: 2-year warranty against color fading, 15 year warranty for fence boards, lifetime in other applications: ... Excerpting:

- General [Using Kopper's treatment chemicals]

Use:

A lifetime limited warranty for products treated with micronized copper azole preservatives by Great Southern Wood for ABOVE GROUND GENERAL USE (treated to 0.06 pcf preservative retention levels) used in residential or agricultural applications and GROUND CONTACT (treated to 0.15 pcf preservative retention levels) used in residential or agricultural applications and Fresh Water immersion (treated to 0.15 pcf preservative retention levels) used in residential or agricultural applications.

- General [Using Kopper's treatment chemicals]

Watch out: all of these treated lumber or treated wood product warranties have limitations and exclusions such as warranting only to original owner, construction details, degree of avoidance of ground contact, &c.

Actual Field Experience with Treated Wood Life for Posts, Steps, Decking

Depending on the efficacy of treatment, I've found older copper-arsenate-treated wood to show a wide range of actual lifetimes from 20+ years above ground to less than 15 years for ground-contact and below-ground use. Failure patterns I have observed are particularly interesting and include:

- limited penetration into 4x and 6x posts, apparently visible when you make a cross cut

- termite attack at very specific soil depths of about 2" to 12" below the ground surface causing significant damage

- deterioration at side-butted treated wood built-up beams at decks where water penetrates between abutting members (so we recommend using a cap flashing over such members)

Watch out: for faux-treated wood. Some garden supply companies, landscape companies, and possibly some lumber yards sell a (usually softwood) "landscape tie" that is green and makes you think it has been treated with wood preservative; the preservative, if any, is a topical spray of very limited durability.

When buying "treated lumber" for outdoor, above ground or ground contact use, look for the plastic tag stapled to the lumber as that gives information about the lumber treatment type, intended use, source, company, and warranty.

Research on Life Expectancy of Treated Lumber or Treated Wood Products

- Bolin, Christopher A., and Stephen Smith. "Life cycle assessment of ACQ-treated lumber with comparison to wood plastic composite decking." Journal of Cleaner Production 19, no. 6 (2011): 620-629.

- Bolin, Christopher A., and Stephen T. Smith. "Life cycle assessment of borate-treated lumber with comparison to galvanized steel framing." Journal of Cleaner Production 19, no. 6 (2011): 630-639.

- CWC, "Treated Wood Products, Applications, Treatments, Fasteners, FAQs", [PDF], Canadian Wood Council, 99 Bank Street, Suite 400 Ottawa, Ontario K1P 6B9 Canada Tel: (613) 747-5544, retrieved 2016/07/02, original source: http://cwc.ca/wp-content/uploads/FAQ-durability-Treated_wood.pdf

- Clausen, Carol A. "Isolating metal‐tolerant bacteria capable of removing copper, chromium, and arsenic from treated wood." Waste Management and Research 18, no. 3 (2000): 264-268.

- Haapio, Appu, and Pertti Viitaniemi. "How workmanship should be taken into account in service life planning." In 11th International conference on durability of building materials and components, Istanbul, Turkey, vol. 45. 2008.

- Khan, Bernine I., Helena M. Solo-Gabriele, Timothy G. Townsend, and Yong Cai. "Release of arsenic to the environment from CCA-treated wood. 1. Leaching and speciation during service." Environmental science & technology 40, no. 3 (2006): 988-993.

Abstract:

Insufficient information exists about the speciation of arsenic leaching from in-service chromated copper arsenate (CCA)-treated products and the overall impact to soils and groundwater.

To address this issue, two decks were constructed, one from CCA-treated wood and the other from untreated wood. Both decks were placed in the open environment where they were impacted by rainfall.

Over a one-year period, rainwater runoff from the decks and rainwater infiltrating through 0.7 m of sand below the decks was collected and analyzed for arsenic species by HPLC−ICP-MS. The average arsenic concentration in the runoff of the untreated deck was 2−3 μg/L, whereas from the CCA-treated deck it was 600 μg/L.

Both inorganic As(III) and As(V) were detected in the runoff from both decks, with inorganic As(V) predominating. No detectable levels of organoarsenic species were observed. The total arsenic concentration in the infiltrated water of the treated deck had risen from a background concentration of 3 μg/L to a concentration of 18 μg/L at the end of the study.

