Relief Valve Leaks or Spillage

Relief Valve Leaks or Spillage

Causes & cures for boilers, water heaters, water pressure tanks

- POST a QUESTION or COMMENT about the causes & cures of leaks and discharges from pressure relief valves or TP valves

Leaks at temperature / pressure relief valves:

This article describes the causes of leaks, drips, or discharges from pressure relief valves, temperature/pressure relief valves, or TP valves found on heating boilers, water heaters, or the simpler pressure relief valves found on water pressure tanks.

We list the wide variety of possible TP Valve leaks and how to find and fix each of those problems, including how to fix a leaky pressure relief valve or leaky TP valve on a boiler, water heater, or water tank - what are the possible causes of leaks at these safety devices. Safety Hazard Warnings About Dripping or Leaking Pressure Relief Valves.

How to use an expansion tank to relieve high water pressure. T&P Valves Installed on Gas Sidearm Heaters: special problems. Closed Hot Water System & Thermal Expansion Problems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Leaky or Dripping Water Heater Pressure & Temperature Relief Valves

Watch out: a dripping or frequently spilling T&P valve is dangerous because those very leaks can eventually cause the valve to clog and then to fail to open when it should.

Watch out: a dripping or frequently spilling T&P valve is dangerous because those very leaks can eventually cause the valve to clog and then to fail to open when it should.

If a relief valve becomes clogged and won't open when it should, the result could be a very serious explosion called a BLEVE EXPLOSION.

So if you see water actually spilling or even if it's just dripping at the temperature/pressure relief valve on your heating boiler or water heater, the cause needs to be found and fixed promptly, and it may be appropriate to install a new T&P valve (also called TPR valve) after those repairs are complete.

Here we list the reasons you may see water spilling or dripping out of the relief valve or out of the end of its discharge tube.

Watch out: also, water spilling at a TPR valve can be scalding hot. Someone could get burned.

Article Series Contents

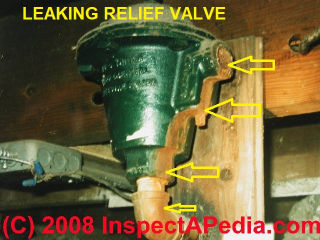

Evidence of dangerous leaks and corrosion at water heater temperature/pressure safety valves

Causes of leaky dripping Pressure/Temperature Relief Valves

Temperature & Pressure Relief valves may open, leak, or drip for a variety of reasons including:

- Boiler limit control problems: On a heating boiler, the boiler temperatures are excessive, possibly due to an improperly set limit control, lack of contact between the limit switch sensor and its mounting well, or a defective control.

See AQUASTAT CONTROL FUNCTIONS and

see BOILER LIMIT SWITCHES - Closed hot water systems: Periodic discharge of the temperature and pressure

relief valve may be due to thermal expansion in a closed

water supply system. Details are

at THERMAL EXPANSION TPR VALVE LEAKS - Gas sidearm heater TP valves: The T&P valve is installed on a sidearm gas heater that is causing an overheat condition at the sensor point of the valve (This thermal expansion is discussed

at GAS SIDEARM COIL SPECIAL PROBLEMS - Expansion tank defects or problems: if the expansion tank or compression tank on a hydronic heating system boiler or on other thermal expansion systems is itself defective (waterlogged, leaky, damaged internal bladder) system pressures will be excessive due to otherwise normal pressure & temperature variations during system operation, resulting in spillage at the relief valve.

See EXPANSION TANKS for diagnosis & repair procedures

See EXPANSION TANK WATERLOGGED, RELIEF VALVE LEAKS for examples of TP valve leaks caused by waterlogged expansion tanks. - Leaks into the heating boiler or water heater: leaks into a heating of water from a higher pressure building source can cause recurrent TP valve leaking. For example, if the tankless coil in a heating boiler is leaky, higher pressure water inside the tankless coil may leak out of the coil into the heating boiler.

Similarly, an internal leak in the heat exchanger coil of an indirect water heater can send water from the water heater's potable water into the coil and thence into the heating boiler.

