Composite or Synthetic Deck Installation

Composite or Synthetic Deck Installation

Deck Design-Build Online Guide

- POST a QUESTION or COMMENT about deck construction

Composite & synthetic decking choices, properties, & installation procedures.

The most common type of composite decking is made of wood fibers mixed with plastic, which is then formed into planks up to 20 feet in length.

Solid synthetic deck boards are sold in various thicknesses, widths, and lengths, of which 1" thick x 5.5" wide x lengths of 12', 16', and 20' are most common.

Some products are made to resemble real wood, at least from a distance, while others offer a range of colors.

This article series describes critical safe-construction details for decks and porches, including avoiding deck or porch collapse and unsafe deck stairs and railings. Our page top photo shows several colors of synthetic decking installed at a New York building supply outlet.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Using Composite Decking: Synthetic or "Plastic" Deck Boards

Good decks are primarily built to promote leisure and comfort, but they can require a fair bit of upkeep to keep them looking good.

Composite decking has been gaining in popularity in recent years because it significantly reduces the maintenance that a deck needs from year to year.

New products are being introduced all the time, though many of them are not available in all areas or carried by all stores.

If you are curious about composite decking, plan to visit as many stores as possible and do some research on the specific products available to you.

The composite deck board photo at left shows that the deck actually collapsed during work on the structure, revealing rotted wood structure over which the deck boards had been added as a "repair".

Some manufacturers have begun offering composite lumber that can be used for railings and fascia boards, giving you the opportunity to construct the most visible portions of a deck out of the same material.

You may also be able to use composite lumber for stair treads and risers.

Watch out: Composite lumber is generally not as strong as wood, which is why it is not used for structural framing.

The strength of composite decking varies from product to product and installation.

Decking made with recycled polyethylene (PE) may require shorter spans than products made with poly- vinyl chloride (PVC), which itself may not be able to span quite as much as some solid wood decking.

Each product is made from a unique mix of materials, and some may fade more than others.

With a growing variety of products available and an expanding list of happy consumers, composite decking is rapidly becoming the material of choice for those seeking a low-maintenance deck. Because of its flexibility, it is also well suited to use in curved decks and even matching benches.

Watch out: synthetic decking is not a "forever" material and can deteriorate, break, even collapse as we illustrate in some photos here and as has been reported elsewhere.

Manufacturers typically cite a 25-30 year life expectancy though we've seen the material fail sooner, within 10-15 years.

Details are at COMPOSITE LUMBER DURABILITY

Cutting and Drilling Composite Deck Materials

Although composite or synthetic decking itself is relatively recent, you do not

to acquire new tools and skills to work with it. Composites can be cut and shaped just like solid wood.

Although composite or synthetic decking itself is relatively recent, you do not

to acquire new tools and skills to work with it. Composites can be cut and shaped just like solid wood.

Use regular carpentry tools to cut, drill, and shape composite lumber. Fine-toothed, carbide- tipped blades work best.

Cutting or drilling composite lumber may produce a sharp burr, which can be quickly eliminated with a rasp or sandpaper.

Staining and Painting Composite / Synthetic Deck Materials

Unlike wood, according to some sources, composite decking does not have to be coated with a protective finish.

If you are not satisfied with the color choices available, however, or if you would like your deck to match the color of your house, most products can be stained or painted.

Keep in mind that if you do apply a finish, you will have to recoat the surface regularly. Some manufacturers suggest oil-based paints and stains for their products, while others recommend latex finishes.

Composite lumber does not necessarily have to be coated with a protected finish, but for decorative purposes you can stain or paint as suggested by the manufacturer.

Watch out: check the coating requirements or recommendations given by the manufacturer of the particular synthetic decking material you are choosing.

Fastening Requirements for Synthetic Decking, Trex, Plastic or Similar Products

Most composite decking can be attached with standard deck screws or nails. Some manufacturers suggest that you drill pilot holes before driving screws, others do not.

Vinyl Decking

Vinyl decking is another low cost option, although one that offers a particularly nontraditional-looking deck. Installation differs as well.

In general, first an aluminum or vinyl track is installed across the joists, and then top pieces are snapped into place.

Note that in this immediate discussion, we have eschewed environmental and health questions concerning the use of treated wood, vinyl and other manmade products, as well as questions of renewable resources and environmental impact. Articles on those topics can be found at InspectApedia.com such as at

Sorting Synthetic Decking by Board Types: solid, webbed, other

Solid Composite Decking

Solid composite decking is the composite product most similar to solid wood and can be fastened accordingly. Hidden fastener systems can also be used with some products, but check with both the fastener and composite manufacturers for compatibility. Some solid composite boards may have a slight cup, which should be installed with the arch facing up ("rainbow position") to allow water to run off.

