Air Conditioning / Heat Pump Compressor

Diagnostic FAQs #3

Air Conditioning / Heat Pump Compressor

Diagnostic FAQs #3

Service call charges

Breaker or fuse trips, electrical failures

Noises

Weak or warm air flow

- POST a QUESTION or COMMENT about air conditioning and heat pump compressors: diagnosis, failure, repair, replacement

HVAC compressor / condenser diagnostic questions & answers or FAQs set 3.

This air conditioning repair article series provides diagnostic questions & answers for the outdoor compressor / condenser unit used on air conditioners & heat pumps.

Page top photo: an outdoor compressor/condenser unit more than 30 years old, still working.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Diagnostic Questions & Answers for HVAC Compressors & Condensers & Fans

These questions and answers about troubleshooting and fixing air conditioner or heat pump compressor/condenser units were posted originally

These questions and answers about troubleshooting and fixing air conditioner or heat pump compressor/condenser units were posted originally

at COMPRESSOR / CONDENSER DIAGNOSTICS - be sure to check out the diagnostic suggestions on that page.

Photo: a pair of outdoor compressor/condenser units, possibly a bit too close together.

Article Contents

- A/C SERVICE CALL CHARGES or ADVICE - do I really need a new A/C system?

- COMPRESSOR / CONDENSER UNIT BLOWS FUSE or TRIPS BREAKER

- COMPRESSOR / CONDENSER UNIT ELECTRICAL FAILURES - other than blowing fuses

- WEAK or WARM AIR from AIR CONDITIONER

...

Compressor/Condenser Unit Service Call Questions

Is your service technician the right person for the job? Were the repair costs fair and proper? Does your repair tech know what he or she is doing?

Diagnostic Starting Point:

- HOW MUCH SHOULD YOU PAY - for any professional service

- OTHER PEOPLE's MONEY - don't scare your service tech or your costs may go up

My HVAC tech came twice and repalced different parts: is that a ripoff?

During 90 degree weather our AC was blowing warm air and AC repairman replaced Capacitor; next day the AC stopped working again and he replaced the Contactor

-charged $125 for service both days and said it was just bad luck that these two parts broke down at different times - should he have replaced both the first time? - Corasoma

Reply by (mod) - No not a ripoff: repair technicians "best guess" is not a bad approach

Cora

No. The tech is sometimes making a "best guess" diagnosis of what's wrong and replaces the most-suspect or obviously bad part.

I sympathize with your irritation at having to "pay twice".

But I've been on both sides of this transaction.

At a mechanical system service call I might point out to a customer:

Me: "Look at this valve - it's corroded and leaky, and sometime soon it's going to leave you without heat - then you'll have the extra cost of an emergency service call. It should be replaced now."

Customer: "Stop trying to build up your bill by adding on stuff I don't need. Just do what I asked you to do - clean and tune the system. Don't replace anything else."

A heating or air condtioning service tech who, under the aegis of being responsible and professional, runs into responses like that from customers eventually gives up and does just what's obviously and un-arguably needed, avoiding getting hassled for "replacing extra parts that probably were not needed".

So you can see it can be difficult to navigate.

Bottom line: hire service people you trust. Then it's up to you to discuss the repair with the tech the time.You have the option of asking if there are other parts that are suspect and that could be replaced now, saving the cost of a second service call.

Once you've given the technician an understanding of your view point, she will be able to accomodate.

My A/C quit blowing cold air - the repairman said "give it a few days" then stopped returning my calls

My ac quit blowing cold. My ac repair man checked for leaks (found none). He cleaned both outside and inside coils.

Still not cooling good so he put a very small amount of coolant in it. My air blowing out of my vents is aaround 80 degrees.

My ac repairmand knew the temp was not cool,he said to give it a few days and let him know.

I called him and told him it is still not working. He said he has all the info and would tell me about it.

Now he does not return my calls and we are burning up. What can I do to correct my ac problem? - Bill

Reply: bad response: repair is needed

Bill it sounds from your note as if your repair tech is either overloaded with work ( after it's all during very hotvweather) or is stumped .

it's time to call your company's service manager to ask for someone else who will respond to you.

How do I know if a new AC or heat pump compressor is really needed?

I have a 22 yr old 3 ton Goodman unit at my home in Dallas, Tx. It recently stopped cooling the house although the inside fan & outdoor unit seemed to be running fine.

There was some cool air blowing inside but not enough to cool the house & temps inside kept increasing.

Didn't seem to be blowing as hard as normal thru the inside vents either. Turned unit off since it was doing no good anyway & to prevent possible additional damage.

Nothing was iced up on the outside unit and there was no moisture on visible lines.

Prayed it just needed a Freon charge since I had just cancelled my AHS 1 month prior(Murphy's Law!). Friend hooked me up with a friend of theirs who works for AC company but moonlights on the side since I'm presently out of work.

Guy comes out, tests something on side of house that is connected to outside unit then opens the side of the unit, tests a few things with a metering device & immediately says my compressor is shot. Shows me a wire running from compressor that is burnt up on the end as evidence.

I read that a clanking noise is a sign of compressor going out & it has been making a clanking noise for a while.

Guy recommended replacing entire unit as the most cost-effective way to go since replacing the compressor, cleaning coils, etc would be almost as much as new unit.

Said he can get the new unit with his discount for approx. $1,000 & will include warranty. Is he taking me for a ride or does he sound legit? Thanks in advance for your feedback! - Dana

---

Bad compressor on 22 year old unit should I replace entire outside unit or just the compressor? - Ken

Reply:

From what you describe I think the that you probably do need a new compressor/condenser unit.

Reader follow-up

Thanks! That's exactly what I did =)

My 15 year old central air conditioner is running fine but I was advised to replace it to avoid risking refrigerant line contamination if the old compressor fails

I have 15 years old central AC unit. It is working fine. I was advised to replace it with a new one because there is a danger of refrigerant contamination of pipes if the old unit fails. If it happens,

to clean/replace pipes would cost additional 2000 dollars. How serious is it? - Salve

Reply: sounds like strange advice: get another opinion

Salve I think you should get advice from a different and more experienced HVAC tech. Like many a good lie, this one has some truth in it: if a compressor motor fails, burned oils in the refrigerant can contaminate the refrigeration piping.

