Sources of Carbon Monoxide CO Gas

in Buildings

Sources of Carbon Monoxide CO Gas

in Buildings

Visual Inspection, Testing, Standards

- POST a QUESTION or COMMENT about testing for dangerous levels of carbon monoxide (CO) gas in buildings including warnings about relying on test instruments

How to perform a visual inspection to check for carbon monoxide hazards:

This article lists visible carbon monoxide gas hazards in buildings: things that you can see during a visual inspection that mean increased risk of carbon monoxide gas (CO) release and poisoning.

This text intends to assist readers in understanding these topics. However it should not be considered complete nor authoritative (no single article is satisfactory); we include additional advice and safety warnings about testing for dangerous carbon monoxide in buildings.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Guide to Inspecting buildings for Visible Evidence of Conditions Likely to Produce Dangerous Carbon Monoxide Gas

IF YOU SUSPECT CARBON MONOXIDE POISONING GO INTO FRESH AIR IMMEDIATELY and get others out of the building, then call your fire department or emergency services for help. Links on this page also direct the reader to carbon dioxide gas information in a separate document.

IF YOU SUSPECT CARBON MONOXIDE POISONING GO INTO FRESH AIR IMMEDIATELY and get others out of the building, then call your fire department or emergency services for help. Links on this page also direct the reader to carbon dioxide gas information in a separate document.

Seek prompt advice from your doctor or health/safety experts if you have any reason to be concerned about exposure to toxic gases.

[Click to enlarge any image]

Carbon monoxide poisoning can be fatal but exposure at lower limits can produce flu-like symptoms and headaches that are often mistaken for ordinary illness.

The fact that you cannot see nor smell dangerous carbon monoxide gas does not mean that there is nothing to look for when assessing the safety of heating equipment. Not only are there easily spotted installation errors (the first list below), there may be more subtle but easily visible errors if you know what to look for (the second list below).

Discussed here: How to inspect buildings where carbon monoxide gas is suspected. List of building defects or conditions likely to create carbon monoxide hazards. List of building conditions likely to create combustion appliance backdrafting.

Testing for Carbon Monoxide presence in buildings. Carbon monoxide hazards in buildings: a visual guide to inspecting for CO leak risks. Two quick combustion air requirement rules of thumb: Definitions of the "rule of 50" and the "rule of one inch per 1000 BTUs".

Visible building conditions risking increased carbon monoxide hazards

This is by no means the complete list of errors that can cause dangerous carbon monoxide exposure in buildings, but here are some common foul ups outside of the workplace that can cause dangerous levels of indoor carbon monoxide:

- Backdrafting heating equipment:

inadequate draft, or inadequate combustion air are likely to cause dangerous carbon monoxide poisoning or backdrafting/leakage of flue gases into the building or both.

See BACKDRAFTING HEATING EQUIPMENT - Car exhaust,

such as to occupants of rooms adjoining or even above a garage where car engines are left running in an attached or "underneath" garage.

Even with the garage door open a carbon monoxide hazard could be present as reader Artie reports in this anecdote:

A home owner was doing vehicle repairs with the car engine running in an attached garage. The garage door was wide open.

But experiencing headache ,nausea and ill-feeling with-in a few minutes and luckily before becoming unconscious the "repairman" called his wife who him to a nearby hospital emergency room.

He was suffering CO poisoning even though the garage door was open. A windy backdraft had allowed a CO buildup and a dangerous situation.

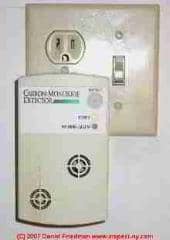

Also see "Garage carbon monoxide hazards & CO Detectors" found below on this page. - CO Detectors

missing or improperly installed.

- Coalstoves:

We have found, observed, measured high levels of CO production at coal stoves, particularly when running at lower heat levels. If the coal stove is properly vented the carbon monoxide hazard may not be detectable in the building but changing conditions such as closing a flue damper might change that picture.

See CHIMNEY FIRE ACTION / PREVENTION

The coal stove shown in our photo (left) was sufficient to heat the entire home in even the coldest winter. But it was an improper and illegal installation because it shared its flue with a gas-fired heating boiler located in the basement below.