Data from the deck study were combined with annual CCA-treated wood production statistics to develop a mass balance model to estimate the extent of arsenic leaching from in-service CCA-treated wood structures to Florida soils.

Results showed that during the year 2000, of the 28 000 t of arsenic imported into the state and utilized for in-service CCA-treated wood products, ap proximately 4600 t had already leached. Future projections suggest that an additional 11 000 t of arsenic will leach during in-service use within the next 40 years. - McQueen, James, and James Stevens. "Disposal of CCA-treated wood." Forest Products Journal 48, no. 11/12 (1998): 86.

- Milota, Michael R., Cynthia D. West, and Ian D. Hartley. "Gate-to-gate life-cycle inventory of softwood lumber production." Wood and Fiber Science 37 (2007): 47-57.

- Morrell, Jeffrey J. "Estimated service life of wood poles." Technical Bulletin, North American Wood Pole Council, http://www. woodpoles. org/documents/TechBulletin_EstimatedServiceLifeofWoodPole_12-08. pdf (Last accessed 5 April 2013) (2008).

- Tjeerdsma, B. F., and H. Militz. "Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood." Holz als roh-und Werkstoff 63, no. 2 (2005): 102-111.

Abstract Excerpts:

Wood specimens of Beech (Fagus silvatica L.) and Scots pine (Pinus sylvestris L.) modified by a hydrothermal treatment process were analysed by means of Fourier transform infra red spectroscopy (FTIR).

The chemical transformation of the cell-wall material was studied and associated with improved wood qualities. For this purpose, FTIR spectroscopy was used as since this technique has been found appropriate to determine the intensity of specific bonds and functional groups within the polymeric structure.

Cleavage of acetyl groups of the hemicellulose has been found to occur in the first treatment step under moist conditions and elevated temperature.

This results in the formation of carbonic acids, mainly acetic acid. Most of the acetyl groups were found to be cleaved during the treatment of wood at high temperature, whereas only partial deacetylation was found to occur at moderate treatment temperature. The concentration of accessible hydroxyl groups was measured by acetylation and found reduced after treating at high temperature.

Esterification reactions were found to occur under dry conditions at elevated temperature in the curing step, indicated by the increase of the specific ester carbonyl peak at 1740 cm−1 in the FTIR spectrum.

The esters that were formed turned out to be mainly linked to the lignin complex, considering that the newly formed carbonyl groups were found present in heat-treated wood, yet were found to be absent in the isolated holocellulose.

Esterification contributes to a decrease of hygroscopicity of wood and consequently improvements of its dimensional stability and durability. However, the role of esterification in the decrease of hygroscopicity in the hydrothermal treatment process examined is believed to be minor compared to the influence of cross-linking reactions known to occur during thermal treatment of wood.

...

Das Holz hydrothermisch modifizierten Buchen- und Kiefernholzes wurde mit FTIR Spektroskopie untersucht. Die chemischen Veränderungen wurden mit dem Hintergrund veränderter Holzeigenschaften diskutiert. Abspaltungen von Acetylgruppen der Hemicellulosen finden vor allem bereits im ersten Prozessschritt unter feuchten Bedingungen und bei erhöhten Temperaturen statt. Dieses führt zur Bildung von Essigsäure und anderen Carbonsäuren. Bei niedrigeren Temperaturen werden weniger Carbonsäuren freigesetzt. Durch Acetylierung wurde der Gehalt an freien Hydroxylgruppen bestimmt.

Durch die Hitzebehandlung reduziert sich der Gehalt freier Hydroyxlgruppen. Die Zunahme des Carbonylesterpeaks bei 1740 cm−1 im FTIR Spektrum lässt sich durch Veresterungsreaktionen im heißen aber trocknen Curingschritt erklären. Diese Ester sind vor allem an den Ligninkomplex gebunden und weniger an die Holocellulose. Durch Veresterungen wird ein hygroskopisches, dimensionsstabiles und dauerhaftes Material geschaffen. Die Veränderung der Materialeigenschaften beruht jedoch vor allem auch auf cross-linking Reaktionen die während des Prozesses ablaufen. - Vick, Charles B., Robert L. Geimer, and James E. Wood Jr. "Flakeboards from recycled CCA-treated southern pine lumber." Forest products journal 46, no. 11/12 (1996): 89.