That's why when a burned out unit is replaced the tech will pull a vacuum on the system, do his/her best to clean the lines, and a special compressor burnout-filter or two will be installed on the refrigerant lines to protect the new motor and other parts from damage or debris clogging.

But a system can fail in a variety of ways, and as I explained there are well known means of dealing with debris in the system. What you were told would make me look elsewhere for my HVAC maintenance and repair services.

Service tech says it may take hours after repair before cool air comes out of the system

I just had a bad capacitor replaced in my Trane heat pump. Technician said it will take 7-8 hours before it begins to blow cool air. Outdoor compressor and fan are running, but air blowing out vents is still warm. Does it seem right that it would not blow cool air pretty quickly? - Anon

Reply:

Anon

I don't blame the service tech for being conservative - not wanting to be called back unnecessarily, but I'm surprised that she thinks it's going to take 8 hours for a heat pump to blow cool air.

It might take hours to cool down a hot humid house and it can take some time to cool down even hot ductwork, but cool air ought to be coming out of the supply registers within less than an hour of turning the system on - just giving time to get past the effects of hot ductwork and air handler parts from having sat off for a time.

I suspect that 7-8 hour guess was more designed to give the service tech time to get out of town.

If after 20 minutes (I'm going out of town too after this note) NO cool air is coming out of your supply registers, call the service manager of your heat pump repair company and politely ask for some more experienced advice.

How can I tell that my HVAC contractor actually cleaned the cooling coils?

How do I know my contractor cleaned the coils with no power source electrical plug - On 2018-06-02 by marie

Reply by (mod) -

Marie

I can't say, in part because I don't know what coils, indoors or out, were cleaned nor by what methods.If there is a removable panel you can look at the coils in the air handler and outside you can look directly at the coils on the condenser unit to see if they're blocked by debris.

But I note that electrical power is not necessary for some coil cleaning operations.

The technician uses a foaming cleaner spray and cleans up the liquid that collects in the drip pan below.

Finally: if the technician was in and out of your home in five minutes the coil wasn't cleaned.

...

Compressor/Condenser Unit Trips Breaker or Blows Fuse

Diagnostic Starting Point:

Diagnose Lennox A/C that sometimes blows the fuse

I Have an older Lennox 5 ton unit. Sometimes when the unit starts it will blow hot air for 20 minutes then it would start cooling but not every time. On some occasions it would blow the fuse. - Jesse

Reply by (mod) -

When a motor is blowing a fuse or tripping a circuit breaker I suspect that there is a failing bearing or other motor component that is drawing excess current and thus blowing the fuse.

It could be the compressor motor or the fan motor that's having trouble starting or has a motor failure. Sometimes the tech will try a quick fix by installing a motor hard start capacitor.

Followup by Jesse

I have a guy coming to look at it tomorrow. So you think it could be in an internal shut off even though the unit runs fine it satisfies itself with the temperature, turns itself off then when it turns itself back on (not every time) it'll run hot for the 20 minutes and then start cooling?

I will definitely let you know what the guy tells me tomorrow. Thank you for the reply

Followup by Jesse - Tech found a loose HVAC duct opening

So the tech came out he replaced a capacitor a relay and for some weird reason there was a panel that wasn't screwed down in the intake that was opening every once in awhile like a 3-foot gap letting in hot air once he did all those things the AC hasn't blown fuses and has been running fine

Compressor unit trips the circuit breaker on hot days

HELP! My home is ancient and small (-1000sqft), it is wood with little or no exterior wall insulation, the a/c is 20+ yrs old.

The compressor/condenser unit has begun to trip its breakers in the heat of the day when it gets to 105+ degrees and when it is running it is nearly impossible to get the house below 85F. Am I short on coolant? On 2011-08-03 by Eric Fisher

Reply by (mod) - compressor is tripping the circuit breaker

Eric if the compressor is tripping the circuit breaker it may be at end of life - but a service tech should check the system before replacing anything.

That's not a low refrigerant issue, it's a failing motor problem.

Watch out: don't just keep re-setting the circuit breaker or you risk an electrical fire.

A/C compressor trips the circuit breaker, what might be wrong?

my compressor shorts out my breaker, I tested the compressor with an ohm meter and reads voltage. what can it be? - Chico

Reply: seized electric motor?

Chico: if your air conditioner compressor shorts out and trips the circuit breaker I'm afraid the compressor motor may be seized.

That causes a high current draw when the motor is trying to start, and that trips the circuit breaker.

My A/C unit kept blowing a fuse, now nothing runs

My Center A/C unit had a tuned up. I clean the evaporator, I put the blower down and put the new motor and clean the blades deeply, I have a clean filter, I clean the condenser deeply, and I bought a new thermostat. OK.

The unit star running normally and you fill the normal warm air in the fan (outside) But 3 to 5 minutes later the heat in the condenser air increased suddenly the condenser stop with noise, and I need to turn it off. what is this? Please give me a clue? - Anon 6/28/22

I have a pretty old Tappan unit, and when the power goes out, if the A/C is running it will blow the fuse, usually we just replace the fuse, and now nothing will run on the A/C unit. any ideas? - Shantel 6/20/11

Reply:

Shantel:

Often when an A/C unit keeps blowing the fuse it's a sign that the compressor is drawing high amps which means it's jamming which, I'm sorry to say, means it's at end of its life.I'd have a service tech look at the unit; it might limp along for a while longer if s/he installs a hard-start capacitor kit. When "nothing runs" you may have meant that the fuse or breaker tripped enough times that you've lost power on that circuit.

Anonymous - from what you describe you need a service call from a trained HVAC tech.

AC Compressor makes weird nose and shuts off

Hi, My AC comes on normally and runs between 15 and 30 mins. Then my compressor makes a weird noise and everything loses power without tripping the breaker.

The display goes off and the compressor will not turn on. After about an hour everything comes back on and the cycle continues. Please help me. by Phil

Reply by (mod) - overheating motor

This sounds as if a motor is overheating and tripping an internal thermal overload.

That would explain why after a cool down period the system will run again.

I'd ask for a service call - of course the problem could be elsewhere (such as an overpressure and shut down by a safety control) so let me know what you're told.