The owners made sure that when the coal stove was in use the gas fired boiler would never operate - it was switched off and a basement flue damper was closed to assure good draft in the chimney.

But we could not safely assume that future owners of the building would take those steps. Before the home was sold to a new owner the coal stove was removed, the opening in the brick flue was closed with bricks and mortar, and the basement boiler controls were returned to normal operation.

See details at SHARED CHIMNEY & FLUE HAZARDS.

- Chimney defects:

Unsafe chimneys, including chimneys that are blocked, leaky, or the wrong size risk flue gas leaks into the building and carbon monoxide hazards. A chimney that is too short can fail to vent properly too: if a chimney is "short" it does not develop sufficient draft.

Example: once we get 15 feet of chimney heated up, a 15 foot column of rising air in that flue gives a much stronger updraft than a 5 foot column of rising air in a 5 foot chimney. Once the flue gases have left the top of the chimney they dissipate and are no longer "pulling" in at the chimney bottom. Also see our note about flue sizes below.

CHIMNEY INSPECTION GUIDE contains detailed suggestions for inspecting building chimneys including the detection of blocked chimney flues or indications that a chimney may be blocked or otherwise unsafe.

Our chimney photo (above left) shows rooftop chimney designs by Gaudi and found on his apartment building in Barcelona, Spain. - Exhaust fans:

measurements of heating appliance performance and tests for carbon monoxide should be taken under the "worst-case" conditions likely to occur in a building. For example, turning on a whole house exhaust fan can cause backdrafting that may otherwise not be present.

Also

see INDOOR AIR QUALITY & HOUSE TIGHTNESS - Fireplaces:

Fireplaces can be significant sources of CO in buildings, especially when the fire is just smoldering, and more so if an enclosed-type glass fire screen is not installed.

Fireplaces can also cause negative pressure increasing the likelihood of back-drafting at gas-fired appliances elsewhere in the building. - Thanks to reader Thomas Gowen for this suggestion. - Flue size or flue vent connector piping diameter mismatch:

while an under-sized flue or any blockage in the chimney or flue vent connector are obvious causes of flue gas spillage in a building, a flue that is too large can also be a source of carbon monoxide production and spillage.

For example, we investigated a building in which a single gas fired water heater was vented into an old brick masonry chimney. The water heater never was able to warm the large chimney enough to create an updraft and every winter all of the heater combustion gas ended up spilling into the home. - Thanks to reader Thomas Gowen for this suggestion.

Watch out: we have observed flue vent connectors that have been left off or have fallen off of heating appliances, creating a deadly carbon monoxide hazard.

At an early morning winter inspection we [DF] broke into a locked home by desperately kicking in a window after we had noticed through a basement window that the gas fired furnace was running and the flue vent connector had fallen off.

Having been told that the owners were at home (but apparently asleep) and fearing the worst we rushed through the house. Happily no one was at home.

See FLUE SIZE SPECIFICATIONS

and FLUE VENT CONNECTORS, HEATING EQUIPMENT for a detailed list of those hazards. - Garage carbon monoxide hazards & CO Detectors

Special thanks to reader R.W. for these suggestions:

Watch out: Running an internal combustion vehicle inside an attached garage kills people from CO poisoning. The CO molecule is very small and capable of penetration through inapparent cracks or other openings.

Watch out: a CO detector cannot be used reliably in a garage:

Residential carbon monoxide detectors are not designed or approved to operate in garage conditions. Temperatures and humidity variations are too large, and the high start-up amounts of carbon monoxide can easily damage or destroy the sensing cell. CO detectors should never be placed or used in the garage.

- source: Iowa State Univesity, CARBON MONOXIDE POISONING: GARAGES (AEN-207) [PDF] (1998) Iowa State University, Department of Agricultural and Biosystems Engineering 1340 Elings Hall 605 Bissell Road Ames, IA 50011-3270 USA Website: https://www.abe.iastate.edu/ Email: abe@iastate.edu TekL 515-294-1434 - retrieved 2021/06/30, original source: https://www.abe.iastate.edu/extension-and-outreach/carbon-monoxide-poisoning-garages-aen-207/

Garage wall sealant to reduce CO hazards?

