Micro-Aire® FS Fiberglass HVAC Ducts

Micro-Aire® FS Fiberglass HVAC Ducts

Johns Manville MicroAire Ductwork

- POST a QUESTION or COMMENT about all types of fiberglass air ducrts used in heating & cooling systems, including installation standards, cleaning, leaks, contamination, & possible sources of small fiberglass fragments found in indoor air & dust samples

Fiberglass air ducts produced by Johns Manville, sold under the Micro-Aire and Micro-Aire FS brand are described here.

We discuss both older or "original" Micro-Aire® duct products like the one shown at the top of this page and current Micro-Aire HVAC duct materials that include flex-duct and rigid-board fiberglass duct construction.

This article series describes the different types of fiberglass heating & cooling ducts including fiberglass duct wrap, flexible fiberglass insulated ductwork, fiberglass duct board, and fiberglass duct inspection, installation, cleaning, and restoration.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Johns Manville Micro-Aire® HVAC Ducts

Current & Recent Micro-Aire® Air Duct Description & Installation Guides

Current & Recent Micro-Aire® Air Duct Description & Installation Guides

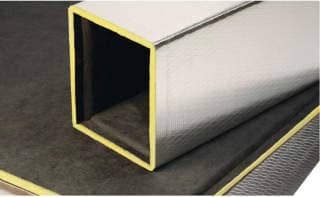

The illustration shown here is of Johns Manville's current Micro-Aire® Mat-Faced fiberglass duct board, type 475 & Type 800, used both as a rectangular HVAC duct product and in related forms as an insulator inside or forming air handlers and supply or return air plenums.

Johns Manville describes this product as follows:

Micro-Aire® duct board is produced from strong glass fibers, bonded with a thermosetting resin.

The airstream side of Micro-Aire duct board features a black fiber glass mat, which minimizes visibility of the duct system at supply air and return air outlets while providing excellent durability in high-velocity conditions.

The exterior surface features a fire-resistant foil-scrim-kraft facing extending the full width of the male edge to serve as an integral closure flap for section joints.

Micro-Aire duct board is molded with double-density, male/

female edges for secure connections.

The airstream surface of Micro-Aire duct

board is treated with an antimicrobial agent specifically registered with the

EPA for HVAC applications to resist potential growth of fungus or bacteria on

the airstream surface. - HVAC Insulation, Micro-Aire® Data Sheet 2018/10/30 cited below.

- Johns Manville, Micro-Aire® MAT-FACED FIBERGLASS DUCT BOARD TYPE 475 & Type 800 DATA SHEET [PDF] 2018/10/30 Johns Manville Corp., 717 17th St. Denver, CO 80202 800-654-3103 www.JM.com - this is a most-recent product description for Micro-Aire HVAC ducts.

Cleaning Fiberglass Duct-board Air Ducts

If cleaning is necessary, the airstream surface may be cleaned using standard industry-recognized dry methods. See the North American Insulation Manufacturers Association (NAIMA) “Cleaning Fibrous Glass Insulated Air Duct Systems” -(Johns Manville 2018)

Watch out: OPINION: using aggressive mechanical cleaning of fiberglass HVAC ducts risks causing severe damage to the ductwork and may also cause fiberglass hazards in indoor air.

Older Johns Manville Micro-Aire® Air Ductwork Condition Assessment

This Johns Manville Micro-Aire® FS fiberglass air duct was installed in a U.S. home in 1977.

(Photos courtesy of an anonymous InspectApedia.com reader)

This Johns Manville Micro-Aire® FS fiberglass air duct was installed in a U.S. home in 1977.

(Photos courtesy of an anonymous InspectApedia.com reader)

Question:

My older home (circa 1977) has Johns-Manville “Micro-Aire FS” Fiberglas wrapped ducting in the attic from my furnace.

It has an Underwriters Lab label No. 2627092 Does it contain asbestos?

Is the old plastic type interior lining stable.

They used this instead of galvanized duct.

Should it be replaced if I add on an AC unit?

The product is 40 years old. Is it common that deterioration may have allowed leaks to develop? Do you think it would withstand a pressure test?

Please let me know. Thanks. - Anonymous by private email 2019/02/06

Reply: OPINION: the ductwork in your photos does not contain asbestos but it should be replaced

I would have at least see some photos of the duct, labeling, runs, connections, and visual evidence of deterioration. [The reader then provided the photos shown here.]

I would have at least see some photos of the duct, labeling, runs, connections, and visual evidence of deterioration. [The reader then provided the photos shown here.]