First sign something was wrong with our Goodman A/C was the abrupt noise.

BTW, the tech told me this older unit did not have the safety control. The new unit they installed is a Goodman 14 SEER.

Both guys that installed the newer unit came out. They were baffled. One of the techs did his pressure or whatever test and showed me the needle not moving (exactly what I was shown when the other unit died).

Our first sign something was wrong was the abrupt noise. It's not been that hot here, so we couldn't judge if it was cooling or not.

The unit, however, on about 50% of the time, from when they gave it the OK on Saturday and it failed Monday night.

Weird, not much pops up when you Google anything related to the fan motor causing this. FYI: A friend recommended these guys who has used them for 4 years. - by JH

Reply by (mod) -

It's not a complete surprise for two pieces of equipment made at the same factory on the same date to fail close together in time.

I've seen that failure pattern in other situations, even the electrical spark plug points contact spring in my old Norton motorcycle.

One spring broke (of course far from home and on a trip) - we were clever enough to buy replacement points sets for both left and right cylinders and lucky enough to find a place to buy them without getting arrested - but that's another story.

We took of down the highway, having replaced the right hand points set. In less than 50 miles the other set failed in the same way.

It's also imaginable that a power surge such as during a thunderstorm or from the electrical company or caused by human error working on equipment damages a capacitor, control board, relay, that in turn causes subsequent major parts failure.

EG a surge that damages a start cap can in turn mean the bad cap ultimately leads to motor failure.

If I wasn't clear earlier, a system will overheat when the fan isn't working. Overheat -> damage.

All of this is SPECULATION - your AC guys have surely seen more failures than I.

Split system air conditioner stopped working - electric wires keep burning up at the terminals

My AC split unit stop working ,because the terminal wires connecting the compressor to the capacitor always burn this happen several times ,and the remedy was to replaced the burned wires,please can you advise what the reason that keep the terminal wire burn, the compressor is newly installed, - Mohamed al lababidi -

Reply:

Mohamed,

If the terminal wires keep burning up I suspect that the problem is one of

- an overcurrent - high amps draw because a motor is seizing and needs replacement - most likely it's this problem

- bad electrical connections, possibly involving aluminum wiring or loose connectors

- improper electrical wiring - such as undersized wires for the length of run, or mis-placed connections

- abnormal voltages in the system or voltage surges

Why does a blown compressor motor burn out wires?

About compressor burn out, I have outdoor unit Daikin VRV III RXQ16PAY1 and the compressor was burned out at cable lug compressor. how can it possible happen? (sorry for bad English) 11/13/2014 Deddy said:

Reply:

Deddy, a failing compressor motor can draw very high current (Amps) that in turn can certainly show up at a wire connector.

This is a companion article for COMPRESSOR / CONDENSER DIAGNOSTICS.

For diagnostic questions focused specifically on the outdoor condenser unit fan or fan motor,

see FAN, COMPRESSOR / CONDENSER DIAGNOSTIC FAQs.

You may also want to see REPAIR & DIAGNOSTIC FAQs for A/C.

Question: My A/C unit kept blowing a fuse, now nothing runs

My Center A/C unit had a tuned up. I clean the evaporator, I put the blower down and put the new motor and clean the blades deeply, I have a clean filter, I clean the condenser deeply, and I bought a new thermostat. OK.

The unit starts running normally and you feel the normal warm air at the fan (outside)

But 3 to 5 minutes later the heat in the condenser air increased suddenly the condenser stops with noise, and I need to turn it off. What is this? Please give me a clue? - Anon 6/28/22

I have a pretty old Tappan unit, and when the power goes out, if the A/C is running it will blow the fuse, usually we just replace the fuse, and now nothing will run on the A/C unit. any ideas? - Shantel 6/20/11

Reply:

Shantel:

Often when an A/C unit keeps blowing the fuse it's a sign that the compressor is drawing high amps which means it's jamming which, I'm sorry to say, means it's at end of its life. I'd have a service tech look at the unit; it might limp along for a while longer if s/he installs a hard-start capacitor kit.When "nothing runs" you may have meant that the fuse or breaker tripped enough times that you've lost power on that circuit.

Anonymous - from what you describe you need a service call from a trained HVAC tech.

Question: causes of repeated AC or heat pump compressor burn-out & circuit breaker failure

I got unit compete burn-up at the compressor unit, all the wires, contactor.

I rewired everything.

But this is the third time this has happened.

First time I believed the 30 amps breaker was defective because I could see one side was burned in the electrical panel.

Somebody put two separate breaker each 20 amps.

I replaced the two 20A breakers with a single double pole 30A breaker..

Now the 30A breaker won't open.

But the main circuit breaker tripped (opened). And I found live voltage only on one side.

So I'm only getting 120V in the place instead 240V.

I disconnected the A/C unit.

Why only would a circuit breaker open on just one side? (June 1, 2014) Voscar

Reply:

Watch out: Repeated compressor burn-out certainly means that there is another problem with the system that has not been found.

Watch out: I suspect some wiring errors or wrong circuit breaker type. When you install a double pole 30A circuit breaker in the electrical panel, an over-current can occur on either of its two 120VAC legs. In that case, an over-current on EITHER side of the double pole breaker should trip BOTH poles OFF. That's called a common internal trip circuit breaker.

In addition to the burned out compressor you have faulty, damaged, or mis-wired circuit breaker(s) that need to be replaced: tell me the circuit breaker and panel brand and I can comment further.

Watch out: But the compressor burn-up is probably not caused by the circuit breakers but by an operating problem in the system - improper charge, setup, or control board. Possibly low voltage or a start capacitor problem.

Watch out: if you are not trained in proper electrical wiring you could cause a buiding fire or be shocked or killed.

Amana RHD60A2A heat pumps keep tripping the breaker

This is 2020. We have a 1996 Amana HUAC system. Last summer running the AC it began popping the circuit breaker once a day or so.

Re-set and all was fine for a day until it popped again. We had service in and he replaced the condenser and at my request, installed a starter kit.

That almost ended the problem but not quite. So on a hunch, I set the electronic thermostat to wait 500 seconds before re-powering the AC after it shut off, adding about 150 seconds to the old setting.