We have found no data suggessting that this is an effective measure;

How should you protect against carbon monoxide from the garage?

- Comply with local building and safety codes including having the proper fire door between house and garage

- Never leave a vehicle running inside of a garage; even with the garage vehicle door open there can be fatal CO poisoning hazards. (It's fine to run the vehicle long enough to drive it out of the garage but don't leave it running while waiting for a passenger, loading, unloading, or any other purpose.)

The American Lung Association suggests building a detached garage. Other possible solutions include: tightly sealing walls and doors to the house, or using an exhaust fan in the garage.

The principal methods to protect building occupants from CO from the garage include the following:

Install CO detectors in the building at proper locations, and test them regularly

Never run a vehicle in the garage any longer than the time required to move it out of the garage

Assure that the passage door between garage and building is the proper type: self-closing, sealed, and that it closes fully. (Don't leave the door propped open).

See details at GARAGE DOOR & DOOR OPENER SAFETY

- Gas fired central heating equipment combined with:

- Improper venting, blocked, under-sized, over-sized, missing parts, improperly sloped chimney or flue. A variety of errors can cause a failure to vent combustion gases out of the building, allowing dangerous flue gases to build up indoors.

- inadequate combustion air. If a heating appliance is installed in a small confined space it must be provided with outside combustion air. A service technician may tune and inspect a gas-fired boiler with the boiler room door open, finding that it seems to operate fine. When s/he closes it on leaving, there may be an inadequate or no opening for combustion air into the room.

- Venting small appliances into large cold chimneys: Installation of small, higher efficiency gas-fired equipment into old homes at which the appliance is vented into a large (cold) masonry chimney. In such instances the heater may never develop sufficient heat and draft to actually vent up the chimney.

- Also sometimes water heaters are left venting into a too-large, too-cold masonry chimney after a gas-fired boiler is converted to a high-efficiency direct-vent (no chimney) unit. One of my clients developed headaches every October - an event I traced to this condition in Poughkeepsie, NY. [DF re E.B. case 1988]

- Space heaters: improper use of gas or kerosene fired heaters can produce high indoor CO levels. Warning: Never go to sleep in an enclosed space with a space heater left operating. In addition to the CO hazards there is a risk of oxygen depletion which can also lead to asphyxiation. Also see Unvented heaters, below.

- Tight House conditions:

even if previously there were no backdrafting or CO problems at a building, retrofits to improve the energy efficiency of a home can change its air leakage rate and might lead to backdrafting.

See INDOOR AIR QUALITY & HOUSE TIGHTNESS. In a Best Practices design, all vented combustion appliances should have their own combustion air supplies.

See COMBUSTION PRODUCTS & IAQ. Atmospherically vented gas appliances such as heaters and water heaters pose special problems because if they backdraft there is little warning and the possible production of carbon monoxide can put lives at risk.

See COMBUSTION GASES & PARTICLE HAZARDS.

Also see VENTILATION, WHOLE HOUSE STRATEGIES. - Unsafe models of heating equipment: for some examples

see SAFETY RECALLS CHIMNEYS VENTS HEATERS - warning: this is not an exhaustive list

- Un-vented heaters or space heaters

Un-vented heaters or space heaters, such as "vent-free" fireplaces or gas-log fireplaces. Un-vented appliances are in stunningly wide-spread use and we [DF] found it interesting to read that for at least some "un-vented" gas log fireplaces even the installation instructions specified a requirement for outside combustion air and venting.

Modern versions of un-vented heaters usually include a sensor that is intended to put out the fire if the oxygen level falls too low. That approach may not detect CO production at all. In this home in Mexico (photo above left) we observed that it was impossible to operate the gas-log fireplaces without the CO detector alarm sounding even when the carbon monoxide sensor was placed more than 20 feet away from the fireplace.Incidentally, CO detectors should be installed about 10 feet away from woodstoves, pellet stove, coal stoves, and gas log fireplaces. Not 20 feet as we did.

- Utility rooms too small: placing into an enclosed utility closet or other confined space one or more gas fired appliances whose BTU rating is too high for the space is likely to cause dangerous production of carbon monoxide.

