Asphalt & SBS Roll Roofing Installation Details

Asphalt & SBS Roll Roofing Installation Details

How to install roll roofing

- POST a QUESTION or COMMENT about roll roofing

Roll roofing installation.

Here we include detailed step-by-step instructions for a typical roll roofing installation job using either traditional asphalt roll roofing or SBS roofing. .

This article series describes mineral-granule coated asphalt or SBS (rubber-based) roll roofing roofing materials, choices, installations, inspection, defects, roofing repairs, and product sources.

This article includes a description of severe wear and early failure of a mineral-granule-surfaced roll roofing installation over an older metal roof.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Asphalt Roll Roofing Installation

Roll roofing is simplest product to install on a small section of low slope

roof is 90-pound roll roofing. This is an inexpensive roofing material often installed (over 15# felt underlayment) by homeowners and do-it-yourself-ers.

Roll roofing is simplest product to install on a small section of low slope

roof is 90-pound roll roofing. This is an inexpensive roofing material often installed (over 15# felt underlayment) by homeowners and do-it-yourself-ers.

"Low Slope" means that these products are installed on roof slopes of 2/12 or more.

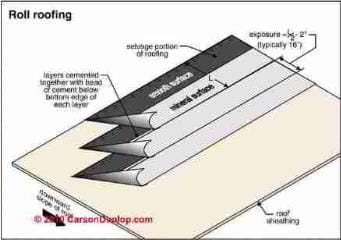

Sketch courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

[Click to enlarge any image]

Traditional asphalt-based roll roofing consists of a heavy, asphalt-saturated organic or fiberglass felt with a granular surface.

SBS or modified asphalt mineral surfaced roll roofing membranes are based on SBS, a synthetic rubber that gives improved performance over traditional asphalt-saturated felt.

Watch out: For flat roofs (slope less than 2/12) you should not be installing roll roofing but rather you should use a flat roof system such as APP or SBS modified roofing or EPDM (rubber roofing) - see details for flat roofs

at MEMBRANE & SINGLE PLY ROOFS

Traditional asphalt-impregnated felt roofing like that in our sketch above is installed overlapped a minimum of 2-3-inches (single coverage) or overlapped half its width or 16-inches (double coverage) or overlapped 2/3 its width to give a 12-inch exposure and a 3-ply roof, or 3/4 of its width to give a 9-inch exposure and a 4-ply roof.

For asphalt-felt roll roofing, less exposure and more plies = longer roof life.

SBS roofing (styrene butadiene styrene) is commonly installed as a single-ply roof with a 3 1/2-inch selvedge edge overlap.

Fiberglass mineral-surfaced roll roofing is installed using mechanical fasteners (nailing), or hot or cold processes to seal between plies. Hot-mopping requires commercial asphalt heating equipment while cold process adhesives are usually brushed-on directly - no heating is required.

Plan the Roll Roofing Job

Plan the roofing job, the job sequence, the purchase of materials, and be sure you have all needed materials on hand before starting the job. The basic roofing sequence is

- Inspect the condition of the existing roof and roof decking

- Plan and schedule any demolition, removal of materials that must precede the new roof installation

- Have roof protection tarps or other materials if the roof might be left open and incomplete across inclement weather

- Measure the roof and calculate the materials and supplies needed: roofing, underlayment, lap sealant, flashings, nails

- Install roofing underlayment

- Install valley flashings and any other sidewall flashings that must extend underneath the finish roof covering

- Install edge cant strips around the roof

- Install the roll roofing

- Install finish flashings or counter flashings where required

Typical Roll Roofing Installation Steps & Specifications

Weather conditions: for applying roll roofing: the roof should be clean and dry, and ambient temperatures should be at or above 50°F.

Weather conditions: for applying roll roofing: the roof should be clean and dry, and ambient temperatures should be at or above 50°F.

Watch out:

If you must install roll roofing at lower temperatures store it indoors and warm it to permit unrolling without cracking the material.

We can sometimes spot roll roofing installed from too-cold rolls by later failures appearing as cracks, at regular (or decreasing) intervals across the width of the material.

Our photo shows our client pointing to a low slope area on a roof where mineral-granule coated asphalt roll roofing was applied after shingles in that location had leaked repeatedly.

- Roof Slope: 2/12 or more. That means 2-inches of rise in 12 inches of horizontal run or steeper. Do not install roll roofing on slopes of less than 2/12.

Really? Well no. Some manufacturers such as MSA specify that their roll roofing product can be installed on slopes down to 1/12 or 1" of slope or rise in 12" of run. - Roll roofing condition: The roll roofing should be clean and dry when it's installed.