So far, that worked. Maybe someone can explain why, and if something else needs replacing? And maybe someone can tell me who re-builds Amana RHD60A2A heat pumps? 2020 is the last year for legal freon, and there's no way we can afford to replace this system. We're pensioners on a shoestring. Re-build or find a less used model is all we can do. - On 2020-01-24 by Reybo -

Reply by (mod) - Amana RHD60A2A heat pump rebuild?

Reybo

What was included in "replaced the condenser" ? The whole condenser unit? That would have meant a new compressor, fan, condensing coil & controls.So we'd not expect a new system to trip the breaker if the setup is properly wired and fused. And you'd not install a starter kit on a new AC compressor motor.

On the other hand if you're using an old compressor motor and it's tripping the breaker, a hard start kit might get it going for a time but you've already been warned that the compressor is at or near the e nd of its life.

Indeed commercial compressor motors are often re-built.

But nobody rebuilds residential A/C or heat pump compressor motors. The compressor is in a hermetically sealed can and is not repairable.You might find a used unit but I'd be pretty reluctant to try that. Few people will remove and salvage an old A/C or heat pump that's still working acceptably, so a used residential compressor on the market is risking having to do the job over multiple times- at a cost greater than having replaced the unit with a new one in the first place.

AC keeps blowing fuses

My 3A fuse keeps blowing when turn AC on? - On 2019-06-07

by Rich

Reply by (mod)

Watch out: Rich; when a fuse keeps blowing there is either a short circuit or a seized motor that's drawing so much current that the fuse blows or circuit breaker trips - to prevent a fire.

Leave the A/C off and call for repair.

Heat pump trips circuit breaker

Problem is that I have an ac heat pump system with Outside condenser and Inside air handler. Once I lower the room thermostat to call for cooling (lower than the room temperature) the breaker for the unit on the main box trips and shuts down. - On 2015-06-16 by Rafael Pagan

Reply by (mod) -

Sounds like an overcurrent such as from a failing compressor or relay.

Watch out: leave power off to avoid risking a fire, then call an HVAC service tech for proper diagnosis and repair of the system.

...

Compressor/Condenser Unit Electrical Problems

Diagnostic Starting Point:

- CAPACITORS for HARD STARTING MOTORS

- DMM DIGITAL MULTIMETER USE - how to use test instruments to perform basic electrical wiring or equipment diagnostic tests

- HARD STARTING COMPRESSOR MOTORS

Outdoor A/C unit fan stopped and is smoking

My a/c was working good until yesterday... it is an older unit, maybe even the original from our home. the fan does not work and it appears to smoke from the unit.

Most likely this needs to be replaced right!? On 2011-07-25 by elizabeth

Reply by (mod) - if you see a smoking electrical component you should shut down that equipment immediately

Elizabeth

Watch out: if you see a smoking electrical component you should shut down that equipment immediately as there is risk of an electrical fire. Sounds as if a motor or wiring has burned up.

A/C is "running" but no cool air is coming out, outdoor unit starts & stops, buzzing

Our air conditioning unit is running and all switches are set to on and cool but no cool air is coming out, just warm air.

There is an intermittent buzzing sound, lasting a second or two, coming from the circuit breaker that happens about every four or five minutes.

When that occurs, the fan at the top of the outdoor unit stops running momentarily and then starts up again.

We have turned off the unit and flipped the circuits in the breaker box for safety reasons already but wonder what it is we could be dealing with. Thanks. On 2011-07-23 by TFN

by (mod) - outside compessor/condenser unit failure & safety warning

TFN:

You are describing an air conditioning system where the indoor air handler is running - blowing air - but the air isn't being cooled because the outdoor compressor/condenser unit is not working.

Re no cool air is coming out, just warm air and buzzing circuit breaker, I worry that you have an overcurrent condition and the circuit breaker is not tripping; especially if your brand is FPE - Federal Pacific Electric, possibly Zinsco or Challenger, these problems have been reported more often.

An "over-current" condition might occur at your A/C unit if the blower motor is seized; that would explain both buzzing and the fan not running so no cool air coming out of your supply registers.

Watch out: The risk is an electrical fire; the underlying cause could be a failing motor drawing high current. Of course it could be something lucky like just an individual defective breaker.

Turn the equipment off and call for repair.

Circuit breaker trips when I turn on my air conditioner

What would cause the circuit breaker to trip to the off position when I try to start my AC?

My blower fan works in the furnace so I'm able to circulate air, but when I try to start the AC, the circuit breaker trips after 1-2 seconds after I reset it.

I have replaced the filter, cleaned the coils, and vacuumed out the debris in the bottom of the compressor/coil housing outside, and my thermostat is set correctly. Any help would be greatly appreciated! On 2011-07-19 by Chris W

Reply by (mod) -

Chris W

If your A/C system trips a breaker at startup then there is most likely a short circuit or a failing compressor motor that is drawing high amps.Leave the A/C system off (for fire safety) and call a service tech.

My A/C capacitor burned up on my Trane XL13i compressor

My capacitor on my Trane XL13i burned up along with all the wiring above it into the compressor area, it appears to have caused a fire, because it melted part of the outside of the unit case.

Is it worth getting the wiring fixed and seeing if the rest of the machine still works or should we just call it quits and replace it? The air conditioner is 9 years old. - Shana

Reply:

Shanna, about a burned up capacitor: it is possible for a capacitor to itself be the point of a failure; I'd try replacing the capacitor and any questionable wiring or connectors; let us know how that works.

If the capacitor blows again I suspect either a wiring error or a failed compressor motor.

Starting capacitor uF microfarad measurements & tests

I am troubleshooting a 7500BTU Danby portable air conditioner (the tall vertical unit with ducting out the back via flexible hose). It appears that the compressor itself is at fault, but I would like to be sure before replacing the unit.

The start capacitor measures OK (meaures 46uF for a 45uF +/-5% unit) and appears in good condition. I measured the resistance between the three compressor terminals and they seem to be OK (C-S=2.8ohms, C-R=1.0ohms, S-R=3.7ohms) and there is high resistance between all terminals and ground.