A rule of thumb, the "Rule of 50"

suggests that we need 50 cubic feet of space per 1000 BTUH or we need to provide outside combustion air [a better approach anyway]. - Thanks to reader Thomas Gowen for this suggestion.

Another rule of thumb, the Rule of 1" per 1000 BTUH

is used by some heating service techs: for oil fired heating appliances we need about one square inch of combustion air intake (from an unlimited source such as outdoors) for each 1000 BTUH of heater capacity. That square inch is counted before an allowance for the impeded airflow caused by screening or louvers that may be placed over the air intake.

Watch out: depending on variations in building air-tightness, the "Rule of 50" or the "One Inch Rule" may not be enough space in some circumstances. - Water Heaters: Un-vented gas fired water heaters, often found venting directly into a basement utility room or even directly into a living area or bedroom.

- Woodburning fireplaces and stoves, especially improperly installed, risk not only fire hazards but backdrafting hazards.

Also see WOOD-OIL COMBINATION HEATERS and see our notes above at Fireplaces.

Your coal stove, wood stove, or pellet stove should be professionally installed and inspected for code compliance and safety. Most comm unties require a building permit for stove installation. - CONTACT us by email to suggest additions to this list.

Other clues which can suggest a risk of carbon monoxide hazards in buildings

- CO detector alarms

Do not ignore this first line of defense. Install CO detectors near the heating equipment as well as in sleeping areas of the home. People have died after not believing their CO detector and taking out the batter to silence the annoying device which they believed was malfunctioning. - Missing heating equipment parts:

Gas fired water heaters, furnaces, boilers which are missing flue vent connector components such as draft hoods and flue gas spill detection switches - it can be difficult to spot that something is missing unless you know what's supposed to be there. Review this topic with a trained heating service technician or plumber. - Clogged heater draft hood

from hair or other debris - Signs of flue gas spillage

Blocked flues will result in combustion gas spillage back into the building. Often this will cause:- Rust on heating equipment at the point of flue gas spillage - you can detect this even when the equipment is not operating

- Rusty debris on the top of gas fired heating equipment below the draft hood

- Water condensation on building surfaces may occur if gas-vented appliances are venting back into the building, especially on cool basement surfaces - you can only observe this when the equipment is operating

- Odors of combustion products: while CO and CO2 are themselves odorless, if they are spilling from heating equipment, odors of other combustion products may be notices.

Testing for Carbon Monoxide

In addition to the installation of CO monitoring alarms in buildings, a variety of electronic and gas sampling equipment is available to make spot checks for hazardous gases. We have and have used a variety of these devices under a wide range of conditions.

Watch out: While a "positive" indication of a gas such as carbon monoxide is an important indicator of a hazard, a "negative" or "not found" result is nothing to rely on.

The fact that dangerous levels of CO are not present in a building at a particular instant is absolutely no guarantee that dangerous levels of CO (for example) may not occur even moments later. For example, opening a window, turning on a fan or clothes dryer, closing a door, and similar innocent acts can significantly change air flow, combustion air, and other building conditions.

Therefore spot tests for dangerous gases should not be relied upon to guarantee building safety.

This is why the list of visual inspection items and proper heating equipment maintenance are so important.

Suggestions and content additions are invited. CONTACT US with items to add to these lists.

CARBON MONOXIDE WARNINGS: HOME HEATERS - CPSC Release 88-92

CHIMNEY INSPECTION GUIDE contains detailed suggestions for inspecting building chimneys including the detection of blocked chimney flues or indications that a chimney may be blocked.

Effects of Carbon Monoxide Gases CO that may be mixed with Warm Flue Gases

Similarly, although a gas may be rated as "heavier than air", an inexpert building inspector or hygienist who tests for such gases only "low" in the building could be making a dangerous mistake.

Carbon monoxide gas, when produced by a heating appliance, will typically be mixed in with other combustion products and will be released as part of warm or hot flue gases that should be venting up a chimney. Therefore testing even for a heavy gas, if it may be mixed with hot flue gases, needs to include testing high in indoor spaces, not just down by the floor.

