Thermostatic Expansion Valve FAQs

Thermostatic Expansion Valve FAQs

Q&A on TEVS & Other Refrigerant Metering Devices

- POST a QUESTION or COMMENT about refrigeration controls: TEVs, AEVs, & others

FAQs on A/C & heat pump Thermostatic Expansion Valves - TEVs:

This air conditioning repair article series explains the function and installation of all types of refrigerant metering devices, beginning with the most-common thermostatic expansion valve or TEV (or thermal expansion valve) that controls release of refrigerant into the evaporator coil of an air conditioning or heat pump system.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Q&A on AEVs, TEVs, Manual Valves, Cap Tubes

These FAQs about TEVs and other refrigerant metering devicves were posted originally

at THERMOSTATIC EXPANSION VALVES - be sure to see that article too.

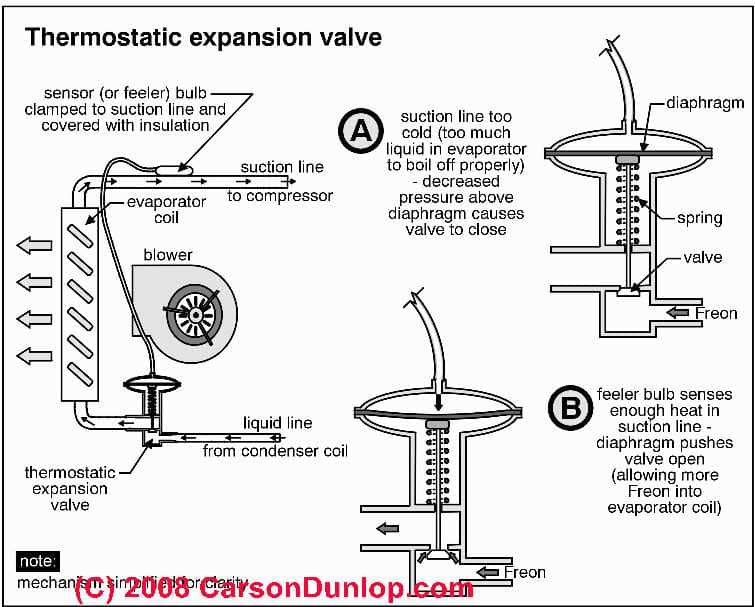

Schematic of a thermostatic expansion valve courtesy of Carson Dunlop Associates.

Question: How to select the proper thermostatic expansion valve

How do I get the right expansion valve to mentain (+5 temp.) on the surface of my evaporator (June 19, 2014) Philip

Reply:

Philip you can bring your specifications to your HVAC supplier; some TEVs are adjustable for fine tuning as well.

Danfoss (2005) points out that there are the following data points that go into selecting the proper TEV:

- Refrigerant gas used

- Evaporator capacity

- Evaporating pressure

- Condensing pressure

- Subcooling temperature requirements

- Pressure drop across the TEV

- Internalor external refrigerant pressure equalization requirements

Each of the manufacturers of Thermostatic Expansion Valves provides catalogs of TEV models, features, specifications, and intended applications.

At THERMOSTATIC EXPANSION VALVES and in theReferences or Citations of that article we list some sources of TEV manufacturers offeringcopies of TEV catalogs and specifications and installation or repair guides.

Question: Screaming sound from expansion valves in refrigeration case

We are looking at purchasing a grocery store. The store has a new refrigeration system and cases.

The one of the expansion valves feeding a row of reach in cases has a screaming sound.

Do you have ideas as to this problem? (Dec 11, 2012) Ralph

Reply:

Ralph, most likely the TEV is screaming in distress as refrigerant flows through a partly obstructed or dirt clogged or iced valve.

If the refrigerant charge is correct and the problem continues I expect your service tech will replace the valve.

Why is the sensor bulb for the TEV (Expansion Valve) installed with its capillary facing the direction of gas flow?

