Modular Metal Shingle Roof Systems

Modular Metal Shingle Roof Systems

- POST a QUESTION or COMMENT about metal shingle roof systems

Modular metal roof systems:

This article explains the selection, use, and properties of modular metal roof shingle systems, including granular-surfaced metal roof shingles and snap-together metal roof shingles. We include a photo guide to types of metal roof shingles including antique metal shingles.

This article series discusses best practices in the selection and installation of residential roofing. This article includes excerpts or adaptations from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

More photos of metal shingle roofs are at Metal Shingle Roofs. Also see our metal roofing home page, METAL ROOFING and see CORRUGATED ROOFING and COPPER ROOFING, our roofing home page: ROOFING INSPECTION & REPAIR.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Modular Metal Roof Shingles: Best Roofing Practices & Installation Details

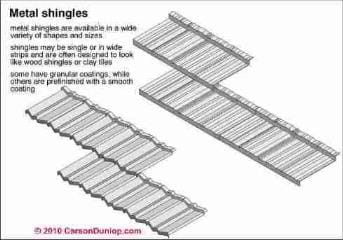

The metal roof shingles at below-right found on a New York home are steel, coated with a granular material that from the ground can be mistaken for asphalt. Carson Dunlop Associates 's metal roof shingle sketch (below left) provides additional details about this roofing option.

[Click to enlarge any image]

Adapted/paraphrased with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter on BEST ROOFING PRACTICES:

Modular metal shingles comprise the fastest growing segment of the metal roofing industry. Using light-gauge steel, copper, or aluminum, panels are stamped to imitate slates, shakes, asphalt shingles, or tiles. Some have aggregate stone finishes that closely resemble asphalt shingles. Most carry warranties from 20 to 30 years against fading and from 50-year to “lifetime” warranties against cracking or delamination of the shingle itself.

Modular shingles carry a Class A or B fire rating, depending on the material and installation details, and are highly resistant to wind uplift and damage from hail. Installed prices range from two to three times the cost of premium asphalt shingles. Installers accustomed to asphalt shingles or tile should have little trouble adjusting to metal shingles.

Materials Used in Modular Metal Roof Shingle Systems

Modular shingles are typically stamped from

lightweight .0165-inch metal, which is thinner than other

types of metal roofing but stiffened by the textured patterns.

Typical rectangular panel sizes range from 24 to 48

inches long by 12 to 16 inches wide, but they also include

tile and diamond shapes and other specialty patterns.

Modular shingles are typically stamped from

lightweight .0165-inch metal, which is thinner than other

types of metal roofing but stiffened by the textured patterns.

Typical rectangular panel sizes range from 24 to 48

inches long by 12 to 16 inches wide, but they also include

tile and diamond shapes and other specialty patterns.

The roof shown in our photo (left) was installed in Molde, Norway, an area of challenging winter weather.

Here is another Molde, Norway modular shingle metal roof showing a different METAL SHINGLE ROOF PATTERN [Image File]

Weights for modular metal shingle roofs range from 40 pounds per square for aluminum shingles to 140 pounds per square for steel shingles with a heavy stone aggregate.

The lightweight patterns are well suited to re roofing where weight is a concern. Most panels can be walked on, if done with care, but areas with heavy foot traffic should be reinforced with foam backers provided by the manufacturer.

Installation Methods for Modular Metal Roof Shingle Systems

Modular shingles are either nailed directly

to the wood deck or attached to 2x2-inch battens installed

at the exposed panel width, usually about 15 inches.

Installation on battens allows more deeply etched patterns,

such as simulated tiles. Either type can be installed with

pneumatic nailers.

Modular shingles are either nailed directly

to the wood deck or attached to 2x2-inch battens installed

at the exposed panel width, usually about 15 inches.

Installation on battens allows more deeply etched patterns,

such as simulated tiles. Either type can be installed with

pneumatic nailers.

Our photograph at left illustrates a variegated colour modular metal shingle roof installed on a home in Christchurch, New Zealand. Metal roofs are the most common roof covering on residential buildings in Christchurch.

In earthquake prone areas such as Christchurch, metal roofing movement noise may be heard as a roaring freight train sound indicating the approach of a shock wave, perhaps giving an extra minute's notice of earthquake warning.