We describe these leaks into the heating boiler through the tankless coil or indirect water heater coil

at EVIDENCE of TANKLESS INTERNAL COIL LEAK INTO BOILER / WATER TANK

This same leak problem can cause high water pressure in a heating boiler that is used to heat water in an indirect-fired water heater. In that case, a coil containing boiler water (typically at 12-29 psi) that develops a leak may accept higher building pressure water from the building water supply to the indirect water eater tank (or cylinder) that is typically between 20 psi and 70 psi.

Diagnose this problem by observing that when the boiler is left OFF and its own water feeder is left OFF but building water supply is left ON into the tankless coil on the boiler or ON into the indirect water heater, boiler pressure will creep up several hours. With a reader we discuss this possible TP valve leak cause in the FAQs section of this article.

Watch out: under normal conditions, because building water supply pressures are above boiler pressures, an internal leak in the tankless coil or indirect water heater's heat exchanger coil will cause boiler pressures to rise. But there can be exceptions in the direction of water leakage, as we explain

at TANKLESS COIL LEAK DIRECTION IN or OUT - Pressure Relief Valve Defects, or Pressure/Temperature Relief Valve Defects that cause leaks

- Dirt or debris are preventing proper closure of the relief valve valve

- A deteriorated gasket inside the relief valve or corrosion on the valve seat can cause leaking at the valve; we find this mess occurring when someone lifts the "test lever" on a older P/T valve that has not been tested or operated for some time. A brittle piece of gasket can be spit out of the valve and it will then keep leaking.

- The wrong T&P valve has been installed or set to too-low a working pressure. (Proper set pressure is at least 20-30 psi above the working pressure of the equipment to be protected).

- Thermal expansion problems: A closed water system with thermal expansion and no means of relief can cause leaks at the pressure/temperature relief valve, such as

- Can occur on a hot water heater (hot water cylinder, calorifier, hot water tank) with some building piping arrangements, particularly where a check valve or pressure reducing valve are used.

See THERMAL EXPANSION TPR VALVE LEAKS for an explanation of why thermal expansion leaks occur at the relief valve on hot water systems & what to do about it - Can occur also a hot water heating boiler (used for building heating) at which the boiler's thermal expansion tank has become waterlogged or has a ruptured internal bladder.

See EXPANSION TANKS for diagnosis & repair procedures for expansion tanks - Water expansion pressure (thermal expansion) increases in any closed plumbing system, particularly where a check valve installed close to the water heater.

The increase in plumbing system pressure to a level that opens the TP valve is called "thermal expansion pressure".

Watts suggests installing a bypass model water pressure regulator that lets the excessive pressure head back to the street main or building water supply system - a solution that only works if the supply pressure is lower than the T&P relief valve spill pressure - which it usually is.

See THERMAL EXPANSION of HOT WATER for an explanation of thermal expansion when water is heated - A failed thermal expansion tank such as an expansion vessel using an internal bladder after the bladder leaks or has burst, can cause

a RELIEF VALVE LEAK DUE TO EXPANSION TANK failure or defect.

- Can occur on a hot water heater (hot water cylinder, calorifier, hot water tank) with some building piping arrangements, particularly where a check valve or pressure reducing valve are used.

- Water hammer: The building plumbing system suffers from water hammer. Water hammer in buildings causes surging in the water piping that in turn can cause leaks at pressure/temperature or other pressure relief valves, particularly at the pressure safety valve found at water pressure tanks.

See WATER HAMMER NOISE DIAGNOSE & CURE - Water heater temperature too high: The water heater temperatures are excessive. For example on an electric water heater a malfunctioning control can overheat the water e.g. the water heater thermostat is not working properly and is not shutting off the heat source when it should -

see ELECTRIC WATER HEATER THERMOSTATS

and

see ELECTRIC WATER HEATER HIGH TEMP CUTOFF TEST - Water pressure too high: The building water supply pressure is too high or periodically water pressure fluctuates and is too high at times. Pressures over 70 psi in a typical building tend to cause leaks at plumbing fixtures and higher pressures are likely to cause or contribute to leaks at TPR valves.