I applied 117Vac directly to the compressor (bypassing the control circuits) and the compressor just hums - the current draw was 30A. Being a protable unit, everything is jammed into the compartment and I don't see any way to access the compressor at all. I'm about to give up on the unit and look for a new one,

but just wanted to see if there are any other things to try. The unit is probably about 9-10 years old, but has only seen regular use in the summer over the last 3 years.

Thank you for any help or advice.

Mike -

Reply:

I agree with your suspicion about the compressor. Often though a tech will just try swapping in a new start/run cap as a cheap simple test.

Question: circuit board replacement on AC unit, now compressor needed

Second repair call in a month. First, not cooling--a board needed replaced, no additional freon added. Now HP compressor has a short and needs replaced.

Trying to determine if it is better to replace entire outdoor unit. What are the chances that other components were damaged due to whatever caused this short before the unit started popping the breaker, whether from a power surge or attempting to run without enough freon or whatever? Wendy

Reply:

Wendy

Indeed the compressor is such a large part of the cost of the compressor/condenser unit that often it makes sense to replace the whole unit of an older installation.

But we'd be more comfortable with some report on the cause of the compressor failure. For example a power surge may indeed have damaged other controls & parts.

Question: Meaning of zero resistance test on AC compressor wiring

I have always thought of this site as providing accurate information and have used it as a reference when writing technical articles. I'm having second thoughts.

This (Zero resistance: If there is zero resistance the winding is open or broken) mistake appears in this article on How to Diagnose & Fix a Burned-out Air Conditioning. Zero resistance indicates a short circuit not an open circuit. Jerry Walch

Reply:

Jerry,

You are quite correct that zero resistance means a connection is made and good, not open and broken' infinite resistance would indicate an open circuit. We've published nearly seven thousand technical articles and are grateful for careful readers who occasionally find and help us fix a mistake.

I trust that an error that slipped by in an article would not be enough to toss out the work of our many editors and contributors.

We welcome content critique, corrections, or suggestions by this comment form or by email. I have corrected the text, added a warning, and would welcome further comments.

We've included a thank-you to you in our References section at the end of this article, keeping your ID private - let us know if you want to be identified by name in that part of the document. Thanks again,

Daniel

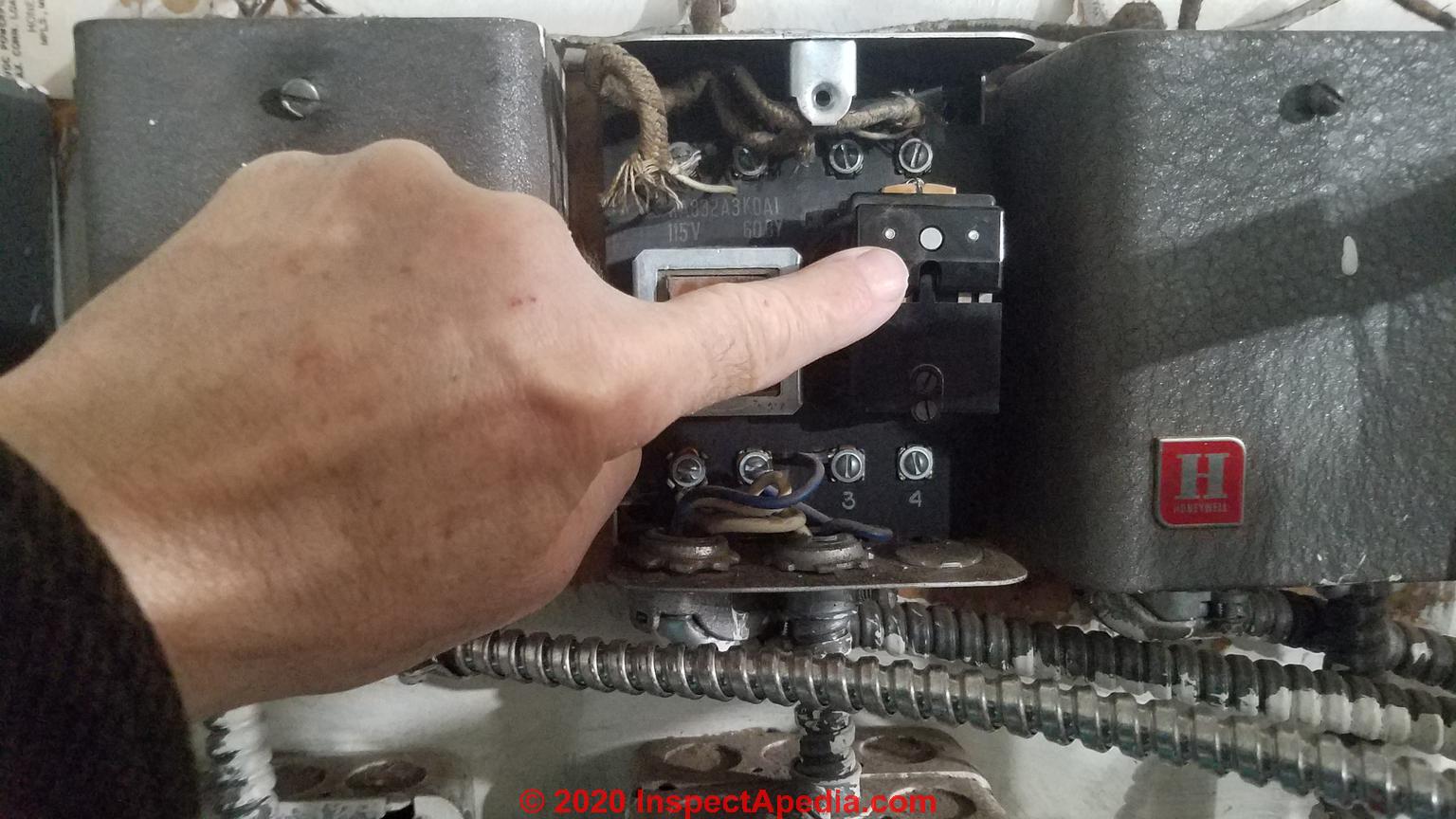

Air conditioner compressor, contactor won't close even though the solenoid is receiving a signal voltage?

Hi guys,

Thanks to all contributors to this forum. I've learned so much I now feel confident in doing basic troubleshooting of my A/C system, which leads me to introduce the following issue I'm experiencing with my Trane XR16i system. The system is 14 years old.