Plastic materials used in some other duct systems such as GOODMAN GRAY FLEXDUCT ( a different design ) deteriorated badly and could be seen by visual inspection to be broken or shredded.

Fiberglass duct-board that is foil faced and whose fiberglass is fabricated far more rigid than fiberglass-insulated flexduct is also in my opinion much more durable and, properly-fabricated, less likely to be leaky.

I am sorry to throw your money at this but if that were my house I would replace ALL of that ductwork if it looks quite dirty, frizzy inside, or if it has ever been wet or otherwise contaminated.

Some of your photos show that the duct interior has been damage.

Your first photo [above] shows lost fiberglass and exposed wire coil inside the duct. I think the fiberglass surface appears roughened.

I suspect someone tried mechanical cleaning. That loosens and damages the fiberglass, resulting in still more-rapid accumulation of house dust (not itself hazardous) in the future and in addition increases the chance of release of airborne fiberglass into building air.

While large fiberglass fragments may not be more than an irritant, small fragments (omitted by too many air and dust test consultants and labs) are potentially harmful and maybe even carcinogenic.

Details are at FIBERGLASS HAZARDS

When the fiberglass is exposed on the inside of the ducts they cannot be cleaned mechanically.

Your second and third photos show that the exterior wrap on the duct is badly deteriorated and is bound to be leaky. That looks like a plastic wrap. Is or was that original?

The NADA National Air Duct Cleaners Association also notes that when ducts need to be cleaned, physically removing the contaminant is preferred, and the use of chemical treatments, sprays, coatings, is not a substitute but rather might be supplementary.

Do Johns Manville Micro-Aire ducts present an asbestos hazard?

To address your question, I found no evidence that asbestos was a component in the fiberglass duct about which you asked.

Carless research on asbestos in air ducts patenented by Johns Manville, Owens Corning and others can lead to confusing findings in part because of this patent classification that appears in some of those patents:

B32B19/02 Layered products comprising a layer of natural mineral fibres or particles, e.g. asbestos, mica the layer of fibres or particles being impregnated or embedded in a plastic substance.

And indeed asbestos was a key ingredient in transite (asbestos cement) pipes used for air ducts.

Details are at TRANSITE & SONNO-DUCT ASBESTOS DUCTS

However the word "asbestos" doesn't appear in the product description in patents I cite below.

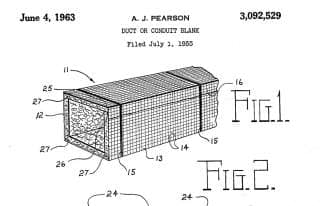

Here is a representative Micro-Aire patent assigned to the Johns Manville Corporation in 1978.

- Ray Jr, Richard James, Daniel Paul Kopy, and Theodore Richard Rohweder. "Thermally insulating duct liner." U.S. Patent 4,101,700, issued July 18, 1978. Current Assignee: Johns Manville Corp.

Abstract:

Disclosed herein is a flexible thermally insulating duct liner comprising a fibrous thermal insulation layer having an organic fibrous layer having an open structure bonded to its working face, the working face being thereafter coated with a flame retardant vinyl polymer containing coating.

The duct liner of the present invention has an extremely smooth surface which reduces air friction to a minimum. Still the product is very flexible, easy to work with, and resistant to delamination or working surface failure.

Notice that the word "asbestos" doesn't appear in the patent

The history of insulating fabrics that became used on HVAC ducts in North America is much older, as we see in

The history of insulating fabrics that became used on HVAC ducts in North America is much older, as we see in

- Seigle, William R. "Insulation fabric." U.S. Patent 1,503,337, issued July 29, 1924. Original Assignee Johns Manville Corp.

- Pearson, Arthur J. DUCT or CONDUIT BLANK [PDF] U.S. Patent 3,092,529, issued June 4, 1963. Original Asignee Owens Corning Corp.

Here are all of the relevant patents I could find for Johns-Manville “Micro-Aire FS” Fiberglas wrapped ducting pertinent Johns Manville Patents

- US4067678A 1976-04-14 1978-01-10 Johns-Manville Corporation Apparatus for making a fibrous board-like product having a male edge and a female edge

- US4070954A 1975-10-30 1978-01-31 Glass Master Corporation Duct forming machine

- US4101700A 1976-03-12 1978-07-18 Johns-Manville Corporation Thermally insulating duct liner

- US4175159A 1978-07-31 1979-11-20 General Electric Company Silicone emulsions for treating silicate particulate matter

- US4179808A 1978-05-10 1979-12-25 Johns-Manville Corporation Cutting guide tool for fabrication of air duct transitions and method of its use

And related patents

- Matthews, Kent R., Eric G. Schakel, and Ricardo R. Gamboa. "Glass fiber airduct with coated interior surface containing a biocide." U.S. Patent 5,487,412, issued January 30, 1996.