See WATER PRESSURE VARIATION CAUSES and also

WATER PRESSURE TOO HIGH: DANGERS and see

WATER PRESSURE REDUCER / REGULATOR - Water pressure reducing valve / water feed valve problems: On a hot water hydronic heating system, if the water pressure reducer/feeder valve is not working properly it may over-feed water into the heating system causing overpressure.

See WATER FEEDER VALVE, HYDRONIC BOILER - Combinations of factors causing TP Valve Leaks: OK so this is more than 12 causes of TPR valve leaks, but keep in mind that the temperature/pressure relief valve leak causes listed above can also occur in combination. For example high incoming water pressure alone may not cause a TPR valve to leak but if we add water hammer then the valve may be leaky.

Safety Hazard Warnings About Dripping or Leaking Pressure Relief Valves

Watch out: a dripping or frequently spilling T&P valve is dangerous because those very leaks can eventually cause the valve to clog and then to fail to open when it should.

Watch out: a dripping or frequently spilling T&P valve is dangerous because those very leaks can eventually cause the valve to clog and then to fail to open when it should.

As our photo shows (above left), mineral salts left behind as hot water evaporates from the mouth of a pressure or temperature relief valve can completely clog the spring that is intended to allow the relief valve to open under excess (unsafe) pressure.

The impaction of the relief valve spring with copper and calcium salts in this photo means that the valve is almost certainly not going to open should the heater's internal pressure become unsafe.

The drip shown at the mouth of this relief valve demonstrates that a relief valve can drip and leak for a long time without anyone observing this dangerous condition.

This relief valve needs to be replaced immediately and the cause for the valve's leakage also needs to be determined.

Accidental or deliberately plugged Temperature & Pressure Relief Valves

Watch out: Never remove nor plug a pressure/temperature relief valve. This [water heater pressure/temperature relief] valve must be marked with the maximum set pressure not to exceed the marked maximum working pressure of the water heater.

Install the valve into an opening provided and marked for this purpose in the water heater, and orient it or provide tubing so that any discharge from the valve exits only within 6 inches above, or at any distance below, the structural floor, and does not contact any live electrical part. The discharge opening must not be blocked or reduced in size under any circumstance. [1] [2]

Technical note: why must the TP Valve point "down"? Take a look at the photo above. If a relief valve is dripping the deposit of minerals inside the valve will accumulate still more rapidly if the valve points to the side or upwards. The result is a clogged valve as we explain above - a dangerous situation that risks an explosion.

See BLEVE EXPLOSIONS for an explanation of why a leaky or plugged TPR valve can cause a large catastrophic explosion.

See WATER HEATER SAFETY for our complete list of water heater safety devices and water heater safety inspection advice.

Closed Hot Water Systems & Thermal Expansion Problems - Why is the Water Heater Relief Valve Leaking?

Watch out, serious safety hazards can be caused by dripping at the TP discharge line: often the dripping is caused by thermal expansion of hot water.

For details please see THERMAL EXPANSION TPR VALVE LEAKS - an explanation of why thermal expansion leaks occur on hot water systems & what to do about it

Also see HOT WATER PRESSURE EXPANSION RATE - for an explanation of just how much pressure increase to expect when heating water. In explaining why the relief valve on a water heater may be dripping

T&P Valves Installed on Gas Sidearm Heaters: special problems

Watts Regulator Co. offers this explanation of T&P leak problems that may be encountered on gas fired sidearm heaters. [10]

Question: What would cause an automatic T&P valve to open and close repeatedly when there is very little hot water in the storage tank?

Reply: troubles at the gas sidearm heater

With a sidearm gas heater a common problem is frequent T&P valve opening even though there is very little hot water in the hot water storage tank. That's because an overheated condition exists right at the sensor point of the T&P valve - most of the overheated water is "congested" at the top of the tank.

This problem can be caused by undersized circulation piping between the sidearm heater and the water tank. Undersized piping between the sidearm heater and the tank (supply or return) amounts to a restriction of the circulation area (or volume).

When this "too small" circulation area or volume is combined with a heater whose BTU input rate is higher than that undersized volume can carry, proper circulating does not occur through the tank nor through the sidearm heater coils themselves - the "congestion" referred to above occurs.

