Refrigerant Line Insulation FAQs

Refrigerant Line Insulation FAQs

Q&A on insulating refrigerant piping

- POST a QUESTION or COMMENT about installing insulation on refrigerant piping

FAQs about proper installation of insulation on refrigerant piping.

This article series explains why refrigerant piping insulation needed and discusses the types of insulation are used on refrigerant tubing sytsems & where can the insulation be purchased and how it should be installed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Q&A on Proper Method for Installing Insulation on Air Conditioning & Heat Pump Refrigeration Lines & Condensate Drains

These questions & answers about refrigerant piping insulation were posted originally

at REFRIGERANT PIPING INSULATION - so please be sure to also check out the refrigerant piping insulation specifications and snafus described there.

Article Contents

- REFRIGERANT LINE INSULATION COST FAQs

- DAMAGED or MISSING INSULATION FAQs

- INSULATION INSTALLATION GUIDELINE FAQs

...

Refrigerant Piping Insulation Cost FAQs

How much does it cost to replace a section of missing refrigerant line insulation?

How much does it cost to replace a section of missing refrigerant line insulation?

insulation is missing from the refrigerant lines near the evaporator coil and should be replace. To do how much would it cost me. - Susan G

Reply by (mod) - around 83 cents per foot in small quantities, less if bought in larger lots

As a representative exmaple on a 1 1/4" diameter x 6-foot length of Amracell Tundra self-sealing polyethylene foam pipe insulation such as used on refrigerant piping costs about $5.00 or about 83 cents per foot.

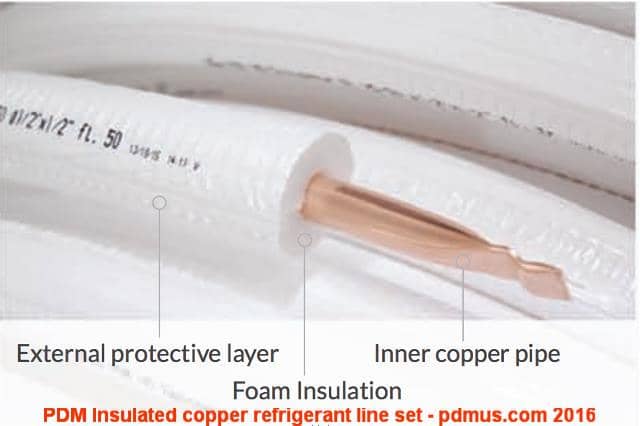

Insulating foam tubing comes either pre-slit or you can slit it before installation with a utility knife so that it van simply be "snapped" around an already-installed length of refrigeration tubing.

Can I replace refrigeration line insulation myself?

Is replacing exterior refrigeration lines insulation a do it yourself task or is it necessary to have a (Mitsubishi) installer do it? - On 2020-09-08 by Rob Shea -

Reply by (mod) - Replacing refrigerant insulation is easy - but not the piping itself

Rob

Certainly you can replace accessible refrigerant piping insulation yourself;

Watch out: take care, however, not to pull on refrigerant piping nor wiggle it around or if there is a nearby connector you could loosen it to cause a refrigerant leak, converting a low cost insulation project into a costly HVAC service call. And don't use a cutting device like a box cutter without taking care not to cut into (and weaken or damage) the copper refrigerant tubing itself.

On the other hand, replacing refrigerant piping itself is not a do-it-yourself project.

The technician needs to use refrigerant collecting devices, refrigerator restoration equipment, and other steps to avoid contamination of the piping system as well as an illegal environmental release of refrigerant as well as replacing the refrigerant with a proper charge quantity when they piping repair or replacement is complete.

Typically you would also add a refrigerant filter drier at that time

Reply by (mod) - Replacing refrigerant insulation is easy - but not the piping itself

Rob

Certainly you can replace accessible refrigerant piping insulation yourself;

Watch out: take care, however, not to pull on refrigerant piping nor wiggle it around or if there is a nearby connector you could loosen it to cause a refrigerant leak, converting a low cost insulation project into a costly HVAC service call.