I tried to use it for the first time since last summer but both the compressor motor and condenser fan did not come on. I made sure the settings on the control panel were correct, especially ensuring that it was demanding Cool air. I replaced the batteries in the control panel. I checked the circuit breaker which was closed.

I went out to the condenser/compressor unit outside and, with a volt/ohm meter and the wiring diagram, I confirmed that the fuses were ok.

The cooling fins for the condenser unit were not clogged with dirt. I confirmed that power was going to the unit all the way to the Relay/Contactor.

Both line 1 and 2 had 120V. All the cutout switches were closed thus allowing me to read 27v coming from them going to the relay solenoid. I also confirmed that both the Start and Run Capacitors were well within their MFD limits.

I confirmed that the condenser fan motor was receiving both 240v and 27v respectively and that it had a good ground connection.

In other words, I traced the entire electrical circuit at the condenser/compressor unit using the wiring diagram and the volt/ohm meter.

As a result I confirmed the condenser fan motor was receiving power. BUT, with the relay/contactor solenoid receiving 27v the contactor was not shifting to energize/power the compressor motor.

I replaced the contactor with an after market unit but that didn't solved the problem.

Before I replaced the contactor, I used two jumper wires and bridged the input voltage across the input and output terminals. The compressor motor, for a split second, came on and shut off after I removed the jumper wires. For the short time it ran it made two very loud clunks.

That's when I thought I had confirmed that the contactor or relay was bad.

However, the new contactor is doing the same thing, it has line voltage at the inputs and it's receiving 27v at the solenoid terminals but it's not closing or pulling in.

Could someone please let me know if I've overlooked anything?

After reading many of the useful articles on this forum, I believe, and do stand to be corrected, that the condenser fan has failed considering there's power going to the motor.

When the condenser fan failed the compressor overheated/over-pressurized and self destruct

THE BIG QUESTION: What could cause the contactor to not close even though the solenoid is receiving a signal voltage?

When the Solenoid is powered is it designed to open the contactor (opening the circuit) or pull it in to complete the circuit?

If the condenser fan motor is bad would that prevent the compressor motor from coming on?

Is it possible I received a bad Contactor? - by Patrick -

Reply by (mod) -

Patrick

Jumping to

What could cause the contactor to not close even though the solenoid is receiving a signal voltage?

The common causes include

- a defective contactor relay itself - mechanical damage, burned points, etc.

- the system is being shut off by a safety device such as a high pressure or over-pressure sensor or a lost refrigerant pressure sensor or (for readers with a failure at an indoor air handler, ) by a failed condensate disposal pump or a condensate tray flood sensor

- the HVAC unit has a deliberate time-delay circuit or device that's not working

- the thermostat, thermostat wiring, or low voltage transformer is damaged or defective - not delivering the full 24VAC to the contactorFollowup by Patrick

Thanks for your speedy response.

"a defective contactor relay itself-mechanical damage, burned points, et."

I replaced the contactor relay with an aftermarket one. I suspect the contactor is faulty because the solenoid is getting the correct voltage to the coil but it's not pulling closed.

"the system is being shut off by a safety device..."

I checked all the safety devices with 27 volts coming from them. Furthermore, if one or more of the safety device(s) were tripped, the 27 volts to the contactor solenoid would've been interrupted. This is not the case because I'm getting the correct voltage to the contactor relay solenoid but the relay is not pulling close.

This is telling me that the contactor is faulty even though it's a new aftermarket one. I really don't know what else to check since I'm getting the correct voltage to the contactor relay.

This is telling me that everything upstream is working thus allowing 27 Volts to go to the solenoid coil.

Anyway, thanks again for your insights.Reply by (mod) - pushing on the HVAC control relay or contactor as a diagnostic step

I agree with you and compliment and appreciate you were careful diagnostic steps. I have a similar problem with the relay in a circulator pump relay and a home in northern Minnesota. I could press the relay close with my fingers and circulator would run but voltage to the proper contacts at the control we're not pulling the relay.

We purchased a new control to solve the problem

Watch out: there is live voltage here; if you don't know what you're doing you could be shocked or killed.

Question: AC compressor dead short to ground - rusty start capacitor

I recently had a compressor failure on my homes heat pump, the warranty sent a rookie out to inspect it. When the repair man shows up he asks me what kind of system I had, I told him a Trane heat pump. He then tells me he knows nothing about HP's.

Anyways he tells my warranty company that the start capacitor is completely rusted which is untrue it is rusty on top but surface rust, he also tells them that lady bugs and spider webs shorted out my board and tells them and improper installation of the cover let the water in to rust the cap. The cap tests fine, will this cause my compressor to short out?

The compressor is dead short to ground. - Ricky Thompson

Reply:

Ricky I'm not sure about your message, but in general if a compressor measures as dead shorted to ground it's time for a new one;

the compressor motor windings might burn out if the unit could not start because it lacked a working start capacitor. I'm curious about the capacitor test involved; in any case the compressor windings could short independent of the capacitor status as well.

Contactor Won't Engage on Goodman A/C

This is a really great website, packed with useful information. I still have a question about my contactor relay

First, I must admit this is a really great website, packed with useful information. I learned a lot just after a half an hour of reading.

Nevertheless, I am still not sure what causes the problem of my unit.

I have a Goodman CPKF48-5N Heat Pump (ten years old).

Recently a problem appeared that when the thermostat sends the signal to start the outside unit, the contactor does not engage (does not pull in), it just keeps repeating a “click” sound every ten seconds or so.

No action from the fan or compressor. At the first signal from the thermostat to the contactor relay, the outside fan moves a bit but then it is only the clinking.

But surprisingly, sometimes I can still start the heat pump normally and it runs OK for a couple of hours before it stops working and is back to the “click” sound. I cannot figure out what actually changes causing the unit to start (OK, possibly the outside temperature is different).

I already replaced the contactor, the capacitor, the relays as well as the control board but no success. On 2020-01-24 by Jiri -

Reply by (mod) -

Jiri

Thanks for the nice note.

I'll offer some comments but with the warning that nobody can fully diagnose a heat pump failure from just some e-text. An onsite expert could for example trace wires, jiggle connections, measure current draw, etc.