Don't install roll roofing whose edges are badly damaged, crushed, torn, as you're likely to see poor seam adhesion and early seam failure. Don't install roll roofing whose roll was badly squashed flat or you may see early failure cracks across the roofing width. - Roofing deck: should be clean, dry, and free of voids. If re-roofing, remove and replace any rotted roof decking before installing the felt underlayment.

Roof decking can be plywood (3/8" or thicker though IMO less than 1/2" thick plywood is asking for a reduced roof life), OSB (oriented strand board) that's 7/16" thick or thicker, or nominal 1" thick dry, seasoned wood boards of 6" in width or less.

Plywood or OSB sheathing should be spaced 1/8" to 1/4" at butt joints to avoid buckling. Wood boards should be butted closely together when nailing in place.

Watch out: if there are sags in the roof deck that will result in ponding (water remains on the roof 24-hours after the end of rainfall), fix those by shimming or filling before proceeding with the roof installation. Ponding will reduce the roof life on a roll roofing job.

Watch out: some products such as GAF Liberty™ one-ply SBS roof system must be installed over a minimum of 4-ply, 15/32" (12 mm) exterior grade plywood decking. Contact GAF Technical Services at 1-800-ROOF-411 for more information on other deck types that may be acceptable. - Roofing underlayment: install the manufacturer's recommended underlayment on the roof deck before bringing up and installing the roof covering itself. The following is excerpted from GAF's roll roofing installation instructions cited below:

Underlayment beneath Mineral Guard® roll roofing has many benefits, including acting as a secondary water resistant ply and preventing sap in some wood decking from reacting with the Mineral Guard® roll roofing.

Underlayment is also required by some code bodies. Consult your local building department for its requirements.

Where an underlayment is to be installed, a breather-type underlayment such as GAF Shingle-Mate® underlayment is recommended.

In areas where leaks may be caused by water backing up behind ice dams, Weather Watch® or StormGuard® Leak Barrier should be used at the eaves. Underlayment must be installed flat, without wrinkles. - GAF op. cit.

See details at FELT UNDERLAYMENT REQUIREMENTS - Roof flashings: be sure that all of your flashing and drip edge is in place before starting to unroll the roofing itself. You won't enjoy trying to lift up roll roofing to install a segment of flashing or drip edge that you forgot.

- Prepare roof edges - cant strips: install drip edge and install 9" cant strips of roll roofing material along the rake and eaves edges (gable ends and lower roof edge) such that the roofing strip overhangs the roof deck by 1/4" to 3/8". Nail the roofing strips parallel to the roof edge, set-in 1" and 8" from the roof edge with nails spaced 4" o.c. in each row.

- Roofing over existing roof membranes: where permitted and where not exceeding your local building department's maximum number of roofing layers (often three), be sure that the roof surface is clean, dry, with no protruding nails.

Cut out any raised wrinkles or blisters or buckles and nail edges of such cuts down so that the re-roof surface is smooth. Don't roof over debris nor over wet existing roofing.

Watch out: some products such as GAF's Liberty™ one-ply self-adhering SBS roofing system (cited below) are installed directly onto cleaned, primed plywood. Any existing roof coverings are completely removed before starting the installation.

- Bringing roll roofing up to the roof deck: distribute rolls on the roof to avoid concentrated weight and place rolls at right angles to slope and stopped against rolling away.

One Standard Pallet of roll roofing carries 28 rolls and weighs about 2,100 lbs. I would avoid placing that much weight in a single spot on the roof. Elsewhere at InspectApedia.com we've documented a truss roof that broke and collapsed, probably because of concentrated loads of roofing materials that exceeded the original roof design capability.

Watch out: how you place rolls of roll roofing on the deck in preparation for installation. They roll.

For a description of what can go wrong when you're dropping rolls of roofing felt onto the roof deck,

see SENECA HOWLAND HOUSE

- Roll roofing installation length: on roofs larger than 36 feet in width you might be able to install entire rolls without cutting by starting the roll at one end and unrolling and nailing, but the risk is that your ply is not kept horizontal. Don't try it.

Cut the roll roofing into working lengths and stack them on the upper roof near the ridge, allowing the cut-lengths to warm and flatten before moving them into position down-roof for installation.

Tarco and other manufacturers recommend that you cut the roll roofing into "manageable lengths" before installation. MSA recommends cutting the roll roofing into lengths no longer than 18 feet. - Roll roofing starter course: the ends of the roll roofing should be flush with the underlying cant strips at the roof gable ends or rakes, and the lower edge of the first course should be flush with the lower edge of the cant strip that was nailed along the lower roof edge.