And don't use a cutting device like a box cutter without taking care not to cut into (and weaken or damage) the copper refrigerant tubing itself.

On the other hand, replacing refrigerant piping itself is not a do-it-yourself project.

The technician needs to use refrigerant collecting devices, refrigerator restoration equipment, and other steps to avoid contamination of the piping system as well as an illegal environmental release of refrigerant as well as replacing the refrigerant with a proper charge quantity when they piping repair or replacement is complete.

Typically you would also add a refrigerant filter drier at that time

...

Refrigerant Line Insulation Installation Procedure FAQs

How should my refrigerant lineset be installed

Installing a 3 ton rooftop condenser and furnace below it on the first floor - On 2021-03-23 by Michael Gaines -

On 2021-03-23 by (mod) - how should my refrigerant lineset be installed?

@Michael Gaines, I wish we could be helpful but I just don't know a thing about your building, its construction, requirements, available chaseways, etc. to say exactly how your A/C / Heat Pump line set (refrigerant piping or tubing) should be routed or installed.

General Refrigerant piping recommendations

- Use the shortest, simplest, most-direct route for refrigerant piping

- Route away from possible mechanical damage or install steel protection plates or other protection from damage as needed

- Allow at least the manufacturer's recommended slack or extra bend(s) near the condenser and at the air handler to allow for vibration and to ease future service.

Trane (Ingersoll Rand) has provided this helpful- Guide to INSTALLING REFRIGERANT PIPING [PDF] (2011) as part of its training series, Trane Corporation, website: https://www.trane.com/, retrieved 2021/03/23 original source: https://www.tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf The company has offices world-wide.

You can download a copy of this PDF at no cost.

Trane Corporation, website: https://www.trane.com/, retrieved 2021/03/23 original source: https://www.tranebelgium.com/files/book-doc/20/en/20.aqerykdx.pdf The company has offices world-wide.- See complete details at REFRIGERANT PIPING INSTALLATION

Wrap the refrigerant line with insulation if running underground in a conduit.?

Is there a requirement to wrap the refrigerant line with insulation if running underground in a conduit. but sealed on both ends? - On 2020-09-11 by tom -

Reply by (mod) -

Tom

I'm not sure we'll find a code citation but certainly you want to insulate the refrigerant piping; otherwise you'll get some un-wanted heat transfer that's likely to affect the system operation, perhaps increasing its operating costs, even if condensation itself isn't a concern.

Should I insulate or "sleeve" refrigerant lines run in building walls?

On residential construction, is the line-set/copper tubing/vapor and suction line, required to be sleeved when installed through a cinder block wall?

Mechanical code references pipe duct for installation in concrete floors, but does not specifically state when installed through walls and/or more specifically through block walls.

Allied guidelines for long line installation suggest a PVC sleeve but I cannot find specific reference or requirement for any. - On 2022-07-07 by RS1227

Reply by (mod) - Should You Sleeve the suction line passing through a block wall?

@RS1227,

Yes.

See details at REFRIGERANT PIPING INSULATION where you will find the following

Suction lines are cold – 40°F (4.4°C) SST – and cause condensation, even in conditioned spaces. In addition, any heat that enters the refrigerant adds to the superheat and reduces system efficiency.

For these reasons, suction lines should be insulated with a vapor proof insulation. This is a requirement of many building codes. Rubatex is the most common form of refrigerant line insulation.

Keep in mind that the local building code official is the final legal authority on code questions.

However that does not change what is good practice or best practice. That is, even if the local inspector doesn't require insulating of the suction line, it should still be done. - On 2022-07-07 by (mod) -

Refrigerant tubing insulation doesn't fit my tubing

I checked plumbing supplies in my area, nothing seems to fit right.