In turn this congestion (think of it as a hot water traffic jam) causes overheating right where the T&P valve sensor is located, thus causing the valve to spill hot water repeatedly.

In other words, hot water is accumulating at the T&P valve location rather than being distributed more evenly throughout the hot water tank.

Because there is just a small volume of "too hot" water where the valve is located, the valve opens, spills the small amount of hot water, then is cooled and closes after just a short interval.

To correct this condition install at least 3/4" piping, preferably not iron pipe, in the circulating loop.

[The system we used for years used 1 1/4" diameter copper piping - Ed.] Non-ferrous piping is preferred to reduce the chances of clogging from rust debris - a clue that warns us that even 3/4" piped gas sidearm heaters can clog from rust or scale formation and will then exhibit this problem if the piping is iron.

With an automatic gas storage heater installation, either the heater thermostat is acting abnormally (not shutting off when it should) or stacking temperature conditions are causing this TP leak. - paraphrased & adapted from information from the Watts Regulator Company. [10]

...

Continue reading at THERMAL EXPANSION of HOT WATER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see RELIEF VALVE LEAK FAQs - questions & answers about leaky temperature/pressure relief valves posted originally at the end of this page

Or see these

Recommended Articles

- DRIPPING WATER SOUND SOURCES

- EXPANSION TANK WATERLOGGED, RELIEF VALVE LEAKS

- HOT WATER EXPANSION TANKS

- RELIEF VALVES - TP VALVES - home

- RELIEF VALVE DISCHARGE TUBE

- RELIEF VALVE LEAKS

- RELIEF VALVE LEAK DUE TO EXPANSION TANK

- RELIEF VALVE, TP VALVE, BOILER

- RELIEF VALVE, TP VALVE, STEAM BOILER

- RELIEF VALVE, TP VALVE TEST

- RELIEF VALVE, WATER HEATER

- RELIEF VALVE, WATER TANK

- TUNDISH used in PLUMBING

- WATER HEATER PRESSURE-ONLY RELIEF VALVES

- THERMAL EXPANSION of HOT WATER

- WATER HEATER LEAK REPAIR

Suggested citation for this web page

RELIEF VALVE LEAKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to T&P RELIEF VALVES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "T&P and ASME Safety Relief Valves", (2011), retreived 10 Dec 2012, original source: http://media.wattswater.com/PG-TP-ASME.pdf,

Watts Water Technologies, No. Andover MA, USA, 978-688-1811, Website: www.watts.com,

Watts Water Technologies, Burlington ON, Canada, Tel: 905-332-7068, Website: www.wattscanada.ca - [1] "Residential Electric Water Heater Installation Instructions and Use & Care Guide", American Water Heater Co., October 2001, American Water Heater Co., Johnson City, TN, [manufacturer of residential & commercial water heaters, also manufacturer of Polaris/Commercial water heaters], Tel: 800-999-9515, web search 1/12/2012, original source: americanwaterheater.com/support/manuals/res-elect.pdf [copy on file] [Technical review requested 1/25/2011]

- [2] ANSI Z21.22 - 1986, provides requirements for pressure/temperature relief valves and automatic shutoff devices for hot water supply systems

- [3] Pounds of lime deposited vs. temperature and hot water usage: see Purdue Bulletin #74 (also provided by A.O. Smith in the article below). Purdue's chart shows the number of pounds of lime deposited per year as a function of the water usage in gallons per day, with an assumed 10 grains of water hardness.

- [4] "When, Why, and How to Remove Water Scale from Tank Type Glass-Lined Water Heaters (for non glass-lined tanks, consult water heater manufacturer)" PDF provided by A.O. Smith Water Products Company - hotwater.com/lit/training/4800r9.pdf 800-433-2545 - 01/07/2009.

- [5] A.O. Smith's Form No. 4800 Rev. 8 Why? When? & How? /UN•LIME Specific De liming Instructions for use with Up-N-Down Transfer Kit for Tank Type Heaters. (Normally supplied in UN-LIME shipping cartons), Supersedes Form Nos. 4800 Rev. 7 and 4813-100.