Hello, very good this page of yours, I was always curious to know why the expansion valve manufacturers ask to install the bulb with its capillary facing in the direction of the gas flow, can you tell me why? -

thermolondri@gmail.com On 2021-07-27 by Mauro

Hello, very good this page of yours, I was always curious to know why the expansion valve manufacturers ask to install the bulb with its capillary facing in the direction of the gas flow, can you tell me why? -

thermolondri@gmail.com On 2021-07-27 by Mauro

by (mod) - proper mounting of the sensor bulb & routing of the small diameteter tube between the TEV and the sensor bulb

@Mauro,

Thanks that's an interesting question;

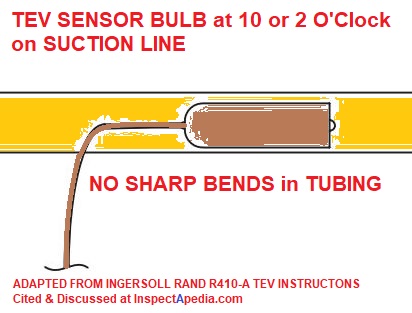

In the cap tube installation instructions and schematics I've seen the installation position that is most critical is the location of the bulb, but I think the manufacturer is also trying to get us to route the tubing on the smoothest, most-direct route without bending it back over itself - causing a crimp and a blockage or leak.Here are excerpts from example installation details for the sensor bulb for a TEV used with R410-A from Ingersoll Rand - you can find that instruction guide above on this page.

Make contact tight between the suction line and the sensor bulb

- Clean the suction line thoroughly before clamping the bulb in place.

- Bulb has to be mounted in tight contact with pipe. (TIP: Shine a flashlight between bulb and suction line, realign the bulb if light is visible.)

- Align the bulb with copper refrigerant gas line and position at 10 or 2 o’clock.

- Pull the bulb strap tight around the copper refrigerant gas line and bulb before tightening the screw.

- After tightening, it should not be possible to move the bulb by hand.

...

- Orient the sensing bulb with the tube exiting out the top to the vapor line extension onto a straight section of the refrigerant gas line as shown in Figure 9. [Shown here as adapted - Ed.]

- Use the supplied TXV bulb strap shown in Figure 5 to secure the bulb in place. In some cases, the bulb strap is required when the new bulb size is different from the existing sensing bulb.

- The entire length of the bulb must be in firm contact with

the refrigerant gas line. The remote bulb tubing must not

be allowed to touch a surface colder than the remote

bulb location.

The remote bulb tubing must be isolated from rubbing all other components. - Ingersoll Rand R410-A TEV Instructions, cited above.

Watch out: at TEV SENSOR BULB LOCATION you will see that various manufacturers give different sensor bulb locations, and that the locations vary also depending on the size or diameter of the suction line. But our point here is that these instructions detail the routing of the small diameter copper tubing between the sensor bulb and the TEV and they specifically have you avoid making a sharp bend in the tubing.

Staebler, a Philco engineer, in a really helpful 1972 article never mentions a requirement for directional orientation so I suspect my bending caveat is what's left.

- Staebler, Lloy A., THE CAPILLARY TUBE AND ITS APPLICATION TO SMALL REFRIGERATING SYSTEMS [PDF] (1972, 2009) Refrigeration Service Engineers Society. RSES

PO Box 248

Arlington Heights, IL 60006-0248 USA, TelL: 800/297.5660 Web: https://www.rses.org/

Website excerpt: RSES is the leading education, training and certification preparation organization for HVACR professionals.

RSES publishes various comprehensive industry training and reference materials in addition to delivering superior educational programs designed to benefit HVACR professionals at every stage of their careers through instructor-led training courses, online training for HVAC, educational seminars, interactive CD and DVD products, industry-related reference manuals, and helpful technical content through Service Application Manual chapters, the RSES Journal, the RSES Journal archives and feature articles, as well as web-exclusive features.

Also

See THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR where we also address AEVs, float valves, manual and automatic expansion valves, etc.

and see CAPILLARY TUBES as the same routing concerns would pertain.

Question: Repeated freeze-up of the expansion valves on our new A/C units

We have 2 ac units in a brand new house. Within 10 days of moving in, both units froze and the repairmen said the expansion valves needed to be replaced on both units. The system ran for a week and one unit froze again with the same issue. The repairman ordered another expansion valve.

These are brand new units and I find it odd that we had 3 valves fail already. Is there another issue that may be going on with the units that is causing the valves to fail? (Apr 29, 2014) Stephen Moore

Reply:

You're right to question authority on HVAC, though they could indeed be perfectly correct, it's likely there's more to the story.

Other causes of freeze-up that might lead to replacing all the TEVs would be

- improper refrigerant charge

- improper TEV valve adjustment settings

- dirt in the system messing up the expansion valve operation.

- batch failures: my invented term for a production run of a part that repeats the same mistake in manufacture, so all or many of the parts made at the same time all fail

- There are other possible causes of freeze-up: a fan failure, too-slow air movement, wrong filter, constructed ductwork, inadequate return air, low refrigerant charge.

If nothing else was changed when the TEVs were replaced and if the system has continued to work since then, that's a vote for having made the right repair. I'd hope that the repair also included replacing the refrigerant filters in the system at the same time.