There is a large amount of caulking used and it is overall not done neatly. I have to come up with something to cover it all (pipe and caulk) and provide some sort of drip edge above the opening.

There are some products that would enclose the wall opening properly and hopefully still look good.

I came across some wall sleeves that seems to be applicable even post-installation, and also some flat wall covers and escutcheons that might provide decent cover and divert the water from the opening (Diversitech is selling them in bulk, I got to see if I can find the small amounts I need). Thank you - 2014-09-09 by NYCitizen -

Reply by (mod)

NYC

Refrigerant tubing insulation comes in standard sizes to fit standard tubing or piping sizes. It's bound to be available.But if the insulation is slightly oversized that ought not matter as long as your installation is complete and no gaps are left in the job.

I agree that better treatment of the point of penetration of refrigerant tubing through walls is a smart idea.

Is the foam insulation on the AC lines supposed to continue into the foundation ?

Is the foam insulation on the AC lines supposed to continue into the foundation or just on the exterior of the home? Thank you - ROD

Reply by (mod) - do not run bare refrigerant piping through concete (nor underground)

Rod,

You do not want to run refrigerant piping bare through concrete. Corrosion and damage and leaks are serious risks.

Here's an example code citation from the UMC as adopted in Utah:

1107.2.1 Piping in Concrete Floors

Refrigerant piping installed in concrete floors shall be encased in pipe ducts.The piping shall be isolated and supported to prevent damaging vibration, stress and corrosion.

Is it OK to use fiberglass insulation on refrigerant piping lines?

I am a retired plumber, not an HVAC Tech.

I am planning to install a condenser on a flat roof just outside of my attic-installed FAU. The distance between the two is only about 15-20ft.

I happen to have some extra fiberglass insulation I had bought for my Potable Hot Water piping system.

Will this work to insulate the liquid and vapor lines between the coil and the condenser? It's approx. 1" wall thickness; and I would use a weather proof jacket where it runs outdoors.

Thanks, Cole. (May 2, 2016) Cole

Reply: bad idea; use moisture resistant insulation, not fiberglass

Cole:

I would hesitate to try fiberglass insulation on outdoor HVAC refrigerant piping: it will pick up and hold moisture, not insulate, deteriorate, and in freezing weather, freeze and ultimately fall apart.

Instead I'd use slip-on or split-and-clip foam insulation designed for use on refrigerant tubing.

In the article links above see REFRIGERANT PIPING INSULATION for details.

OK to only insulate 1 of the 2 refrigerant lines?

I'm insulating just one refrigerant line. Is that bad practice? 2016-08-04 by King -

Reply by (mod) - insulate both lines, for different reasons

Best practice is to insulate both refrigerant lines, though for different reasons, and practices vary by climate and local practice.

Insulation on the suction line (the larger diameter pipe) reduces the risk of condensation and water damage inside the building

Insulation on the high pressure line on a cooling-only system is sometimes omitted by some installers as that line is normally warm - not a condensation problem.

But in a heat pump system insulating both lines makes more sense as refrigerant flow swaps direction dependin on whether you're in cooling or heating mode.

Do we need to insulate the small refrigerant line in a system used mostly for heating in a cold-weather area (MN)?

What about recommended insulation of the liquid and vapor lines for a HP that is primarily used for heating in a cold-weather area (MN).

The large line was insulated at install-time (and I added another layer, and a loose fitting, flexible aluminum dryer hose over that for protection against the sun and environment.

But, should the small line also be insulated? 99% of the run-time on this unit, it is heating. On 2012-08-06 by derek terveer -

Reply by (mod) -

Derek

Interesting question. Considering that at times the heat pump is trying to send heat from outside into the building, it would make perfect sense to insulate all of the refrigerant piping. In my OPINION I would definitely do that.But, though I've worked in Minnesota, I'm not a MN super-cold weather (we've seen -20 in Two Harbors) HP expert - I'd also ask the local HVAC techs.

