Evaporation-Transpiration & Evapo-Transpiration Absorption Septic Systems

Evaporation-Transpiration & Evapo-Transpiration Absorption Septic Systems

- POST a QUESTION or COMMENT about evaporation-transpiration and evaporation transpiration absorption septic systems for disposing of septic effluent and wastewater

Evaporative Septic or Transpiration Septic system design alternatives:

This article discusses the selection, design, installation, inspection, repair, and maintenance of Evaporation-Transpiration & Evapo-Transpiration Absorption as Alternative Septic Systems, also called Evapotranspiration Septic Systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Evaporative Septic Systems Design Specifications

We include information from both state (New York) and federal (US EPA Wastewater Treatment Manual) sources as well as the advanced Tafgard™ evaporation/transpiration wastewater treatment system design by Taisei Kogyo Co., Ltd., Japan.

Evaporation - transpiration septic or effluent disposal systems may be selected for wastewater treatment and disposal at difficult sites. We also provide lists of product sources or specialists in this field. (Listings can be added here at no fee.) Citation of this article by reference to this website and brief quotation for the sole purpose of review are permitted. Use of this information at other websites, in books or pamphlets for sale is reserved to the author. Technical review by industry experts has been performed and is ongoing - reviewers welcomed and are listed atReferences or Citations .

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Evaporation-Transpiration (ET) and Evapo-Transpiration Absorption (ETA) Septic Systems Design Criteria

Evaporation-Transpiration (ET) Septic Systems, and Evapo-Transpiration Absorption Septic Systems (ETA) dispose of septic effluent from the septic tank by providing

a surface area intended to allow the effluent to evaporate. ET systems depend entirely on evaporation while ETA systems

make use of both evaporation and (limited) soil absorption of septic effluent.

Evaporation-Transpiration (ET) Septic Systems, and Evapo-Transpiration Absorption Septic Systems (ETA) dispose of septic effluent from the septic tank by providing

a surface area intended to allow the effluent to evaporate. ET systems depend entirely on evaporation while ETA systems

make use of both evaporation and (limited) soil absorption of septic effluent.

The ETA gravel bed system shown in the center of our septic evaporation/transpiration system (left) was observed in the Hudson Valley, New York state and appears to be using evaporation to help dispose of septic effluent from a private onsite septic system.

If you click to enlarge the photo you 'll see a local storm drain basin at the far end of the graveled area.

The storm drain catchbasin receives runoff from the paved street and nearby storm drains. We worried that the added water draining absolutely adjacent to the septic effluent evaporation bed will reduce the effectiveness of that system, particularly when in the foreground-left we see that the area includes intermittent rocky shale close to and even above the ground surface.

An inspection of older residential properties down-slope from this relatively new neighborhood confirmed that once dry grassy lawns were a sodden, smelly mess, and we suspected that older properties were now receiving sewage effluent and storm drain runoff from the neighborhood shown here.

Watch out: don't pave-over nor drive over the septic fields or you may destroy the system.

See DRIVING OVER SEPTIC SYSTEMS

The following is from:

- New York - Appendix 75-A.9 - ALTERNATIVE SEPTIC SYSTEMS [Regulation and System Design Criteria for Raised Septic Systems, Septic Mound Systems, Intermittent Sand Filter Bed Systems, Evaporation-Transpiration Septic Systems, Evaporation-Transpiration Absorption Septic Systems, and Other Alternative Septic Systems] Effective Date: 12/01/1990

[Regulation and System Design Criteria for Raised Septic Systems, Septic Mound Systems, Intermittent Sand Filter Bed Systems, Evaporation-Transpiration Septic Systems, Evaporation-Transpiration Absorption Septic Systems, and Other Alternative Septic Systems]

Effective Date: 12/01/1990

(1) Evaporation/Transpiration/Absorption Septic Systems - General

(1) Evaporation/Transpiration/Absorption Septic Systems - General

ET systems rely on the upward movement of moisture through the soil, surface vegetation and into the air rather than absorption into the soil. ETA systems also use the absorptive capabilities of the soil and are less dependent on evaporation and transpiration.