See EARTHQUAKE DAMAGE PHOTOS CA 1994

Underlayment for modular or "snap together" metal shingle roofs is minimum No. 30 asphalt felt held with plastic caps to avoid contact between incompatible metals.

Many manufacturers recommend proprietary laminated underlayments, such as VersaShield (Elk Premium Building Products, Inc.), which are tougher and less slippery than felt and provide better fire ratings. Aluminum shingles require fire-resistant underlayments to achieve an A or B fire rating.

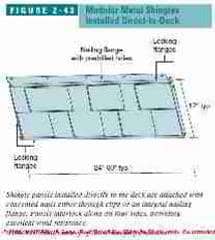

Direct to Deck Modular Roof Shingle Attachment Method

Direct to deck Modular Metal Roof Shingle Method: Shingle panels installed directly to the deck are attached with concealed nails, either through clips or a nailing flange along the top, and have interlocking edges along all four sides (Figure 2-43 shown at left).

As they are installed, each panel locks to the panel below and to the left.

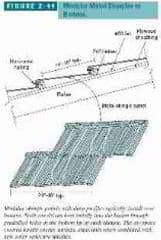

Installing Modular Metal Roof Shingle Over battens

Modular Metal Roof Shingle Over battens: Modular panels designed for installation on battens have a nailing flange along the bottom of each shingle panel with nails going horizontally into the batten (Figure 2-44).

Roof battens are useful for modular metal roof shingle retrofits where the surface is irregular. Also, the air space boosts energy savings, especially when using shingles with solar-reflective surfaces.

Both systems begin with the installation of a drip edge and gable trim designed for the specific system.

Working from left to right, the first shingle panel hooks into the drip edge, which also serves as a starter strip.

Successive courses for modular metal shingles are staggered as specified by the manufacturer.

Re roofing Using Modular Shingles On Top of Other Roof Coverings

As we discuss at METAL ROOFING, the rusted metal shingles on the church roof (Clintondale, NY) shown in our photo (left) demonstrate more about the history of how metal roofing was used in the U.S. Here the original wood shingle roof was re-roofed using metal shingles, probably before 1900.

In general, most modular shingles can be installed over existing asphalt shingles [or wood or some other surfaces] if they are in good condition without excessive curling and deformation.

Metal modular roof shingles that are designed to go over battens (see above) have more flexibility, since the battens can be shimmed to create a level surface.

Flashing and Sealing Details for Modular Metal Roof Shingles

[Click to enlarge any image]

Manufacturers provide standard flashings similar to those for standing-seam products.

Eaves and rake flashings typically have concealed fasteners and lock the shingles in place.

Ridge and headwall flashings often require exposed fasteners.

Depending on the shingle profile, sidewall, chimney, and skylight flashings are either pan or step flashings.

Typical flashing and sealing details for metal modular roof shingles are shown at above left in Figure 2-45.

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Other Antique Modular or Snap-Together Metal Shingle Roofing Systems

As we discuss at METAL ROOFING, here are photographs of other modular metal roof shingle systems.

Metal Shingle Roofs, Embossed, Antique

The antique embossed metal shingles (below) are found on the Justin Morrill Smith historic homestead, Vermont.

Quoting Grapefine Design Guidelines:

Metal roofing in America is principally a 19th-century phenomenon. Before then the only metals commonly used were lead and copper.

Tin-plate iron, commonly called "tin roofing," was used extensively in Canada in the 18th century, but was not commonly used in the United States until rolling mills were established in this country. The low cost, light weight, low maintenance and ease of shipping of tin plate made it a common roofing material.

Embossed tin shingles, whose Grapevine Design Guidelines – Roof Design Guidelines 4.9 - 2 surfaces created interesting patterns, were popular throughout the country in the late 19th century. Tin roofs were often kept well-painted in red or green to imitate the green patina of copper. Unfortunately, few of these roofs remain intact today.

Similar snap-together metal roof shingles made of copper are discussed

at COPPER ROOFING.

Soldered Flat Shingle and Flat Copper Metal Roofs

Flat metal shingles with interlocking edges were produced in both steel and copper, then soldered when in place. Usually we find these installed on flat or low-slope roofs such as at dormer insets on homes constructed in the U.S. before 1920.