- Winandy, Jerrold E. "Thermal degradation of fire-retardant-treated wood: predicting residual service life." Forest Products Journal 51, no. 2 (2001): 47.

Deck & Porch Wood Treatment Companies

- Arch Wood Protection, Arch Wood Protection, Inc., Arch Treatment Technologies, Inc., 5660 New Northside Dr., Suite 1100

Atlanta, GA 30328, (678) 627-2000- http://www.archchemicals.com

Arch produces Wolmanized® pressure-treated wood

(www.wolmanizedwood.com Copper-azole and borate-treated wood products with optional water repellent) and

Wolmanized® L3, described as a low-impact, long-lasting preservative treatment with lasting resistance to termites and fungal decay. The biocides used in Wolmanized® L3 are biodegradable so they do not accumulate in soils below a deck constructed of this material.

2007 MSDS for Wolmanized Treated Wood, web search 11/9/2010, original source:

http://petersonwoodtreating.com/PDF/Wolmanized%20L3%20Outdoor%20Wood%20MSDS%20041007.pdf

1998 MSDS for Wolmanized Treated Wood, web search 11/9/2010, original source: http://longlifetreatedwood.com/pages/msds%20form.htm

| Also see Wood Construction Products MSDS - Chemical Specialties www.treatedwood.com

ACQ-treated wood products with optional water repellent

Chemical Specialties, Inc. . Great Southern Wood Preserving, Incorporated, P.O. Box 610, Abbeville, Alabama 36310, Tel: 334) 585-2291

YellaWood® MSDS MICRONIZED COPPER QUATERNARY (MSDS)

Original source: http://www.greatsouthernwood.com/uploadedFiles/YW_MSDS_063008.pdf

Micronized Copper Azole Treated Wood(MSD)

Original: http://www.greatsouthernwood.com/GSWPCMS/uploadedFiles/YW_MCA_MSDS 81908.pdf

N-Durz® MSDS N-Durz® Borate Treated Wood (MSDS)

Original: http://www.greatsouthernwood.com/uploadedFiles/NDurzMSDSv2.pdf

ACQ MSDS ACQ Treated Wood (MSDS)

Original: http://www.greatsouthernwood.com/uploadedFiles/ACQ_MSDS_022608.pdf

CCA MSDS CCA Treated Wood (MSDS)

Original: http://www.greatsouthernwood.com/uploadedFiles/CCAMSDS.pdf

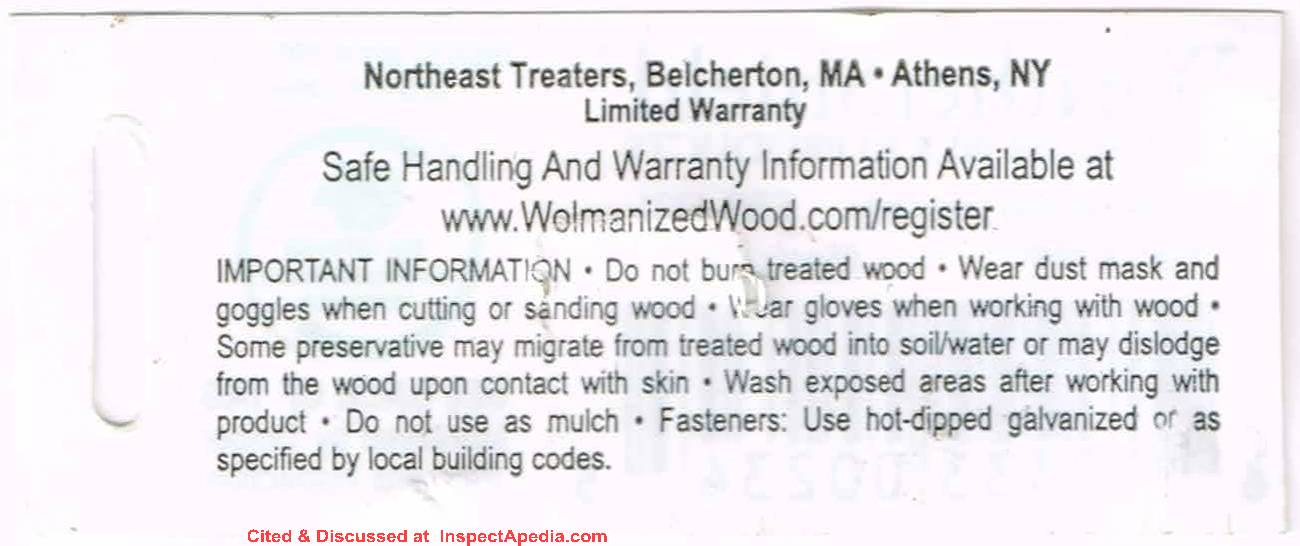

Above and below: Northeast Treater's Premium Wood Products Weather Shield treated lumber label found stapled to the ends of these products. WeatherShield lumber is rated for above-tround use only.