When the contractor keeps clicking I suspect a bad contactor itself but you could also have a failed compressor, a bad control board, or of course something else.

The fact that the system runs ok once in a while is an argument for a bad connector or one of the little or big parts I named above failing.

Typically, because it often works for a time and is cheaper than a thorough diagnosis, a service tech will often start by slapping on a compressor unit hard start capacitor kit. If that works it's also diagnostic: the compressor is failing.

As you have replaced the parts you listed, we're left with

- a hard start kit that gives a bigger kick to try to start what's probably a failing compressor motor

wait wait

one more thought occurs: a stuck TEV or other valve in the refrigerant system can leave high head pressure stuck on the high side of the system; if so the compressor may not be able to start against that high pressure.

And of course other diagnostic suggestions are on this page.

Shorted, melted wires on Goodman AC unit

I also have a Goodman central air unit. It was running fine but the wires going into the compressor corroded and shorted and melted the compressor terminals.

My plan is to replace the compressor. Do I have to worry about burnt freon? And also my model H23B223ABCA compressor is obsolete. There is a replacement for it but do you know if I will have to change any of the plumbing?

Or should it be pretty much plop it in kinda thing? I plan on having a tech doing the work. Nick

Reply:

Nick,

The compressor replacement process should remove all refrigerant, pull a clean out vacuum on the system, and include burnout filter-drier canisters on the refrigerant lines to protect the repaired system.For a bad compressor burnout some techs return a year later to replace the filter-drier canister once again. Going all that you should be ok.

Air Filters vs Cooling System Amperage Draw: Could Removing the Air Filters Cause the Electric Motor in the Air Handler to Draw Higher Amps?

Question: got one for you. I put an ammeter on my air handler and it read 8.25 amps, I removed the filters and it went up to 9.75 lmao at the situation the amperage should have gone down. what gives here

Reply: causes of variations in electric motor efficiency and current draw measured in amps

Lost: this amps variation is beyond my expertise, but in general reducing the load on an electric motor will show up as lower amps or current draw, not higher amps.

Here are two interesting explanations of amps or current variations on an electric motor that I found when researching the question:

1. Voltage variations and current draw at electric motors:

If your supply voltage is varying from your power company that can show up as higher amps draw on the motor (though it's a suspicious coincidence to see it exactly when you removed the filters and supposedly reduced the load on the motor).

Quoting from motorsanddrives [dot] com: "The effect of low voltage on electric motors is pretty widely known and ...

The amount of power the motor draws is roughly related to the voltage times current (amps). Thus, when voltage gets low, the current must get higher to provide the same ... To summarize the situation, low voltage can cause high currents"2. Load variations and electric motor efficiency:

A second possible source of seeing higher amps or current draw on your blower motor when you pulled out the air filters and thus reduced the load on the blower motor might be illuminated by this helpful reference:US DOE, DETERMINING ELECTRIC MOTOR LOAD AND EFFICIENCY [PDF] U.S. Department of Energy, - retrieved 2025/01/11 - local copy on file as Determining-electric-motor-load-and-efficiency-DOE.pdf

- Quoting:Most electric motors are designed to run at 50% to 100% of rated load. Maximum efficiency is usually near 75% of rated load.

Thus, a 10-horsepower (hp) motor has an acceptable load range of 5 to 10 hp; peak efficiency is at 7.5 hp.A motor’s efficiency tends to decrease dramatically below about 50% load.

...

Weak A/C Air Flow or A/C producing Warm Air

Diagnostic Starting Point:

Question: air conditioner air flow is reduced and air is not cold - cooling fan not running?

Blower fan running but reduced air flow (Dirty filter?) Air is not cold. System was on for a couple of hours when I noticed condenser fan.

It was not running. Turned system off, waited a while, turned system on. Condenser fan hummed but was not turning.

Used a BBQ fork (ok, not smart but I’ve never been accused of being too bright) to hit fan and it started. Still no cold air, ran for an hour, compressor fan motor and compressor VERY hot (Burned my fingers twice to confirm, that "not so bright thing again.”) Suggestions? - William 6/21/11

Reply:

William: when the outside compressor motor runs but the cooling fan does not, I suspect a bad start/run capacitor on the fan motor (if yours uses one) or a bad fan motor; sometimes it's a bad control board circuit.

If (with power turned off for safety) the fan spins freely if pushed, the motor is probably not frozen; in that case also see if there is a motor overload reset switch that can be pressed.

Question: Outside compressor runs but no air is coming out of air conditioning supply registers

my outside unit is running but there is no air being put out inside the house - Monica 7/20/11

Reply:

Monica,

If the compressor/condenser is running but the indoor air handler blower fan won't run you want to start diagnosing with the article linked to at the ARTICLE INDEX the bottom of this article titled

BLOWER FAN OPERATION & TESTING

Check for power on at the air handlerCheck for a loose fan belt or pulley

Check for a blower fan motor that is off on thermal reset

Question: no air is coming out of our supply registers

I have a coleman unit. Had heating probs 2 years ago leading to complete computer panel replaced, evaporator coils cleaner, gas regulator replaced. Two days ago, my A/C decided to stop working. I hear the freon flowing into the coil region, the fan outside is turning, but no air is coming out of registers. What can it be? - Cheryl

Reply:

Cheryl if you have no air coming out of supply registers the blower fan is not working or the duct system has become disconnected or blocked. Coil ice-over in the air handler can also block airflow.

Start by determining that the blower is running and that the air filter is clean.

Question: My hi line is cold, low line is warm and the condenser blows hot air

In my situation the high pressure line is colder than the low pressure line. The condensor coil blows mainly hot air, but the end closest to the compressor blows hotter air than the end furthest from the compressor line. Any suggestions? - Jim T. 7/13/11

Reply:

Mundo suggested: hey jim t check for restriction at the evaporator

Jim T:

Also, is your unit a heat pump or only an air conditioning system? - Editor. Let's be sure your system is in cooling mode.

A/C unit blowing warm air, not cooling, how do we diagnose the problem?

The central a/c unit at church is blowing warm air, both lines going to the outside unit are at outside temp, motor contactor was pulled-in and fan was running. Pastor thought we had a bad capacitor. Where should I proceed from here? - On 2016-06-13 by Christopher

Reply by (mod) -

If the compressor motor and fan motor run I think the Pastor may be mistaken.