I insulate the suction line only

I tested which lines the HP uses for heating and cooling and in both modes the vapor line is used for sending heat into the building (heating mode) and cool into the building (cooling mode)

So, that works out nicely - I insulated the vapor line only. I made some calculations based on 1 meter of uninsulated and poorly insulated copper tubing (3/4" in my case) and it worked out to 51 W/m for uninsulated and I guesstimated 10W/m for the partially insulated pipe.

After insulating, I estimated that I had brought that value down to 1.5W/m.

The savings was on the order of 15 seconds of running of my furnace, per hour.

That was around 0.16% (not 16%, but point one six percent) of my furnace capacity (at -7C). So, given the savings, at least percentage-wise, I'm not surprised that my local contractor didn't bother insulating more. On 2012-08-08 by derek terveer -

Some of my split tubing insulation isn't re-sticking

During installation of insulation on refrigerant piping for air conditioners, I used the split insulation.

I did not know there was plastic on both sides. Therefore I removed the plastic only from one side before sticking together. It seems to be stuck well but will it be ok in the long run ?

Or should I open and and remove the plastic from the other side and join again ? It is sticking quite well and in 4 places I have tape around the insulation also. Thanks for your help. On 2015-05-16 by Gopal Ramakrishnan -

Reply by (mod) -

If you can not easily separate the insulation to re-stick it properly you may be able to improve the installation by adding a suitable weatherproof tape over the seams.

Where to buy decorative covers & escutcheons for refrigerant piping outside of a home - at an entry

Are there any decorative covers/escutcheons to use for the outside entrance point of the piping into a house? Contractor used black caulking of some sort and it is very ugly.

Any suggestions? On 2014-05-02 by NYCitizen -

Reply by (mod) -

Sounds ugly NYC.

Measure the diameter that the escrutcheon has to fit around - the diameter of the pipe.

Then you'll probably have to end up with a stainless steel (or paintable plastic) add-on escrutcheon of the sort used around pipes indoors. These are hinged so that they can be opened, then latched around the pipe.

You'll want a weather resistant material so don't buy chromed steel. It'll rust.

...

Damaged / Missing Refrigerant Line Insulation FAQs

No Insulation on Refrigerant Lines, Increase in electric bill ?

I had a new rheem central heat & air unit installed 3 months ago, since then my electric bill has increased 113%.

The ac stopped cooling within the first 2 wks, said the breaker was tripped but took them 2 trips to figure it out. My heating stopped working 2 days ago, they said the breaker was tripped but there was also a hole in the cooper line.

Why does it keep tripping the breaker? I have read a lot of info online & it seems that I might be in for the long haul of future repair bills.

The copper pipes/tubing on the outside is are not insulated, I ask when they installed why it wasn’t, I was told it didn’t need to be. Is it suppose to be insulated?

And I’ve read where using aluminum instead of cooper is better when it comes to leaks because the Formic acid won’t affect aluminum the same way it does copper, is it possible for the hvac guys to go back & change those?

I just paid several thousand for this unit & I can not afford future issues so I’m trying to find solutions now rather than later. On 2019-11-14 by Renée -

Reply by (mod)

Renee

I really do not know but that won't stop a guess: a wiring error including a short or current leak could be at fault here. You might get better diagnosis with an experienced electrician on site.

I like copper wire but PROPERLY MADE with pre-abrading through the antioxidant, use of antoxidant on the connectors, proper torquing of the connectors can give reasonable reliability on a single-use aluminum circuit such as to an A/C compressor/condenser unit.

Why do we insulate the suction line?

Why we providing insulation in low pressure side On 2018-05-03 by Kumar -

Reply by (mod)

To stop condensation and related water damage in the building. Also insulating the line increases the system efficiency, thus reducing energy costs.

Condensate leaks at incompletely-insulated refrigerant piping

I have my air handler in the attic. I went up in the attic last year and noticed a small puddle of water on the plywood.

I found a tear in the bottom of the insulation around the pipe and this is causing water (sweating/condensation) to sit in the insulation and drip out.