Because the text on these WeatherShield treated wood labels is nearly impossible to read without a magnifying glass, we include them here, enlarged for easier reading.

- Wolmanized Wood: Northeast Treaters, WeatherShield Premium Wood Products, rated for above ground use only.

Really? Note that the website given on this data tag www.WolmanizedWood.com/register, attached to lumber purchased by the author (DF) at a Poughkeepsie New York Home Depot store in September 2024, redirects to https://www.arxada.com/en/wood-protection/americasregister and gives a 404 Not Found page area citing Arxada logo Arxada AG,Peter Merian-Strasse 80 4052 Basel, ✆+41 61 563 80 00 According to that company's website, Arxada is a global science-based specialty chemicals business creating innovative chemistry and solutions.

WolmanE is a lumber preservation treatment system using Copper Azole Outdoor (R). The company says

The original developer of copper azole technology more than 20 years ago, we are now supplying the fifth generation formulation. Our Wolman® E outdoor wood preservative with BARamine® technology is the most advanced copper azole system on the market. Only available from us, this formulation incorporates patented technology that provides enhanced protection against decay organisms, including copper-tolerant fungi, and a deeper and more consistent penetration of preservative in the wood. This enhanced technology is available in both dissolved and micronized formulations.

Wolmanized® Outdoor® Wood is ideal for decks, retaining walls, fences, picnic tables, planter boxes, raised garden beds, walkways, sill plate and structural members. Wolmanized® Outdoor® Wood, at appropriate retention levels, can be used for Above Ground, Ground Contact, and Heavy Duty Ground Contact applications.

Wolmanized® Outdoor® Wood is produced by independent treated wood producers who follow strict quality control standards.

Wolmanizing Product Information Sheets are at https://www.arxada.com/en/wood-protection/americas/products/residential-preservative-products/wolman-e

Example: Wolman Product Info Sheet CA-C [PDF] gives these safe andling instructions for Wolmanized CA-C treated lumber (this is just one of a number of treatment systems and products - Ed.)

Follow guidelines similar to those for handling untreated wood. For example: wear a dust mask to control inhalation of sawdust; wear gloves when working with wood; wear goggles to protect eyes from flying particles; and wash after working with wood and before eating, drinking, toileting, or using tobacco products. Do not use treated wood under circumstances where the preservative may become a component of food or animal feed. For other precautions see the website.Note: WolmanizedWood.com which as we note, does not exist by that name and is simply a redirect to https://www.arxada.com/en/wood-protection/americas

- Osmose, Inc. 1016 Everee Inn Road, Griffin, Georgia 30224,

Phone: (770) 233-4200 Fax: (770) 229-5225http://osmosewood.com/,

www.osmose.com ACQ- and borate-treated wood products with water repellent

EndCoat™ BROWN Pressure Treated Wood Material Safety Data Sheet (MSDS)

EndCoat™ SOFT GREEN Pressure Treated Wood Material Safety Data Sheet (MSDS)

- web search 11/9/2010, original source: http://www.osmosewood.com/canada/endcoat/msds.html