Webbed Decking

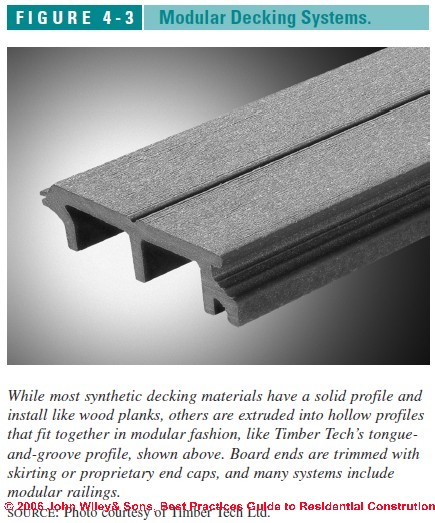

Webbed, or hollow-core, composite decking is available in both rectangular and tongue-and-groove profiles. Because of the products’ design, manufacturers specify exactly where fasteners must be driven in each board.

Shown at left is a non-solid composite decking product. This image is used with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , by Steven Bliss, courtesy of Wiley & Sons.

Also see our review of that book.

In a companion article on this topic, SYNTHETIC & COMPOSITE DECK BOARDS - Best Construction Practice,

Mr. Bliss points out that the oldest solid composite decking on the market is Trex®, but competitors now include Boardwalk® (Certainteed), ChoiceDec® (Weyerhaeuser), and products from several smaller manufacturers

Some products are made with a surface groove to accommodate fasteners. You can buy matching caps to enclose board ends, or you can install fascia boards.

Attach composite decking with screws and nails, as recommended by the manufacturer. Some products tend to flare up a bit when the screw head enters the decking. If that happens, draft the screw about 1/8 inch beneath the surface, this step will hide the screw.

With webbed decking, fastener placement can be particularly important. This 2 X 6 product requires that screws be driven only through the outer cores, not the center one.

Where to Buy Composite & Plastic Decking Materials

Building Supply Stores such as Home Depot & Lowes stock a variety of composite and synthetic decking products including those shown in the photographs above. At left is an image of the Veranda Composite Decking warranty.

- Azek Composite Decking

- Certainteed Corp.

www.certainteed.com

Boardwalk solid composite decking with hidden fasteners and optional railing system - Clubhouse Composite Decking

- Composite Building Products International

www.xtendex.com

Xtendex hollow composite decking system with optional railing - Correct Building Products www.correctdeck.com

Solid composite decking with hidden fasteners and optional railing system - Endeck Composite Decking

- Fiber Composites www.fibercomposites.com

Fiberon solid composite decking and optional railing system - Fiberon Composite Decking

- Kadant Composites www.geodeck.com

Geodeck hollow composite decking and railing system - Kroy Building Products www.kroybp.com

Timberlast solid composite decking with optional hidden fastening system - Louisiana-Pacific Corp www.weatherbest.lpcorp.com

WeatherBest solid composite decking, railings, and accessories - Nexwood Industries Limited www.nexwood.com

Hollow composite decking and railing systems - Tendura www.tendura.com

TenduraPlank solid tongue-and-groove composite flooring for porches; natural finish or primed for painting - Thermal Industries www.thermalindustries.com

Dream Composite solid tongue-and-groove composite decking system with optional vinyl railings - TimberTech Limited www.timbertech.com

Floorizon hollow composite decking system, solid composite decking planks, and optional railing system - Trex Company www.trex.com

Solid composite decking - Weyerhaeuser Building Products www.choicedek.com

ChoiceDeck solid composite lumber and optional railings

Plastic Decking Systems

- Kroy Building Products www.kroybp.com

Classic Manor embossed vinyl decking with clip system - L.B. Plastics www.lbplastics.com

Sheerline interlocking vinyl decking system and deck cladding systems - Renew Plastics www.renewplastics.com

Solid recycled high-density polyethylene (HDPE) plastic decking with embossed wood-grain texture - Royal Crown Limited www.royalcrownltd.com

Brock Deck and Deck Lok interlocking vinyl decking systems - Thermal Industries www.thermalindustries.com

Dream Deck interlocking vinyl decking and railing system - Trunorth Composite Decking

- U.S. Plastic Lumber Corp www.carefreexteriors.com

Carefree Xteriors recycled plastic HDPE decking with embossed wood grain and optional railings - Vekadeck Composite Decking

- Zuri Composite Decking

...

Continue reading at COMPOSITE LUMBER DURABILITY or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- COMPOSITE DECK BOARDS

- DECK CONSTRUCTION BEST PRACTICES - home

- DECK FLASHING LEAKS, ROT - a case of deck rot ascribed in part to how composite decking lumber was used

- DECK FLOOR LAYOUT

- SYNTHETIC & COMPOSITE DECK BOARDS - Best Practices

Suggested citation for this web page

COMPOSITE DECK BOARDS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING DECKS & PORCHES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - [2] Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- [3] Prescriptive Residential Wood Deck Construction Guide, based on the 2009 International Residential Code, American Forest & Paper Association, Inc., provided by reader Mark Morsching from Everflashing.

- [2] Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- [5] Claudia Hudson, Asheville NC, Tel: 828-252-0644 Email: claudiahudson@charter.net . Ms. Hudson is an SEO copyrighter / content writer. She has provided background research and text for InspectApedia's articles on deck and porch construction methods & procedures. April 2013.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.