- Smith, Harvell M. "Cutting guide tool for fabrication of air duct transitions and method of its use." U.S. Patent 4,179,808, issued December 25, 1979.

- Toas, Murray S., and John O. Ruid. "Moisture repellent air duct products." U.S. Patent 7,220,470, issued May 22, 2007.

Abstract:

Water-resistant fibrous air duct insulation products and methods for making such products.

The products may include a duct board or a duct tube including a first layer of resin-bonded fibrous mat having a second layer of durable, preferably non-woven, facing material adhered thereto, wherein the facing material defines the air stream surface for the board or tube.

The duct board or tube is preferably rendered water-repellent at the air stream surface by incorporating a hydrophobic agent into the adhesive used to adhere the second layer to the first layer.

The Toas patent disclosure (last in the list above) also includes these non-patent but relevant citations for understanding the properties of Johns Manville fiberglass duct products and their history.

- Johns Manville, Fiber Glass Mat (Acrylic Binder), Material Safety Data, Sheet ID: 1014, Section 1-Chemical Product and Company Identification pp. 1-6, Oct. 21, 2002.

- Johns Manville, Glass Fiber Mats, Elasti-Glass(R) 3200B Series, 1 p., Oct. 30, 2002.

- Johns-Manville Fiber Glass, "Micro-Aire Duct Systems Fabrication Manual", USA.

- Johns-Manville Manufacturing, "Finished Product Specification-Mat Faced Mad Board Spec No. 4365-15.6", 1971-1973, USA.

- Johns-Manville Manufacturing, "Finished Product Specification-Micro-Aire Duct Board Standard Duty Heavy Duty Spec No. 4365-15", 1971-1973, USA.

- Johns-Manville Manufacturing, "Product Specification-Micro-Aire Duct Board Standard Duty Heavy Duty Spec No. 4365-20", 1971-1973, USA.

- Johns-Manville, "Air Handling Systems-Linacoustic RC(TM) Fiber Glass Duct Liner with Reinforced Coating System," (preliminary product information), AHS-329 Feb. 2002.

- Johns-Manville, "Super Duct(TM)" Air Duct Board Fabrication Instructions, AHS-204, Feb. 1998.

- Johns-Manville, Air Handling Systems-SuperDuct(TM) Coated High Performance Air Duct Board, Type 475 & 800, AHS 200 Jun. 2000.

Rigid & Flexible Fiberglass / Micro-Aire® Duct Construction, Cleaning & Inspection References

- DISINFECTANTS, SANITIZERS, FUNGICIDAL-SEALANTS SOURCES

- Design Guide for Heating, Ventilating, and Air Conditioning Systems [PDF] (2006) U.S. Department of the Interior, Bureau of Recleamation, Denver CO USA retrieved 2019/02/07 original source: https://www.usbr.gov/tsc/techreferences/mands/mands-pdfs/HVACManl.pdf

Scope excerpt: This guide assumes that prospective users will have some heating, ventilating, and air conditioning (HVAC) design experience but are not familiar with the specific requirements for the Bureau of Reclamation (Reclamation) facilities.

The guide emphasizes design considerations and recommendations for applications specific to powerplants, pumping plants, and confined spaces such as tunnels, gate chambers, and valve vaults.

The guide also identifies recognized codes and standards that should be referred to as necessary when designing HVAC systems for Reclamation facilities. Most HVAC system designers should be familiar with the design requirements for office buildings. Except for recommended ambient conditions, office HVAC systems are not included in this guide. - Messer, John D. AIR CONDITIONING, HEATING, AND VENTILATING: CONSTRUCTION, SUPERVISION, AND INSPECTION [PDF] course materials.

Course of Study. INSTITUTION California Community Colleges, Sacramento. Office of the Chancellor.; Los Rios Junior Coll. Distr,ict, Sacramento, Calif. PUB DATE 73 NOTE 337p.;

ABSTRACT

This course of study on air conditioning, heating, and ventilating is part of a construction, supervision, and inspection series, which provides instructional materials for community or junior college technical courses in the inspection program.

Material covered pertains to: piping and piping systems; air movers; boilers; heat exchangers; cooling and heating coils; pumps; refrigeration; temperature control and natural draft venting systems; sound control; insulation; air ducts; ventilation systems; instrumentation.