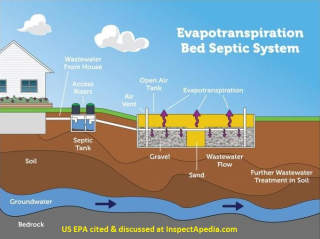

Illustration: Evapotranspiration bed septic system schematic, Image source: - U.S. EPA, Types of Septic Systems, retrieved 2019/04/22 original source: https://www.epa.gov/septic/types-septic-systems

(2) Site Requirements for Evaporation, Transpiration-Absorption Type Septic Systems

(i) All systems previously discussed, except intermittent sand filters, have been determined to be unacceptable for the planned building site.

(ii) An expansion area equal to or greater than 50% of the required basal area shall be available on the site.

(iii) All minimum vertical and horizontal separation distances can be maintained as described in Table 2 from both the edges of the basal area and the designated expansion area.

(iv) An environmental assessment determines that the development of the site with this system is consistent with the overall development of the area and will cause no adverse environmental impacts.

(3) Design Criteria for Evaporation, Transpiration-Absorption Type Septic Systems

(i) The designer must consider all of the items listed below and be able to document from reliable sources (i.e., National Weather Service, Soil Conservation Service) the parameters used and show that the net outflow from the system exceeds the inflow without the exposure of sewage or partially treated sewage on the surface of the ground:

Total rainfall and snowfall.

The percentage of the rainfall and snowfall that will infiltrate into the soil and the percentage that can be expected to runoff the system.

The annual land evaporation rate of the area.

The vertical rise of water than can be expected in the soil due to capillary action.

The amount of transpiration expected from the surface vegetation.

The permeability of the underlying soil and the impact the system will have on the groundwater level.

(ii) The design must provide for a trench depth that is not greater than 30 inches below the surface.

(iii) Pressure distribution of effluent throughout the system is required.

Volume: A-1a

Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

Onsite Wastewater Treatment Systems Technology Fact Sheet 6 - EPA 625/R-00/008

Description of Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

Onsite evapotranspiration wastewater treatment systems are designed to disperse effluent exclusively by evapotranspiration. Evapotranspiration (ET) is defined as the combined effect of water removal from a medium by direct evaporation and by plant transpiration. The evapotranspiration/infiltration (ETI) process is a subsurface system designed to dispose of effluent by both evapotranspiration and infiltration into the soil. Both of these systems are preceded by primary pretreatment units (e.g., septic tank) to remove settleable and floatable solids.

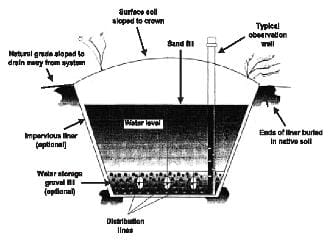

The influent to the ET or ETI units enters through a series of distribution pipes to a porous bed. In ET systems, a liner is placed below the bed to prevent water loss via infiltration unless the soil is impermeable. The surface of the sand bed is planted with water-tolerant plants.

Effluent is drawn up through fine media by capillary wicking and evaporated or transpired into the atmosphere. In ETI systems, effluent is allowed to percolate into the underlying soil.Modifications to ET and ETI systems include mechanical evaporating devices and a broad array of different designs and means of distribution, storage of excess influent, wicking, and containment or infiltration prevention. Some newer studies are using drip irrigation with distribution to forested areas with purported success.

Tafgard Soil-Based Evaporation Transpiration Systems

[Click to enlarge any image]

Tafgard soil based wastewater treatment systems - developed in Japan by Taisei Kogyo Co., Ltd., this system uses a combination of a five-chamber waste treating septic tank designed by Taisei, effluent disposed-of by an evaporation-transpiration system through a Tafgard geotextile and aerated soil (effluent spread horizontally and upwards from distribution piping). The Taisei septic tank utilizes a chain of bacteria, protozoan, metazoans and various kinds of enzymes.

Illustration (above) of the Tafgard soil based evaporation transpiration system using Tafgard geotextile over effluent distribution piping is courtesy of Taisei Kogyo Co., Ltd.

Consequently, the developer asserts, sludge does not increase, thus it does not need to be desludged, minimizing the maintenance cost. The longer the food chain becomes, the more energy is consumed by respiration. We pose that tank cleaning will in fact probably be needed, but apparently at a much less frequent interval than other less sophisticated treatment systems.