So I put a pan down to catch the water.

As you can see by one picture, the copper pipe comes through the handler with no insulation or putty to stop the cold air from coming out into the attic and causing the line to sweat.

This also runs down to where the hole is in the insulation. I went back the other night and found water in the pan again and notices a new spot where water was dripping. I also found that where the installers supported the lines that the strapping material was damp to wet.

Note: My attic is foamed so it does not get very hot up there even in the summer.

I plan on replacing most all the foam, putting a barrier where the pipes come out of the handler, putting some cut sections of PVC pipe where the strap supports are to stop the insulation from being crushed.

Questions.

Should the new foam fit snug around the pipe or have room for movement. The current foam is a one size fits most all.

If I get loos or snug foam, seal the ends/joints with a foam tape, close off the handler hole and better support the copper, will this stop my sweating or will it always be there?

The copper pipe and foam run down into the wall and out to the outside unit. That wall is also foamed, do I need to worry about it sweating?

Thanks - On 2019-05-31 by Anonymous -

Reply by (mod)

Since foam insulation is not hard, it should have enough flex that it can seal tightly around a condensate drain pipe and still handle vibration and thermal expansion/contraction dimensional changes.

However let's be sure we're addressing the main problem here. We want the condensate to enter the drain not sit in an overflow or find a leak in a condensate pan.

If the refrigerant piping insulation is intact over its length and not compressed (for example by being squeezed in a hanger strap) you ought not see condensation on that piping run (it's actually condensate - water condenses out of air onto the cooler pipe surface, the pipe isn't really "sweating" as does our skin when it exudes moisture out through its pores).

But In addition to adding a little insulation right at the air handler - your first photo - for which you could simply use a short length of refrigerant piping insulation cut and slipped snugly in place - you ought to take a look inside the air handler to be sure that the condensate drain is working properly and the pan slopes to the drain.We don't want a puddle of condensate to accumulate inside the air handler such that its depth causes the level of condensate to reach and leak out at the air handler opening where the suction line enters the air handler - as shown in your photo.

Moisture lines on walls near refrigerant tubing - missing insulation / condensation

I have solid plaster walls, split system Fujitsu airconditioner cooling/heater system installed 1.5 years ago.

Now seeing 'shade' line on inside plaster wall from airconditioner down to floor level. The outer part of the airconditioner is installed on the solid brick wall directly behind the internal airconditioner section (second level of house).

This could be condensation/moisture and will your article above may be the answer. We are calling the installers back to investigate and will ask questions from your article. Thank you for publishing this information. On 2017-04-26 by Lisa -

Reply by (mod) - if shade lines mean moisture, investigate further

Lisa:

Refrigerant piping run in an insulated wall cavity ought to be insulated not just by its own insulating jacket but also by the wall insulation itself.

If those were omitted or if there were air or water leaks into the wall would I expect a problem along the refrigerant line piping route that would show up as mold or moisture stains.

I have also found wall and ceiling cavity leaks along the route of improperly-sloped or otherwise leaky condensate disposal lines from the wall-mounted split system indoor unit whose condensate has to drain to the outdoors.

I'd like to see photos of the staining you're seeing - use the page top or bottom CONTACT link;

Also I'd consider modest invasive inspection (cutting a small opening say 2x4" to inspect for wetness or mold or leaks in the most-suspect areas along the stain; Sometimes a moisture meter or thermography can help find leaks too but those are not foolproof since if used at a time when the wet area has dried they'll not see a thing.

If you have photos of the system being installed those can help pinpoint the actual routing and insulation on refrigerant piping in walls, and they can help show if the condensate disposal drain runs in the same area and whether or not it is sloped properly.A drywall screw or nail puncturing a refrigerant line will be discovered right away but a puncture of a condensate drain may not show up until later.

Cause of melted insulation on the refrigerant suction line

I'm Trying to diagnose problem on R-22 home a/c unit with electric heat furnace attached to air handling system.