Many charts and diagrams are interspersed thrcughout the document to assist the reader; the 75-page appendix is made up entirely of charts and diagrams.

The course of study may contain more material than can be covered in one semester. (Parts of this document may not reproduce clearly.) (EA)

DOCUMENT RESUME ED 087 880 CE 000 970 AUTHOR Retrieved 2019/02/06, original source: https://files.eric.ed.gov/fulltext/ED087880.pdf

For related documents, see CE 000 969, CE 000. 971 EDRS PRICE MF-$0.75 HC-$16.20 DESCRIPTORS* *Air Conditioning; Community Colleges; Construction (Process); *Heating; Inspection; Junior Colleges; Performance Specifications; Standards; *Study Guides; Supervision; *Technical Education; *Ventilation IDENTIFIERS California

- retrieved 2019/02/06 original source: https://vdocuments.mx/air-conditioning-heating-and-ventilating-construction-supervision-.html also available at https://archive.org/stream/ERIC_ED087880/ERIC_ED087880_djvu.txt - Oberg, Brad, AIA, USES AND MISUSES OF DUCT BOARD:

UNDERSTANDING THE NEW

HIGH-PERFORMANCE MATERIALS [PDF] ASHRAE, retrieved 2018/02/06 original source https://web.ornl.gov/sci/buildings/conf-archive/2004%20B9%20papers/016_Oberg.pdf

Abstract:

This paper is based on a white paper developed at the author’s firm, which discusses the appropriate uses for fibrous glass duct board for residential HVAC applications.

Here the author describes the characteristics and benefits of fibrous glass duct board and addresses issues specific to fibrous glass duct construction, including the concern that fiberglass ducts collect water and support growth of mold. - Owens Corning, OWENS CORNING FIBERGLAS® ENDURACOAT® DUCT SYSTEM [PDF] (1995) Submittal Sheet + supplemental data including clearance to combustibles, Louisiana Office of State Fire Marshal, 8181 Independence Blvd. Baton Rouge, Louisiana 70806

1-800-256-5452 http://lasfm.org/ retrieved 2019/02/07,

Includes additional information including clearance to combustibles and installation instructions, original source: http://sfm.dps.louisiana.gov/doc/gbmemos/Bad%20Memos/bm_28.pdff - White, Mike, et als., USING CHEMICAL PRODUCT USE in HVAC SYSTEMS [PDF] NADCA position paper, National Air Duct Cleaners Association

1120 Rt. 73, Suite 200

Mt. Laurel, NJ 08054

Fax: 856‐439‐0525

Email: jodi@nadca.com

Phone: 856‐380‐6810 retrieved 2019/02/07 original source: https://nadca.com/system/files/nadca_white_paper_on_chemical_applications_in_hvac_systems_0.pdf

Excerpt:

One topic that has generated both substantial interest and concern is the use of chemicals, cleaners, sealants and coatings inside air handling systems. Currently a broad diversity of information exists regarding the use and efficacy of these chemical products.

In working with all parties associated with indoor air quality, NADCA recognizes the need to provide direction in this complicated and evolving area. It is generally agreed that source removal of contaminants remains the single best method for cleaning and decontaminating HVAC systems. However, chemicals may be applied within HVAC systems for a variety of reasons.

This position paper provides an overview of the products and associated techniques utilized in and around HVAC systems.

...

Continue reading at FIBERGLASS DUCT, RIGID CONSTRUCTION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Fiberglass HVAC Duct Articles

- FIBERGLASS AIR DUCT MOLD TEST

- FIBERGLASS DETECTION in BUILDING AIR & DUST

- FIBERGLASS DUCT, RIGID CONSTRUCTION

- FIBERGLASS HAZARDS - home

- FIBERGLASS HVAC DUCTS

- AIR HANDLER FIBERGLASS INSULATION

- FIBERGLASS DUCT WRAP

- FOIL-COVERED FIBERGLASS FLEX DUCT

- MICRO-AIRE® HVAC DUCTS

- PLASTIC-COVERED FIBERGLASS FLEX DUCT

- RIGID BOARD FIBERGLASS DUCTS

- RIGID ROUND FIBERGLASS DUCTS

- FIBERGLASS HVAC DUCT FAQs

- FIBERGLASS INSULATION MOLD

Or see ASBESTOS DUCTS, HVAC

DISINFECTANTS, SANITIZERS, FUNGICIDAL-SEALANTS SOURCES if you need to sanitize or seal air duct interiors

Suggested citation for this web page

MICRO-AIRE® HVAC DUCTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to FIBERGLASS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.