This design uses no pumps or electrical power, and is described as most suited for homes, mountain lodges and public toilets in remote areas, such as beaches, national parks, ski resorts and campgrounds where there is no electric power source, or where there is no place to discharge effluent.

Typical applications of Evapotranspiration and Evapotranspiration / Infiltration Systems for Septic Effluent Disposal

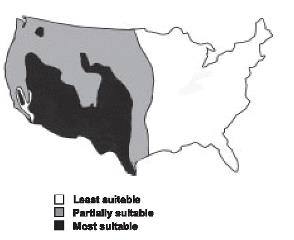

ET and ETI systems are best suited for arid (evaporation exceeds precipitation) climates. If ETI is selected, soil percolation is also an important consideration. Both systems are often selected when site characteristics dictate that conventional methods of effluent disposal are not appropriate (e.g., unprotected sole source aquifer, high water table or bedrock, tight soils, etc.).

Although these systems normally follow septic tanks, additional pretreatment may be employed to minimize clogging of the ET/ETI system piping and media. They are sometimes used as alternative systems during periods when normal disposal methods are inoperable, for example, spray or other surface irrigation.

Also, these systems have been widely used for seasonal homes in areas where year-round application of ET/ETI is not practical and conventional methods are not feasible.

Year-round ET systems (see figure 1) require large surface areas and are most feasible in the areas shown on figure 2.

ETI systems can be employed to reduce the infiltrative burden on the site during the growing season. Such applications can also result in some reduction in nutrients, which are transferred to the overlying vegetation (USEPA, 1999).

Figure 1. Cross section of a generic evaportranspiration bed (adapted from NSFC)

Figure 2. Relative suitabilityof Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

Design assumptions & calculations for septic evaporation transpiration systems

The design evapotranspiration rate is site specific. Some areas are arid (precipitation < evaporation) but lack the solar radiation or wind velocities necessary to efficiently evaporate wastewater throughout the year. Therefore, simple use of well-known evaporation estimates like Pentman, Blaney-Criddle, and Jensen-Haise will not likely be satisfactory.

In fact, historically, the definition of workable ET rates for an area has been a trial and error process, which is further complicated by the system design and the plants used. The primary variables that have an impact on the potential ET rate are climate, cover soil, and vegetation.

The most important system variables, which control the movement of wastewater to the surface, are media and the depth to saturated (stored) water. Most published designs are suspect because they store the wastewater so deep that the wicking properties of the fill and the area (voids) through which water must rise restrict delivery of water to the surface where it is evaporated.

Present ET system designs normally employ 20-mil polyethylene liners where the soil is too permeable and ground water contamination is likely. Most employ distribution systems placed in 12 inches of gravel (0.75 to 2.5 inches) at the bottom of the bed.

Spacing of the distribution pipes is 4 to 12 feet, with lower values preferred for better distribution. Wicking is accomplished by a 2- to 2.5-foot layer of sand (0.1 millimeter) and a loamy soil-sand mix to raise the water to the surface or a thin layer of soil at the surface. Most have employed the formula:

A = nQ/ET - P

where:

A = surface area required to evaporate the wastewater

n = coefficient, which varies from 1 to 1.6

Q = annual flow volume

ET = annual evapotranspiration rate

P = annual precipitation rate

Each of these factors is open to some degree of interpretation. Because these systems are large and expensive, there has been a tendency to minimize their design size and cost, resulting in significant failure rates. Typical ET estimates range from 0.01 to 2.0 centimeters per day.

The contribution of plants has remained a matter of controversy. ET bed sizing has varied from 3,000 to 10,000 square feet and higher. A water balance based on at least 10 years of data is calculated to provide sufficient storage for nonsurfacing operations or to estimate nonatmospheric volumes to be infiltrated.

The modern use of shallow trenches for SWIS is strongly related to the maximization of ET, and such systems could be classified as ETI systems. Further, the use of shallow serial distribution where topographic relief is available is a classic application of the ETI concept, that is, shallow trenches close to the surface, full of wastewater, with only a short wicking distance to the evaporative surface.

Such a system fulfills all the described features of an ideal ETI system. Similarly, drip irrigation uses the shallowest of all SWIS burial requirements and, by nature, maximizes ET potential.