Question: selecting the proper thermostatic expansion valve

How do i get the right expansion valve to mentain (+5 temp.) on the surface of my evaporator (June 19, 2014) Philip

Reply:

Philip you can bring your specifications to your HVAC supplier; some TEVs are adjustable for fine tuning as well.

Danfoss (2005) points out that there are the following data points that go into selecting the proper TEV:

- Refrigerant gas used

- Evaporator capacity

- Evaporating pressure

- Condensing pressure

- Subcooling temperature requirements

- Pressure drop across the TEV

- Internalor external refrigerant pressure equalization requirements

Each of the manufacturers of Thermostatic Expansion Valves provides catalogs of TEV models, features, specifications, and intended applications. at THERMOSTATIC EXPANSION VALVES and in theReferences or Citations of that article we list some sources of TEV manufacturers offeringcopies of TEV catalogs and specifications and installation or repair guides.

Question: how to solder TEVs or TXVs on HVAc equipment

Bubs

Can you solder 95/5 on txv's in leu of silfos?

Reply:

Bubs

If you take a look at the solder sold by companies who provide TEVs (thermostatic expansion valves) used on HVACR equipment, such as Danfoss, you'll see that only two types are even listed: 15% silver and 45% silver solder brazing rods.

Keep in mind that silver brazing is much stronger than lead or tin soldering of copper and that it is done at a higher temperature - your ordinary LP tank soldering or even MAPP soldering tools are not hot enough. We use acetylene.

Question: Difference between a "TXV" or Thermostatic Expansion Valve and a Reversing Valve

I have Rheem AC/HEAT PUMP.The cooling mode works fine,but the Heat Mode won;t provide heat. Could the problem be the TEV and/or Reversing Valve? (Oct 25, 2014) Anonymou

Reply:

A reversing valve is a different component from an expansion valve.

A reversing valve reverses the direction of flow of refrigerant in an HVAC system such as a heat pump, permitting change between cooling mode and heating mode.

Trouble with Trane heat pump after leak fixed: did they damage the TXV?

Residential Trane heat pump -11 yrs old without issues. HVAC tech found a very small leak in a pipe going to the indoor unit during a routine maintenance visit. Paid $1300 to have leaking pipe soldered, and refrigerant evac/recharge.

After service, heat pump ran continuously, never saw aux heat kick in and cool air came from vents; however,

attributed this to colder than average temperatures for a couple weeks.

Realized that heat pump wasn’t functioning when weather returned to normal so HVAC company sent tech back. Told that TXV was bad and not metering properly and quoted another $2000 to replace TXV and evac/recharge refrigerant.

What is standard procedure?

Were TXV’s checked at first repair? Could the initial repair, and evac/recharge have damaged the TXV?

Had a working Heat Pump prior to routine maintenance inspection, a non-working heat pump after ‘leak’ repair and now a request of another $2K, to return to a working heat pump. Thanks for any guidance.On 2018-03-11 by Dexter

by (mod) - trouble with Trane heat pump

My sympathy for what sounds like a costly mess.

At the first repair the tech surely confirmed that the system was working properly, right? Proper refrigerant charge, checked temperatures, pressures, and heating or cooling function, right?

I am slow to blame the tech, but in fact soldering a system can leave debris in piping that can then foul a TXV, especially if soldering was near the TXV and moreso if no filter/drier was installed.

If the aux heat never kicked in I'm left confused - was that because temperatures never required the aux heat or because aux is not working either?

Question: how to solder TEVs or TXVs on HVAc equipment

Bubs

Can you solder 95/5 on txv's in leu of silfos?

Reply:

Bubs

If you take a look at the solder sold by companies who provide TEVs (thermostatic expansion valves) used on HVACR equipment, such as Danfoss, you'll see that only two types are even listed: 15% silver and 45% silver solder brazing rods.

Keep in mind that silver brazing is much stronger than lead or tin soldering of copper and that it is done at a higher temperature - your ordinary LP tank soldering or even MAPP soldering tools are not hot enough. We use acetylene.

Question: can a capillary tube refrigerant metering device be replaced?

can a metering cap be changed out? (Apr 1, 2014) Richard

Reply: yes

Richard, IF I understand the question correctly you're asking if some TEVs have replaceable parts. Yes. Else the whole TEV is replaced.

If you are asking if the capillary tube (which is a simpler refrigerant metering device than a TEV) can be replaced, also yes - it's a cut and braze job plus some more work to evacuate, then re-fill, and clean the system refrigerant piping system.