The upper edge of the starter course is nailed in place. Keep nails high enough that the successive course will overlap the nails by at least 1".

The lower edge of the first course of roll roofing is cemented down to the cant strip by coating the cant strip with lap cement.

Watch out: when lifting the lower edge of the starter course to apply lap sealant in cold weather take care to lift as little as possible and to avoid bending the material backwards or you'll create a future stress crack or roofing failure.

We sometimes see this roofing failure as a crack along the starter course that's parallel to the roof edge. - Roll roofing overlap - horizontal choose the overlap width according to the number of plies of roof to be installed: 2" or 3" (varies by manufacturer) or 16", 12" or 9" exposure for 2, 3, or 4 ply roofs respectively.

SBS roll roofing overlap width is commonly 3.4" or 3.6", varying by product, and also referred to as the selvage edge width.

The minimum head-overlap of successive roll roofing courses would be 2" in a one-ply roof job.

When rolling out and positioning the roofing, I prefer to measure up the proper exposure from the lower edge of the course below to the lower edge of the new course to mark or lay out the proper exposure between courses and to mark the adhesive or mop line. - Roll roofing end overlaps - where you must abut the ends of adjacent sections of roll roofing overlap and seal those by 6-inches.

- Roll roofing at hips and ridges - bring the roofing courses on either side of a hip or ridge up so that the roofing edges meet along the hip or ridge. Then seal the hip or ridge using 12" x 36" strips of roll roofing bent lengthwise so that 6" lies on either side of the hip or ridge.

Overlap the ridge or hip sealing strips at abutting ends by 6" and seal these with lap seal. Lap these strips so that the exposed ends are facing away from the direction of prevailing winds.

Watch out: be sure to warm these strips before bending and nailing if the weather's cold, otherwise the hip or ridge will fail with a crack that you'll later see running close to the peak of the ridge or hip. - Lap sealant - manufacturers typically recommend no more than 1/8" thickness of lap cement. Spread lap sealant evenly, smoothly, and without voids.

Watch out: adhesives between plies should be spread evenly and cover all of the lapped surface (2" 3", 16", 12" or even 9" for a 4-ply roof).

But don't blob on so much adhesive that runout streams down the lower roof surface. Not only is that a cosmetic defect but a too-thick adhesive coating will cause blistering leading to a reduced roof life. Sealant that's too thin or too thick are both errors. - Roofing nails: use galvanized #11 or #12 roofing nails, typically 1" (or longer) with a 3/8" head (never smaller). In 1/2" roof decking, the nail shaft must be long enough to penetrate the roof deck so that the point of the nail is visible. Otherwise there is not enough shaft-to-wood contact to avoid nail withdrawal and wind damage.

GAF instructions for applying mineral roll roofing recommend use of galvanized, zinc-coated steel, or aluminum 10-12 gauge barbed, deformed, or smooth-shank roofing nails and note that the nail must be long enough to penetrate at least 3/4" into the wood roof deck or "just through" plywood or OSB decks.

Watch out: do not count the point or tip of the nail when measuring the amount of penetration into the wood deck.

We mentioned nail location and spacing above. All of this discussion presumes you're using the concealed nail method for installing roll roofing - in my OPINION that's a more-durable roof job than using exposed roofing nails.

How to Install Roll Roofing for Maximum Life

Nonetheless roll roofing installations will have a longer life if installed according to the product manufacturer's instructions, nailed at proper intervals, and with seams properly sealed.

It's also important to install roll roofing over a smooth sound roof deck.

If the roof decking sags, ponding on the roof surface after rain may reduce its life.

Overlapping strips of asphalt roll roofing are installed over the roof surfaces with overlapped edge joints sealed, usually with a heated asphalt compound, or cold-applied using a similar sealant that functions at lower temperatures.

Sketch courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Probably in part because asphalt roll roofing is typically used on low slope and nearly flat roofs, it can have an anticipated wear life of less than ten years, often five years.

The life of roll roofing may be extended by coatings.

Roll Roofing Manufacturer's Installation Instructions & Product Specifications

Illustration: SBS type roll roofing or BUR rolls from MTechnology cited below.

- BP Slate Surface Roll Roofing and BP Mineral Surface roll roofing and related products are described in BP's FIBERGLASS CAP SHEET RR701 INSTRUCTIONS [PDF] - retrieved 2022/0717

- BP ASPHALT SHINGLE APPLICATION INSTRUCTIONS [PDF], Building Products of Canada, Co., 9510, St. Patrick Street, LaSalle (Quebec), Canada H8R 1R9 and BP Canada 3703-101 Avenue N.E., Edmonton (Alberta), Canada T5J 2K8, retrieved 2019/05/01

- GAF MINERAL GUARD® RESIDENTIAL ROLL ROOFING APPLICATION INSTRUCTIONS [PDF] (2011) GAF Corporation, 1361 Alps Road, Wayne NHJ 07470 USA

- GAF LIBERTY™ SBS SELF-ADHERING ROOFING SYSTEM [PDF] One Ply Installation Instructions for Plywood, self-adhesive cap sheet roofing (2016) GAF, Op. Cit.