For this reason, if you call a fire department or emergency worker to test a building for the presence of a dangerous gas such as flue gases, leaks in natural or LP or propane gas lines or equipment, or carbon monoxide levels, even if the worker detects no gas leak present at the time of the inspection that is not a guarantee that the building is safe.

What should you do about this gas test reliability problem? Where there are reasons to be concerned about unsafe gas levels in a building, a more thorough building investigation is in order. Such an investigation includes at least

- Taking a history of building related indoor air or safety or gas leak complaints

- A visual inspection of the entire building for possible conditions that could produce or hide a dangerous gas leak, such as the condition of chimneys, vents, heating equipment and appliances as well as building fans and ventilation systems.

- Tests for the presence of leaking chimneys, flues, appliances, gas piping etc. These may include introducing of a tracer gas into heating equipment to test for leaks in a heat exchanger or flue.

Safety Warnings About Using a Gas Detection Device to Check for Carbon Monoxide in buildings

In general, we should never detect the presence of carbon monoxide or "CO" in buildings beyond a possible brief and insignificant "belch" of gases from the draft hood of some heating appliances during appliance start-up when chimneys and vents are cold. In other words there should never be a continuous release of flue gases nor a stream of even low levels of CO in a building.

Watch out: Testing for any gas in a building by relying solely on test instruments can be dangerously misleading.

False positive gas test results:

The TIF8800 or other equipment that can detect CO can detect very low levels of flue gas or combustible gases or carbon monoxide. But instruments such as the TIF 8800 that are not specifically designed for CO will also respond to other substances that are miscible in air.

Dangerous gas detection instruments work best in the hands of a very experienced building investigator and instrument user.

False negative results:

any gas detection instrument is vulnerable to variations in building conditions or in the operation of mechanical systems in the building that can temporarily hide the presence of a dangerous gas leak. For example, a leaky heat exchanger in a heating furnace may leak detectable gases into the warm air plenum only until the blower fan comes on. Changes in building pressures, open or shut windows or doors, fans on or off, and other such variables can completely change the detectable presence of a dangerous gas indoors.

See GAS DETECTOR WARNINGS for additional recommendations.

Safety Suggestions: Install Carbon Monoxide Detectors in addition to Smoke Detectors

Carbon monoxide detectors are inexpensive and readily available, both as a battery-operated unit and as a unit that plugs into an electrical outlet in the home. No home should be without this safety protection, and homes with gas-fired equipment (natural gas or LP propane), space heaters, or other sources of risk should be extra cautious. S

moke detectors do not protect against carbon monoxide poisoning, and the opposite is also true. Carbon monoxide detectors do not warn of smoke or fire.

References & Research on Carbon Monoxide Testing at Heating Systems

- COMBUSTION ANALYSIS BASICS[PDF] "An overview of measurements, methods, and calculations used in combustion analysis", TSI Inc., offices in China, Germany, Sweden, The United Kingdom, the United States, in the U.S. Tel: 1-800-874-2811, Website: www.tsi.com, in the U.K. tel +44 1275 847837, retrieved 2017/03/14, original source: http://www.tsi.com/uploadedFiles/_Site_Root/Products/Literature/Handbooks/CA-basic-2980175.pdf

- "CO and COMBUSTION RATIO CHECKS using an Electronic Combustion Gas Analyser (ECGA) when commissioning a condensing boiler incorporationg air/gas ratio control valve technology", Technical Bulletin No. 143 [PDF] Developed with HHIC, retrieved 2017/03/14, c original source: http://www.centralheating.co.uk/system/uploads/attachments/0000/5417/TB_143_-_CO_and_Combustion_Ratio_Checks_-_Boiler_commissioning.pdf

...

Continue reading at CO ALARM CAUSES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CARBON MONOXIDE INSPECTION FAQs - questions & answers about CO posted originally on this page

Or see these

Carbon Monoxide Gas Articles

- CARBON MONOXIDE - CO

- CARBON MONOXIDE WARNINGS: HOME HEATERS

- GAS DETECTION INSTRUMENTS

- GAS EXPOSURE EFFECTS, TOXIC

Suggested citation for this web page

CARBON MONOXIDE INSPECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS HAZARDS in BUILDINGS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.