Carson Dunlop Associates's standing seam metal roof sketch (below) includes a sketch of soldering used to connect flat metal roofing panels.

Watch out: large expanses of metal roofing with soldered connections may flex and break open the soldered joints due to thermal movement.

Modular Metal Roofing / Metal Roof Shingle Materials & Suppliers

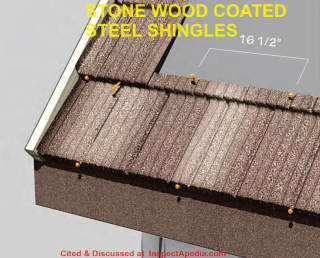

Illustration: "Stone Wood Shingles" - stone coated steel roof shingles from Roser Roofing Sytems, cited in detail below.

- Accel, ATAS, ADVANTA (Metal) SHINGLE INSTALLATION GUIDE [PDF] ATAS International, Inc., Allentown PA 18106, Tel: 610-395-8445, Web: atas.com

- ASC Profiles Inc., LIGHT GAUGE METAL ROOF & WALL PANELS INSTALLATION GUIDE [PDF] (2019) ASC Profiles LLC, 2110 Enterprise Boulevard West Sacramento, CA 95691 USA, Website: www.ascbp.com retrieved 2021/03/02 original source: https://www.ascbp.com/files/BR128_LtGaugeInstall.pdf

- Atas International, website: www.atas.com

Modular metal shingle, tile, and standing-seam panels - BMRD BUY METAL ROOFING DIRECT MANUAL [PDF] installation details and care & maintenance details for most types of metal roofing

- Central States Manufacturing, HORIZON-LOC™ METAL ROOF INSTALLATION DETAILS [PDF] (2018) Central States Manufacturing Co., Metal building components, Email: info@centralstatesmfg.com Website: www.CentralStatesMfg.com retrieved 2019/09/11 original source: http://www.centralstatesmfg.com/wp-content/uploads/GUID_INSTL_HorizonLoc.pdf

- Classic MRS, RUSTIC (METAL) SHINGLE INSTALLATION MANUAL [PDF] Residential Roofing Systems (2007), Classic Metal Roofing Systems, 8510 Industry Park Dr., PO B 701, Piqua OH 45356, Tel: 937-778-5116, email: info@classicroof.com Web: classicroof.com

- Metal Roofing Alliance, E. 4142 Hwy 302, Belfair, WA 98528, Telephone:(360) 275-6164, Customer Support 410-534-6900, Email: support@metalroofing.com,

Website: www.metalroofing.com. Quoting:

The Metal Roofing Alliance was formed in 1998 by a small group of forward-thinking metal roofing manufacturers with the main goal of educating consumers about the many benefits of metal roofing. Since our inception, we've shown millions of people just how beautiful, durable and money-saving metal roofing can be for them. - The Metal Initiative, 4700 W. Lake Ave., Glenview, IL 60025, P:847.375.4785 Website: www.themetalinitiative.com/, Email: Louise Ristau lristau@connect2amc.com Quoting:

The Metal Initiative is a coalition of manufacturers, individuals and associations that have come together to provide information on the features and benefits of metal in construction. Carrying its message of metal primarily to the professional building owner community, The Metal Initiative seeks to gather and disseminate useful information for decision-makers. - NRCA, Smith, Thomas L., AIA, CRC, METAL ROOFING: 'FIXING' FOR THERMAL MOVEMENT [PDF] Professional Roofing, [date pending] p. 72, NRCA - Web: http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, METAL ROOF SYSTEMS: DESIGN CONSIDERATIONS FOR SNOW AND ICE [PDF] Professional Roofing, [date pending] p. 74, NRCA, http://www.nrca.net/

- NRCA, Smith, Thomas L., AIA, CRC, STEEL [ROOF] DECK CORROSION BULLETIN [PDF] Professional Roofing, [date pending] p. 58, NRCA, http://www.nrca.net/

- "Steel [Roof] Deck Corrosion Bulletin, NRCA [ copy on file as /roof/Steel_Roof_Deck_Corrosion_NRCA.pdf ] - ", Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] p. 58, NRCA nrca.net