- Gap, APPLYING ROLL ROOFING [PDF] G.A.P. Roofing Inc., G.A.P. Roofing Inc. 4444 Hunt St, Pryor, OK 74361 USA, Tel: 800-880-9808 or G.A.P. Roofing of FL, LLC 12120 SE County Rd 137 Jasper, FL 32052 USA, retrieved 2019/05/01 original source: https://gaproofing.us/wp-content/uploads/2014/01/app_roll_roofing.pdf

- MB Technology, SUPERCAP SBS Modified MINERAL SURFACED ROLL ROOFING APPLLICATION INSTRUCTIONS [PDF] MB Technology CO., 188 South Teilman Ave, Fresno CA 93706-1224 USA, Website: www.mbtechnology.com, Tel: 559-233-2181, Email: info@mbtechnology.com retrieved 2019/05/01 Lowes - in English & Spanish. Instrucciones para la aplicación de Cubierta de Tela Asfáltica SBS

de Superficie Mineral Modificada

MBTechnology specializes in manufacturing SBS Modified Bitumen Roofing & Underlayment systems. Layflat SBS is available in four weights, 25-40-50 & 60 lbs/square, reinforced by polyester, glass, or fiberglass scrim.

Product description excerpt:

Supercap SBS is an SBS modified asphalt mineral surfaced roll roofing membrane. Supercap is reinforced with a fiberglass mat and fire rated.

SBS is a synthetic rubber that gives asphalt enhanced performance characteristics.

SBS modified membranes exhibit high multi-directional strength and excellent cold temperature flexibility in addition to elongation and recall properties far superior to traditional asphalt roofing membranes.

These outstanding properties provide supercap SBS with excellent resistance to “thermal shock,” a major contributor to roof failure. - MSA MSR MINERAL SURFACED ROLL ROOFING APPLICATION INSTRUCTIONS [PDF], MSA Mid States Asphalt & Cant Strip Inc., 1637 51st Avenue, Tuscaloosa, AL 35402 USA, Tel: 800-489-2391

- Owens Corning, FIBERGLAS® MINERAL SURFACED ROLL ROOFING APPLICATION INSTRUCTIONS [PDF] (2008) Owens Corning Roofing and Asphalt LLC, One Owens Corning Pkwy, Toledo OH 43659 USA, website: www.owenscorning.com Tel: 1-800-GET-PINK , 2" & 4" Selvedge Mineral Surfaced Roll Roofing Instructions, retrieved 2019/05/01 original source: https://www.owenscorning.com/NetworkShare/Roofing/100491-D-MSR-Roofing-Installation-Instructions.pdf in English and Spanish.

Instrucciones de aplicación de rollos de superficie mineral para techos FIBERGLAS® - Tamko® SLATE SURFACED ROLL ROOFING APPLICATION INSTRUCTIONS [PDF] Tamko Roofing Products, Inc., Website www.tamko.com

- Tarco, ROLL ROOFING INSTALLATION GUIDE [PDF] (2011) Tarco, One Information Way, Suite 225, Little Rock AR 72202 USA, Tel: 800-365-4506, Website: www.tarcoroofing.com retrieved 2019/05/01 from Home Depot

...

Continue reading at MODIFIED BITUMEN ROOFING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ROLL ROOFING, ASPHALT & SBS FAQs - questions & answers posted originally on this page.

Recommended Articles

- MEMBRANE & SINGLE PLY ROOFS

- MODIFIED BITUMEN ROOFING

- ROLL ROOFING, ASPHALT & SBS

- ROLL ROOFING, ASPHALT & SBS INSTALLATION

- ROOF LEAK DIAGNOSIS & REPAIR - home

- ROOFING INSPECTION & REPAIR - home

- RUBBER ROOF SHINGLES & SLATES

Suggested citation for this web page

ROLL ROOFING, ASPHALT & SBS INSTALLATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about roll roofing installation, life, leaks, repairs..

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- Low Slope Roofing, Manual of, 4th Ed., C.W. Griffin, Richard Fricklas, McGraw-Hill Professional; 4 edition, 2006, ISBN-10: 007145828X, ISBN-13: 978-0071458283

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.