Performance of Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

There have been few studies of ET and ETI systems. Most ET system studies have been less than impressive.

In most cases the fault has been related to poor design assumptions, for example, over-estimating the ET potential of shrubs and trees planted on the surface and of the overall potential of ET itself. Poor system design has been somewhat offset by leaking liners that give the appearance that the system is performing adequately. Inadequate wicking has been overcome by raising water levels.

However, better ET assessment and more rational designs will improve performance at increased costs.

ETI systems have generally worked well, but no scientific studies have been performed to verify this observation. ETI systems do fail when the ET contribution is overestimated, but many times the placement of the wastewater higher in the soil profile offsets that error by increasing the infiltrative capacity of the site.

Management needs of Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

ET systems are very sensitive to variations in construction techniques. Poor construction can defeat their utility through poor liner installation, poor placement and choice of wicking media, compaction, and inadequate surface drainage mitigation.

Operation and maintenance requirements are minimal, often consisting of simply mowing the grass on the surface. Replanting cover crops to improve cold season performance has been suggested but offers little return. Shrubs or small trees planted on the ET system generally improve active (warm) season ET and hinder ET in the dormant (cold) season.

Therefore, the O/M needs of the system should be limited to two to three short visits to observe and record the water height in the observation well.

These tasks require about 1 to 2 hours per year of unskilled labor. No energy is required. ET system salt buildup, if not diluted by precipitation, may require some media replacement after 5 to 10 years of operation depending on water supply characteristics. There are no known safety issues with these systems as long as they are fenced or otherwise isolated from children's play areas.

ETI systems are very similar to SWIS systems, and their management requirements are similar to those of ET systems. Because ETI systems infiltrate wastewater, they have ground water and surface water contamination concerns like those of other SWIS designs, and they may require monitoring of effluent impacts depending on the uses of ground water and performance standards to protect them.

Risk management issues of Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

Because ET systems are large, there may be some visual aesthetic problems. Odors are usually not a problem, but they can be on occasion.

Flow peaks during low ET periods could result in overflows, thus leading to the usual restriction for year-round ET use in areas where ET does not exceed precipitation by more than 2 inches per month.

These systems do not function when their surface freezes. They are typically unaffected by power outages since they are generally fed by gravity. Toxics also have no impact unless they are phytotoxic and would then kill the surface vegetation.

Typical Costs of Evapotranspiration and Evapotranspiration/Infiltration Systems for Septic Effluent Disposal

Because of their large size and specific media (and often liner) requirements, ET systems are generally expensive, reinforcing their use as a "last resort" alternative.

Installed costs of $10,000 to $15,000 and higher are possible depending on climate and location. O/M costs are relatively low, on the order of $20 to $30 per year, but they could increase if the system fills and requires pumping.

ETI systems have capital and O/M costs similar to a SWIS.

Evaporation Transpiration Septic Design Research

- Bauer, D.H., E.T. Conrad, and D.G. Sherman. 1979. Evaluation of Existing and Potential Technologies for Onsite Wastewater Treatment and Disposal. EPA/600/S2-81-178. U.S. Environmental Protection Agency, Cincinnati, OH.

- Beck, A.F. 1979. Evapotranspiration bed design. Journal of Environmental Engineering Division-American Society of Civil Engineers 105(2): 411-415.

- Frank, W.L. 1996. Engineering parameters in the design of evapotranspiration beds. Water and Engineering Management November, 31-37.

- Ingham, A.T. 1987. Guidelines for Evapotranspiration Systems. State Water Resources Control Board, State of California. Sacramento, CA.

- Lomax, K.M., et al. 1978. Guidelines for Evapotranspiration Systems. State Water Resources Control Board, State of California. Sacramento, CA.

- National Small Flows Clearinghouse (NSFC). 1998. Evapotranspiration Systems Fact Sheet. Cooperative Agreement CX825652, U.S. Environmental Protection Agency, Washington, DC.

- National Small Flows Clearinghouse (NSFC). 2000. Evapotranspiration systems. Pipeline 11(1).

- Peters, E.C. 1988. An Evaluation of Enhanced ET Onsite Sewage Treatment and Disposal Systems. Master's thesis, University of Maryland, College Park.

- Salvato, J.A. 1982. Rational design of evapotranspiration bed. Journal of Electrical Engineering-American Society of Civil Engineers 109(3):646-660.