- McElroy, MILAN STEEL SHINGLE INSTALLATION INSTRUCTIONS [PDF] McElroy Metal, 1500 Hamilton Rd. Bossier City, LA 71111 USA Web: mcelroymetal.com info@mcelroymetal.com 800.562.3576

- Metal Roofing, an Illustrated Guide, R.A. Knowlton , [metal shingle roofs]

- NRCA, Smith, Thomas L., AIA, CRC, THE MANY ASPECTS of METAL [ROOF] SHINGLES [PDF] Professional Roofing, [date pending] NRCA, Web: nrca.net

- Roser, STONE WOOD [Metal] SHAKE INSTALLATION MANUAL [PDF] Roser Roofing Systems, (Stone Coated Steel Roof Shingles), Web: roser-usa.com

- "Steel [Roof] Deck Corrosion Bulletin, NRCA [ copy on file as /roof/Steel_Roof_Deck_Corrosion_NRCA.pdf ] - ", Thomas L. Smith, AIA, CRC., Professional Roofing, [date pending] p. 58, NRCA

- Tamko, STEEL SHINGLE INSTALLATION GUIDE [PDF] (2017) Tamko Building Products, retrieved 2023/12/16, original source: .tamko.com/docs/default-source/application-instructions/tamko-metalworks-application-instructions.pdf?sfvrsn=bbb56a0_4

- Terrabella® STONE COATED STEEL ROOF INSTALLATION MANUAL (shakes, shingles) [PDF] Terrabella® part of Alucom Group, Alucom LLC 2145 NW 115TH AVE. Miami, FL 33172 USA Technical Advisor Tel: (786) 651-4993 Fax: (305) 677-2232 Website: www.terrabellaroof.com retrieved 2019/09/11 original source http://www.terrabellaroof.com/wp-content/uploads/2015/02/Manual_Classic,_Shake_&_Single.pdf

Metal Roofing Manufacturers - current

- Classic Products www.classicroof.com Modular metal shingle panels and standing seam panels

- Decra Roofing Systems www.decra.com Modular metal shingle, tile, and shake panels

- Dura-Lok Roofing Systems www.duraloc.com Modular metal roofing shingles with granular coating

- Fabral www.fabral.com Exposed fastener and concealed clip metal roofing panels

- Gerard Roofing Technologies www.gerardusa.com Modular metal shake and tile panels with granular coating

- Met-Tile www.met-tile.com Modular metal roof-tile panels

- Atas International www.atas.com Modular metal shingle, tile, and standing-seam panels

- Custom-Bilt Metals www.custombiltmetals.com Modular metal shakes and standing seam panels

- Zappone Manufacturing,

Zappone Manufacturing, 2928 North Pittsburg St. Spokane, WA 99207 1-800-285-2677, Washington State Copper Roofing Supplier of Copper scallop shingles, copper shingles, copper bay windows, vertical walls, aluminum roof shingles website www.zappone.com/

- - Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Continue reading at LIFE EXPECTANCY of METAL ROOFS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- COPPER SHINGLE METAL ROOFING - soldered metal or copper shingle roofing on flat or low-slope roofs.

- FLASHING for METAL ROOFS

- ROOF NOISE TRANSMISSION - reduce roof noise heard inside a building

- SNOW GUARDS on METAL ROOFS

- LIFE EXPECTANCY of METAL ROOFS

- METAL ROOFING - home

- METAL ROOF EXPOSED FASTENER SYSTEM - barn roofing material, installation, fasteners, and for barn roof flashing

Suggested citation for this web page

MODULAR METAL ROOF SHINGLE SYSTEM at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Grapevine Design Guidelines - Web Search 07/12/2010

- Sweetser, Sarah M., ROOFING for HISTORIC BUILDINGS [PDF] (1978) Preservation Brief 4, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source: http://www.nps.gov/history/hps/tps/briefs/brief04.htm

- Park, Sharon C., AIA, THE USE OF SUBSTITUTE MATERIALS ON HISTORIC BUILDING EXTERIORS [PDF] Preservation Brief 16, Technical Preservation Services, National Park Service, U.S. Department of the Interior, web search 9./29.10, original source:

http://www.nps.gov/history/hps/tps/briefs/brief16.htm - Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.