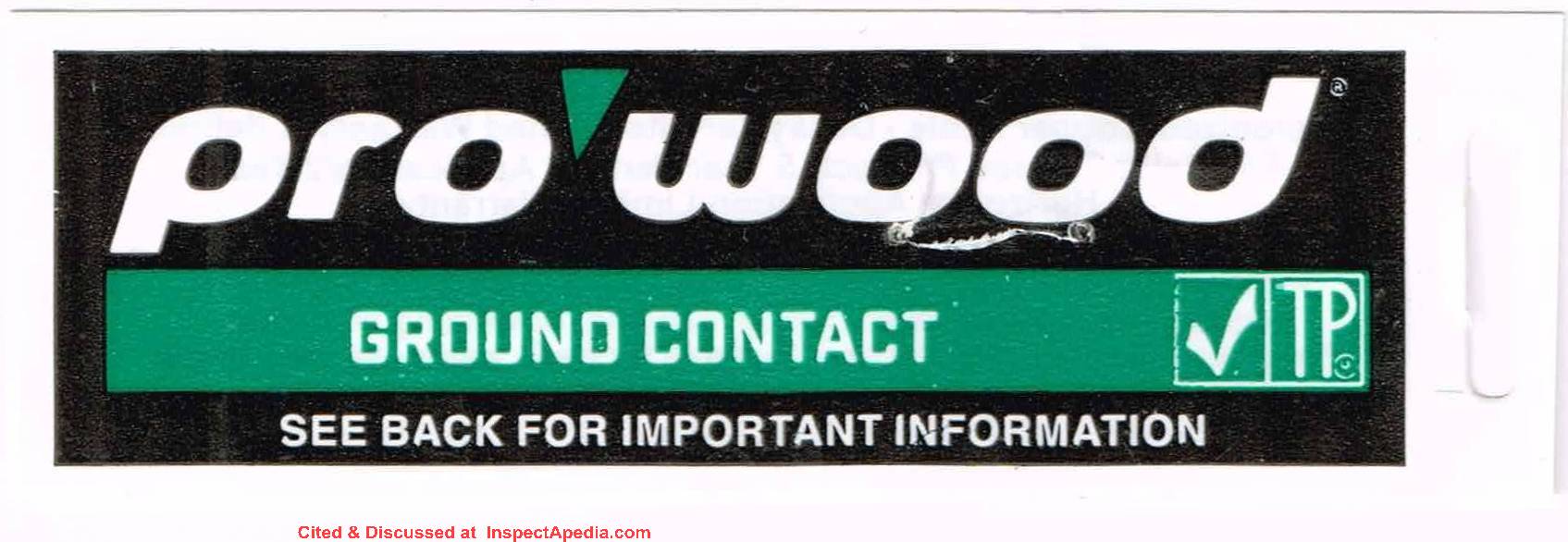

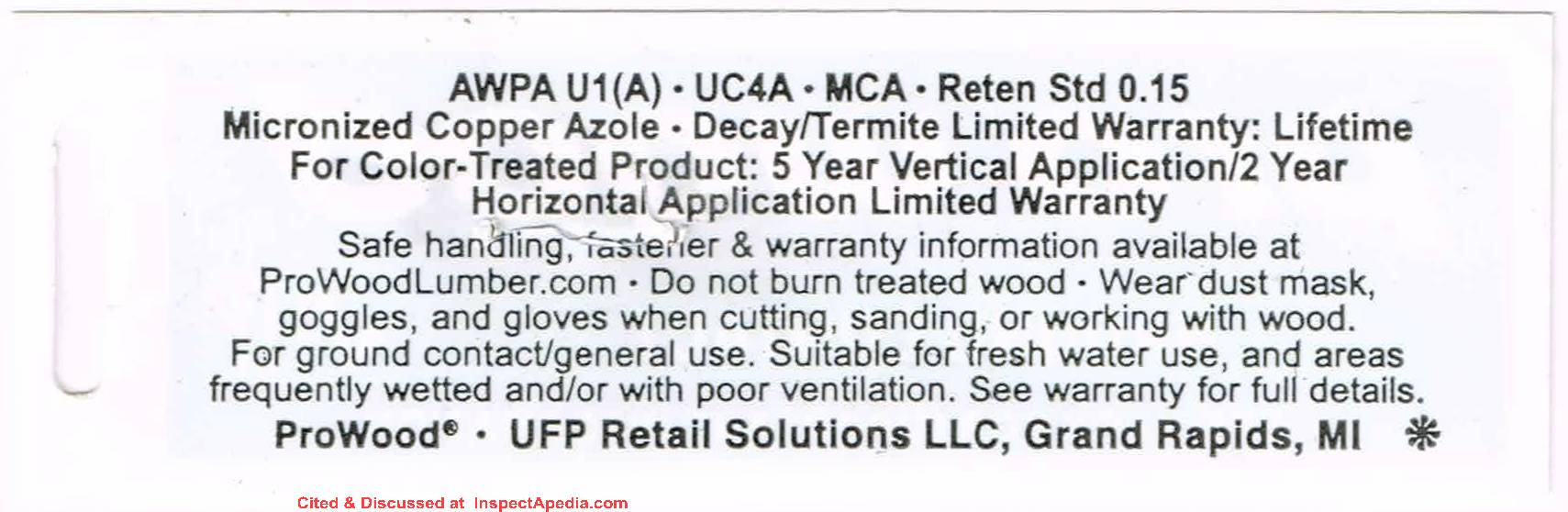

Above and below: UFP's Pro'Wood ground contact rated treated lumber label found stapled to the ends of these products. Because the text on these labels is nearly impossible to read without a magnifying glass, we include them here, enlarged for easier reading.

- UFP, Pro'Wood, ,UPF Retail Solutions LLC, Grand Rapids MN, produces ProWood treated lumber (illustration above) rated for ground-contact.

This article series discuss best porch & deck construction practices, including choice of framing materials, decking or flooring choices & installation, how to select and use deck and porch structural and flooring fasteners, actual deck & porch framing construction details & connections, deck joist & beam span tables, how to build leak-proof rooftop decks, construction of covered & screened porches, deck & porch railing construction & materials, choices of finishes and stains for decks & porches, and past & current deck lumber preservative treatments with related health & environmental concerns.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: Does treated lumber off-gas VOC's

(Mar 28, 2014) Gene Young said:

Does treated lumber have VOC's

Reply:

Gene, using the current MSDS data from Georgia Pacific's MSDS #33Q: ACQ Pressure Treated Lumber as an example we see that the active ingredient in the treatment process is Alkaline Copper and Quaternary Ammonium Compounds Type D, and that there are appropriate warnings about inhaling or contact with dust from the product. There is no mention of airborne gases nor VOCs.

Here is the handling instruction:

Handling

Caution. Do not burn treated wood. Do not use pressure treated wood as mulch. Use only with adequate ventilation. Use personal protective equipment as required. Avoid contact with skin, eyes and clothing. Wash hands thoroughly after handling.

Dust can form an explosive mixture in air. Keep formation of airborne dusts to a minimum. Keep away from heat and sources of ignition

Question: are there VOC offgas hazards from the treated plywood in my sauna?

(Sept 9, 2014) Anonymous said:

The floor of my sauna is pressure treated plywood. Is there danger of VOCs? Is there a recommended sealer or covering that would mitigate this?

Reply:

Anon

There may be formaldehyde off gassing from some plywood and other products constructed using adhesives, though not from the wood preservatives as we answered just above.

See FORMALDEHYDE HAZARDS - home

VOC outgassing from plywood is likely to be so low (if any) as to be hard to detect, especially after it's been cooked in a sauna. And our research about formaldehyde off gassing in laminate flooring cites a Korean study that confirmed that at high temperatures the formaldehyde is "baked out" rather rapidly.

You can certainly paint plywood with low VOC paint though I'd be worried about slip and fall hazards if the surface is then too smooth or slippery.

...

Continue reading at DECK FLASHING LEAKS, ROT Case Study or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- COMPOSITE LUMBER DURABILITY

- PRESERVATIVE TREATED FRAMING LUMBER - home

- WOOD PRESERVATIVES & CORROSION where we describe structural fasteners designed for use in pressure-treated lumber.

- ROT-RESISTANT Deck Lumber & Flooring for a disucssion of lumber and flooring alternatives to preservative-treated wood.

- WOOD STRUCTURE ASSESSMENT

Suggested citation for this web page

PRESERVATIVE TREATED WOOD LIFE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- Prescriptive Residential Wood Deck Construction Guide, based on the 2009 International Residential Code, American Forest & Paper Association, Inc., provided by reader Mark Morsching from Everflashing.

- Mark Morsching, Everflashing, Tel: 800-550-1667, Email: everflashing@gmail.com. The Everflashing product comes in G-185 and Stainless Steel and is intended for use with treated lumber with copper in it. Everflashing produces a variety of specialty flashing products including flashings for use with decks at deck ledgers and deck perimeters.

- Wikipedia, "Wood preservation", retrieved 2016/07/02, original source: https://en.wikipedia.org/wiki/Wood_preservation

- Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.