Compressor unit is Goodman and is 8 years old. Evaporator and air handling system is about 15 years old - probably Rheem system.

Problem: Rubber insulation on suction line from evaporator to about 15 to 18 inches down the line (towards compressor) has melted from heat.

It appears the suction line where it connects to evaporator is getting very hot. I'm familiar with this line frosting or freezing at this point, but have never seen one get hot and melt insulation.

System is cooling, but I don't know how efficient. Any input as to problem would be appreciated, but in the simples terms the better. Earl (Feb 19, 2015)

Reply:

Anon

The suction line is normally cold - which is why it's insulated; if your unit's suction line got hot enough to melt the insulation I worry that there is a failing component, possibly compressor unit; yet you say the unit's cooling. So other things to check:

- has someone done work on the refrigerant piping involving brazing - heating the line during a repair might melt insulation that should have first been removed

- is there evidence (burned wires, odors) of an electrical problem? if so the unit is probably unsafe and should be shut down

Damaged refrigerant piping insulation from acids or rodents?

The acidic parts damaged our refrigerant tubing lines. - (Oct 30, 2015) shankar guggari

Rats have chewed all the black insulation off the copper refrigerant line in my mother's split system, it's the type of insulation that is actually bonded to the pipe somehow, what is best way to repair this? thank you. (Nov 1, 2015) Daniel

Reply:

Bummer. I think you'll have to pull off enough of the remaining insulation that you can install slip-over add on insulation; you'll buy insulation in lengths that have a split along one side to just open and slip onto the existing refrigerant lines.

Why is there no insulation between the suction line and the charging valve?

Why Doesn't insulate Suction line Between compressor & Charging Valve On 2016-06-19 by Eshanya -

Reply by (mod) -

The line between compressor and charging valve in a cooling system contains warm liquid refrigerant; it doesn't present a problem with condensation.

I think installers thus consider this energy improvement optional

Refrigerant pipe insulation Foam was painted, now it's cracked and shedding - how to repair?

It appears the foam cover has been painted but it's cracking and there are small chunks missing from the foam cover. There are several lines.

What the best way to repair this? Tape over all of it; remove the foam and replace it with new covers (if so what do you recommend); coat it with some kind of coating? ETC. On 2012-10-25 1 by Carol -

Reply by Anonymous - Snap around foam insulation for refrigerant pipes

Carol,

Snap around foam insulation in sizes for refrigerant piping is widely available, eg at home depot. Loews, HVAC suppliers, and is inexpensive. Just replace that which is damaged, deteriorated, or incomplete. Take note of our advice at REFRIGERANT PIPING INSULATION about how to attach without over tightening

...

Thank you to our readers for their generous comments

On 2019-12-16 by Rohit Patel - points covered in the article are incredibly insightful Refrigerant line insulation installation

Hi, The points covered in the article are incredibly insightful Refrigerant line insulation installation Thank you for the information.

On 2019-12-16 - by (mod) -

Thank you Rohit; we're very grateful when you find our information accurate, useful, un-biased. We also welcome criticism, content suggestions, questions.

On 2014-12-11 by Jameel Pasha - sending your refrigerant insulation article to our plant manager

I have visited a plant having uninsulated refrigerant piping .This topic do discuss the application but i would like to forward the plant manager the document showing losses due to uninsulated piping.

Kindly for forward it on my e-mail pashatherm@yahoo.com

JAMEEL PASHA

On 2014-12-11 by (mod) - printed copy of articles at InspectApedia

Jameel

You are welcome to either make a printed copy of articles at InspectApedia that you can give to the plant manager, or you can simply give a copy of the web link to this page

https://inspectapedia.com/aircond/Refrigerant_Insulation.php

...

...

Continue reading at REFRIGERANT PIPING INSULATION - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

Suggested citation for this web page

REFRIGERANT PIPING INSULATION FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.