- [6] A.O. Smith's Form No. 4778* All about Deliming Coil-Type/Tube-Type Commercial Water Heaters and Hydronic Boilers *Normally supplied when ordering Part No. 4930 Motorized Deliming Pump Kit

- [7] "Building Owner Water Heater Safety Notice", Building Department, City of Colleyville TX, web search 09/24/2010, original source: http://www.colleyville.com/dmdocuments/Building%20

Owner%20Water%20Heater%20Safety%20Notice%203-6-102.pdf

Quoting:

Water heater safety is imperative to the occupants of a building or structure. If improperly installed, water heaters can be detrimental to the structure, as well as being potentially fatal to its occupants. The proper installation of a water heater is so important that according to Texas State Law all water heater installations must be inspected by a state licensed plumbing inspector. - [8] Rheem Electric Water Heater "Owners Guide and Installation Instructions", (Australian models) rheem.com.au/images/pdf/owners_dom-elec_121996C_0707.pdf

- [9] Watts, 815 Chestnut Street, North Andover, MA, USA 01845-6098, web search 09/18/2010 original source: http://www.watts.com/pages/learnAbout/reducingValves.asp?catId=64

- [10] 52 Questions and their Answers [about] Hot Water [Heaters, Explosions & Water Heater Safety], Watts Regulator Company (1973)

- [11] "Four hurt as water heater explodes", Elaine Porterfield, Paul Shukovsky, Lewis Kamb, Seattle Post Intelligencer, 28 July 2001, web search 25 Sept 2010, original source: http://www.seattlepi.com/local/33094_boom28.shtml

Quoting from the original news article:

The powerful blast occurred at 10:23 a.m. at Plaza Zacatecas -- a small strip mall that includes four Mexican American-run businesses: a video store, a butcher shop, a Mexican restaurant and a shop that sold clothing and other items. ... The steam-powered tank hurtled across the busy intersection at First Avenue South and South 152nd Street -- over at least six lanes of traffic -- before landing more than 439 feet away in the parking lot of a Pizza Hut. ... The tank then tumbled another 25 feet before coming to rest. Four people were injured in the blast. Three were treated and released from a local hospital, but one woman was admitted to Harborview Medical Center with second-degree burns to her arm. - [12]

Water heater rocket myth: Mythbusters water heater explosion video produced in 2007, web search Sept 25 2010, original source:

http://www.youtube.com/watch?v=JmJoyuUJj2Q

Website: http://dsc.discovery.com/tv/mythbusters/

Quoting from Mythbusters: (Discovery Communications,

In small scale testing, the Mythbusters started with a small six gallon water heater and disabled all of its safety features under the theory of poor installation or neglect. While the water heater eventually ruptured, it did not explode like a rocket. The Mythbusters then upgraded to larger thirty gallon water heater which exploded with significantly greater force, sending the water heater several hundred feet into the air. In order to confirm the stated myth, the Mythbusters obtained a full size fifty two gallon water heater and built a shack around it with a roof that followed standard California building codes. The water heater eventually exploded, shooting through the roof five hundred feet into the air and disintegrating the shack. In light of these results, and the fact that there is documented evidence corroborating the myth, the Mythbusters deemed it confirmed. - [13]

Water heater video #2, Mythbusters exploding water heater demonstration, a 50 gallon water tank explosion

http://www.youtube.com/watch?v=0rXwcDkobUY&feature=related

http://www.waterheaterblast.com/

Because of built in safety devices most water heaters safely operate day in, day out without any major problems. But don't let the excellent safety record of water heaters lull you into forgetting about the explosive potential of these marvels of convenience. When a water heater explodes, it releases a tremendous blast force which can easily demolish a building.

Randall Hilton and crew, with help from the Service Roundtable has prepared this video of a water heater explosion as a demonstration of the explosive power of a simple water heater. The hot water tank explodes using the steam pressure that any water heater can generate when the thermostat and temperature pressure relief valve (T&P valve or PT valve) malfunction. We were impressed by how far the tank flew after the water heater exploded. Click on the links below to view the video. Then, visit the Q&A page for warning signs as well as simple steps which can help you prevent your own water heater from exploding. - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.