First take a look at DIAGNOSTIC GUIDE A/C or HEAT PUMP for a list of simple diagnostic things to check, step by step.

That will take you to this article (or use this link)

Followup by Christopher: Found oil film over components in the outdoor compressor/condenser unit

I took the fan off of the top and peering down inside found the manifold piping shiny with a film of oil.

I suspect it is time to call a service tech and have the tech do a leak test? I am assuming it must be a pinhole leak as the unit was running fine earlier in May and is only a few years old. Thank you so much for your help danjoefriedman!

This site is awesome! Thanks very much for helping this old man do basic troubleshooting on a/c unit! I highly recommend people read f.a.q. 1st, then follow steps as suggested - On 2016-06-14 by Christopher -

Reply by (mod) -

Indeed, Christopher, as refrigerant systems include some oil, often the first sign we see of a small leak is an oily residue on refrigerant piping, below connections, or around other components (such as a compressor or expansion valve) that carry refrigerant.

It's best to find and fix the leak rather than just adding refrigerant.

Question: air conditioner just blows hot air

air conditioner blowing hot air - Ann 8/4/12

Reply:

Ann,

with just the info you provided - blowing hot air - first make sure your thermostat is set to COOLING mode - and presuming it is and that all of the equipment inside and out are turned on, check

DIAGNOSE & FIX AIR CONDITIONER / HEAT PUMP

the article link found at the ARTICLE INDEX the bottom of this article - for a starting point in diagnosing why an air conditioner is not working.

Question: My high pressure refrigerant line is cold, low line is warm and the condenser blows hot air

In my situation the high pressure line is colder than the low pressure line.

The condensor coil blows mainly hot air, but the end closest to the compressor blows hotter air than the end furthest from the compressor line. Any suggestions? - Jim T. 7/13/11

Reply: is your heat pump in "Heat" mode?

Mundo suggested: hey jim T check for restriction at the evaporator,

Jim T:

Also, is your unit a heat pump or only an air conditioning system? - Editor. Let's be sure your system is in cooling mode.

Question: Weak air flow, HVAC tech says replace the TXV (TEV - thermostatic expansion valve)

Two of my air ducts are not blowing air. Can this affect the air temperature differential? - 28 June 2015 Sandy said:

Reply:

I'm not sure what temperature differential you ask about but certainly if two ducts have lost air flow that would mean that the areas served by those ducts won't be cooled.

If the airflow into those ducts is blocked or shut off by a damper, then yes, the air handler will be pushing more air into the other remaining ducts in your heating or cooling system.

Look for disconnected, crimped, or closed dampers in those duct systems.

Reader follow-up: tech says replace "TXZ" - probably meant TEV - Thermostatic expansion valve

Sandy said:

Does the blocked air ducts affect the reading of the return register and the supply register. Our differential reads at 12 which does not meet state standards for a home inspection. They say a minimum of 14.We had an AC guy come over and says we need a TXZ valve replacement. The unit is only 6 yrs. old. The job will be $1070.00 just wondering if the two blocked ducts are the problem and not the TXZ.

Reply: The TEV does not affect air flow

Sandy

If by TXZ valve you are referring to a thermostatic expansion valve (usually written TEV), that is a refrigerant metering device.

The relationship between a TXV or TEV valve problem and low air flow would be indirect: a faulty thermostatic expansion valve MIGHT cause icing of the cooling coil in the indoor air handler unit. In turn, an ice-blocked cooling coil would reduce air flow through the system.

But that problem is easily and quickly discoverable by mere inspection of the cooling coil for icing after the system has been on for a time.

In the ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS given above you'll find more diagnostic articles on blocked HVAC duct air flow, weak air flow, inadequate return.

Or skip directly to AIR FLOW TOO WEAK at InspectApedia.com

Note that if only some of your ducts have poor air flow then it's not a TEV problem since an iced coil would reduce the air flow into ALL of the supply ducts.

Watch out: I would not pay a thousand dollars for a TEV replacement before knowing that the problem has been correctly diagnosed.

Comment by Anonymous

Sandy, send this AC company home. The cost of replacement, (even if need to be done) shouldn't get over $350.

But first he needs to eliminate other problems, like blocked ducts and dirty coils. The blocked coil problem can be caused by quick inexpensive fixes that shoud be looked at first before replacing the expansion valve.

Blower works ok in heat mode but air flow is weak in cooling mode

The two-stage blower works fine with my furnace, moves hot air just fine.

I get very little air movement with my central air conditioning though, just the gentlest of air flow. Utterly unacceptable. Any ideas as to what is wrong? On 2016-07-21 by John C

by (mod) inadequate air movement

John,

Assuming you're using the same air handler, the problem is more likely to be one of these :A bad or mis-wired or mis-set (bad dip swithc setting) A/C control that is setting fan speed.

Ice-blocking of the cooling coil.See the diagnosis and repair details at AIR FLOW TOO WEAK

...

Thank you to our readers for their generous comments

On 2016-06-14 by Christopher

This site is awesome! Thanks very much for helping this old man do basic troubleshooting on a/c unit! I highly recommend people read f.a.q. 1st, then follow steps as suggested.

...

...

Continue reading at COMPRESSOR / CONDENSER DIAGNOSTICS - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- A/C COMPRESSOR PROBLEMS - Diagnostic articles for the compressor/condenser unit.

- A/C - HEAT PUMP CONTROLS & SWITCHES - Is it turned on?

- AIR CONDITIONING & HEAT PUMP SYSTEMS - home

- BURNED-OUT COMPRESSOR

- CAPACITORS for HARD STARTING MOTORS to try to kick start a reluctant compressor motor

- COMPRESSOR / CONDENSER REPAIR - home

- COMPRESSOR / CONDENSER DIAGNOSTICS -

- DIAGNOSTIC GUIDE A/C or HEAT PUMP - home

- NOISES, HVAC SYSTEM DIAGNOSIS - home

- SPLIT SYSTEM AC / HEAT PUMP REPAIRS

Suggested citation for this web page

COMPRESSOR / CONDENSER DIAGNOSTIC FAQs-3 at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.