Effect of TEV on Compressor Operation FAQs

HVAC tech discusses repairing a Coolair Split Unit - one compressor unit is not cooling

I'm working on a coolair split unit with 2 evaporator's 1condenser and 2 compressor's all fan belt's and condenser belt are good .

All filter's were changed, one of the evaporator section is discharging 55deg air at 86deg outside temp and gauge pressures of 65/245 and the other evaporator unit at 86deg out side temp is discharging 64deg with pressures of 78/265 can you help - by Tony -

Reply by (mod) -

Tony: Those pressures for the two units are both practically in the same range.

It's possible that the TEV adjustments are not identical on the two units. Did you check the TEV (Thermal expansion valve) ?

How do I check the thermostatic expansion valve?

Any idea on how to check / diagnose the TXV (TEV)? by TN-Goose

By (mod) - Tip for Checking the TEV:

Checking the TEV:

A simple step that can tell something about the TEV (TXV in your lingo) is to just try warming it up with a hand or a hair blow-dryer.If the valve is frozen and it's warmed it'll start working.

Watch out: however this is not a complete test.

For example a TXV that is mis-adjusted or that is debris clogged won't respond to simple heating.

Other tests involve using a gauge set and making adjustments to the valve while watching the frost line on the cooling coil.On occasion we might hear chattering at the TEV - an indication it's not working properly.

Can a bad Thermostatic Expansion Valve cause the compressor motor to "short out"?

Can a faulty TXV (TEV) cause the compressor to short-out? by TN-Goose

Reply by (mod) - it may harm the compressor but "short out" ? not so sure.

A bad TEV can cause abnormal system pressures, including excessive high side pressure that one would hope would cause a safety control to stop the system.

But I don't know why it'd cause a short circuit - maybe due to excessive current draw from a failed motor?

None of us knows it all, but that failure is not one we learned about in my HVAC classes.

by TN-Goose - information on the effect of TXV on compressor - Hunting

I found this information on the effect of TXV on compressor.

TXV superheat set too low:

The superheat must be allowed to change in order for the sensing bulb to make corresponding adjustments to the valve opening while it maintains the set superheat.

A low superheat setting can allow the superheat to fall to zero. This condition will cause the valve to close and the superheat will soon rise well above its setting.

This in turn can cause the valve to reopen wider than necessary and overshoot the superheat setting.This condition is called hunting. On one of the valve's swings to the wide open position, liquid refrigerant can flood the suction line and allow liquid to enter the compressor, a potentially damaging condition.

by (mod) - Superheat and hunting thermostatic expansion valve -

Thanks for that detail about superheat and hunting thermostatic expansion valve - I'll be sure the text is added to the TEV article.

In other words, an improper TEV setting can cause rapid opening/closing of the valve resulting in liquid refrigerant flooding the suction line, entering the compressor motor.Because compressor motor moving parts and valves are designed to compress a gas, and because a liquid (refrigerant) is not particularly compressible, the compressor motor, piston, crank, or more immediately its refrigerant valves are likely to be damaged or destroyed.

It is possible that dirt, debris, or even water in the refrigerant piping system and that enters the TEV could cause this malfunction by freezing the valve's moving parts.

And of course a seized compressor would be expected to trip the circuit breaker the next time it tries to turn on. The TEV didn't cause a short circuit but it could have damaged the compressor leading to an overcurrent and a tripped circuit breaker.

...

Thank you to our readers for their generous comments

(June 30, 2011) James Wrobel said:THERMOSTATIC EXPANSION VALVES is an extremely useful article. Well done.

(July 18, 2011) rhomz said: thankz for this article,i have learned a lot

(July 19, 2011) Ervin Berrios said: Thanks guys, this explanation is very helpfull to me, as I'm learning and working in AC in residential. Now I have a very reliable information to provide to my customers

(Sept 13, 2011) George Martinez said: Thank you very informative article.

Reply:

Ervin and others, thanks for the nice notes. We welcome questions and critique - together we're smarter than anybody alone.

...

...

Continue reading at THERMOSTATIC EXPANSION VALVES - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CAPILLARY TUBES

- REVERSING VALVE on HEAT PUMPS

- REFRIGERANT PRESSURE READINGS & CHARTS - home

- THERMOSTATIC EXPANSION VALVES - topic home

- THERMOSTATIC EXPANSION VALVE TEV INSTALL, DIAGNOSE, REPAIR

Suggested citation for this web page

THERMOSTATIC EXPANSION VALVE FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about refrigeration controls: TEVs, AEVs, Capillary Tubes, Float Valves, & Other Refrigerant Controls

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.