- Tafgard soil based wastewater evaporation / transpiration system by Taisei Kogyo Co., Ltd., Japan. Contact Shuichi Sato, Manager of Taisei Kogyo Co., Ltd., 15-36 Yonehara 6-chome, Yonago, Tottori, 683-0804 Japan Tel. +81-859-32-1135 Fax. +81-859-34-0933, info@taisei-wastewater.jp

- U.S. Environmental Protection Agency (USEPA). 1999. Manual: Constructed Wetlands Treatment of Municipal Wastewaters. EPA/625/R-99/010. U.S. Environmental Protection Agency, Cincinnati, OH.

- Victoria (AUS)-Environmental Protection Agency. 1980. The Use of Transpiration Beds for Domestic Wastewater Disposal. EPA Report No. 104. Melbourne, Australia.

- Wheeter, D.W. 1979. The Use of Evapotranspiration as a Means of Wastewater Disposal. Research Report No. 73. Tennessee Water Resources Research Center, University of Tennessee, Knoxville

...

Continue reading at FILTERS SEPTIC & GREYWATER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- EVAPORATION SEPTIC SYSTEM DESIGN SPECIFICATIONS a model code discussing evaporative or transpiration septic system designs based on New York State's septic code.

- SEPTIC SYSTEM DESIGN ALTERNATIVES - home

- SEPTIC SYSTEM DESIGN BASICS - home

- TYPES OF SEPTIC SYSTEMS - master list

Suggested citation for this web page

EVAPORATION-TRANSPIRATION SEPTIC SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- US EPA Onsite Wastewater Treatment Systems Manual - original citation epa.gov/nrmrl/pubs/625r00008/html/625R00008.htm and for effluent evaporation and transpiration systems for septics, see EPA http://www.epa.gov/nrmrl/pubs/625r00008/html/tfs6.htm

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES. - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Advanced Onsite Wastewater Systems Technologies, Anish R. Jantrania, Mark A. Gross. Anish Jantrania, Ph.D., P.E., M.B.A., is a Consulting Engineer, in Mechanicsville VA, 804-550-0389 (2006). Outstanding technical reference especially on alternative septic system design alternatives. Written for designers and engineers, this book is not at all easy going for homeowners but is a text I recommend for professionals--DF. US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL [online copy, free] Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm Onsite wastewater treatment and disposal systems, Richard J Otis, published by the US EPA. Although it's more than 20 years old, this book remains a useful reference for septic system designers. U.S. Environmental Protection Agency, Office of Water Program Operations; Office of Research and Development, Municipal Environmental Research Laboratory; (1980)

- "International Private Sewage Disposal Code," 1995, BOCA-708-799-2300, ICBO-310-699-0541, SBCCI 205-591-1853, available from those code associations.

- "Manual of Policy, Procedures, and Guidelines for Onsite Sewage Systems," Ontario Reg. 374/81, Part VII of the Environmental Protection Act (Canada), ISBN 0-7743-7303-2, Ministry of the Environment,135 St. Clair Ave. West, Toronto Ontario M4V 1P5 Canada $24. CDN.

- Manual of Septic Tank Practice, US Public Health Service's 1959.

- Onsite Wastewater Disposal, R. J. Perkins; Quoting from Amazon: This practical book, co-published with the National Environmental Health Association, describes the step-by-step procedures needed to avoid common pitfalls in septic system technology. Valuable in matching the septic system to the site-specific conditions, this useful book will help you install a reliable system in both suitable and difficult environments. Septic tank installers, planners, state and local regulators, civil and sanitary engineers, consulting engineers, architects, homeowners, academics, and land developers will find this publication valuable.

- Onsite Wastewater Treatment Systems, Bennette D. Burks, Mary Margaret Minnis, Hogarth House 1994 - one of the best septic system books around, suffering a bit from small fonts and a weak index. (DF volunteers to serve as indexer if Burks/Minnis re-publish this very useful volume.)While it contains some material more technical than needed by homeowners, Burks/Minnis book on onsite wastewater treatment systems a very useful reference for both property owners and septic system designers. We refer to it often.

- Septic Tank/Soil-Absorption Systems: How to Operate & Maintain, Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf

- US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.